Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Epson SureColor F2270

- Page 1 ® ® Epson SureColor F2270 User's Guide...

-

Page 3: Table Of Contents

Contents SureColor F2270 User's Guide ........................9 Introduction to Your Printer........................10 Printer Features ..........................10 Optional Equipment and Replacement Parts................. 11 Notations Used in the Documentation ....................12 Printer Part Locations......................... 13 Printer Parts - Front/Top ........................ 14 Printer Parts - Inside ........................15 Printer Parts - Back........................ - Page 4 Data Creation and Transmission Guidelines ................. 47 Printable Area for Each Platen ...................... 48 Preparing Your Printer........................51 Attaching the Grip Pad to the Platen....................52 Removing the Grip Pad from the Platen ..................55 Attaching or Removing Spacers ....................57 Installing the Platen ........................

- Page 5 Aligning the Print Head ........................ 112 Shaking and Replacing Ink Packs ....................114 Shaking the Ink Packs ......................... 114 Replacing the Ink Packs ......................117 Using the Ink Cleaning Solution ....................... 122 Cleaning Around the Print Head....................... 124 Cleaning the Suction Cap......................... 126 Cleaning the Sensor Cover ......................

- Page 6 LCD Screen Shuts Off ......................... 165 Solving Printing Problems ........................ 166 Nothing Prints ..........................166 Cannot Print Over a Network....................... 167 Print Head Moves But Nothing Prints ..................167 Platen Height Error Is Displayed While Printing................168 Message Is Displayed After Cleaning the Encoder Strip (Carriage Scale) ........169 Printing Is Slow or Stops Intermittently ..................

- Page 7 Ink Specifications ..........................189 Cleaning Ink Supply Unit Specifications ................... 190 Pre-treatment Solution Specifications ....................190 Ink Cleaning and Tube Cleaning Solution Specifications ..............191 Safety and Approvals Specifications ....................192 Notices ..............................193 Important Safety Instructions......................193 List of Safety Symbols on the Product ..................193 General Product Safety Instructions ....................

-

Page 9: Surecolor F2270 User's Guide

SureColor F2270 User's Guide Welcome to the SureColor F2270 User's Guide. For a printable PDF copy of this guide, click here. -

Page 10: Introduction To Your Printer

High Resolution • UltraChrome DG2 pigment ink optimized for textile printing for smooth gradations and high color reproducibility • High-density white printing using White ink and pre-treatment solution developed specially for Epson pigment ink textile printers Easy-to-use setup and operation features •... -

Page 11: Optional Equipment And Replacement Parts

(Canada), select your product series and product, and click the Where to Buy button. Or call 800-GO-EPSON (800-463- 7766) in the U.S. or 800-807-7766 in Canada. In addition to the accessories listed below, 1-year, 2-year, and 4-year extended service plans are available. -

Page 12: Notations Used In The Documentation

Option or part Part number Extra small garment platen (7 × 8 inches [17.8 × 20.3 cm]) C12C938971 Large hanger platen C12C938911 Medium hanger platen C12C938931 Small hanger platen C12C938951 Sleeve platen (4 × 4 inches [10.2 × 10.2 cm]) C12C939011 Large platen grip pad C13S210075... -

Page 13: Printer Part Locations

• Cautions must be observed to avoid damage to your equipment. • Notes contain important information about your printer. • Tips contain additional printing information. Parent topic: Introduction to Your Printer Printer Part Locations Check the printer part illustrations to learn about the parts on your printer. Printer Parts - Front/Top Printer Parts - Inside Printer Parts - Back... -

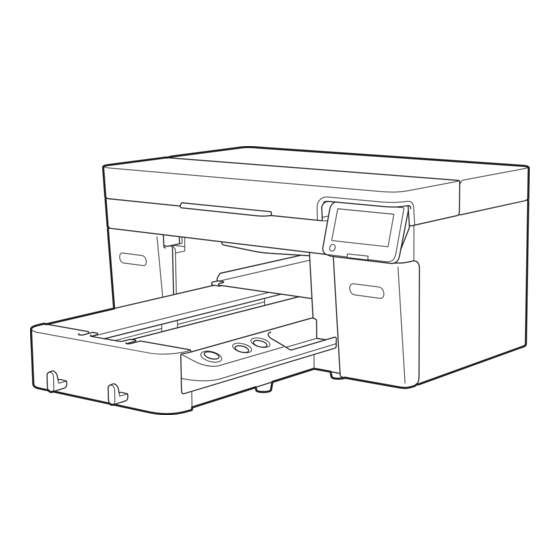

Page 14: Printer Parts - Front/Top

Printer Parts - Front/Top Printer cover Ink covers (left and right) Platen Moveable base Hooks (to hang platen frame) Platen gap lever... -

Page 15: Printer Parts - Inside

start button pause button moveable base button External USB port Ink tray Control panel Parent topic: Printer Part Locations Printer Parts - Inside... -

Page 16: Printer Parts - Back

Capping station Flushing pad Sensor covers (left and right) Print head Wiper unit Suction cap Encoder strip (carriage scale) Parent topic: Printer Part Locations Printer Parts - Back... -

Page 17: Control Panel

AC inlet Rear cover Waste ink outlets Waste ink tubes Waste ink bottle holder Waste ink bottle USB port LAN (Ethernet) port Data light Status light Parent topic: Printer Part Locations Control Panel home icon power button... - Page 18 Error alert light; check the control panel for error details when lit LCD touchscreen LCD Screen Note: When a print job has been sent to the printer, you can select the screen switching icon to toggle between the job preview screen and the Home screen. Access menu items Displays the printer's status, error messages, and other information Displays the current media setting...

- Page 19 Displays the amount of ink remaining The abbreviation below each bar indicates the ink color. BK: Black Y: Yellow M: Magenta C: Cyan WH: White ML: Maintenance Liquid When the notification icon is displayed, the corresponding ink color is running low. Tap the display area to check the model number of the ink pack.

- Page 20 Network status icons : No Ethernet connection : Ethernet connection established : Ethernet connection disabled Turns the internal light on or off; turn on to check print in progress Parent topic: Printer Part Locations...

-

Page 21: Printer Usage Guidelines

Printer Usage Guidelines Follow the guidelines in these sections as you use your printer, consumables, and print media. Using Your Printer Storing Your Printer Handling Ink and Cleaning Packs Handling White Ink Handling T-shirts (Media) Handling Pre-treatment Solution Using Your Printer Follow these guidelines as you use your printer: •... -

Page 22: Storing Your Printer

Note: To keep the print head in the optimum operating condition, ink and cleaning solution are also used in maintenance operations such as head cleaning in addition to printing. Parent topic: Printer Usage Guidelines Related references Environmental Specifications Related topics Maintenance Storing Your Printer Follow these guidelines if you need to store your printer for a long period:... -

Page 23: Handling Ink And Cleaning Packs

Handling White Ink Related tasks Performing a Nozzle Check Storing the Printer Related topics Maintenance Handling Ink and Cleaning Packs Follow these guidelines as you handle the ink and cleaning packs: • Extra ink is required to charge the print head nozzles the first time the printer is used. Be sure to have replacement ink packs ready. -

Page 24: Handling White Ink

• Do not drop ink packs or subject them to impacts. It may cause ink to leak. • Periodically remove and thoroughly shake ink supply units that are loaded in the printer. Shake color ink packs once a month and shake white ink packs once every 24 hours. You do not need to shake the Cleaning Liquid or Maintenance Liquid packs. -

Page 25: Handling T-Shirts (Media)

Related topics Shaking and Replacing Ink Packs Handling T-shirts (Media) Follow these guidelines as you handle and store printed T-shirts: • Avoid storing T-shirts in direct sunlight, or in locations that are subject to excessive dust, heat, or humidity. If T-shirts are stored in a hot place after printing, the printed surface may soften and become sticky. -

Page 26: Handling Pre-Treatment Solution

Handling Pre-treatment Solution Follow these guidelines as you handle and store pre-treatment solution: • We recommend that the pre-treatment solution be stored at room temperature, out of direct sunlight, and used before the expiration date printed on the packaging. • Stir the polyester pre-treatment solution before opening. If you use it without stirring, the effect of pre- treatment may not be sufficient. -

Page 27: Basic Printing

Basic Printing Refer to these sections to learn how to perform basic print functions. Overview of the Printing Process Required Equipment Pre-treating a T-shirt Creating Your T-shirt Design Preparing Your Printer Loading a T-shirt Finishing a T-shirt Overview of the Printing Process This section explains the basic workflow from preparing a T-shirt for printing to post-treatment after printing. -

Page 28: Required Equipment

8. Removing the T-shirt Remove the T-shirt from the platen or grip pad. 9. Post-treating the T-shirt Fix the ink to the T-shirt. Parent topic: Basic Printing Related references Required Equipment Related tasks Preparing Your Printer Starting a Print Job Removing a Printed T-shirt Related topics Pre-treating a T-shirt... - Page 29 For best results, use a paint roller or sprayer to apply pre-treatment solution to the T-shirt. Note: Using non-Epson pre-treatment solution may yield poor color, image quality, or washability. Note: The cotton pre-treatment solution must be diluted with distilled water at a minimum 1:1 ratio.

-

Page 30: Pre-Treating A T-Shirt

Pre-treatment roller set (optional item or commercially available) A paint roller can be used to apply the pre-treatment solution to the T-shirt, and makes it easier to apply the solution to uneven areas such as pockets. The tray is used to allow the pre-treatment solution to soak into the roller. -

Page 31: Pre-Treatment Solution Safety Precautions

Pre-treatment Solution Safety Precautions Preparing the Pre-treatment Solution Agitating the Polyester Pre-treatment Solution Filtering the Cotton Pre-treatment Solution Diluting the Pre-treatment Solution Pre-treating a T-shirt with a Roller Pre-treating a T-shirt with a Pre-treatment Machine Fixing the Pre-treatment Solution (Heat Press) Parent topic: Basic Printing Pre-treatment Solution Safety Precautions... -

Page 32: Preparing The Pre-Treatment Solution

• Do not put waste pre-treatment solution in the waste ink bottle as it will solidify if mixed with waste ink. Caution: Pre-treatment solution is classified as industrial waste and must be disposed of by an industrial waste disposal company according to local laws and regulations. When handing over the pre-treatment solution to an industrial waste disposal company, make sure you include these safety precautions. - Page 33 3. Remove the cap. 4. Remove the tap from the bag and turn the tap's handle section until the hole is visible as shown. Note: If you cannot see the hole or if the tap is damaged, contact Epson.

- Page 34 5. Attach the tap. 6. Remove the cap from the end of the tap and turn the lever until the hole is facing down. 7. To pour the solution, tilt the cardboard box and pour the pre-treatment solution into the desired container.

-

Page 35: Agitating The Polyester Pre-Treatment Solution

Related references Where to Get Help (U.S. and Canada) Where to Get Help (Latin America) Agitating the Polyester Pre-treatment Solution Follow these steps to stir the polyester pre-treatment solution before opening. If you use it without stirring, the effects of pre-treatment may not be sufficient. Note: You do not need to stir the polyester pre-treatment solution after opening. - Page 36 2. Turn the container to the right five times. Turn the container at a speed of about one turn every two seconds. 3. Turn the container to the left five times, and at the same speed. 4. Turn the container back to the right five times, and at the same speed.

-

Page 37: Filtering The Cotton Pre-Treatment Solution

5. Turn the box up so that the section where the top comes out is at the top. Parent topic: Pre-treating a T-shirt Related references Handling Pre-treatment Solution Filtering the Cotton Pre-treatment Solution Coagulation may develop in the cotton pre-treatment solution during storage and can cause uneven print results if the solution is used. - Page 38 • A bottle for filtration with a capacity of at least one liter (a bottle with measurement markings is recommended) Note: • Replace the filter with a new one after every liter of pre-treatment solution that is filtered • Do not reuse filters even if they did not filter one liter of solution. Any pre-treatment solution on the filter could get mixed in and cause unevenness to occur.

- Page 39 2. Open up a new filter and plate it over the funnel as shown.

- Page 40 3. Insert the funnel into the mouth of the bottle. 4. Remove the cap from the spout of the pre-treatment solution.

- Page 41 5. Open the lever and carefully pour one liter of the pre-treatment solution through the filter into the bottle. Note: Be careful not to overfill the funnel and filter with the pre-treatment solution. If there is only a small amount left in the container, carefully tip the container forward to pour it out.

- Page 42 6. Once you have poured out a liter of solution, or the container is empty, close the lever and replace the spout cap. 7. Transfer the filtered pre-treatment solution to the intended container for use. If you want to filter more pre-treatment solution, replace the filter with a new one and repeat the steps.

-

Page 43: Diluting The Pre-Treatment Solution

9. Rinse the used funnel and bottle with water and then wipe the funnel dry with a soft, dry cloth. Note: If you are using tap water to rinse the funnel and bottle, make sure you use distilled or pure water at the end. -

Page 44: Pre-Treating A T-Shirt With A Roller

Pre-treating a T-shirt with a Roller To prevent colored T-shirt fibers on the roller from sticking to other T-shirts, use a different roller for each color. Note: Apply approximately 0.5 ounces (15 grams) of pre-treatment solution to printing areas of letter- /A4-size. -

Page 45: Pre-Treating A T-Shirt With A Pre-Treatment Machine

6. Fix the pre-treatment solution with a heat press and parchment (silicone) paper. Note: The T-shirt fibers must be pressed flat to produce even whiteness. Even if you use a heat tunnel to fix the ink, use a heat press with parchment (silicone) paper to fix the pre-treatment solution before printing. -

Page 46: Fixing The Pre-Treatment Solution (Heat Press)

4. Place the T-shirt on the pre-treatment machine platen. 5. Set the controls to adequately cover the desired printed area with pre-treatment solution. (On 1 to 100 dial controls, this may be 30 to 45.) We recommend applying the pre-treatment solution to an area larger than the target print area. -

Page 47: Creating Your T-Shirt Design

Creating Your T-shirt Design After creating the data, use the Garment Creator 2 software to transmit it to the printer. U.S. and Canada: Visit your product's support website at epson.com/support (U.S.) or epson.ca/support (Canada) and select your product to download the Garment Creator 2 software and utilities. -

Page 48: Printable Area For Each Platen

• You can transmit data only when the printer is not printing. • While the printer is receiving data, only these operations are possible: • Turning off the power • Moving the platen • Cancelling a print job Note: When a USB memory device is connected to the printer, printing starts after saving the data to the USB memory device. - Page 49 Sleeve platen 0.47 inch (12 mm) margins Platen frame Printable area...

- Page 50 Medium-grooved platen 0.24 inch (6 mm) margins Platen frame Printable area Rectangle part (you cannot print on this area if this part is removed [for zippers]) 2.60 inches (67 mm) 7.79 inches (198 mm) 6.65 inches (169 mm) 1.61 inches (41 mm) 6.33 inches (161 mm)

-

Page 51: Preparing Your Printer

L, M (standard), S, and XS platens 0.24 inch (6 mm) margins Platen frame Printable area Parent topic: Creating Your T-shirt Design Preparing Your Printer Before transmitting print data from the Garment Creator 2 software, check the printer's status and make sure that the print head nozzles are not clogged. -

Page 52: Attaching The Grip Pad To The Platen

Parent topic: Basic Printing Related tasks Performing a Nozzle Check Attaching the Grip Pad to the Platen A grip pad prevents the T-shirt from moving around during printing and can reduce print misalignment. We recommend attaching a grip pad to the platen supplied with the printer. You do not need the platen frame when a grip pad is attached to the platen. - Page 53 2. Place the platen on a flat surface, align the corners of the grip pad so that they are slightly inside the corners of the platen, and then set the adhesive side of the grip pad to the platen. Note: Do not allow the corners of the grip pad where the backing has not been removed to protrude past the edges of the other side of the platen.

- Page 54 4. Carefully lift the grip pad and peel off the other two sections of the grip pad backing. 5. Carefully adhere the rest of the grip pad to the platen and rub each section to adhere it. Parent topic: Preparing Your Printer...

-

Page 55: Removing The Grip Pad From The Platen

Related references Optional Equipment and Replacement Parts Related tasks Removing the Grip Pad from the Platen Loading a T-shirt on the Grip Pad Removing the Grip Pad from the Platen You can remove the grip pad from the platen. Grip pads that have been on the platen for a long time may be hard to peel off. You can use a commercially available spatula to assist in removal. - Page 56 2. Using your other hand, peel off the grip pad. If any glue remains on the platen, soak a soft cloth in diluted neutral detergent, wring it out thoroughly, and wipe off the glue. Caution: Do not use solvents such as alcohol to remove the glue. You can damage, warp, or discolor the platen or other parts.

-

Page 57: Attaching Or Removing Spacers

Attaching or Removing Spacers You may need to attach or remove spacers, depending on the platen type and the fabric thickness. You need a Phillips-head screwdriver. 1. If the platen is not in the forward position, press the moveable base button to move the platen forward. - Page 58 4. Rotate the fixing lever as shown to loosen it.

- Page 59 5. Move the lever to the right to set the scale to setting 8.

- Page 60 6. Secure the platen gap lever in the raised position by lifting the part shown below and then tightening the fixing lever. 7. Lift the platen gap lever and remove the spacer.

- Page 61 8. Combine the spacers according to the type of platen you are using and the thickness of the media. Note: The letters A and B are stamped on the side of the spacers. When you are using two spacers, stack them as shown below. 9.

-

Page 62: Installing The Platen

10. Lift the part shown below and then loosen the fixing lever. 11. Lower the part you lifted and then tighten the fixing lever again to secure the platen gap lever. Parent topic: Preparing Your Printer Installing the Platen After you have removed or attached spacers as necessary, you can install a platen on the printer. 1. - Page 63 3. Align the platen to fit into the holes in the moveable base and place the platen on the printer. • Install a large, medium, or small hanger platen with the hanger positioned toward the front. Then go to step 5. •...

- Page 64 • If you are installing a sleeve platen, install it as shown. Then go to step 4.

- Page 65 4. Pass the fixing band under the parallel adjustment plate and align it with the groove on top of the platen and secure it tightly. Make sure the end of the fixing band is on the side of the platen. 5.

-

Page 66: Changing The Platen Height

Related tasks Aligning the Print Head Changing the Platen Height Follow these steps to change the height of the platen. 1. If the platen is not in the forward position, press the moveable base button to move the platen forward. 2. - Page 67 3. Move the lever to set the scale to the desired position. Move the lever to the right to lower the platen. Move the lever to the left to raise the platen. When the scale is at position P, the platen is at its highest point.

-

Page 68: Loading A T-Shirt

4. Tighten the fixing lever and then secure the platen gap lever. Parent topic: Preparing Your Printer Loading a T-shirt Refer to these sections to load a T-shirt into the printer. If you notice any creases on the T-shirt, use a heat press to iron them out before loading the shirt. Caution: Do not load polyester T-shirts on a platen that is covered with a grip pad;... -

Page 69: Loading A T-Shirt On The Grip Pad

Cancelling a Print Job Parent topic: Basic Printing Loading a T-shirt on the Grip Pad Before printing, carefully load a T-shirt on the platen with a grip pad attached. Do not use the platen frame with the grip pad. Note: Make sure that the platen you want to use is installed on the printer. 1. - Page 70 Note: The line inside the frame in the illustration below indicates the center of the platen. 4. Gently pull the T-shirt over the edges of the grip pad to flatten it. Note: Do not pull the T-shirt too much; otherwise, the print quality may decline, and any white under- base print may extend outside of the image.

- Page 71 5. Remove any lint from the printing surface and press the fibers flat. Note: There may be lint on the T-shirt if you have not applied pre-treatment solution. Use a lint roller or sticky tape to remove the lint and then press the fibers flat using a hard roller. Lint and fibers may stick to the print head and stain other areas.

- Page 72 7. Press the T-shirt with the grip pad tool and move the grip pad tool across the T-shirt vertically and horizontally from the edges as shown to flatten the printing surface. Repeat as needed to remove any slack or creases from the surface. Note: If the grip pad tool gets dirty, wipe it with a damp cloth.

-

Page 73: Loading A T-Shirt On The Platen

Note: If the T-shirt is coated with pre-treatment liquid or the grip pad tool catches on the fabric, you can use a heat-resistant release sheet with the grip pad tool as shown. 8. Tuck the T-shirt around the platen so that it does not drape over the movable base. Parent topic: Loading a T-shirt Related tasks... - Page 74 2. If the platen is not in the forward position, press the moveable base button to move the platen forward. 3. Remove the platen frame. 4. Load the T-shirt by sliding the hem of the T-shirt over the platen from the front. Note: The line inside the frame in the illustration below indicates the center of the platen.

- Page 75 5. Gently pull the T-shirt over the edges of the platen to flatten it. Note: • Do not pull the T-shirt too much; otherwise, the print quality may decline, and any white under- base print may extend outside of the image. •...

- Page 76 7. Remove any lint from the printing surface and press the fibers flat. Note: There may be lint on the T-shirt if you have not applied pre-treatment solution. Use a lint roller or sticky tape to remove the lint and then press the fibers flat using a hard roller. Lint and fibers may stick to the print head and stain other areas.

- Page 77 8. Gently pull the edges of the T-shirt outside of the frame to remove any slack. Note: The printer detects the highest part of the garment surface and adjusts the height accordingly. If there are any wrinkles, creases or slack near the inside edge of the frame, a platen height error may occur or print quality may decline, and any white-under base print may extend outside of the image.

-

Page 78: Loading A Sleeve On The Sleeve Platen

9. Press down the frame of the platen so that it does not become loose. Note: Using the platen frame to place the garment surface under a suitable amount of tension can reduce swelling of the garment surface during printing. 10. - Page 79 3. Remove the platen frame. 4. Slide the sleeve over the platen. 5. Gently pull the sleeve over the edges of the platen to flatten it.

- Page 80 Note: • Do not pull the sleeve too much; otherwise, the print quality may decline, and any white under- base print may extend outside of the image. • Load the T-shirt so that the side seams and sleeve seams are not on the top. If there are raised sections, such as seams, an error may occur or the print quality may decline.

- Page 81 7. Gently pull the edges of the sleeve outside of the frame to remove any slack. Note: The printer detects the highest part of the garment surface and adjusts the height accordingly. If there are any wrinkles, creases or slack near the inside edge of the frame, a platen height error may occur or print quality may decline.

-

Page 82: Loading A Shirt On The Medium-Grooved Platen

Loading a Shirt on the Medium-Grooved Platen Before printing, carefully load a shirt onto the medium-grooved platen. Note: Make sure that the correct platen is installed on the printer. 1. Turn on the printer, if necessary. 2. If the platen is not in the forward position, press the moveable base button to move the platen forward. - Page 83 • For shirts with zippers: Go to steps 4 and 5 to remove the middle piece of the platen. Replace the platen and make sure that the zipper section of the shirt fits into the removed section on the platen. 5.

- Page 84 6. Slide the middle part of the platen back, then lift it up to remove it. Note: Keep the removed screw and part in a safe place. To install the middle part, perform the removal steps in reverse. Make sure to align the piece with the hole as shown.

- Page 85 7. Gently pull the shirt over the edges of the platen to flatten it. Note: • Do not pull the shirt too much; otherwise, the print quality may decline, and the white under-base print may extend outside of the image. •...

- Page 86 9. Remove any lint from the printing surface and press the fibers flat. Note: There may be lint on the T-shirt if you have not applied pre-treatment solution. Use a lint roller or sticky tape to remove the lint and then press the fibers flat using a hard roller. Lint and fibers may stick to the print head and stain other areas.

- Page 87 10. Gently pull the edges of the shirt outside of the frame to remove any slack. Note: The printer detects the highest part of the garment surface. If there are any wrinkles, creases or slack near the inside edge of the frame, a platen height error may occur or print quality may decline.

-

Page 88: Determining The Height Of The Platen

Determining the Height of the Platen The printer is equipped with a sensor that determines the height of the media surface loaded on the platen, and the printer automatically adjusts to the optimum print head height (platen gap) for printing. To use this function, you need to optimize the platen height for the type of platen you are using and the thickness of the media you are loading. - Page 89 1. Make sure the platen you want to print on is installed and the correct media is loaded. Note: The Platen Height Adjustment setting is adjusted to match the media loaded in the printer. Load the media so it is flat with no slack or creasing on the media surface as shown. 2.

- Page 90 5. Rotate the fixing lever beneath the platen as shown to loosen it.

- Page 91 6. Rotate the height adjustment lever to set the scale to 8. 7. Select Done, and then select Start on the next screen. The platen moves into the printer. 8. Do one of the following: • If a message about the media surface height or movable base appears, you need to adjust the spacers.

- Page 92 Media thickness* Spacers 0.63 to 0.94 inch (16 to 24 mm) Remove all * When using a platen without a grip pad, 0.04 inch (1 mm) thicker than the values in the table is acceptable. When using the sleeve or medium grooved platen: Media thickness Spacers 0.28 to 0.55 inch (7 to 14 mm)

- Page 93 11. Move the lever to the right by one notch to locate the position where the error sound stops. 12. Select OK and then select Done on the next screen. 13. Rotate the fixing lever as shown to tighten it and then secure the platen gap lever. Parent topic: Determining the Height of the Platen...

-

Page 94: Registering And Using Media Settings

Related references Platen Height Error Is Displayed While Printing Related tasks Attaching or Removing Spacers Registering and Using Media Settings You can store and recall commonly used media settings. Note: You can register up to 30 media settings. 1. Turn on the printer, if necessary. 2. - Page 95 Note: If you send print jobs using any of the following methods, the number of copies displayed on the control panel does not indicate the number of copies to be printed, even when multiple copies have been specified: • When using a hot folder that was created in the Garment Creator Easy Print System •...

-

Page 96: Cancelling A Print Job

• Printing was started by pressing the start button on the printer, but was canceled before printing was complete Parent topic: Loading a T-shirt Cancelling a Print Job You can cancel a print job or cancel data that is being received by the printer using the printer's control panel. -

Page 97: Fixing The Ink

1. Remove the platen frame, if necessary. 2. Hold the T-shirt by the shoulders and carefully remove it from the platen; the ink is still wet and can be easily smudged. 3. Use a heat press or a heat tunnel to fix the ink on the T-shirt. Parent topic: Finishing a T-shirt Related topics... -

Page 98: Fixing Conditions (Heat Press)

Fixing conditions differ between the heat press and the heat tunnel. Optimum conditions vary depending on the type of heat press or heat tunnel used and the amount of ink, so use the values in these sections only as a guide. Fixing Conditions (Heat Press) Fixing Conditions (Heat Tunnel) Parent topic:... -

Page 99: Fixing Conditions (Heat Tunnel)

Note: If you are not printing with White ink and the ink is not completely dry after 30 seconds, extend the duration while carefully checking if the pre-treatment solution is dry. Parent topic: Fixing the Ink Fixing Conditions (Heat Tunnel) Optimum conditions vary depending on the heat tunnel. - Page 100 Type of heat tunnel Temperature Time Batch 284 °F (140 °C) 5 to 10 minutes Conveyer Fixing White ink Type of heat tunnel Temperature Time Batch 284 °F (140 °C) 10 minutes Conveyer Parent topic: Fixing the Ink...

-

Page 101: Printing From A Usb Memory Device

Printing from a USB Memory Device You can connect a USB memory device to the printer and print jobs saved from Garment Creator 2. You can also save print jobs to a USB memory device that is connected to your computer or to the printer. Note: When a USB memory device is connected to the printer, the last print data sent from Garment Creator 2 is automatically saved to the USB memory device as temporary reprint data with the filename Epson_repeat_print.prn. -

Page 102: Connecting And Printing From A Usb Memory Device

Parent topic: Printing from a USB Memory Device Connecting and Printing from a USB Memory Device You can print from a USB memory device connected to your printer. 1. Make sure the power light on your printer is not flashing. Note: Do not connect or disconnect a USB memory device when the power light is flashing. - Page 103 6. Select the number of copies on the screen and select Done. Note: If you want the print head to only print in the first direction, select Uni-Directional as the Head Move Direction setting. 7. When the preview is on the screen and the start light is on, load the shirt on the platen and press start button.

-

Page 104: Maintenance

Maintenance See the instructions in these sections to maintain your printer for optimum results. Maintenance Guidelines Maintenance Safety Instructions Print Head Maintenance Print Head Alignment Shaking and Replacing Ink Packs Using the Ink Cleaning Solution Cleaning Around the Print Head Cleaning the Suction Cap Cleaning the Sensor Cover Disposing of Used Consumables and Optional Parts... -

Page 105: Maintenance Safety Instructions

• Soft cloth Parent topic: Maintenance Related references Optional Equipment and Replacement Parts Maintenance Safety Instructions When performing any printer maintenance procedures, follow these safety instructions: • Always wear protective eyewear, gloves, and a mask when performing printer maintenance. Should any waste ink or ink cleaner come in contact with your skin or enter your eyes or mouth, immediately take the following actions: •... -

Page 106: Print Head Maintenance

• Use only distilled water to clean specified areas. Do not use tap water. • Do not wipe the suction cap or the capping station with organic solvents such as alcohol; otherwise, you may damage the print head. Parent topic: Maintenance Related tasks Removing a Printed T-shirt... - Page 107 1. If the platen is not in the forward position, press the moveable base button to move it forward. 2. Remove the platen frame. 3. Load media onto the platen you are using: • For L, M, or S size platens, use A4- or letter-size. •...

- Page 108 • For medium grooved platens, load media on the front-right side of the platen. • For sleeve platens, load media in the center of the raised section. Note: Make sure to place the media in the correct position for the platen you are using or the platen may be soiled with ink.

- Page 109 6. Set the height adjustment lever to position P. 7. Select Menu > Maintenance > Print Head Nozzle Check. 8. Confirm that the pattern and platen settings match the type of nozzle check you want to perform. Select Current Settings and make any changes, if necessary. 9.

-

Page 110: Cleaning The Print Head

• If there are gaps in the pattern, clean the print head. 11. Replace the platen frame. Parent topic: Print Head Maintenance Related tasks Attaching or Removing Spacers Cleaning the Print Head Changing the Platen Height Cleaning the Print Head If printouts are faint or have gaps, you should clean the print head to clear the clogged nozzles. -

Page 111: Print Head Alignment

• All Nozzles: Select this option when you see faint printing or gaps in all rows of nozzles in the check pattern. Go to step 5. 4. On the LCD screen, select the nozzle rows for cleaning and then select OK. A confirmation message appears. -

Page 112: Aligning The Print Head

Parent topic: Maintenance Aligning the Print Head If your printouts are grainy or blurry and contain vertical lines or faint text, you can realign the print head for each platen size and each ink color. Note: Before making any adjustments, select the registered media setting number you wish to save the settings to. - Page 113 7. Look at each printed check pattern, and choose the number that corresponds to the thinnest line. Note: You may see more than one row of patterns. For example, in the image here, -1 is the best line. 8. Do one of the following: •...

-

Page 114: Shaking And Replacing Ink Packs

If image quality has not improved after making adjustments, do one of the following: • If you selected Standard to make adjustments, try using Micro Adjust. • If you selected Micro Adjust to make adjustments, try setting the Platen Gap setting to Manual. Otherwise, you can try printing the with Uni-Directional (Low Speed) setting enabled in Garment Creator 2. - Page 115 1. Make sure the product is turned on. 2. Open the ink covers.

- Page 116 3. Pull one of the ink trays out of the printer. Caution: Place your hand on the bottom of the tray while removing it. If you use only one hand, the weight of the tray may cause it to fall and damage the ink pack. 4.

-

Page 117: Replacing The Ink Packs

Note: This printer is designed for use with Epson ink packs only, not third-party ink packs or ink. Other brands of ink supplies are not compatible and, if described as compatible, may not function properly or continuously. - Page 118 Caution: Leave your old ink packs in the ink unit until you are ready to replace them to prevent the print head nozzles from drying out. Do not open ink packs until you are ready to install the ink. If you see a message to replace the White ink packs, replace the ink pack immediately or the printer may be damaged.

- Page 119 3. Pull out the ink tray for the ink pack that you are replacing. Caution: Place your hand on the bottom of the tray while removing it. If you use only one hand, the weight of the tray may cause it to fall and damage the ink pack. 4.

- Page 120 Caution: Be careful handling the ink pack as there may be ink around the ink supply port. Do not touch the areas on the ink pack shown below. Warning: If ink gets on your skin, wash it thoroughly with plenty of soap and water. If ink gets into your eyes, flush them immediately with water.

- Page 121 Caution: Make sure the ink pack fits onto the pegs and is aligned with the top of the tray. 6. Use a seesaw motion to gently shake the tray about 5 times within 5 seconds. If you are replacing a White ink pack, shake it about 25 times within 25 seconds.

-

Page 122: Using The Ink Cleaning Solution

10. Follow the instructions on the LCD screen to begin ink charging. Note: Do not turn off the printer, open any covers, or try to perform any other operations while the printer is charging or you'll waste ink. Your product begins charging the ink delivery system. A message appears on the LCD screen when ink replacement is complete. - Page 123 • Do not use ink cleaning solution that has already been used to clean something else. Using dirty ink cleaning solution causes stains. • Used ink cleaning solution is classified as industrial waste. Dispose of it in the same way as waste ink. •...

-

Page 124: Cleaning Around The Print Head

Parent topic: Maintenance Related tasks Cleaning the Suction Cap Cleaning the Encoder Strip (Carriage Scale) Cleaning Around the Print Head Related topics Disposing of Used Consumables and Optional Parts Cleaning Around the Print Head Clean around the print head to remove any lint or fibers that have accumulated around the print head nozzles. - Page 125 Note: When the sleeve platen is installed, make sure to remove the fixing band before lifting the platen. 6. Read the message on the LCD screen and then select Start. The platen moves to the maintenance position. Caution: Do not move the print head or the platen manually. A malfunction may occur. Note: A buzzer sounds 10 minutes after the platen and print head move to the maintenance position.

-

Page 126: Cleaning The Suction Cap

Cleaning the Suction Cap You need to clean the suction cap whenever you see a message on the LCD screen or if the printing surface is soiled with ink. You may also need to clean the suction cap if you experience difficulty cleaning nozzles after performing a nozzle check. -

Page 127: Cleaning The Sensor Cover

The print head returns to its normal position. 6. Perform a nozzle check. Parent topic: Maintenance Related tasks Using the Ink Cleaning Solution Performing a Nozzle Check Related topics Disposing of Used Consumables and Optional Parts Cleaning the Sensor Cover Clean the sensor cover when you see a message on the LCD screen to do so. -

Page 128: Disposing Of Used Consumables And Optional Parts

When handing over the pre-treatment solution to the industrial waste disposal company, make sure you include the Safety Data Sheet found on Epson's support website. To download it, visit epson.com/support/sds (U.S. -

Page 129: Waste Ink Disposal Guidelines

• Wiper unit • Capping station • Flushing pad • Media after printing • Empty ink packs, cleaning liquid packs, and used pre-treatment solution containers • Funnel filters Waste Ink Disposal Guidelines Parent topic: Maintenance Waste Ink Disposal Guidelines When you see a message on the printer's LCD screen that the waste ink bottle is nearing or at the end of its service life, you need to replace the waste ink bottle according to these guidelines: •... -

Page 130: Replacing The Waste Ink Bottle

When handing over the waste ink to the industrial waste disposal company, make sure you include the Safety Data Sheet found on Epson's support website. To download it, visit epson.com/support/sds (U.S. - Page 131 2. Remove the waste ink bottle from the waste ink bottle holder. 3. Insert the waste ink tube into the mouth of the new waste ink bottle and set the waste ink bottle in the holder. Caution: Verify that the waste ink tube is still inserted into the neck of the bottle. If the waste ink tube comes out of the bottle, waste ink will spill out.

-

Page 132: Replacing The Head Cleaning Set

5. Select OK on the LCD screen. The waste ink counter is cleared. 6. Dispose of the waste ink with the waste ink bottle. Do not pour it into another container. Note: If you replaced the waste ink bottle before the replacement message appeared on the control panel, select Menu >... -

Page 133: Cleaning The Encoder Strip (Carriage Scale)

4. Select How To... to view the steps and follow the on-screen instructions. Note: A buzzer sounds 10 minutes after the platen and print head move to the maintenance position. Select OK to continue cleaning. The buzzer sounds again after 10 minutes. Nozzles can be clogged if more time passes, so finish cleaning as soon as possible. - Page 134 Note: If you continue to use the printer without cleaning the encoder strip, the printer may not read the print area accurately and print quality may decline. 1. Turn on the printer, if necessary. 2. Press the moveable base button to move the platen into the printer to the maintenance position. Caution: Do not manually move the platen;...

- Page 135 Caution: • Make sure that ink cleaning solution does not drip into the printer. If any cleaning solution does drip, wipe it with a dry cleaning wipe. • Do not touch the carriage shaft. Doing so may cause a malfunction or failure to occur. Do not use anything other than a clean wipe.

-

Page 136: Changing The Printer Mode

6. Use a dry cleaning cloth to wipe away any ink cleaning solution or dust remaining on the encoder strip (carriage scale). 7. Close the printer cover. Parent topic: Maintenance Related references Optional Equipment and Replacement Parts Related tasks Using the Ink Cleaning Solution Changing the Printer Mode Change the printer's color mode if you will not use White ink for a longer period of time and when using White ink in the printer again. -

Page 137: Cleaning The Platen Without A Grip Pad

When the change is complete, the settings screen is displayed. Note: If you switched from White ink mode to Color ink mode, clean the ink supply port for the White ink packs you removed before storing them. Lightly touch the corner of a wide cleaning stick from the supplied Maintenance Kit to the ink supply port to absorb any ink. -

Page 138: Cleaning The Printer

3. Wipe the platen with a soft, clean cloth to carefully remove any dust or dirt. Note: If the dirt is difficult to remove, use a soft, clean cloth dampened with water and a small amount of ink cleaning solution or detergent and wrung tight. After that, dry the platen with a soft cloth. - Page 139 4. Use a soft, clean cloth to carefully remove any dust or dirt from the platen. If necessary, clean the platen using a soft, clean cloth dampened with water and a small amount of detergent. Wipe off excess moisture with a dry, soft cloth. 5.

-

Page 140: Moving Or Transporting The Printer

Moving or Transporting the Printer Follow the instructions in these sections to prepare and move the printer, and set it back up after moving it. When transporting the printer, protect it from shock and vibration by packing it using the packing materials it came with. - Page 141 • When lifting the printer, touch only the necessary areas and grip it where indicated in the illustration below. There are recessed hand holds on the bottom of the printer and the * marks in the illustration denote non-slip pads. Moving the Printer Setting Up the Printer After Transport Storing the Printer...

-

Page 142: Moving The Printer

Moving the Printer You can move the printer across the room or to another room on the same floor, or transport it to another building or location as described here. Note: Wear the protective gloves included in the maintenance kit to prevent your hands from being soiled by waste ink. - Page 143 2. Loosen the fixing lever.

- Page 144 3. Move the platen gap lever to the right to set the scale to 8.

- Page 145 4. Tighten the fixing lever and then secure the platen gap lever. 5. Make sure the printer is turned off and disconnect any cables. 6. Do one of the following: • If you are moving the printer nearby, go to step 9. •...

- Page 146 7. Move the moveable base by hand to the position shown below. Caution: Never move the moveable base by hand except as outlined for this purpose; otherwise, a malfunction may occur.

- Page 147 8. Re-install the carriage lock that you removed during initial setup and then secure it with the screw.

- Page 148 9. Carefully remove the waste ink tube from the waste ink bottle. 10. Remove the waste ink bottle. 11. Remove the waste ink tube from the tube clamps.

- Page 149 12. Unscrew the rear cover fixing screws. 13. Remove the rear cover.

- Page 150 14. Hold the waste ink tubes from the bottom with a wipe and then pull them out as shown. Use the wipe to wipe waste ink from the waste ink outlets. Note: Be careful when removing the waste ink tubes; waste ink may spill from the outlet or tube.

-

Page 151: Setting Up The Printer After Transport

15. Attach the waste ink outlet caps that were removed during printer assembly. See the Start Here sheet for more information. Parent topic: Moving or Transporting the Printer Related tasks Setting Up the Printer After Transport Setting Up the Printer After Transport Follow these steps to set up the printer after moving it. -

Page 152: Storing The Printer

Parent topic: Moving or Transporting the Printer Related tasks Performing a Nozzle Check Aligning the Print Head Installing the Platen Storing the Printer If you will not use the printer for an extended period of time with the power off, you must properly prepare it for storage. - Page 153 7. When you turn on the printer after the storage period, follow the instructions on the control panel to install and charge the ink packs and to install a new waste ink bottle. Note: • Select How To... on the screen to view the steps. •...

-

Page 154: Using The Control Panel Menus

Using the Control Panel Menus Follow the instructions in these sections to access the printer menu system and select settings. Accessing the Printer's Menus Basic Settings Menu Printer Settings Menu Maintenance Settings Network Settings Menu Media Settings Maintenance Menu Printer Status Menu Accessing the Printer's Menus You can use the printer menus to adjust the settings that control how your printer works. - Page 155 Setting Options Description LCD Brightness 1 to 9 Adjusts LCD screen brightness Sounds Button Press Adjusts the volume of control panel sounds Completion Notice Adjusts the volume of print job and maintenance completion notification Ready Notice Adjusts the volume of printer alerts Print Completion Notice Adjusts the volume of print completion notification...

-

Page 156: Printer Settings Menu

Setting Options Description Unit Settings Length unit Select the unit for length and temperature displayed on the LCD Temperature screen Parent topic: Using the Control Panel Menus Printer Settings Menu Select Menu > General Settings > Printer Settings to customize paper and printing options. Setting Options Description... - Page 157 Setting Options Description Cleaning Setting Threshold of Clogged Threshold of Clogged Nozzles sets Nozzles the number of clogged nozzles at which head cleaning should be Max Retry Cleaning performed. When Color ink mode is Count selected, set a value from 1 to 1600. When White ink mode or High speed color mode is selected, set a value from 1 to 3200.

-

Page 158: Network Settings Menu

Network Settings Menu Select Menu > General Settings > Network Settings to configure your printer's network settings. Setting Options Description Network Status Wired LAN Status Select Wired LAN Status to view the current network settings. Print Status Sheet Select Print Status Sheet to print the current network connection information. - Page 159 Print Adjustments options Setting Options Description Print Head Alignment Standard Select to run the head alignment utility to correct grainy or blurry print results Micro Adjust by realigning the print head for each platen size Note: This does not affect your print results if you set uni-directional printing for the print job.

-

Page 160: Maintenance Menu

Maintenance Menu Settings on the Maintenance menu let you run essential printer maintenance utilities. Caution: Follow the instructions in the topic links below the table to use these menu settings correctly. Setting Options Description Print Head Nozzle Check Pattern Type Select to run the nozzle check utility and inspect the printed pattern to Platen Type... -

Page 161: Printer Status Menu

— Displays the firmware version of the printer Printer Name — Displays the name of the printer set in Epson Edge Dashboard Fatal Error Log — Displays fatal error information Operation Report Total Print Numbers Displays the total number of the... -

Page 162: Solving Problems

Solving Problems Check these sections for solutions to problems you may have using your product. Product Status Messages Solving Printer Problems Solving Printing Problems Solving Print Quality Problems Uninstall Your Product Software Where to Get Help (U.S. and Canada) Where to Get Help (Latin America) Product Status Messages You can often diagnose problems with your product by checking the messages or icons on its LCD screen. - Page 163 LCD screen message Condition/solution Cannot move the Check the following and then select OK: movable base. • Remove anything that is on the platen that is not media. Check around the • Make sure there are no wrinkles on the surface of the loaded media. movable base, and then Reload the media so that it is flat.

- Page 164 A part used in the printer is nearing or at the end of its service life. Contact Replace Parts Soon your dealer or Epson for support and provide them with the displayed maintenance request code. The error persists until you replace the requested (maintenance request part.

-

Page 165: Solving Printer Problems

Related tasks Performing a Nozzle Check Cleaning the Print Head Cleaning the Sensor Cover Cleaning the Encoder Strip (Carriage Scale) Changing the Platen Height Attaching or Removing Spacers Checking Spacer Combinations and Platen Height (Scale) Related topics Printing from a USB Memory Device Solving Printer Problems Check these sections if you have problems operating your product. -

Page 166: Solving Printing Problems

Solving Printing Problems Check these sections if you have problems printing with your product. Nothing Prints Cannot Print Over a Network Print Head Moves But Nothing Prints Platen Height Error Is Displayed While Printing Message Is Displayed After Cleaning the Encoder Strip (Carriage Scale) Printing Is Slow or Stops Intermittently Cannot Access the USB Memory Device Red Light Shines Inside the Printer... -

Page 167: Cannot Print Over A Network

• Print a nozzle check pattern and then clean the print head, if necessary. If there are still clogged nozzles, clean the suction cap and around the print head and then clean the print head again and check if the clogged nozzles were cleared. If the problem remains, contact your dealer or Epson for support. -

Page 168: Platen Height Error Is Displayed While Printing

• Make sure the platen height is adjusted correctly. The printer cannot print if the platen is too far from the print head. If Platen Gap is set to Manual, check that the spacer combination and platen height (scale) are suitable for the type of media you are using. Parent topic: Solving Printing Problems Related references... -

Page 169: Message Is Displayed After Cleaning The Encoder Strip (Carriage Scale)

If a cleaning message is displayed on the LCD screen after you have cleaned the encoder strip (carriage scale), make sure that no dust or ink cleaner remains on the encoder strip (carriage scale). If the cleaning message appears again, contact Epson for support. Parent topic:... -

Page 170: Printing Is Slow Or Stops Intermittently

Related tasks Cleaning the Encoder Strip (Carriage Scale) Printing Is Slow or Stops Intermittently If printing is slow or stops in the middle of a print job, try these solutions: • Make sure Print Direction is set to Bi-Direction (High Speed) in the Garment Creator 2 software. •... -

Page 171: Forgot The Administrator Password

We recommend that you change the preset password as soon as possible to prevent unauthorized access. If you forgot the administrator password you created during network setup, contact Epson for support. Parent topic:... -

Page 172: Overall Print Quality Is Poor

Parent topic: Solving Print Quality Problems Related tasks Performing a Nozzle Check Cleaning the Print Head Cleaning the Suction Cap Cleaning Around the Print Head Related topics Shaking and Replacing Ink Packs Overall Print Quality Is Poor If you notice that your print quality is uneven, too light, too dark, or there are lines in the print (banding), try these solutions: •... - Page 173 (within a year of installation in the printer). Replace expired ink packs with new ones. • Make sure you are using genuine Epson ink supply units (ink packs). If you use non-Epson ink packs, printouts may be faint, or the color of the printed image may be uneven because the remaining ink level is not correctly detected.

- Page 174 to move the platen back. Repeat the process until a message that says the media surface is too high appears on the screen. Note: If the A and B spacers are installed and aligned with the P scale, you cannot raise the platen height any further.

-

Page 175: Lines Are Misaligned

Diluting the Pre-treatment Solution Optional Equipment and Replacement Parts Related tasks Performing a Nozzle Check Cleaning the Print Head Checking Spacer Combinations and Platen Height (Scale) Cleaning Around the Print Head Aligning the Print Head Cleaning the Suction Cap Cleaning the Encoder Strip (Carriage Scale) Related topics Shaking and Replacing Ink Packs Loading a T-shirt... -

Page 176: White Ink Quality Is Poor

• Run a nozzle check to see if any of the print head nozzles are clogged. Then clean the print head, if necessary. • Align the print head and save the adjustments to a registered media setting. • Change the Platen Gap setting to Manual. •... - Page 177 2. If the problem still remains after running the cleaning once or twice, change the printer mode to Color ink mode, and then back to White ink mode. 3. If changing the printer mode does not resolve the issue, contact your dealer or Epson for support. Parent topic:...

-

Page 178: Ink Stains Appear Outside The Printed Areas

Aligning the Print Head Cleaning the Print Head Changing the Printer Mode Related topics Pre-treating a T-shirt Shaking and Replacing Ink Packs Ink Stains Appear Outside the Printed Areas If you notice ink stains outside of the printed area of the T-shirt, there may be residual ink on the platen's frame or top plate or lint and ink may have built up on the print head. -

Page 179: Printer Status Sheet Or Logs Print Incorrectly

Then select the program you want to uninstall and select Uninstall. • Windows 10: Right-click and select Control Panel > Programs > Programs and Features. Select the uninstall option for your Epson product, then select Uninstall/Change. Note: If you see a User Account Control window, click Yes or Continue. -

Page 180: Uninstalling Product Software - Mac

Uninstalling Product Software - Mac In most cases, you do not need to uninstall your product software before re-installing it. However, you can download the Uninstaller utility from the Epson support website to uninstall your product software as described here. -

Page 181: Where To Get Help (U.s. And Canada)

You can purchase genuine Epson ink, paper, and accessories from an Epson authorized reseller. To find the nearest reseller, visit proimaging.epson.com (U.S.) or proimaging.epson.ca (Canada), select your product series and product, and click the Where to Buy button. Or call 800-GO-EPSON (800-463- 7766) in the U.S. or 800-807-7766 in Canada. Parent topic: Solving Problems... -

Page 182: Where To Get Help (Latin America)

Visit Epson's support website at latin.epson.com/support for solutions to common problems. You can download drivers and documentation, get FAQs and troubleshooting advice, or e-mail Epson with your questions. Speak to a Support Representative Before you call Epson for support, please have the following information ready: •... - Page 183 If your country does not appear in the list, contact the sales office in the nearest country. Toll or long distance charges may apply. Purchase Supplies and Accessories You can purchase genuine Epson ink, paper, and accessories from an Epson authorized reseller. To find the nearest reseller, visit latin.epson.com or call your nearest Epson sales office.

-

Page 184: Technical Specifications

Technical Specifications These sections list the technical specifications for your product. Note: Epson offers a recycling program for end of life Epson products. Please go to this site (U.S.) or this site (Canada) for information on how to return your Epson products for proper disposal. -

Page 185: Mac System Requirements

Rear port: for computer connection Front port: for external USB device connection Ethernet 1000Base-T Display resolution XGA (1024 × 768) or higher Note: For the latest product software available for your operating system, visit the Epson support site at epson.com/support (U.S.), epson.ca/support (Canada), or latin.epson.com/support... -

Page 186: Printer Specifications

Printer Specifications Printing method On-demand ink jet Nozzle configuration White Ink Mode: White: 400 nozzles × 4 Color: 400 nozzles × 4 colors Color Ink Mode: 400 nozzles × 4 colors High-Speed Color Mode: 400 nozzles × 2 (×4 colors) Thickness of height regulation 0.3 inch (7.5 mm);... -

Page 187: Interface Specifications

Material Fabric with a cotton blend ratio of 50 to 100% (100% cotton, thick fabric with a high weave density recommended) Fabric with a polyester blend of 50 to 100% (100% polyester recommended) Note: Apply pre-treatment solution when printing on polyester T- shirts or when printing white ink on cotton T-shirts. -

Page 188: Environmental Specifications

Power consumption Printing: 46 W (approximately) Ready mode: 30 W (approximately) Sleep mode: 7 W (approximately) Power off mode: 0.3 W (approximately) Parent topic: Technical Specifications Environmental Specifications Temperature Operating: 50 to 95 °F (10 to 35 °C) Operating (recommended): 59 to 77 °F (15 to 25 °C) Storage (before unpacking): –4 to 104 °F (–20 to 40 °C);... -

Page 189: Ink Specifications

Technical Specifications Ink Specifications Note: This printer is designed for use with Epson ink packs only, not third-party ink packs or ink. Other brands of ink supplies are not compatible and, if described as compatible, may not function properly or continuously. -

Page 190: Cleaning Ink Supply Unit Specifications

Dimensions 800 ml Width: 4.6 inches (117 mm) Depth: 14.2 inches (360 mm) Height: 1.2 inches (30 mm) Note: Do not refill the ink. Parent topic: Technical Specifications Cleaning Ink Supply Unit Specifications Expiration date See the date printed on the package; at normal temperature Temperature Operating: 50 to 95 °F (10 to 35 °C) -

Page 191: Ink Cleaning And Tube Cleaning Solution Specifications

Temperature Operating: 50 to 95 °F (10 to 35 °C) Storage (in package): Cotton pre-treatment solution: –4 to 104 °F (–20 to 40 °C); within 4 days at –4 °F (–20 °C) and 1 month at 104 °F (40 °C) Polyester pre-treatment solution: 32 to 104 °F (0 to 40 °C);... -

Page 192: Safety And Approvals Specifications

Parent topic: Technical Specifications Safety and Approvals Specifications United States Safety: UL62368-1 EMC: FCC part 15 Subpart B class A Canada Safety: CAN/CSA C22.2 No. 62368-1 EMC: ISED ICES-003 Class A Note: This is a class A product. In a domestic environment, this product may cause radio interference in which case the user may be required to take adequate measures. -

Page 193: Notices

Notices Check these sections for important notices about your product. Note: Epson offers a recycling program for end of life Epson products. Please go to this site (U.S.) or this site (Canada) for information on how to return your Epson products for proper disposal. -

Page 194: General Product Safety Instructions

Symbol Description General prohibition To identify actions or operations that are prohibited. Contact prohibition To indicate injury that could occur due to touching a specific part of the equipment. Caution, risk of danger To identify general caution when using the product. Caution, keep hands clear To identify a part of the product that should not be touched. - Page 195 • Do not install the printer in locations subject to oily smoke and dust, or in locations subject to humidity or where it could easily get wet. • Use only the type of power source indicated on the product's label. •...

- Page 196 • Place the product on a flat, stable surface that extends beyond its base in all directions. It will not operate properly if it is tilted or at an angle. • Do not tilt the product more than 10 degrees in any direction while moving it. Doing so may cause the product to fall and cause damage or personal injury.

- Page 197 If any abnormalities occur, turn off the power and unplug the power cable immediately, then contact your dealer or Epson Support. • Only route the cables as indicated in the Start Here sheet. When connecting cables or optional accessories, make sure they are installed in the correct direction and that you follow the procedures exactly.

-

Page 198: Lcd Screen Safety Instructions

• Do not use a pointy or sharp object, such as a pen or your fingernail, to operate the LCD screen. • If the LCD screen chips or cracks, do not touch or attempt to remove the broken pieces; contact Epson for support. -

Page 199: Fcc Compliance Statement

• If fluid gets in your eyes, rinse immediately with water. Failure to observe this precaution could result in bloodshot eyes or mild inflammation. If problems persist, consult with a physician. • If swallowed, do not induce vomiting and consult with a physician as soon as possible. •... -

Page 200: Binding Arbitration And Class Waiver

1.3 Pre-Arbitration Steps and Notice. Before submitting a claim for arbitration, you and Epson agree to try, for sixty (60) days, to resolve any Dispute informally. If Epson and you do not reach an agreement to resolve the Dispute within the sixty (60) days), you or Epson may commence an arbitration. Notice to Epson must be addressed to: Epson America, Inc., ATTN: Legal Department, 3131 Katella Ave., Los... - Page 201 Orange County, California, at your option. a) Initiation of Arbitration Proceeding. If either you or Epson decides to arbitrate a Dispute, both parties agree to the following procedure: (i) Write a Demand for Arbitration.

- Page 202 Epson's last written offer, if any, to settle the Dispute, Epson will: (i) pay you $1,000 or the amount of the award, whichever is greater; (ii) pay you twice the amount of your reasonable attorney's fees, if any;...

-

Page 203: Trademarks

Seiko Epson Corporation. The information contained herein is designed only for use with this Epson product. Epson is not responsible for any use of this information as applied to other products. -

Page 204: A Note Concerning Responsible Use Of Copyrighted Materials

Seiko Epson Corporation shall not be held liable for any damage resulting from electromagnetic interference that occurs from the use of any interface cables other than those designated as Epson approved Products by Seiko Epson Corporation. This information is subject to change without notice.