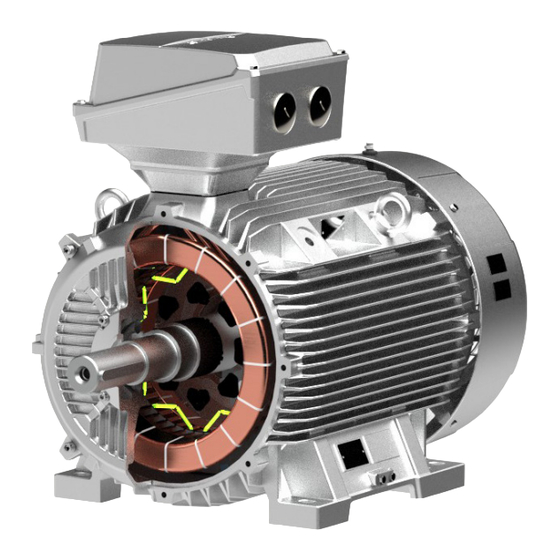

User Manuals: Siemens SIMOTICS DP Crane Motors

Manuals and User Guides for Siemens SIMOTICS DP Crane Motors. We have 5 Siemens SIMOTICS DP Crane Motors manuals available for free PDF download: Compact Operating Instructions, Operating Instructions Manual

Advertisement

Advertisement

Siemens SIMOTICS DP Compact Operating Instructions (26 pages)

Low-voltage motor, Functionally safe encoder

Table of Contents

Advertisement