Siemens SINAMICS S120 Commissioning Manual

With startdrive

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Summary of Contents for Siemens SINAMICS S120

- Page 1 Commissioning Manual SINAMICS S120 With Startdrive Edition 06/2020 www.siemens.com/drives...

- Page 3 Introduction Fundamental safety instructions Startdrive engineering tool SINAMICS Fundamentals S120 Commissioning with Startdrive Commissioning Diagnostics Commissioning Manual Appendix Valid as of: Firmware Version 5.2 SP3, Startdrive V16 Update 3 06/2020 6SL3097-5AA10-0BP2...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Table Of Contents

Table of contents Introduction ............................9 The SINAMICS converter family .................... 9 General information about SINAMICS documentation............10 Usage phases and their documents/tools ................13 Where can the various topics be found?................14 Training and support......................15 Directives, standards, certificates..................16 Additional information ....................... - Page 6 Table of contents Online and diagnostics....................... 59 Information system......................61 3.7.1 Tooltip ..........................63 3.7.2 Help for the current context ....................64 3.7.3 Help for messages and diagnostics ..................64 Project protection and user administration ................. 66 Fundamentals ............................69 Requirements for commissioning ..................

- Page 7 Table of contents 5.3.5.2 Specifying an infeed unit....................112 5.3.5.3 Connecting infeed units in parallel ................... 114 5.3.5.4 Editing inserted and specified components ............... 116 5.3.5.5 Editing DRIVE-CLiQ connections ..................117 5.3.5.6 Making detailed settings ....................119 5.3.6 Inserting a Motor Module or Power Module ..............121 5.3.6.1 Inserting and specifying a Motor Module................

- Page 8 Table of contents 5.7.1.1 Activating function modules .................... 180 5.7.1.2 Configuring the web server ....................180 5.7.1.3 Web server user accounts....................183 5.7.1.4 Enabling "SINAMICS" and "Administrator" user ..............184 5.7.1.5 Creating a password for the users "SINAMICS" and "Administrator" ........185 5.7.1.6 Deleting the password for the user "SINAMICS"...

- Page 9 Table of contents 5.9.3.2 Relative positioning ......................248 5.9.3.3 Absolute positioning ......................249 5.9.3.4 Modify traversing block....................250 5.9.3.5 Active homing ......................... 251 5.9.3.6 Direct homing........................252 5.9.4 One Button Tuning (OBT) ....................253 5.9.4.1 Performing One Button Tuning..................253 5.9.5 Stationary/rotating measurement..................

- Page 10 Table of contents 6.1.4.5 Terminal Module TM150 ....................310 Diagnostics via Startdrive ....................311 6.2.1 Device diagnostics ......................311 6.2.2 Trace function........................315 6.2.2.1 Creating or calling a trace ....................318 6.2.2.2 Configuring a trace ......................319 6.2.2.3 Transferring the trace configuration to the device ............. 323 6.2.2.4 Activating the trace recording ..................

-

Page 11: Introduction

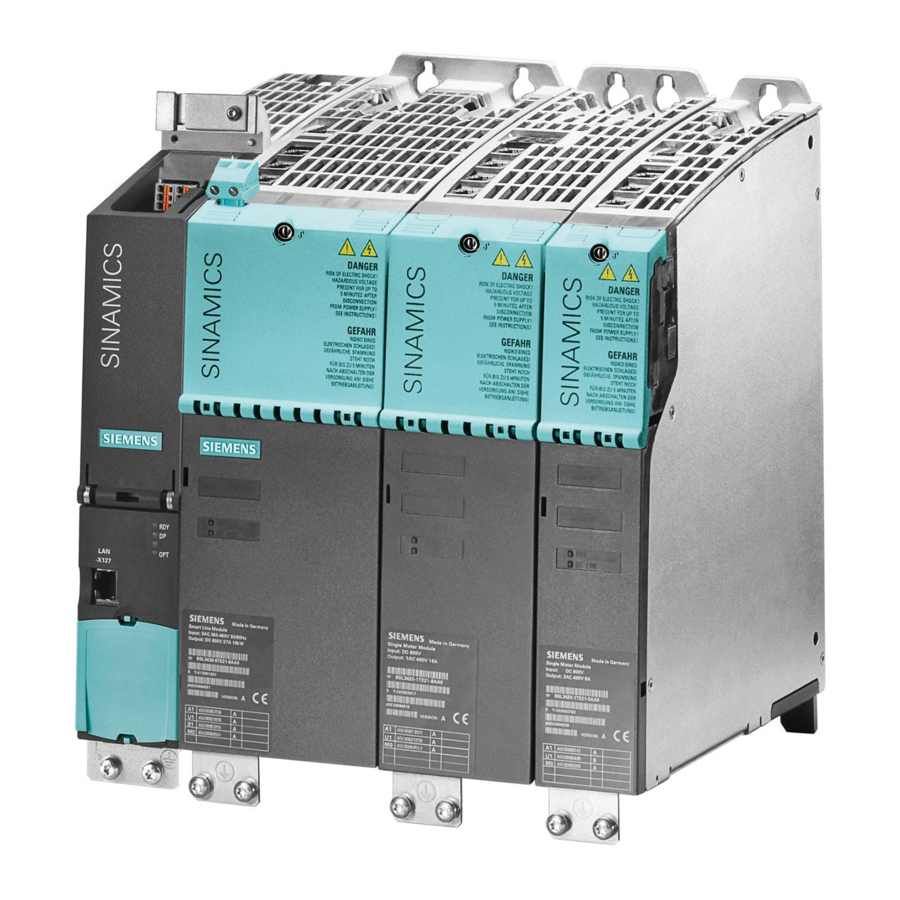

With the SINAMICS converter family, you can solve any individual drive task in the low-voltage, medium-voltage and DC voltage range. From converters to motors and controllers, all Siemens drive components are perfectly matched to each other and can be easily integrated into your existing automation system. -

Page 12: General Information About Sinamics Documentation

Siemens MySupport/Documentation You can find information on how to create your own individual documentation based on Siemens content and adapt it for your own machine documentation at the following address (https://support.industry.siemens.com/My/ww/en/documentation). Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2... - Page 13 Siemens Support while on the move With the "Siemens Industry Online Support" app, you can access more than 300,000 documents for Siemens Industry products – any time and from anywhere. The app supports you in the following areas, for example: •...

- Page 14 This document includes hyperlinks to websites of third-party companies. Siemens is not responsible for and shall not be liable for these websites or their content, as Siemens has not checked the information contained in the websites and is not responsible for the content or information they provide.

-

Page 15: Usage Phases And Their Documents/Tools

SINAMICS S210 Servo Drive System (D 32) • SINUMERIK 840 Equipment for Machine Tools (Catalog NC 62) Installation/assembly • SINAMICS S120 Equipment Manual for Control Units and Supplementary System Components • SINAMICS S120 Equipment Manual for Booksize Power Units •... -

Page 16: Where Can The Various Topics Be Found

Of a simple SINAMICS S120 drive with Getting Started STARTER Commissioning With STARTER SINAMICS S120 Commissioning Manual Commissioning Of a simple SINAMICS S120 drive with Start‐ Getting Started with Startdrive drive Commissioning With Startdrive SINAMICS S120 Commissioning Manual with Startdrive Web server... -

Page 17: Training And Support

Introduction 1.5 Training and support Training and support Training You can find information on SITRAIN at the following address (http://www.siemens.com/sitrain). SITRAIN offers training courses for products, systems and solutions in drive and automation technology from Siemens. Technical Support To ask a technical question or create a support request, click on "Support Request" at the following address and select "Create Request". -

Page 18: Directives, Standards, Certificates

Relevant directives and standards You can obtain an up-to-date list of currently certified components on request from your local Siemens office. If you have any questions relating to certifications that have not yet been completed, please ask your Siemens contact person. - Page 19 SINAMICS S devices showing the test symbols fulfill the EMC requirements for Australia and New Zealand. • Quality systems Siemens AG employs a quality management system that meets the requirements of ISO 9001 and ISO 14001. Not relevant standards China Compulsory Certification SINAMICS S devices do not fall in the area of validity of the China Compulsory Certification (CCC).

-

Page 20: Additional Information

This document contains recommendations relating to third-party products. Siemens accepts the fundamental suitability of these third-party products. You can use equivalent products from other manufacturers. Siemens does not accept any warranty for the properties of third-party products. Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2... - Page 21 Introduction 1.7 Additional information Ground symbols Table 1-1 Symbols Icon Meaning Connection for protective conductor Ground (e.g. M 24 V) Connection for function potential bonding Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2...

-

Page 22: Using Openssl

Introduction 1.8 Using OpenSSL Using OpenSSL Many SINAMICS products include OpenSSL. The following applies to these products: • This product contains software (https://www.openssl.org/) that has been developed by the OpenSSL project for use in the OpenSSL toolkit. • This product contains cryptographic software (mailto:eay@cryptsoft.com) created by Eric Young. -

Page 23: Scope Of The Document

Scope of the document Scope of the document The commissioning of a SINAMICS S120 drive system with Startdrive is described in this manual. The commissioning manual applies both to SINAMICS S120 drives and to the following drive systems that use a CU320-2 PN: •... -

Page 24: General Data Protection Regulation

For the SINAMICS Startdrive product – including the installed SINAMICS DCC option package – this means the following: The product only sends personal data to SIEMENS AG if the user explicitly requests this. This occurs in the following cases: • If the SINAMICS Startdrive program and the SINAMICS DCC option package end unexpectedly, then the user is given the opportunity to send diagnostics information to SIEMENS AG for analysis. - Page 25 Introduction 1.10 General Data Protection Regulation By generating the login or user name, personal data can be pseudonymized for the functions. Deleting the project will cause all personal data saved within it to be deleted too. The particularities of multi-user engineering should be taken into consideration here (e.g. that the project not only needs to be deleted locally from the user's PC, but also from the server used).

- Page 26 Introduction 1.10 General Data Protection Regulation Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2...

-

Page 27: Fundamental Safety Instructions

Fundamental safety instructions General safety instructions WARNING Electric shock and danger to life due to other energy sources Touching live components can result in death or severe injury. • Only work on electrical devices when you are qualified for this job. •... - Page 28 Fundamental safety instructions 2.1 General safety instructions WARNING Risk of electric shock and fire from supply networks with an excessively low impedance Excessively high short-circuit currents can lead to the protective devices not being able to interrupt these short-circuit currents and being destroyed, and thus causing electric shock or a fire.

- Page 29 Fundamental safety instructions 2.1 General safety instructions WARNING Electric shock due to unconnected cable shield Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected cable shields. • As a minimum, connect cable shields and the conductors of power cables that are not used (e.g.

- Page 30 • Therefore, if you move closer than 20 cm to the components, be sure to switch off radio devices or mobile telephones. • Use the "SIEMENS Industry Online Support app" only on equipment that has already been switched off. NOTICE...

- Page 31 Fundamental safety instructions 2.1 General safety instructions WARNING Fire due to inadequate ventilation clearances Inadequate ventilation clearances can cause overheating of components with subsequent fire and smoke. This can cause severe injury or even death. This can also result in increased downtime and reduced service lives for devices/systems.

- Page 32 Fundamental safety instructions 2.1 General safety instructions WARNING Unexpected movement of machines caused by inactive safety functions Inactive or non-adapted safety functions can trigger unexpected machine movements that may result in serious injury or death. • Observe the information in the appropriate product documentation before commissioning. •...

-

Page 33: Equipment Damage Due To Electric Fields Or Electrostatic Discharge

Fundamental safety instructions 2.2 Equipment damage due to electric fields or electrostatic discharge Equipment damage due to electric fields or electrostatic discharge Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules or devices that may be damaged by either electric fields or electrostatic discharge. NOTICE Equipment damage due to electric fields or electrostatic discharge Electric fields or electrostatic discharge can cause malfunctions through damaged individual... -

Page 34: Warranty And Liability For Application Examples

Fundamental safety instructions 2.3 Warranty and liability for application examples Warranty and liability for application examples Application examples are not binding and do not claim to be complete regarding configuration, equipment or any eventuality which may arise. Application examples do not represent specific customer solutions, but are only intended to provide support for typical tasks. -

Page 35: Security Information

Siemens’ products and solutions undergo continuous development to make them more secure. Siemens strongly recommends that product updates are applied as soon as they are available and that the latest product versions are used. Use of product versions that are no longer supported, and failure to apply the latest updates may increase customer’s exposure to cyber... -

Page 36: Residual Risks Of Power Drive Systems

Fundamental safety instructions 2.5 Residual risks of power drive systems Residual risks of power drive systems When assessing the machine- or system-related risk in accordance with the respective local regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must take into account the following residual risks emanating from the control and drive components of a drive system: 1. -

Page 37: Startdrive Engineering Tool

Startdrive engineering tool Overview The Startdrive engineering tool is available for configuring and parameterizing drives in the TIA Portal. You can perform the following tasks, for example, with Startdrive: • You create projects for drive-specific solutions. • You insert drives in the project as single drives or link the drives to higher-level controllers. •... - Page 38 You can order and download SINAMICS Startdrive V16 and available updates from the address specified below. You can find information about requirements that must be fulfilled before installation as well as installation notes on the website. • SINAMICS Startdrive V16 (https://support.industry.siemens.com/cs/ww/en/view/ 109771710) Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2...

-

Page 39: Structure Of The User Interface

Startdrive engineering tool 3.1 Structure of the user interface Structure of the user interface 3.1.1 Project view The following figure shows an example of the most important sections of the project view. ① The components and project data are displayed in the "Project tree" window. ②... -

Page 40: Project Navigation

Startdrive engineering tool 3.1 Structure of the user interface 3.1.2 Project navigation Drives, drive components and project data are displayed in the project tree and can be edited in the working area. After inserting, drives and drive components are displayed as follows: ①... -

Page 41: User Interface - Parameterization

Startdrive engineering tool 3.2 User interface - parameterization User interface - parameterization 3.2.1 Modules in the hardware catalog Overview As soon as the device configuration is active, a hardware catalog can be displayed/hidden at the right-hand edge of the program window. The device configuration automatically becomes active as soon as a drive device was inserted. -

Page 42: Device View

Startdrive engineering tool 3.2 User interface - parameterization Components Designation Types of construction CU310-2 PN CU320-2 PN Supplementary system Communication Boards – components DRIVE-CLiQ Hub Modules Terminal Boards – Terminal Modules Voltage Sensing Modules The PM240-2 Power Module is inserted together with a Control Unit Adapter (CUA) in the device configuration. The following types are available: CUA31, CUA32. - Page 43 Startdrive engineering tool 3.2 User interface - parameterization Display of configured drives The following figure shows an example of the most important parts of a configuration that are displayed in the device view. ① Control Unit ② Infeed ③ DRIVE-CLiQ interfaces and connections ④...

-

Page 44: Parameterization Editor

Startdrive engineering tool 3.2 User interface - parameterization 3.2.3 Parameterization editor Overview The parameterization editor is comprised of 2 tabs in which you can parameterize the drive: • In the function view, you parameterize the drive using a graphic user interface. The individual screen forms are based on the function diagrams –... -

Page 45: Function View

Startdrive engineering tool 3.2 User interface - parameterization 3.2.4 Function view Overview You parameterize the drive using a graphical user interface in the "Function view". The individual screen forms are based on the function diagrams – and include the parameters required. Layout of the function view The following figure shows an example of a screen form structure in the function view. -

Page 46: Parameter View

Startdrive engineering tool 3.2 User interface - parameterization Icon Meaning Activate Safety processing Save Safety processing Default with drive-specific parameters If you call interconnection screen forms in the function view, then a series of parameters are already preassigned values. For less experienced users, we recommend that they first work with the preassigned values. - Page 47 Startdrive engineering tool 3.2 User interface - parameterization Structure of the parameter view The following figure shows an example of the structure of the parameter view. ① Secondary navigation: Depending on the selected function, the parameter view shows the corresponding parameter groups. This applies to the following product groups: S120, S150, G150 and G130.

- Page 48 Startdrive engineering tool 3.2 User interface - parameterization Icon Meaning Compares the parameters of the drive object with another parameter set. • In offline mode, the parameters are compared to the factory settings by default. • In online mode, the parameters are compared to the offline settings by default. •...

- Page 49 Startdrive engineering tool 3.2 User interface - parameterization Using parameter lists You can find additional information about using parameter lists in Chapter "Using parameter lists (Page 79)". Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2...

-

Page 50: Inspector Window

Startdrive engineering tool 3.2 User interface - parameterization 3.2.6 Inspector window Overview Properties and parameters of the selected object are displayed in the inspector window. You can edit these properties and parameters. As a result, S120 drive objects that are newly inserted into the device view can be specified, for example. -

Page 51: Device Configuration Detection

Division of the "Properties" tab Each main tab contains information that is displayed via secondary tabs. The most important information for SINAMICS S120 drives can be found in the "Properties" main tab. The following secondary tabs are displayed in this main tab: •... - Page 52 Startdrive engineering tool 3.2 User interface - parameterization Structure of the dialog The following figure shows an example of the structure of the dialog. ① Drive object type of the motor controls ② Activation of the parallel connection view. In the parallel connection view, only the parallel connection-capable components are displayed.

-

Page 53: User Interface - Control Panel

Startdrive engineering tool 3.3 User interface - Control panel User interface - Control panel Overview The control panel is used for the control and monitoring of individual drives. You traverse drives from the control panel by specifying values (e.g. speed setpoint). Layout of the control panel The following figure shows as example the various components of the control panel: ①... - Page 54 Startdrive engineering tool 3.3 User interface - Control panel Further information You can find further information in Chapter "Using the control panel (Page 244)". Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2...

-

Page 55: User Interface - One Button Tuning (Obt)

Startdrive engineering tool 3.4 User interface - One Button Tuning (OBT) User interface - One Button Tuning (OBT) Overview One Button Tuning (OBT) is used to determine the optimum control parameters of a servo drive. Structure of the screen form The following diagram shows as example the various components of the "One Button Tuning"... - Page 56 Startdrive engineering tool 3.4 User interface - One Button Tuning (OBT) Restrictions ② • Option "Dynamic response factor" in the setting range "Dynamic response settings" is only available when using a CU320-2 PN. ④ • Option "Switch-on/switch-off infeed" is only available when using a CU320-2 PN. Further information You can find further information in Chapter "One Button Tuning (OBT) (Page 253)".

-

Page 57: User Interface - Trace Function

Startdrive engineering tool 3.5 User interface - trace function User interface - trace function Structure of the user interface The user interface of the trace function is made up of several display areas. The following figure shows an example of the structure of the trace user interface. ①... -

Page 58: Curve Diagram

Startdrive engineering tool 3.5 User interface - trace function 3.5.1 Curve diagram Overview The curve diagram displays the selected signals of a recording. Binary signals are shown in the lower diagram as bit track. You can adapt the display of the signals in the signal table and with the toolbar of the curve diagram. -

Page 59: Signal Table

Startdrive engineering tool 3.5 User interface - trace function 3.5.2 Signal table Overview The signals of the selected measurement and setting options for individual properties are displayed in a list in the signal table. Recording data of traces and changed settings in the signal table are only displayed in online mode. - Page 60 Startdrive engineering tool 3.5 User interface - trace function Layout of the "Measurements" tab The following figure shows an example of the structure of the "Measurements" tab. ① "Trigger/measurement point": This option facilitates the alignment of the measurements in accordance with the trigger or meas‐ urement point.

-

Page 61: Online And Diagnostics

Startdrive engineering tool 3.6 Online and diagnostics Online and diagnostics Overview You can check the status of the online accesses using function "Online & Diagnostics", and if necessary, you can establish or disconnect an online connection. Layout of working area "Online access" The following figure shows an example of the structure of the "Online access"... - Page 62 Startdrive engineering tool 3.6 Online and diagnostics Further information You can find further information in Chapter "Online diagnostics (Page 328)". Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2...

-

Page 63: Information System

Startdrive engineering tool 3.7 Information system Information system Overview The Startdrive information system opens in a separate window. The following diagram shows an example of the Startdrive information system in the TIA Portal: Figure 3-15 Example: Configuring drives The information system is divided into the following sections: •... - Page 64 Startdrive engineering tool 3.7 Information system You receive the following support when working in Startdrive: • Information system The Startdrive information system provides background information, step-by-step instructions and examples that are needed for working in Startdrive. • Tooltips The tooltips in Startdrive provide information on interface elements. In some instances, tooltips are supplemented by cascades containing more precise information.

-

Page 65: Tooltip

Startdrive engineering tool 3.7 Information system Opening the information system with the menu To open the Startdrive information system, select the command "Display help" in the "Help" menu. The start page of the information system opens. Further information You can find further information in the Startdrive information system by searching for "Help on information system". -

Page 66: Help For The Current Context

Startdrive engineering tool 3.7 Information system Opening further information If there is more detailed information in the tooltip, you can open it as follows: 1. Click on a link in the lower section of the opened tooltip dialog. The information system opens and the additional help topic appears. 3.7.2 Help for the current context Overview... - Page 67 Startdrive engineering tool 3.7 Information system Opening the help for messages and diagnostics Some messages offer further help. To display the help for a message, proceed as follows: 1. Ensure that the inspector window is open. 2. Click on the question mark behind a message.

-

Page 68: Project Protection And User Administration

Startdrive engineering tool 3.8 Project protection and user administration Project protection and user administration Overview You can also use the user administration in the TIA Portal for Startdrive projects. In this way, for example, a project can be protected against unintentional or unauthorized modification. A user sets up the project protection to activate user management. - Page 69 Startdrive engineering tool 3.8 Project protection and user administration Roles When you enable user administration, the system creates the following two roles: • ES Administrator This role is assigned to the project user first created and has all three function rights by default.

- Page 70 Startdrive engineering tool 3.8 Project protection and user administration Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2...

-

Page 71: Fundamentals

• A programming device (PG/PC) • TIA Portal with integrated Startdrive engineering tool • A communications interface, e.g. PROFINET, Ethernet • Completely wired-up drive line-up (see SINAMICS S120 manuals) Configuration example A configuration example with booksize components and PROFINET communication is shown in... -

Page 72: Safety Instructions For Commissioning

• Observe the safety instructions provided in the hardware documentation. • When assessing the risk, take into account residual risks. Note Please observe the installation guidelines and safety instructions in the SINAMICS S120 Manuals. Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2... -

Page 73: Bico Interconnections

Fundamentals 4.3 BICO interconnections BICO interconnections 4.3.1 Binectors and connectors Overview Each drive contains a large number of connectable input and output variables and internal control variables. The BICO technology (Binector Connector Technology) allows the drive to be adapted to a wide variety of conditions. -

Page 74: Interconnect Bico Inputs

Opens an interconnection dialog in which you can create a bit-by-bit interconnection (multiple interconnections). Further information Further information on BICO technology and BICO connections can be found in Section "Basics of the drive system" in the SINAMICS S120 Drive Functions Function Manual. 4.3.2 Interconnect BICO inputs Overview You perform the interconnection of binector or connector inputs in the interconnection dialog. - Page 75 Fundamentals 4.3 BICO interconnections Procedure To interconnect a BICO input, proceed as follows: 1. Click the binector or connector symbol of the signal that you want to connect. A connection dialog for the selection of the possible parameters opens. The drive object for which you want to make an interconnection is displayed automatically in the "Drive object"...

-

Page 76: Interconnecting Bico Outputs

Fundamentals 4.3 BICO interconnections 3. Select the parameter bit that you want to connect. 4. Confirm with OK. The connection dialog closes. Result The binector or connector input is connected to the selected parameter (bit). 4.3.3 Interconnecting BICO outputs Overview You perform the interconnection of binector or connector outputs in the interconnection dialog. - Page 77 Fundamentals 4.3 BICO interconnections Procedure To interconnect a BICO output, proceed as follows: 1. Click the binector or connector symbol of the signal that you want to connect. A connection dialog for the selection of the possible parameters opens. The drive object for which you want to make an interconnection is displayed automatically in the "Drive object"...

- Page 78 Fundamentals 4.3 BICO interconnections 3. Activate the check boxes for the parameter bits that you want to connect. 4. Confirm with OK. The connection dialog closes. Result The binector or connector output is connected to the selected parameter (bit). Multiple connections at outputs Several interconnections can be set simultaneously for a parameter, which for reasons of space however, cannot be displayed in the interconnections field.

-

Page 79: Activating / Deactivating Individual Drive Components

Fundamentals 4.4 Activating / deactivating individual drive components Activating / deactivating individual drive components Function description Configure the drive, which comprises a CU and additional components, in the device view (DRIVE-CLiQ Editor). All drive components are activated by default. When replacing parts, carrying out testing or service, it may be necessary to briefly deactivate and then reactivate individual components. - Page 80 Fundamentals 4.4 Activating / deactivating individual drive components Deactivating / activating component Proceed as follows to deactivate a component in the device view: 1. In the device view, select the drive object, (e.g. infeed) with the component that you wish to ①...

-

Page 81: Using Parameter Lists

Fundamentals 4.5 Using parameter lists Using parameter lists 4.5.1 Editing the parameter list Overview The following functions are available in the parameter view: • Monitoring and editing parameter values • Changing/restricting parameter view • Exporting the parameters as CSV Additional information on the user interface structure is provided in Chapter "Parameter view (Page 44)". -

Page 82: Searching For Parameters

Fundamentals 4.5 Using parameter lists Proceed as follows to export the parameter list as CSV file: 1. Click on the arrow icon in the button A menu selection opens. The following export options are available: – Exporting displayed parameters in a CSV file –... -

Page 83: Comparing Parameters

Fundamentals 4.5 Using parameter lists Proceed as follows to search for individual parameters or terms: 1. Ensure that the parameter view is selected. The parameter is selected if the upper editor bar is dark blue. 2. Enter <Ctrl+F>. 3. Enter a parameter number or a search term in the search field (e.g. control word). 4. - Page 84 Fundamentals 4.5 Using parameter lists Procedure Proceed as follows to make a comparison: 1. Open the parameter view of the drive object whose parameter set you wish to compare. 2. Click on the arrow icon in the button A selection list containing the comparison options opens: Mode Options Offline...

- Page 85 Fundamentals 4.5 Using parameter lists Icon Meaning At least one of the two comparison values has a technological or syntax error. The comparison is not possible. At least one of the two comparison values is not available (e.g. snapshot). Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2...

-

Page 86: Saving Settings

Fundamentals 4.6 Saving settings Saving settings To permanently save the settings, you have the following options: • Saving settings in the project. • Saving settings (offline/online) on the memory card of the converter. 4.6.1 Saving settings in the project Overview In Startdrive, settings are predominantly made via screen forms. - Page 87 Fundamentals 4.6 Saving settings Saving offline data Proceed as follows to save the offline configuration retentively: 1. Load the project data into the converter. For information on this, see Chapter "Loading the project data into the converter (Page 242)". 2. Click the icon in the function view of the active Startdrive project.

-

Page 88: Restoring Factory Settings

Fundamentals 4.7 Restoring factory settings Restoring factory settings Overview In online operation, you can restore the factory settings for the drive control. Procedure To restore the factory settings for the drive control, proceed as follows: 1. Establish an online connection (Page 152) to your drive unit. 2. -

Page 89: Loading Project Data From The Converter

Fundamentals 4.8 Loading project data from the converter Loading project data from the converter Overview You can load the saved project data from your drive unit into your current project in Startdrive. Requirements • A project is open. • The hardware configuration and software to be loaded must be compatible with the Startdrive (see Chapter "Checking the firmware version (Page 154)"). - Page 90 Fundamentals 4.8 Loading project data from the converter Result The project data has been loaded from the drive unit into your Startdrive project on the PC. Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2...

-

Page 91: Updating The Firmware

4.9 Updating the firmware Updating the firmware Overview The firmware for the SINAMICS S120 drive system is distributed in the system. It is installed on the Control Unit and in every individual DRIVE-CLiQ component. When is a firmware update required? A firmware update is required if you want to use a new firmware version with an extended range of functions. - Page 92 Fundamentals 4.9 Updating the firmware 6. Insert the memory card with the new firmware version. 7. Turn your Control Unit on again. The drive unit now starts with a self-configuration and downloads the firmware data from the memory card to the Control Unit. Explanation of LED displays Firmware update is active: •...

-

Page 93: Using Libraries

Fundamentals 4.10 Using libraries 4.10 Using libraries 4.10.1 Overview Function description In the TIA Portal, libraries are used to archive elements that you wish to reuse in a specific project or across projects. In a project involving several drives, you can create copies of drives using master copies. You can then insert these elements at the required location in your project. - Page 94 Fundamentals 4.10 Using libraries Figure 4-3 Example: Folder functions Explanation of icons The following table provides an overview of the icons that are displayed in the "Project library" palette. Icon Explanation Creating a new folder: Creates a new folder in the selected folder. Opening or closing the element view: All elements are displayed in the "Elements"...

-

Page 95: Using Copy Templates

Fundamentals 4.10 Using libraries 3. Select a device / several devices in the project tree. Select one network / several networks in the network view. 4. Drag your selection and drop it into folder "Master copies". The selected device is inserted as master copy in the library. Procedure (global libraries) Proceed as follows to create a master copy in a global library: 1. - Page 96 Fundamentals 4.10 Using libraries 4. Select a master copy. 5. Drag the master copy and drop into the project folder in the project tree. 6. If the master copy originates from the network view, drag the master copy and drop it into the network view.

-

Page 97: Commissioning

Commissioning Overview You perform the commissioning of your SINAMICS S120 drive in the TIA Portal with the integrated Startdrive engineering tool. Requirements • TIA Portal is installed on your PG/PC. The version of the following software component applies exclusively to the current edition of this documentation: –... - Page 98 Commissioning 5. Commission the drive via the control panel. (Page 244) 6. Result: The motor turns. Loading the configuration of the drive offline into the project For commissioning a drive by uploading the drive configuration to the project, the following steps are required: 1.

-

Page 99: Calling The Tia Portal

Commissioning 5.1 Calling the TIA portal Calling the TIA portal To start the TIA Portal, click on the TIA Portal icon of your user interface or call it up via the Start menu of your PG/PC. Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2... -

Page 100: Check Lists To Commission Sinamics S

Commissioning 5.2 Check lists to commission SINAMICS S Check lists to commission SINAMICS S You will find the checklists that must be observed before the commissioning of SINAMICS S120 drives in the following. Checklist for commissioning booksize power units Carefully observe the content of the following checklist, and read the safety instructions in the manuals before starting any work. - Page 101 Commissioning 5.2 Check lists to commission SINAMICS S Check Do the temperature monitoring circuits fulfill the specifications of protective separation? Have the rules for the DRIVE-CLiQ topology been observed? Have the line-side and motor-side power cables been dimensioned and routed in accord‐ ance with the environmental and routing conditions? Have the maximum permitted cable lengths between the frequency converter and the motor (depending on the type of cables used) been observed?

-

Page 102: Creating A Project Offline

Commissioning 5.3 Creating a project offline Creating a project offline The following options are available to you for Startdrive projects: • You create a new project (see Chapter "Create a new project (Page 100)"). • You open an existing project and subsequently change the project configuration (see Chapter "Opening an existing project (Page 100)"). - Page 103 Startdrive (V15 or higher). If you wish to upgrade older S120 projects of version V14 SP1 to version V15 or higher, proceed as described in the following document: "Migrating SINAMICS S120 projects in Startdrive from V14 to V15 (https:// support.industry.siemens.com/cs/ww/en/view/109755173)"...

-

Page 104: Sequence When Creating Drive Components

Commissioning 5.3 Creating a project offline This information is generated and administered in the user administration of the TIA Portal. You can find further information about project protection in the Startdrive information system under "Using user administration". 5.3.3 Sequence when creating drive components Overview As a rule, the needed components must be inserted into the device configuration and specified after a new project is created. -

Page 105: Inserting The Control Unit

5.3.4 Inserting the Control Unit A Control Unit must be inserted as the first component of a drive. You insert a SINAMICS S120 Control Unit into a new project via one of the following described ways: • Via the project view (recommended) •... - Page 106 Commissioning 5.3 Creating a project offline Procedure Proceed as follows to insert a Control Unit into the project view: 1. Double-click "Add new device" in the project tree. The appropriate dialog opens. ① "Device name" input field (default: Drive unit_x) ②...

- Page 107 Commissioning 5.3 Creating a project offline 3. Click on the required Control Unit in the "Control Units" list. Note Comparing and possibly changing version numbers The latest firmware version is always suggested when creating a Control Unit. Under certain circumstances, the recommended firmware version does not match the version number on the memory card of your converter.

-

Page 108: Inserting A Control Unit Via The Portal View

5.3.4.2 Inserting a Control Unit via the portal view Overview Alternatively to the recommended main method, you can insert a SINAMICS S120 Control Unit into a new project via the portal view. Requirements • A project has been created (Page 100), or an existing project is open. -

Page 109: Inserting A Control Unit Via The Network/Topology View

5.3.4.3 Inserting a Control Unit via the network/topology view Overview Alternatively to the recommended main method, you can insert a SINAMICS S120 Control Unit into a new project via the network or topology view Requirements • A project has been created (Page 100), or an existing project is open. -

Page 110: Copying Drives From Existing Projects

To insert a drive via the network/topology view, proceed as follows: 1. Open the network/topology view in the project view. 2. In the hardware catalog, open entry "Drives & starters > SINAMICS drives > SINAMICS S120 > Control Units". 3. Drag the required Control Unit and drop it into the network/topology view. -

Page 111: Copying Drives From Existing Libraries

Commissioning 5.3 Creating a project offline Copying drives from a reference project You can also copy drives from a reference project. Additional information about using reference projects is provided in the Startdrive information system under "Editing projects". Note Copying and inserting between protected projects It is not possible to copy and insert drives and drive components between protected projects. -

Page 112: Inserting An Infeed Unit

• The recommended ON and OFF sequence for activating the SLMs must be adhered to. You can find further information on the wiring of Smart Line Modules with the Control Unit and for the recommended ON/OFF sequence in the Equipment Manual SINAMICS S120 booksize power units. - Page 113 Commissioning 5.3 Creating a project offline Requirements • A SINAMICS S120 CU320-2 PN Control Unit is inserted in the device configuration. • Insert an Active, Basic or Smart Line Module in the device configuration. Restrictions • The use of a Line Module excludes the use of a PM 240-2 Power Module in a drive configuration.

-

Page 114: Specifying An Infeed Unit

Commissioning 5.3 Creating a project offline 5.3.5.2 Specifying an infeed unit Overview Initially, after creating an infeed unit in the configuration, only one non-specified placeholder is available. Using an article number, this placeholder must be specified in more detail. As a result, you ensure that the component in the device view corresponds to the component that is contained in your drive configuration. - Page 115 Commissioning 5.3 Creating a project offline 3. In the "General" tab, select the entry "Line Module - Selection - xxx". A selection of the available infeed units is displayed. 4. Select the required infeed unit based on the article number. The following is automatically set based on your selection: –...

-

Page 116: Connecting Infeed Units In Parallel

Commissioning 5.3 Creating a project offline The infeed unit is inserted and specified in accordance with your drive configuration. Note If an Active Line Module or a Smart Line Module with the chassis format was inserted, then a Voltage Sensing Module is automatically added and wired. 5.3.5.3 Connecting infeed units in parallel Overview... - Page 117 Motor supply lines must be opened. Further information Further information on rules, requirements, and restrictions for the parallel connection of Line Modules and Motor Modules can be found in the SINAMICS S120 Function Manual Drive Functions. Commissioning with Startdrive...

-

Page 118: Editing Inserted And Specified Components

Commissioning 5.3 Creating a project offline 5.3.5.4 Editing inserted and specified components Overview All of the inserted components are graphically displayed in the device view. The device view provides the following editing options for the inserted components: • Moving the component •... -

Page 119: Editing Drive-Cliq Connections

Commissioning 5.3 Creating a project offline Deleting components Delete the components that you no longer require. 1. Right-click in the gray border. A shortcut menu opens. 2. To delete the DRIVE-CLiQ component, select "Delete" from the shortcut menu. The component is deleted. Note You can undo the deletion via the shortcut <Ctrl>... - Page 120 Commissioning 5.3 Creating a project offline Automatic wiring of components With most drive systems, the DRIVE-CLiQ connections are automatically established with the default settings when creating a component. Note No automatic wiring With an S120 drive system with a CU310-2 PN, the components are not automatically wired via DRIVE-CLiQ.

-

Page 121: Making Detailed Settings

Commissioning 5.3 Creating a project offline Creating a DRIVE-CLiQ connection To create a DRIVE-CLiQ connection between two DRIVE-CLiQ ports, proceed as follows. 1. Left-click the output port and keep the mouse button pressed. 2. Drag the line displayed to the target port. A DRIVE-CLiQ connection is established between the ports and is displayed as a blue line. - Page 122 Commissioning 5.3 Creating a project offline Note Switching on a new/modified network When first switched on with a new/modified network, an automatic controller setting must be implemented using the line and DC link identification routine (p3410). While the identification routine is running, it is not permissible for other loads to be switched in/switched out. Procedure To make detailed settings for an infeed unit, proceed as follows: 1.

-

Page 123: Inserting A Motor Module Or Power Module

Commissioning 5.3 Creating a project offline 3. In order to parameterize the device supply voltage, click the icon next to the "Line data / operating mode" entry. The "Line data / Operating mode" screen form is opened: Set the required device supply voltage here (see Chapter "Line data/operating mode (Page 208)"). - Page 124 Commissioning 5.3 Creating a project offline Many of the following settings depend on the set drive object type. The setting of the correct type is therefore prerequisite for all other settings during the commissioning and parameterization of the Motor Module or Power Module. Important notes •...

-

Page 125: Inserting And Specifying A Motor Module

Commissioning 5.3 Creating a project offline Vector control features The motor connected to a vector control is simulated in a vector model based on data from the equivalent circuit diagram. The motor module is emulated as precisely as possible to obtain the best results regarding control control accuracy and control quality. - Page 126 5.3 Creating a project offline Requirements • A SINAMICS S120 CU320-2 PN Control Unit is inserted in the device configuration. • An infeed unit is inserted. You can also add an infeed unit at a later point in time. In this case, you must manually wire the infeed unit with the other components.

-

Page 127: Inserting And Specifying An Ac Power Module

Requirement • A SINAMICS S120 Control Unit has been inserted in the device configuration. Restrictions • Only chassis format AC Power Modules can be specified in the Startdrive engineering tool. - Page 128 Commissioning 5.3 Creating a project offline Procedure Proceed as follows to insert and specify an AC Power Module in the device configuration: 1. Open the "Power Modules" entry in the hardware catalog. 2. Select component "AC Power Module". 3. Drag the unspecified AC Power Module and drop it into the device view. The Power Module is automatically interconnected with the Control Unit via DRIVE-CLiQ.

-

Page 129: Inserting And Specifying Pm240-2

Commissioning 5.3 Creating a project offline 7. Confirm the procedure with "Yes". The Power Module selection list is now refreshed. 8. Select the Power Module based on the Article No. The data of the selected Power Module is assigned to the Power Module in the device configuration. - Page 130 Commissioning 5.3 Creating a project offline Requirement • A SINAMICS S120 CU320-2 PN Control Unit is inserted in the device configuration. Restrictions • Only blocksize format PM240-2 can be specified in the Startdrive engineering tool. Procedure Proceed as follows to insert and specify a PM240-2 together with a Control Unit Adapter (CUA) in the device configuration: 1.

- Page 131 Commissioning 5.3 Creating a project offline 8. Select the Power Module based on the Article No. The data of the selected Power Module is assigned to the Power Module in the device configuration. The Power Module has therefore been specified. The corresponding component is shown in the device configuration in dark gray.

-

Page 132: Making Detailed Settings

Commissioning 5.3 Creating a project offline 5.3.6.4 Making detailed settings Overview The following detail settings can be carried out in the inspector window for Motor Modules and Power Modules: • Settings – Allows the modification of the preallocated supply voltage. –... -

Page 133: Copying And Inserting Motor Modules

Copying and inserting Motor Modules Overview In a project with SINAMICS S120 drives, Motor Modules can be copied and inserted within the same drive or in another drive of the same type. As a consequence, it is only necessary to configure a Motor Module once. - Page 134 5.3 Creating a project offline Restrictions • Command option "Paste" is not listed for Control Units that do not belong to the SINAMICS S120 product category (e.g. G150). • The procedure is not possible under a SIMATIC Drive Controller. Procedure (project tree) Proceed as follows, to copy and insert a configured Motor Module within the project tree.

-

Page 135: Interconnecting Motor Modules In Parallel

You can interconnect additional Motor Modules in the same way. Requirements • A SINAMICS S120 CU320-2 PN Control Unit is inserted in the device configuration. • The Motor Module inserted in the device configuration has the following specifications: – Format: "Booksize"... -

Page 136: Inserting A Motor

Commissioning 5.3 Creating a project offline Procedure To connect several Motor Modules in parallel, proceed as follows: 1. Open "Motor Modules" in the hardware catalog. 2. Drag & drop a Motor Module into the light gray area of the already existing Motor Module. 3. -

Page 137: Inserting And Specifying Motors From The Motor List

5.3 Creating a project offline Requirements • A SINAMICS S120 Control Unit has been inserted in the device configuration. • An infeed unit is inserted. You can also add an infeed unit at a later point in time. In this case, you must manually wire the infeed unit with the other components (see Chapter "Inserting an infeed unit... -

Page 138: Inserting And Specifying Motors That Are Missing From The Motor List

Commissioning 5.3 Creating a project offline 6. In the inspector window, select entry "Motor- Selection - xxx". 7. Select your motor with the corresponding motor encoder in the drop-down list based on the article number. Motor data – The data of the selected motor are assigned to the unspecified motor. The white area turns dark gray. - Page 139 Commissioning 5.3 Creating a project offline 7. If you want to record motor data under "Optional motor data" and "Equivalent circuit diagram data", activate the following options in the "Rating plate values" screen form: – "Activate display of the optional motor data" –...

-

Page 140: Configuring Motor Details

Commissioning 5.3 Creating a project offline 5.3.7.3 Configuring motor details Overview You can configure the following motor details for motors during commissioning: • Basic parameter assignment • Rating plate values • Motor brake Procedure To configure the motor details, proceed as follows: 1. - Page 141 Commissioning 5.3 Creating a project offline 6. In the inspector window, select the "Motor details > Motor brake" menu. The current configuration of the motor holding brake is displayed in the screen form. 7. To change the configuration of the motor holding brake, click the icon next to the "Brake control"...

-

Page 142: Inserting Measuring Systems (Encoders)

This is the reason that high quality encoders must be used for motor encoders. – Siemens motors that have already been configured are created in the device view with the matching encoder and the encoder evaluation. -

Page 143: Inserting An Encoder

Note Encoders from the hardware catalog SIEMENS in-house encoders which are listed in the hardware catalog no longer have to be parameterized as they are already preassigned the appropriate settings. In contrast, third-party encoders must be parameterized as described below. -

Page 144: Specifying The Encoder Evaluation

Commissioning 5.3 Creating a project offline Procedure Proceed as follows to insert and specify an encoder in your device configuration: 1. Open "Measuring systems" in the hardware catalog. 2. Select the desired, unspecified encoder in the device overview. 3. Drag the desired, unspecified encoder to the lower area of the Motor Module. An encoder and a Sensor Module are created. -

Page 145: Encoder System Connection

Control Unit. The encoder system connection to SINAMICS S120 drives is exclusively done via DRIVE-CLiQ. In conjunction with motor encoders, the motor temperature can also be evaluated using Sensor Modules. -

Page 146: Making Detailed Settings

Commissioning 5.3 Creating a project offline Assignment of measuring system to Sensor Modules The following table gives an overview of the assignment of the various measuring systems to the available Sensor Modules. Measuring systems SMC10 SMC20 SMC30 SMC40 SME20 SME25 SME120 SME125 Resolver... - Page 147 Commissioning 5.3 Creating a project offline 3. To configure the actual value processing, click the icon next to the "Actual value processing" entry. The "Actual value processing" screen form opens: Make the required settings here (see chapter "Actual value processing (Page 218)"). 4.

-

Page 148: Inserting Additional System Components

Commissioning 5.3 Creating a project offline Result You have made the detailed settings for the selected encoder in your device configuration. 5.3.9 Inserting additional system components The following components can be inserted additionally in the device configuration of your drive: •... - Page 149 Commissioning 5.3 Creating a project offline Requirement • A SINAMICS S120 Control Unit (or a SIMATIC Drive Controller) has been inserted in the device configuration. Restriction • When using a CU310-2 PN, DRIVE-CLiQ Hub Modules inserted in the device configuration are not automatically wired via DRIVE-CLiQ.

-

Page 150: Insert Communication Board Cbe20

The CBE20 Communication Board is a flexible component, which can be operated in Startdrive with the "SINAMICS link" communication profile. Requirements • A SINAMICS S120 Control Unit has been inserted in the device configuration. • No Terminal Board TB30 is contained in the device configuration. Note A TB30 Terminal Board and a CBE20 Communication Board cannot be created simultaneously in the device configuration. -

Page 151: Insert Terminal Module

With Terminal Modules, you can expand the interfaces of the Control Unit. They are connected to the Control Unit via DRIVE-CLiQ. Requirement • A SINAMICS S120 Control Unit has been inserted in the device configuration. Procedure To insert a Terminal Module into the device configuration, proceed as follows: 1. -

Page 152: Insert Voltage Sensing Module Vsm10

5.3 Creating a project offline Requirements • A SINAMICS S120 Control Unit has been inserted in the device configuration. • No Communication Board CBE20 is contained in the device configuration. TB30 and CBE20 cannot be created simultaneously in the device configuration. - Page 153 Control Unit. Further information You can find further information on the system rules for operating multiple VSMs per Line Module in the SINAMICS S120 Function Manual Drive Functions. Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2...

-

Page 154: Establishing An Online Connection To The Drive

5.4 Establishing an online connection to the drive Establishing an online connection to the drive Overview Most SINAMICS S120 control units (e.g. CU320-2 PN) have 2 interfaces, via which you can connect the drive online. Industrial security guidelines Observe the following information and follow the instructions in them when selecting and configuring the interfaces. - Page 155 Commissioning 5.4 Establishing an online connection to the drive IP addresses in the project A SINAMICS S120 Control Unit is created with the following IP addresses in a project in the TIA Portal: • Commissioning and service interface X127: – IP address: 169.254.11.22 –...

-

Page 156: Checking The Firmware Version

Commissioning 5.4 Establishing an online connection to the drive 3. In display area "Preset connection path for online access", define the interface type and the interface. 4. Enable the option "Display dialog for setting the default connection path for the online access". - Page 157 Commissioning 5.4 Establishing an online connection to the drive Checking the firmware consistency To check the firmware consistency between your Startdrive project and drive, proceed as follows: 1. Check the firmware version on your memory card using the "General" diagnostics screen form.

-

Page 158: Online Connection Via Standard Service Interface X127

The interface X127 with a default IP address is available for commissioning your drive. Requirements New project • A SINAMICS S120 Control Unit has been inserted in the device configuration. • You have connected your PG/PC with the drive via the X127 service interface. Note You can go directly online as the service interface X127 has already been assigned an IP address. - Page 159 Commissioning 5.4 Establishing an online connection to the drive Procedure To establish an online connection between your PG/PC and the drive, proceed as follows: 1. Select the drive unit with which you want to go online in the project tree (or in the device view).

-

Page 160: Online Connection Via Profinet Interface

Commissioning 5.4 Establishing an online connection to the drive 8. Select your drive unit from the table. 9. To establish an online connection to the drive unit, click "Connect". The online connection between the PG/PC and the drive unit is established. The settings are used automatically the next time you go online and the "Go online"... -

Page 161: Searching For A Drive

Commissioning 5.4 Establishing an online connection to the drive 5.4.3.2 Searching for a drive Overview You can search for your drive in the TIA Portal using the "Online access" option. Requirements • You have inserted a drive in the project. •... -

Page 162: Assigning An Ip Address

Commissioning 5.4 Establishing an online connection to the drive 3. Double click on "Update accessible devices". The drive is displayed in the project tree. If the communication parameters of the drive are set to factory settings (IP address 0.0.0., no device name), then the default device name of the TIA Portal (in this case: "Accessible device") and the MAC address are displayed. - Page 163 Commissioning 5.4 Establishing an online connection to the drive Overview Upon delivery, the PROFINET interface X150 of the drive does not have an assigned IP address. If a cyclic connection already exists from SINAMICS to the controller, it is no longer possible to assign an IP address.

-

Page 164: Assigning Profinet Device Names

Commissioning 5.4 Establishing an online connection to the drive 5.4.3.4 Assigning PROFINET device names You must assign a device name to the drive so that you can operate the drive in a PROFINET subnet. Assign device name This name must comply with DNS name conventions. For detailed information, refer to the information system of the TIA Portal. -

Page 165: Ip Address And The Subnet Mask In The Project

Commissioning 5.4 Establishing an online connection to the drive 5.4.3.5 IP address and the subnet mask in the project Overview After you have assigned an IP address to the drive, check the IP address and subnet mask set in the project. An online connection can only be established when the settings in the project and in the drive are identical. -

Page 166: Setting Up The Preferred Pg/Pc Interface

Commissioning 5.4 Establishing an online connection to the drive 5.4.3.6 Setting up the preferred PG/PC interface Overview The PROFINET communication between the drive and the PG/PC takes place via an Ethernet interface. For the communication via the X150 PROFINET interface, the IP address and subnet mask of the PG/PC interface must lie within the number range of the PROFINET subnet. - Page 167 Commissioning 5.4 Establishing an online connection to the drive Add IP address for PG/PC interface in the subnet 1. Click in the toolbar on button The "Go online" dialog opens. 2. Select the device and click "Connect" to confirm. 3. Assign an IP address to the PG/PC, which is located in the subnet of the drive. If you have not yet done this via the Windows system control, you will be offered at this point to temporarily assign a suitable IP address from the subnet of the drive to your PG/PC.

-

Page 168: Restoring Factory Settings

Commissioning 5.4 Establishing an online connection to the drive To display the overview of all of the temporary IP addresses and to delete temporary IP addresses, proceed as follows: 1. Navigate in the project tree to "Online access" and from there to the appropriate interface. 2. - Page 169 Commissioning 5.4 Establishing an online connection to the drive 3. Double-click the "Restore factory settings" entry in the secondary navigation. The dialog box with the current settings is displayed. 4. Click the "Reset" button. The drive communication settings are reset to the factory settings. 5.

-

Page 170: Alternative 1: Loading The Drive Configuration Into The Project

Commissioning 5.5 Alternative 1: Loading the drive configuration into the project Alternative 1: Loading the drive configuration into the project 5.5.1 Create a new project Overview You can create new projects once you have opened the Startdrive application in the TIA Portal. Procedure Proceed as follows to create a new project: 1. - Page 171 Commissioning 5.5 Alternative 1: Loading the drive configuration into the project Procedure To upload a device as a new station, proceed as follows: 1. In the project tree, click on the arrow icon next to the "Online access" function. The following options are then displayed: 2.

-

Page 172: Post-Processing The Drive Configuration

Commissioning 5.5 Alternative 1: Loading the drive configuration into the project 5.5.3 Post-processing the drive configuration Overview In an ideal scenario, all of the drive components are transferred into the drive configuration and specified via the automatic configuration. In this case, the error-free configuration is confirmed in the message display and the configuration does not have to be post-processed. -

Page 173: Alternative 2: Creating A Project With A Determined Drive Configuration

The new project is created and simultaneously opened. 5.6.2 Inserting the drive offline Overview The following describes how to insert a SINAMICS S120 Control Unit into a new project via the project view. Requirements • A project has been created, or an existing project is open. - Page 174 Commissioning 5.6 Alternative 2: Creating a project with a determined drive configuration Procedure Proceed as follows to insert a Control Unit into the project view: 1. Double-click "Add new device" in the project tree. The appropriate dialog opens. ① "Device name" input field (default: Drive unit_x) ②...

- Page 175 Commissioning 5.6 Alternative 2: Creating a project with a determined drive configuration 3. Click on the required Control Unit in the "Control Units" list. Note Comparing and possibly changing version numbers The latest firmware version is always suggested when creating a Control Unit. Under certain circumstances, the recommended firmware version does not match the version number on the memory card of your converter.

-

Page 176: Determining The Drive Configuration

Commissioning 5.6 Alternative 2: Creating a project with a determined drive configuration Result The Control Unit is inserted and can then be configured. Example: CU310-2 PN inserted Example: CU320-2 PN inserted 5.6.3 Determining the drive configuration Overview The individual steps for automatically determining the drive configuration via the function "Detection of the device configuration"... - Page 177 Commissioning 5.6 Alternative 2: Creating a project with a determined drive configuration Performing device configuration identification To determine the drive configuration via the function "Detection of the device configuration", proceed as follows: 1. Select the desired drive in the project tree or in the device configuration. 2.

- Page 178 Commissioning 5.6 Alternative 2: Creating a project with a determined drive configuration Non-assignable components Components that are not automatically assigned to a main component during device configuration detection are listed at "Non-assignable components". These components can be manually assigned via drag-and-drop or via the shortcut menu of a main component. Note All of the components listed in the "Non-assignable components"...

- Page 179 Commissioning 5.6 Alternative 2: Creating a project with a determined drive configuration Changing the assignment of components To change the assignment of the components, proceed as follows: 1. Select a component in the list that you want to assign to a different main component. 2.

-

Page 180: Importing The Drive Configuration Into The Project

Commissioning 5.6 Alternative 2: Creating a project with a determined drive configuration Cancelling a parallel connection To eliminate an existing parallel connection, proceed as follows: 1. Move individual components to the higher-level drive using the drag-and-drop feature. 2. Select a component that is connected in parallel and then the shortcut menu "Disconnect parallel connection". -

Page 181: Post-Processing The Drive Configuration

Commissioning 5.6 Alternative 2: Creating a project with a determined drive configuration 5.6.5 Post-processing the drive configuration Overview In an ideal scenario, all of the drive components are transferred into the drive configuration and specified via the automatic configuration. In this case, the error-free configuration is confirmed in the message display and the configuration does not have to be post-processed. -

Page 182: Basic Parameterization Of The Drive Objects

2. Save the project to back up the settings. 5.7.1.2 Configuring the web server Overview The web server provides information on a SINAMICS S120 device via its web pages. Access is via an Internet browser. Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2... - Page 183 Commissioning 5.7 Basic parameterization of the drive objects Configuration in Startdrive You configure the web server in the Startdrive commissioning tool in the "Web server" screen form. Generally you can perform the configuration both in the online and in the offline mode of the Startdrive.

- Page 184 2. Then save the project to accept the settings. Restricting web server access to just secure connections Using the default configuration of the web server, you can access the SINAMICS S120 converter via an HTTP connection or via an encrypted HTTPS connection. Using the configuration, access can be restricted so that only a secure HTTPS connection is possible.

-

Page 185: Web Server User Accounts

HTTPS" in the configuration dialog. Further information You can find further information on access to the web server and the functions of the web server in the Chapter "Web server" of the SINAMICS S120 Function Manual Drive Functions. 5.7.1.3 Web server user accounts Overview For SINAMICS S120, the rights of both user accounts "SINAMICS"... -

Page 186: Enabling "Sinamics" And "Administrator" User

Commissioning 5.7 Basic parameterization of the drive objects Defaults The web server provides the following default settings for the users "SINAMICS" and "Administrator": • "SINAMICS" user – No password set. For these users we recommend that a password is assigned. With a password, you prevent an attacker from assigning a password and thereby blocking other commissioning engineers. -

Page 187: Creating A Password For The Users "Sinamics" And "Administrator

Commissioning 5.7 Basic parameterization of the drive objects 5.7.1.5 Creating a password for the users "SINAMICS" and "Administrator" Overview You can use this function for the users "SINAMICS" and "Administrator" in online or offline mode. The procedure is the same for both users. Requirements •... -

Page 188: Changing The Password For The Users "Sinamics" And "Administrator

Commissioning 5.7 Basic parameterization of the drive objects Procedure To delete the password for the "SINAMICS" user, proceed as follows: 1. Click the "Delete password" button. The "Delete password" dialog opens. 2. Enter the password for the "SINAMICS" user. The entry is checked. "Password has been deleted" is displayed if you entered the correct password. -

Page 189: Password Forgotten

Commissioning 5.7 Basic parameterization of the drive objects Procedure To change a password, proceed as follows: 1. Click "Change password". The "Change Password" dialog opens. 2. In the "Old password" input field, enter the user's existing password. 3. Enter the new password in the "New password" input field. Pay attention to upper and lower case. -

Page 190: Activating/Deactivating Write Protection

• Parameters with attribute "WRITE_NO_LOCK" are generally not affected by write protection. You can find a list of parameters with the attribute "WRITE_NO_LOCK" in the chapter "Parameters with "WRITE_NO_LOCK"" of the SINAMICS S120/S150 List Manual. The following functions are not affected by write protection: •... -

Page 191: Know-How Protection

However, if necessary, it is possible to activate write protection in addition when know-how protection is activated. Requirements • A SINAMICS S120 control module has been inserted in the device configuration. Procedure Proceed as follows to activate/deactivate write protection: 1. Establish an online connection to your drive. - Page 192 Commissioning 5.7 Basic parameterization of the drive objects Activated know-how protection has the following effects: • Parameter view: In the parameter view, know-how-protected parameters are not shown in the parameter lists. • Function view: – Know-how-protected parameter values ("KHP_ACTIVE_READ") that can be read but not ①...

- Page 193 (parameter and DCC data): Figure 5-6 Available protection settings Note Siemens memory card Use of know-how protection with basic copy protection and extended copy protection is only possible with a Siemens memory card. Commissioning with Startdrive Commissioning Manual, 06/2020, 6SL3097-5AA10-0BP2...

- Page 194 You can find a list of the adjustable parameters that can be read and changed in the SINAMICS S120/S150 List Manual in the chapter "Pa‐ rameters with "KHP_WRITE_NO_LOCK"". Note: Adjustable parameters without know-how protection cannot be added to an exception list (see Chapter "Managing the exception list (Page 197)").

-

Page 195: Configuring Know-How Protection

More information on the individual protection settings can be found in Chapter "Know-how protection (Page 189)". Requirements • A SINAMICS S120 control module has been inserted in the device configuration. • An online connection to the drive has been established. • Write and know-how protection are disabled. - Page 196 Commissioning 5.7 Basic parameterization of the drive objects • A Siemens memory card is inserted in the converter. This requirement applies to know-how protection with basic copy protection and extended copy protection. • Optional: – The drive unit is fully commissioned.

- Page 197 Commissioning 5.7 Basic parameterization of the drive objects 7. To activate know-how protection with the selected protection setting, click "Specify password for the activation". The corresponding dialog is opened. 8. Assign a password and confirm with "OK". Note Recommendation for secure passwords When assigning a password, make sure that it contains the following: •...

- Page 198 Commissioning 5.7 Basic parameterization of the drive objects Proceed as follows to deactivate the know-how protection temporarily: 1. Click on "Deactivation". The corresponding dialog is opened. The following options are available: 2. Select option "Temporary deactivation for configuration changes" option. Know-how protection is deactivated.

-

Page 199: Managing The Exception List

Commissioning 5.7 Basic parameterization of the drive objects Additional protective measures After configuration of know-how protection, make sure that the Startdrive project file is not retained by the end user. 5.7.1.13 Managing the exception list Overview In the exception list, you manage all parameters that are to remain readable and modifiable with activated know-how protection. - Page 200 Commissioning 5.7 Basic parameterization of the drive objects Adding parameters to the exception list Note Parameters in the exception list can be read and modified With activated know-how protection, parameters in the exception list can be read and modified in other commissioning tools and in the web server. Therefore, do not add any critical parameters to the exception list.

-

Page 201: Configuring Digital Inputs

The modified exception list is taken into account after activation of know-how protection in online mode. All of the parameters that were removed from the list are then know-how protected again. Parameters (see SINAMICS S120/S150 List Manual) • p7763 Know-how protection OEM exception list, number of indices for p7764 •... -

Page 202: Bidirectional Digital Inputs/Outputs

Commissioning 5.7 Basic parameterization of the drive objects 5.7.1.15 Bidirectional digital inputs/outputs Overview The bidirectional inputs/outputs of terminals X122 and X132 on the CU (DO1) can be used by a drive object as well as by a higher-level controller (resource sharing). The assignment to a terminal is defined by means of BICO interconnections which are either connected to a controller via the DO1 telegram p0922 = 39x or to a drive object. -

Page 203: Measuring Sockets

Commissioning 5.7 Basic parameterization of the drive objects To parameterize the digital inputs/outputs 8 to 15, proceed as follows: 1. Select the digital input/output on the required terminal. 2. Interconnect the signal source of the digital input (8 to 15). 3. - Page 204 Commissioning 5.7 Basic parameterization of the drive objects Interconnect signal sources To interconnect signal sources with the available measuring sockets, proceed as follows: 1. Select one of the following settings in the "Limitation" drop-down list of a measuring socket: – Limitation On If signals are output outside the permissible measuring range, the signal is limited to 4.98 V or to 0 V.

-

Page 205: Digital Output, Isolated (Cu310-2 Pn)

Commissioning 5.7 Basic parameterization of the drive objects Function diagrams (see SINAMICS S120/S150 List Manual) • 8134 Diagnostics - measuring sockets (T0, T1, T2) Parameters (see SINAMICS S120/S150 List Manual) Adjustable parameters • p0771[0...2] CI: Measuring sockets signal source • p0777[0...2] Measuring sockets characteristic curve value x1 •... -

Page 206: Analog Input (Cu310-2 Pn)

Commissioning 5.7 Basic parameterization of the drive objects 5.7.1.18 Analog input (CU310-2 PN) Overview The analog input is used to acquire external analog signals. These signals can be voltages or currents, for example. Analog inputs are used, for example, to be able to enter a speed or torque as analog signal. - Page 207 Commissioning 5.7 Basic parameterization of the drive objects Procedure Proceed as follows to configure the scaling: 1. Click on "Scaling". The "Scaling TM31 analog input AI 0" dialog opens. 2. Enter the x and y values for 2 points of the scaling line: –...

-

Page 208: Infeed Unit

Commissioning 5.7 Basic parameterization of the drive objects Additional functions (optional) Function Description Absolute-value Activate the absolute-value generation in the screen form if the absolute value of the scaled input value is generation to be generated. The activated absolute-value generation is indicated by the icon. - Page 209 Commissioning 5.7 Basic parameterization of the drive objects Note The display of the function modules that can be activated is dynamic and depends on the selected infeed and the configuration of this infeed. The following table provides an overview of the function modules that can be used. In addition to the individual function modules, the table includes an explanations of how each function module can be used.

-

Page 210: Line Supply Data / Operating Mode

Commissioning 5.7 Basic parameterization of the drive objects 5.7.2.3 Line supply data / Operating mode Overview You set the most important parameters for the operation of an infeed in the function view of the "Line data / operating mode" screen form. The corresponding parameters are displayed depending on the infeed type. -

Page 211: Enable Logic

Commissioning 5.7 Basic parameterization of the drive objects Setting the line data and operating mode The parameters in this screen form are assigned default values when creating the device. 1. Enter a value for the device supply voltage in the "Device supply voltage" field (p0210). 2. -

Page 212: Line Contactor Control

Commissioning 5.7 Basic parameterization of the drive objects 5.7.2.5 Line contactor control Overview This function allows an external line contactor to be controlled. The closing and opening of the line contactor can be monitored by evaluating the feedback contact of the line contactor. The line contactor can be controlled with the following drive objects via r0863.1: •... -

Page 213: Function Modules

Commissioning 5.7 Basic parameterization of the drive objects The following table provides an overview of the maximum number of options of the basic parameterization and lists the conditions under which individual options can be displayed and selected. Table 5-1 Basic parameterization: selectable options Option "Basic parameterization"... - Page 214 Commissioning 5.7 Basic parameterization of the drive objects The following table provides an overview of the function modules that are available. In addition to the individual function modules, the table includes an explanations of how each function module can be used. Function module Explanation Frequently used function modules...

-

Page 215: Control Mode