Siemens SINAMICS S120 Function Manual

Safety integrated

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Siemens SINAMICS S120

- Page 3 Preface ___________________ Fundamental safety instructions General information about SINAMICS SINAMICS Safety Integrated Overview of Safety Integrated functions S120 Safety Integrated ___________________ Description of Safety Integrated functions Control of the safety functions Function Manual ___________________ Commissioning ___________________ Acceptance test ___________________ System features ___________________ Maintenance ___________________...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Preface

Siemens' content, and adapt it for your own machine documentation. Training At the following address (http://www.siemens.com/sitrain), you can find information about SITRAIN (Siemens training on products, systems and solutions for automation and drives). FAQs You can find Frequently Asked Questions in the Service&Support pages at Product Support (https://support.industry.siemens.com/cs/de/en/ps/faq). - Page 6 SINAMICS Converters for Single-Axis Drives – Distributed Converters (D 31.2) • SINUMERIK 840 Equipment for Machine Tools (Catalog NC 62) • Installation/assembly SINAMICS S120 Equipment Manual for Control Units and Additional System • Components SINAMICS S120 Equipment Manual for Booksize Power Units •...

- Page 7 Basic and Extended Functions SINAMICS S120 Safety Integrated Function Manual Basic Functions SINAMICS S120 Function Manual Drive Functions Commissioning Of a simple SINAMICS S120 drive with Getting Started (up to Firmware V5.1 SP1) STARTER Commissioning With STARTER SINAMICS S120 Commissioning Manual (up to firmware V5.1 SP1)

- Page 8 (https://support.industry.siemens.com/sc/ww/en/sc/2090) in the "Contact" area. Compliance with the General Data Protection Regulation Siemens respects the principles of data protection, in particular the data minimization rules (privacy by design). For this product, this means: The product does not process neither store any person-related data, only technical function data (e.g.

- Page 9 Preface Notation for faults and alarms (examples): Fault 12345 • F12345 Alarm 67890 • A67890 Safety message • C23456 Notation for parameters (examples): Adjustable parameter 918 • p0918 Display parameter 1024 • r1024 Adjustable parameter 1070, index 1 • p1070[1] Adjustable parameter 2098, index 1 bit 3 •...

- Page 10 Preface Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

-

Page 11: Table Of Contents

Table of Contents Preface ..............................3 Fundamental safety instructions ......................17 Fundamental safety instructions ..................... 17 1.1.1 General safety instructions ..................... 17 1.1.2 Warranty and liability for application examples ..............17 1.1.3 Industrial security ........................18 Fundamental safety instructions for Safety Integrated ............20 Residual risk ........................... - Page 12 Table of Contents 3.3.1 Preconditions for Safety Integrated Extended Functions ............63 3.3.2 Safely-Limited Position (SLP) ....................64 3.3.3 Transferring safe position values (SP) ................... 65 3.3.4 Safe referencing ........................65 3.3.5 Safe Cam (SCA) ........................67 Description of Safety Integrated functions ..................... 69 Safety Integrated basic functions ...................

- Page 13 Table of Contents 4.2.11 Safely Limited Acceleration (SLA) ..................135 4.2.12 Safe Brake Test (SBT) ......................138 4.2.12.1 Communication via SIC/SCC ....................147 4.2.12.2 Function diagrams and parameters ..................149 4.2.13 Safe Acceleration Monitor (SAM) ..................150 4.2.14 Safe Brake Ramp (SBR) ....................... 152 4.2.15 Safe actual value acquisition ....................

- Page 14 Table of Contents 5.5.2 Initiating ESR for a communication failure ................239 Control of the Extended/Advanced Functions via F-DI (for CU310-2)......... 241 5.6.1 Assigning Safety Integrated Functions to the F-DI/TM54F ..........243 5.6.2 Overview of the F-DIs ......................244 5.6.3 Function of the F-DO ......................

- Page 15 Table of Contents 6.9.2.1 Test mode 1: Evaluation of internal diagnostic signal (passive load) ........308 6.9.2.2 Test mode 2: Read back F-DO in DI (relay circuit) ............... 309 6.9.2.3 Test mode 3: Read back F-DO into the DI (actuator with feedback signal) ......310 6.9.2.4 Test stop mode parameters ....................

- Page 16 Table of Contents 8.4.7 Control of Extended Functions without encoder via PROFIsafe (CU310-2 and CU320-2) ..........................363 8.4.8 Control of Extended Functions without encoder via terminals (only CU310-2) ....365 8.4.9 Control of Extended Functions without encoder via TM54F (CU310-2 and CU320-2) ..366 8.4.10 Control of Advanced Functions with encoder via PROFIsafe (CU310-2 and CU320-2) ..

- Page 17 Table of Contents Documentation overview ...................... 413 Change history ........................414 Stop versions ........................415 Index..............................417 Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

- Page 18 Table of Contents Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

-

Page 19: Fundamental Safety Instructions

Fundamental safety instructions Fundamental safety instructions 1.1.1 General safety instructions WARNING Danger to life if the safety instructions and residual risks are not observed If the safety instructions and residual risks in the associated hardware documentation are not observed, accidents involving severe injuries or death can occur. •... -

Page 20: Industrial Security

Siemens’ products and solutions undergo continuous development to make them more secure. Siemens strongly recommends that product updates are applied as soon as they are available and that the latest product versions are used. Use of product versions that are no longer supported, and failure to apply the latest updates may increase customer’s exposure... - Page 21 Fundamental safety instructions 1.1 Fundamental safety instructions WARNING Unsafe operating states resulting from software manipulation Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe operating states in your system that may lead to death, serious injury, and property damage.

-

Page 22: Fundamental Safety Instructions For Safety Integrated

Fundamental safety instructions 1.2 Fundamental safety instructions for Safety Integrated Fundamental safety instructions for Safety Integrated Additional safety instructions and residual risks Additional safety information and residual risks not specified in this section are included in the relevant sections of this Function Manual. DANGER Risk minimization through Safety Integrated Safety Integrated can be used to minimize the level of risk associated with machines and... - Page 23 Fundamental safety instructions 1.2 Fundamental safety instructions for Safety Integrated WARNING Danger to life as a result of undesirable motor movement when automatically restarting The Emergency Stop function must bring the machine to a standstill according to Stop Category 0 or 1 (STO or SS1) (EN 60204-1). It is not permissible that the motor automatically restarts after an Emergency Stop, as this represents danger to life as a result of the associated undesirable motor motion.

- Page 24 Fundamental safety instructions 1.2 Fundamental safety instructions for Safety Integrated Note EDS switchover for safe motion monitoring An encoder which is used for safety functions must not be switched over when a drive data set (DDS) is switched over. The safety functions check the safety-relevant encoder data for changes when data sets are switched over.

-

Page 25: Residual Risk

Fundamental safety instructions 1.3 Residual risk Residual risk The fault analysis enables machine manufacturers to determine the residual risk at their machine with regard to the drive unit. The following residual risks are known: WARNING Danger due to short, limited movements If two power transistors simultaneously fail in the power unit (one in the upper and one in the lower inverter bridge), then this can cause cause brief, limited movement. - Page 26 Fundamental safety instructions 1.3 Residual risk WARNING Residual risk for a single-encoder system Within a single-encoder system: a) A single electrical fault in the encoder b) A break of the encoder shaft (or loose encoder shaft coupling), or a loose encoder housing will cause the encoder signals to remain static (that is, they no longer follow a movement while still returning a correct level), and prevent fault detection while the drive is in stop state (for example, drive in SOS state).

-

Page 27: General Information About Sinamics Safety Integrated

General information about SINAMICS Safety Integrated Supported functions All of the Safety Integrated functions available under SINAMICS S120 are listed in this section. The safety functions listed here conform to: ● Safety Integrity Level (SIL) 2 according to IEC 61508 ●... -

Page 28: Safety Integrated Basic Functions

General information about SINAMICS Safety Integrated 2.1 Supported functions 2.1.1 Safety Integrated Basic Functions The Safety Integrated Basic Functions are part of the standard scope of the drive and can be used without an additional license. These functions are always available. These functions do not require an encoder and/or do not place any special requirements on the encoder used. -

Page 29: Safety Integrated Extended Functions

General information about SINAMICS Safety Integrated 2.1 Supported functions 2.1.2 Safety Integrated Extended Functions The Safety Integrated Extended Functions require an additional Safety Extended license. Extended Functions with encoder require an encoder with safety capability (see Chapter "Notes regarding safe actual value sensing using an encoder system (Page 155)"). ●... -

Page 30: Safety Integrated Advanced Functions

General information about SINAMICS Safety Integrated 2.1 Supported functions Note regarding Power/Motor Modules in the chassis format: For the chassis format, SBC is only supported by Power/Motor Modules with article number ...3 or higher. A Safe Brake Adapter is also needed for this design. Note regarding Power/Motor Modules in the blocksize format: Blocksize Power Modules also require a Safe Brake Relay for this function. -

Page 31: Supported Functions: Hla Module

General information about SINAMICS Safety Integrated 2.2 Supported functions: HLA module Supported functions: HLA module SINAMICS HLA supports the following Safety Integrated functions: ● Safety Integrated Basic Functions ● Safety Integrated Extended Functions ● Safety Integrated Advanced Functions Note Only "linear" axis type permitted For SINAMICS HLA, only the "linear"... -

Page 32: Hla: Safety Integrated Extended Functions

General information about SINAMICS Safety Integrated 2.2 Supported functions: HLA module 2.2.2 HLA: Safety Integrated Extended Functions SINAMICS HLA and Safety Integrated SINAMICS HLA supports the following Safety Integrated functions: ● The Safety Integrated Extended Functions require an additional Safety Extended license. Extended Functions with encoder require an encoder with safety capability (see Chapter "Notes regarding safe actual value sensing using an encoder system (Page 155)"). -

Page 33: Hla: Safety Integrated Advanced Functions

General information about SINAMICS Safety Integrated 2.2 Supported functions: HLA module – Safely-Limited Speed (SLS) Safely-Limited Speed ensures that the drive does not exceed a preset speed limit. – Safe Speed Monitor (SSM) Safe Speed Monitor is used for safely identifying when a speed limit is undershot in both directions of motion, e.g. -

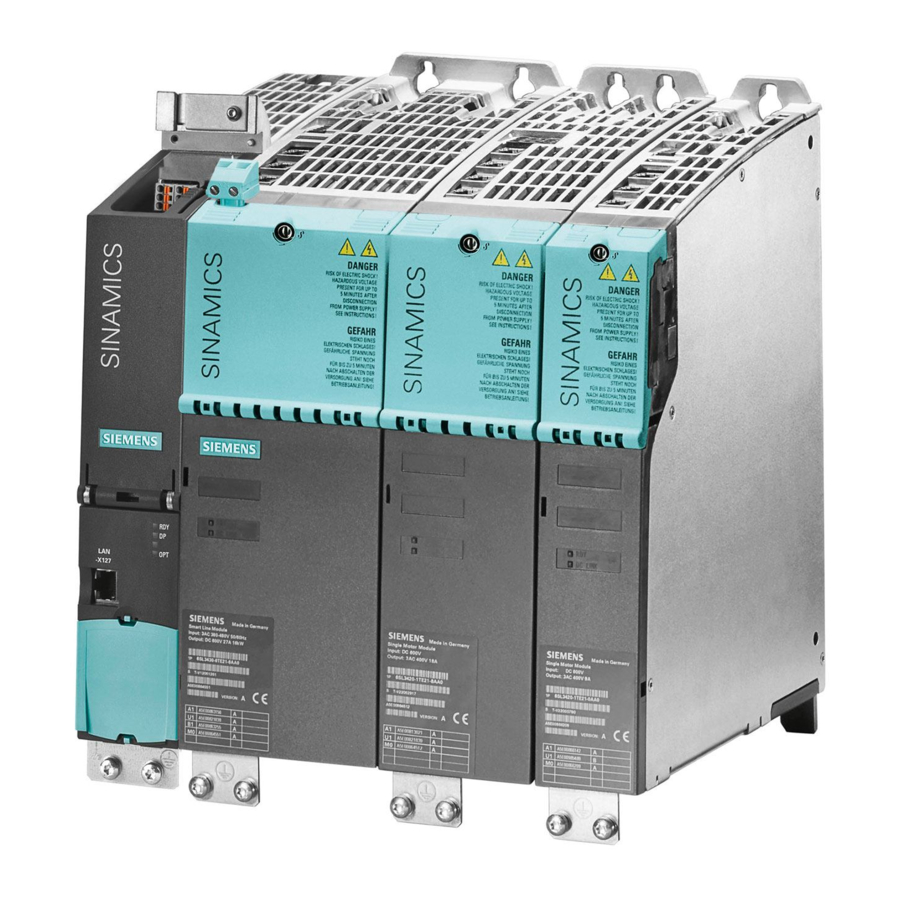

Page 34: Drive Products With Integrated Safety Functions

General information about SINAMICS Safety Integrated 2.3 Drive products with integrated safety functions Drive products with integrated safety functions Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1... - Page 35 However, these descriptions essentially also apply in the same way for hydraulic systems. You will find parameters and messages for the drive object HLA in the SINAMICS S120/S150 List Manual. Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

-

Page 36: Examples Of How The Safety/Diagnostic Functions Can Be Applied

General information about SINAMICS Safety Integrated 2.4 Examples of how the safety/diagnostic functions can be applied Examples of how the safety/diagnostic functions can be applied Safety function Application examples Possible solution It is only permissible to open a protective door if the Select STO in the converter via a terminal •... - Page 37 General information about SINAMICS Safety Integrated 2.4 Examples of how the safety/diagnostic functions can be applied Safety function Application examples Possible solution The drive must not exit the specified position ranges. Selection of SLP in the converter; inhibits the range that is not permitted. It is necessary to transmit a "safe position,"...

-

Page 38: Drive Monitoring With Or Without Encoder

General information about SINAMICS Safety Integrated 2.5 Drive monitoring with or without encoder Drive monitoring with or without encoder If motors without a (safety-capable) encoder are being used, not all Safety Integrated Functions can be used. Note Definition: "Without encoder" When "without encoder"... - Page 39 General information about SINAMICS Safety Integrated 2.5 Drive monitoring with or without encoder Functions Abbr. With With- Brief description coder coder Advanced Safely-Limited Position Safely Limited Position Functions Transfer safe Transfer safe position values position values Safe Cam Safe cam The use of this safety function without an encoder is permitted only for the following motors: - Induction motors - SIMOTICS A-1FU synchronous motors (previously: SIEMOSYN)

-

Page 40: General Information About Operating Components With Safety Integrated Activated

General information about SINAMICS Safety Integrated 2.6 General information about operating components with Safety Integrated activated General information about operating components with Safety Integrated activated It is not permissible to withdraw and insert components. Malfunctions can occur when components are withdrawn or inserted that are used for Safety Integrated. However, this does not mean that the fail-safe state is exited. -

Page 41: Overview Of Safety Integrated Functions

Overview of Safety Integrated functions Safety Integrated Basic Functions Note Basic Functions do not require an encoder The Safety Integrated Basic Functions are functions for safely stopping the drive. You do not require an encoder. Note Application of the Basic Functions Basic Functions are available in all control modes with and without encoder for synchronous and induction motors without any restrictions. -

Page 42: Safe Torque Off (Sto)

Overview of Safety Integrated functions 3.1 Safety Integrated Basic Functions 3.1.1 Safe Torque Off (STO) Definition according to EN 61800-5-2: "The STO function prevents energy from being supplied to the motor, which can generate a torque." Examples of how the function can be used Example Possible solution It is only permissible to open a protective door if the... -

Page 43: Safe Stop 1 (Ss1)

Overview of Safety Integrated functions 3.1 Safety Integrated Basic Functions 3.1.2 Safe Stop 1 (SS1) Definition according to EN 61800-5-2: "The function SS1 brakes the motor and trips the function STO after a delay time." Example of how the function can be used Example Possible solution After an Emergency Stop button has been pressed,... -

Page 44: Safe Brake Control (Sbc)

Overview of Safety Integrated functions 3.1 Safety Integrated Basic Functions 3.1.3 Safe Brake Control (SBC) Definition according to EN 61800-5-2: "The SBC function supplies a safe output signal to control a holding brake." Safe Brake Control (SBC) Example of how the function can be used Example Possible solution The safe control of a motor holding brake must be... -

Page 45: Safety Integrated Extended Functions

SMC30, EnDat-2.2 encoder with SMC40 The list of approved encoders can be found on the Internet at: Approved encoders (https://support.industry.siemens.com/cs/ww/en/) Enter the number 33512621 there as search term or contact your local Siemens office. Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1... -

Page 46: Control Possibilities

Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions 3.2.2 Control possibilities The following options are available for controlling Safety Integrated Extended Functions: ● PROFIsafe ● TM54F ● Onboard F-DI (CU310-2) ● Permanent selection (Safety Integrated functions without selection) 3.2.3 Safe Torque Off (STO) For the control options and the functionality for "Safe Torque Off"... - Page 47 Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions How does SS1 function in detail? Overview Using the SS1 function, the converter brakes the motor and monitors the absolute speed. If the motor speed is low enough or the delay time has expired, the converter safely switches off the motor torque using STO .

- Page 48 Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions Brake ramp monitoring Acceleration monitoring (with or without encoder) (with or without encoder) The converter monitors the speed of the mo- Using the SBR (Safe Brake Ramp) function, • • the converter monitors whether the motor tor with the SAM function.

-

Page 49: Safe Operating Stop (Sos)

Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions 3.2.5 Safe Operating Stop (SOS) Definition according to EN 61800-5-2: "This SOS function is used for safe monitor- ing of the standstill position of a drive." Example of how the function can be used Example Possible solution A protective door must only be opened if a motor is... -

Page 50: Safe Stop 2 (Ss2)

Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions Figure 3-1 Standstill tolerance Details and parameterization For further details and information on how to parameterize this function, see Section "Safe Operating Stop (SOS) (Page 103)". 3.2.6 Safe Stop 2 (SS2) Definition according to EN 61800-5-2: "The function SS2 brakes the motor, moni- tors the magnitude of the motor decelera-... - Page 51 Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions Example of how the function can be used Example Possible solution A protective door must only be opened if a motor is Select SS2 in the converter via a terminal or •...

- Page 52 Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions Braking behavior Figure 3-2 Braking behavior and diagnostics of the safety function SS2 (example of SS2 with SAM) Note SS2 with external stop (SS2E) If you use SS2E, neither of the two monitoring functions (SBR, SAM) is active. The drive must be shut down in SS2E within the delay time, for example, by a user program of a CPU.

-

Page 53: Safely Limited Speed (Sls)

Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions 3.2.7 Safely Limited Speed (SLS) Definition according to EN 61800-5-2: "The SLS function prevents the motor from exceeding the specified speed limit." Examples of how the function can be used Example Possible solution The machine operator must be able to enter the... - Page 54 Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions 3. SLS monitors the absolute value of the current speed. The SLS setpoint limit can be transferred to the higher-level motion controller (e.g. SIMOTION), where the speed setpoint can be limited. In addition, you can configure the setpoint limit provided by SLS as maximum speed in the ramp-function generator.

- Page 55 Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions With braking ramp monitoring Without braking ramp monitoring (only without encoder) (with or without encoder) The converter monitors the load velocity after After the adjustable "delay time for the brak- •...

- Page 56 Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions Selecting SLS at low velocities If the motor velocity when selecting SLS is less than the SLSlimit, then the drive responds as follows: Deselecting SLS If the higher-level controller deselects SLS , then the converter deactivates limiting and monitoring.

- Page 57 Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions Switching to a lower speed level With braking ramp monitoring Without braking ramp monitoring (only without encoder) (with or without encoder) Once the "delay time for braking ramp" has The converter monitors the velocity with the •...

- Page 58 Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions Switching to a higher speed level If you switch over from a lower to a higher speed level, the converter immediately monitors the actual velocity against the higher velocity. Details and parameterization For further details and information on how to parameterize this function, see Section "Safely- Limited Speed (SLS) (Page 112)".

-

Page 59: Safe Speed Monitor (Ssm)

Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions 3.2.8 Safe Speed Monitor (SSM) Definition according to EN 61800-5-2: "The SSM function supplies a safe output signal to indicate whether the motor speed is below a specified limit value." Note SSM is a pure signaling function Contrary to other Safety Integrated functions, a violation of the SSM limit does not result in a... - Page 60 Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions How does SSM function in detail? Requirements The safety function SSM cannot be selected or deselected using external control signals. SSM is active when you have set a monitoring velocity > 0 for SSM . Evaluating the speed The converter compares the load speed with the speed limit and signals if the limit value is undershot to the high-level control.

-

Page 61: Safe Direction (Sdi)

Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions 3.2.9 Safe Direction (SDI) Definition according to EN 61800-5-2: "The SDI function prevents the motor shaft mov- ing in the wrong direction." Examples of how the function can be used Example Possible solution A protective door must only be opened if a drive... - Page 62 Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions Selecting and deselecting SDI As soon as the converter identifies that SDI has been selected via a failsafe input or via PROFIsafe safe communication, the following happens: ● You can also set a delay time, within which you can ensure that the converter moves in the enabled (safe) direction.

-

Page 63: Safe Brake Test (Sbt)

Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions 3.2.10 Safe Brake Test (SBT) The diagnostic function "Safe Brake Test" func- tion (SBT) checks the required holding torque of a brake (operating or holding brake). You can test linear axes and rotary axes. The drive purposely generates a force/torque against the applied brake. -

Page 64: Safely-Limited Acceleration (Sla)

Overview of Safety Integrated functions 3.2 Safety Integrated Extended Functions 3.2.11 Safely-Limited Acceleration (SLA) Definition according to EN 61800-5-2: "The SLA function prevents the motor from exceeding the defined acceleration limit." Examples of how the function can be used Example Possible solution In the setup mode, it is not permissible that the Select SLA in the converter via PROFIsafe. -

Page 65: Safety Integrated Advanced Functions

SMC30, EnDat-2.2 encoder with SMC40 The list of approved encoders can be found on the Internet at: Approved encoders (https://support.industry.siemens.com/cs/ww/en/) Enter the number 33512621 there as search term or contact your local Siemens office. Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1... -

Page 66: Safely-Limited Position (Slp)

Overview of Safety Integrated functions 3.3 Safety Integrated Advanced Functions 3.3.2 Safely-Limited Position (SLP) Definition according to EN 61800-5-2: "The SLP function prevents the motor shaft from exceeding the specified position limit(s)." The Safely-Limited Position function (SLP) is used to safely monitor the limits of two traversing and/or positioning ranges, which are toggled between using a safe signal. -

Page 67: Transferring Safe Position Values (Sp)

Overview of Safety Integrated functions 3.3 Safety Integrated Advanced Functions 3.3.3 Transferring safe position values (SP) The "Safe Position (SP)" function enables you to transfer safe position values to the higher- level fail-safe controller (F-CPU) via PROFIsafe (telegram 901 or 902). On the F-CPU side, you can also calculate the current speed from the change in position per time. - Page 68 Overview of Safety Integrated functions 3.3 Safety Integrated Advanced Functions General description In most cases, an external control performs referencing to an absolute position. The converter only performs this task in special cases (for example, EPOS). ● Referencing using an external control Requirement: No movement of the drive The reference position determined by the control is entered into parameter p9572 and is declared to be valid using p9573 = 89.

-

Page 69: Safe Cam (Sca)

Overview of Safety Integrated functions 3.3 Safety Integrated Advanced Functions 3.3.5 Safe Cam (SCA) Definition according to EN 61800-5- The function "Safe Cam" (SCA) safe supplies a safety-related output sig- nal to indicate whether the motor shaft position is within a defined range. - Page 70 Overview of Safety Integrated functions 3.3 Safety Integrated Advanced Functions Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

-

Page 71: Description Of Safety Integrated Functions

Because Startdrive sets the safety-related parameters of the 2nd channel by copying, only the parameters of the 1st channel are given in this manual. You will find the relevant parameters of the 2nd channel in the parameter description, e.g. in SINAMICS S120/S150 List Manual. -

Page 72: Safety Integrated Basic Functions

If you want to control the Safety Integrated Basic Functions via TM54F, set p9601.6 = 1. Note PFH values The PFH values of the individual SINAMICS S120 safety components can be found at: PFH values (https://support.industry.siemens.com/cs/ww/en/view/76254308) 4.1.1 Safe Torque Off (STO) In conjunction with a machine function or in the event of a fault, the "Safe Torque Off"... - Page 73 Description of Safety Integrated functions 4.1 Safety Integrated basic functions ● When the "Safe Torque Off" function is selected, the following applies: – The motor cannot be started accidentally. – The pulse suppression safely disconnects the torque-generating energy supply to the motor.

- Page 74 Description of Safety Integrated functions 4.1 Safety Integrated basic functions Enabling the "Safe Torque Off" function The "Safe Torque Off" function is enabled via parameter p9601: ● STO for the Safety Integrated Basic Functions: – p9601 = 1 hex (Basic Functions via onboard terminals) –...

- Page 75 • 2810 SI Basic Functions - STO (Safe Torque Off), safe pulse suppression • 2811 Overview of important parameters (see SINAMICS S120/S150 List Manual) SI enable functions integrated in the drive (Control Unit) • p9601 CO/BO: SI Motion drive-integrated control signals •...

-

Page 76: Safe Torque Off (Sto) For Sinamics Hla

Description of Safety Integrated functions 4.1 Safety Integrated basic functions 4.1.1.1 Safe Torque Off (STO) for SINAMICS HLA For the HLA module, safe torque off (STO) corresponds to shutting off a safety-relevant shutoff valve. Special features of STO for HLA ●... -

Page 77: Safe Stop 1 (Ss1, Time Controlled)

• 2810 SI Basic Functions - STO (Safe Torque Off), safe pulse cancellation • 2811 Overview of important parameters (see SINAMICS S120/S150 List Manual) SI HLA shutoff valve wait time (CU) • p9625[0...1] SI HLA shutoff valve feedback contacts configuration (CU) •... - Page 78 Description of Safety Integrated functions 4.1 Safety Integrated basic functions Functional features of Safe Stop 1 SS1 is enabled by p9652 (delay time) ≠ 0. ● Setting parameter p9652 has the following effect: – p9652 = 0 SS1 is not enabled. Only STO can be selected via TM54F, the onboard terminals and/or PROFIsafe.

-

Page 79: Ss1 With External Stop

Description of Safety Integrated functions 4.1 Safety Integrated basic functions 4.1.2.2 SS1 with external stop In drive line-ups (e.g. drives that are mechanically connected via the material), the drive- independent braking on the respective OFF3 ramp can cause problems. If the SS1E function is used, the safe delay time (p9652) is started when the function is selected, but no OFF3 is triggered. -

Page 80: Function Diagrams And Parameters

SI Basic Functions - STO (Safe Torque Off), SS1 (Safe Stop 1) • 2810 SI Basic Functions - STO (Safe Torque Off), safe pulse cancellation • 2811 Overview of important parameters (see SINAMICS S120/S150 List Manual) OFF3 ramp-down time • p1135[0...n] Motor holding brake closing time •... - Page 81 Description of Safety Integrated functions 4.1 Safety Integrated basic functions Note Controlling the brake via a relay for "Safe Brake Control": If you use the "Safe Brake Control (SBC)" function, the use of relays/contactors can cause faults in the brake control when brakes are switched. For this reason, this type of control is not generally permissible.

- Page 82 Description of Safety Integrated functions 4.1 Safety Integrated basic functions 2-channel brake control Note Connecting the brake The brake cannot be directly connected to the Motor Module in chassis format. A Safe Brake Adapter is also required. The brake is controlled from the Control Unit. Two signal paths are available for applying the brake.

-

Page 83: Sbc For Motor Modules In The Chassis Format

Description of Safety Integrated functions 4.1 Safety Integrated basic functions 4.1.3.1 SBC for Motor Modules in the chassis format To be able to set higher power in the brakes of devices of this format, an additional Safe Brake Adapter (SBA) module is needed. For more information about connecting and wiring the Safe Brake Adapter, refer to the "SINAMICS G130/G150/S120 Chassis/S120 Cabinet Modules/S150 Safety Integrated"... - Page 84 Description of Safety Integrated functions 4.1 Safety Integrated basic functions There are two options for registering this power unit with the system: ● Automatic brake identification when commissioning the system for the first time – Requirements: - No Safety Integrated functions enabled - p1215 = 0 (no motor holding brake available) –...

-

Page 85: Hardware Required For Sbc

Description of Safety Integrated functions 4.1 Safety Integrated basic functions 4.1.3.2 Hardware required for SBC ● Safe Brake Relay The command for releasing or applying the brake is transferred to the Motor Module / Power Module via DRIVE-CLiQ. The Motor Module / Safe Brake Relay then carries out the action and appropriately activates the outputs for the brake. - Page 86 Description of Safety Integrated functions 4.1 Safety Integrated basic functions Figure 4-4 Interconnecting the Safe Brake Adapter Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

-

Page 87: Function Diagrams And Parameters

Function diagrams (see SINAMICS S120/S150 List Manual) SI Basic Functions - SBC (Safe Brake Control), SBA (Safe Brake • 2814 Adapter) Overview of important parameters (see SINAMICS S120/S150 List Manual) CU inputs/outputs, sampling time • p0799 Motor holding brake configuration •... -

Page 88: Safety Faults

Description of Safety Integrated functions 4.1 Safety Integrated basic functions 4.1.4 Safety faults The fault messages of the Safety Integrated Basic Functions are saved in the standard message buffer and can be read out from there. By contrast, the fault messages of the Safety Integrated Extended Functions are stored in a separate Safety message buffer (see Chapter "Message buffer (Page 382)"). - Page 89 Description of faults and alarms Note References The faults and alarms for SINAMICS Safety Integrated Functions are described in the following document: References: SINAMICS S120/S150 List Manual Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

-

Page 90: Forced Checking Procedure (Test Stop)

Description of Safety Integrated functions 4.1 Safety Integrated basic functions 4.1.5 Forced checking procedure (test stop) Forced checking procedure or test of the switch-off signal paths (test stop) for Safety Integrated Basic Functions The forced checking procedure (test stop) at the switch-off signal paths is used to detect software/hardware faults at both monitoring channels in time and is automated by means of activation/deactivation of the "Safe Torque Off"... -

Page 91: Function Diagrams And Parameters

Extended Functions. It is otherwise not possible to verify the correct control through the terminals. 4.1.6 Function diagrams and parameters Function diagrams (see SINAMICS S120/S150 List Manual) SI Basic Functions - Parameter manager • 2800 SI Basic Functions - Monitoring functions and faults/alarms •... -

Page 92: Safety Integrated Extended Functions

● A trial license is available for test purposes; this allows you to use Safety Integrated functions for a specific time without having a valid license. Details on the trial license can be found in the "SINAMICS S120 Function Manual Drive Functions", Chapter "Licensing". - Page 93 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Activation For activation of the Safety Integrated Extended Functions "with encoder" and "without encoder", set the parameters p9306 and p9506 (factory setting = 0). You can also make this setting by selecting "with encoder" or "without encoder" on the Safety-Integrated Startdrive screen.

- Page 94 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Taking into account the slip of an induction motor For Safety Integrated without encoder (depending on the drive load), as a result of slip (deviations between electrical and mechanical speed), deviations can occur between the safely determined electrical speed and the mechanical speed at the motor shaft.

- Page 95 When using Extended Functions, observe the following restrictions: Synchronous reluctance motors with Safety Integrated Functions "without encoder" SINAMICS S120 supports synchronous reluctance motors with Safety Integrated Functions "without encoder". Note the following information for this application case: ● Synchronous reluctance motors may only be operated with vector control.

- Page 96 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Inadmissible operating modes for Safety Integrated Functions "without encoder" ● No operation with SINAMICS Hydraulic Drive (HLA) ● Current controller clock cycles 31.25 µs and 62.5 μs (for Double Motor Modules with two configured safety drives) are not permissible.

- Page 97 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions ● Current limiting of the power unit When the current limiting of the power unit responds, then it can be assumed that this will result in errors in the encoderless safe actual value sensing and in turn with an associated stop response.

- Page 98 ● Closed-loop controlled operation down to f = 0 Hz with test signal (see corresponding chapter in the SINAMICS S120 Function Manual Drive Functions) If you use Safety Integrated without encoder simultaneously with the function "Closed- loop controlled operation up to f = 0 Hz with test signal", the drive may react with an undesired safety message and a stop reaction.

-

Page 99: Safe Torque Off (Sto)

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions ● Before commissioning the safety functions, we recommend that the motor data are identified at standstill and a rotating measurement is carried out. ● For the basic commissioning, i.e. before the safety commissioning, the closed-loop control should be optimally set. -

Page 100: Safe Stop 1 (Ss1)

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.4 Safe Stop 1 (SS1) 4.2.4.1 Safe Stop 1 with encoder For function SS1 of the Extended Safety Functions, braking monitoring is included. ● If p9506 = 0: Braking is monitored with the "Safe Acceleration Monitor" function (see Chapter "Safe Acceleration Monitor (SAM) (Page 150)"). - Page 101 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Commissioning The delay time (SS1 time) is set by entering parameter p9556. The wait time until safe pulse suppression (STO) can be shortened by specifying a shutdown speed in p9560. To enable the drive to brake to standstill after selection, the time in p9556 must be selected to be large enough for the drive to be able to brake along the OFF3 ramp (p1135) from any speed of the work process to below the shutdown speed (p9560).

-

Page 102: Safe Stop 1 Without Encoder

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.4.2 Safe Stop 1 without encoder Two encoderless Safe Stop 1 (SS1) monitoring functions can be set with parameter p9506: ● p9506 = 3: Safe monitoring of acceleration (SAM) / delay time The function is identical to "Safe Stop 1"... -

Page 103: Safe Stop 1 With External Stop

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.4.3 Safe Stop 1 with external stop General description NOTICE Any axis motion is possible During the delay time (p9652), for "Safe Stop 1 (time-controlled) with external stop", any axis movements are possible. •... -

Page 104: Function Diagrams And Parameters

Function diagrams (see SINAMICS S120/S150 List Manual) SI Extended Functions - SS1, SS2, SOS, internal STOP B, C, D, F • 2819 Overview of important parameters (see SINAMICS S120/S150 List Manual) OFF3 ramp-down time • p1135[0...n] SI Motion enable safety functions (Control Unit) •... -

Page 105: Safe Operating Stop (Sos)

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.6 Safe Operating Stop (SOS) This function serves for failsafe monitoring of the standstill position of a drive. WARNING Drive can be forced out of the SOS position by mechanical forces A drive under position control can be forced out of the "Safe Operating Stop"... - Page 106 Function diagrams (see SINAMICS S120/S150 List Manual) SI Extended Functions - SS1, SS2, SOS, internal STOP B, C, D, F • 2819 Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion enable safety functions (Control Unit) • p9501 SI Motion standstill tolerance (Control Unit) •...

-

Page 107: Safe Stop 2 (Ss2)

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.7 Safe Stop 2 (SS2) Note The "Safe Stop 2" (SS2) safety function can only be used with an encoder. The safety function "Safe Stop 2" (SS2) is used to brake the motor of the OFF3 deceleration ramp (p1135) safely with transition after the delay time (p9552) has expired in to the SOS state (see Chapter "Safe Operating Stop (SOS) (Page 103)"). - Page 108 Function diagrams (see SINAMICS S120/S150 List Manual) SI Basic Functions - SBC (Safe Brake Control), SBA (Safe Brake Adapter) • 2814 Overview of important parameters (see SINAMICS S120/S150 List Manual) OFF3 ramp-down time • p1135[0...n] SI Motion enable safety functions (Control Unit) •...

-

Page 109: Ss2 With External Stop (Ss2E)

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.7.1 SS2 with external stop (SS2E) WARNING Unexpected axis motion When function "Safe Stop 2 with external stop" (SS2E) is active, during the delay time (p9553) the speed follows the setpoint issued from the higher-level control system. As a consequence, unexpected axis motion is possible, which can lead to severe injury and death. - Page 110 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions ● The PROFIsafe status word S_ZSW2.28 indicates whether the SS2E function is active. PROFIsafe status word S_ZSW2.28 is contained in telegrams 31, 901, 902 and 903. The associated diagnostics parameter is r9722.28. In the "Safety Info Channel", status word S_ZSW3B.11 indicates whether function SS2E is active.

-

Page 111: Safe Stop 2 Extended Stop And Retract (Ss2Esr)

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.7.2 Safe Stop 2 Extended Stop and Retract (SS2ESR) WARNING Unexpected axis motion When function SS2ESR is active, during the delay time (p9554) the speed follows the setpoint issued from the higher-level control system. As a consequence, unexpected axis motion is possible, which can lead to severe injury and death. - Page 112 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions ● In addition, in the "Safety Info Channel", status word S_ZSW1B.14 = 1 is set. This bit corresponds to diagnostic parameter r9734.14. ● You can use p0890[1] to interconnect to an ESR integrated in the drive. ●...

-

Page 113: Overview Of Important Parameters

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.7.3 Overview of important parameters Overview of important parameters (see SINAMICS S120/S150 List Manual) EPOS maximum delay • p2573 CI: EPOS maximum speed, externally limited • p2594 BI: EPOS intermediate stop (0 signal) •... -

Page 114: Interaction With Epos

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.7.4 Interaction with EPOS Since the function SS2 – with its setpoint-independent braking – is not suitable for use with EPOS, the Safe Operating Stop (SOS) function can be used with delay. On selection of SOS, the EPOS function "intermediate stop"... - Page 115 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions An override can also be added to SLS limit value 1. In operation, this override can be varied using a PROFIsafe telegram. Note Deviation of the displayed speed limit The SLS speed limit displayed in r9714[2] can deviate slightly from the specified SLS speed limit.

-

Page 116: Safely Limited Speed (Sls)

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.8.1 Safely Limited Speed (SLS) Features ● When SLS is selected, the monitoring only takes effect after the configured delay time has expired (p9551). Within this time, the actual speed must be below the (selected) limit. The delay time is not effective when SLS is deselected. - Page 117 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Changeover of SLS limit values The changeover is executed binary-coded via 2 F-DIs or 2 PROFIsafe control bits. The speed selection status can be checked using parameters r9720.9/r9720.10. Parameters r9722.9 and r9722.10 indicate the actual speed limit, bit r9722.4 must carry a "1" signal. Table 4- 2 Changeover of speed limits: F-DI for bit 1...

- Page 118 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Transferring the first limit value via PROFIsafe SINAMICS offers the option of influencing the first SLS limit value via PROFIsafe: ● The transfer of the first SLS limit value via PROFIsafe is active if the speed level 1 in the PROFIsafe telegram is selected and the bit "Enable transfer SLS (SG) limit via PROFIsafe"...

-

Page 119: Safely Limited Speed Without Encoder

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.8.2 Safely Limited Speed without encoder Functions 2 different encoderless Safely-Limited Speed monitoring functions can be set with parameter p9506: ● p9506 = 3: Safe monitoring of acceleration (SAM) / delay time The function is identical to "Safely-Limited Speed with encoder"... - Page 120 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Configuring the limits ● The speed limits for Safely-Limited Speed without encoder are configured in exactly the same way as described for Safely-Limited Speed with encoder. ● Only STOP A and STOP B may be configured as stop responses for "Safely-Limited Speed"...

-

Page 121: Safely-Limited Speed Without Selection

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.8.3 Safely-Limited Speed without selection Differences between Safely-Limited Speed with and without selection ● As an alternative to controlling via terminals and/or PROFIsafe, there is also the option to parameterize the SLS function without selection (see Section "Motion monitoring without selection (Page 249)"). -

Page 122: Function Diagrams And Parameters

Function diagrams and parameters Function diagrams (see SINAMICS S120/S150 List Manual) SI Extended Functions - SLS (Safely-Limited Speed) • 2820 Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion enable safety functions (Control Unit): • p9501.0 Enable SOS/SLS (SBH/SG) Select SI Motion safety functions without selection (CU) •... -

Page 123: Epos And Safe Setpoint Velocity Limitation

This required braking time is determined by the current speed, the jerk limit in p2574 and the maximum delay in p2573. Overview of important parameters (see SINAMICS S120/S150 List Manual) EPOS maximum delay • p2573 EPOS jerk limitation •... - Page 124 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions The function is activated automatically as soon as the Safety Integrated Extended Functions are enabled with parameter p9501.0 = 1 and p9546 > 0. The SSM function is deactivated with setting p9546 = 0. Note Relationship between SSM and SAM If you enter "0"...

-

Page 125: Safe Speed Monitor With Encoder

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.9.1 Safe Speed Monitor with encoder Functional features of "Safe Speed Monitor" with encoder The parameter p9546 "SI Motion SSM (SGA n < nx) speed limit n_x" is used to set the speed limit. - Page 126 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions During safe motion monitoring, the "hysteresis and filtering" functions can be activated or deactivated together using the enable bit p9501.16. In the default setting, the functions are deactivated (p9501.16 = 0). Note Exception: SSM as an active monitoring function If the "hysteresis and filtering"...

-

Page 127: Safe Speed Monitor Without Encoder

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.9.2 Safe Speed Monitor without encoder Set p9506 = 1 or p9506 = 3 (factory setting = 0) to activate Safety Integrated Extended Functions without encoder. You can also make this setting by selecting "Without encoder" on the Safety screen in Startdrive. - Page 128 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Sequence diagram The following diagram shows the signal characteristic for the case p9509.0 = 0. Figure 4-16 Safe Speed Monitor without encoder (p9509.0 = 0) The speed remains below the limits of p9546 throughout the entire monitoring period. Therefore, the SSM feedback signal remains r9722.15 = 1.

- Page 129 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Restart after pulse cancellation for p9509.0 = 0 If the drive pulses have been suppressed using OFF1/OFF2/STO, the following steps must be carried out for a restart: 1. Case State after switching on •...

-

Page 130: Function Diagrams And Parameters

• 2905 = 0) SI TM54F - Extended Functions assignment (F-DO 0 ... F-DO 3) • 2907 Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion enable safety functions (Control Unit) • p9501 SI Motion function specification (Control Unit) •... -

Page 131: Safe Direction With Encoder

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.10.1 Safe Direction with encoder The Safe Direction function (SDI) allows reliable monitoring of the direction of motion of the drive. If this function is activated, the drive can only move in the enabled direction. Principle of operation After SDI has been selected via terminals or PROFIsafe, the delay time p9565 is started. - Page 132 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Enabling the Safe Direction function The "Safe Direction" function is enabled with p9501.17 = 1. Figure 4-17 Functional principle SDI with encoder Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

-

Page 133: Safe Direction Without Encoder

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.10.2 Safe Direction without encoder Set p9506 = 1 or p9506 = 3 (factory setting = 0) to activate Safety Integrated Extended Functions without encoder. You can also make this setting by selecting "Without encoder" on the Startdrive safety screen. - Page 134 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 2. Case Situation • Traversing to standstill with SDI selected • Initiate OFF1 • Pulses are canceled; internal selection STO becomes active • Select STO • Deselect STO • STO activated internally via pulse suppression: This activation must be undone by se- lecting/deselecting STO.

-

Page 135: Safe Direction Without Selection

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.10.3 Safe Direction without selection Differences between Safe Direction with and without selection ● As an alternative to controlling via terminals and/or PROFIsafe, there is also the option of parameterizing SDI without selection. In this case, SDI will be permanently active after POWER ON (with encoder) or will be active after switch-on (without encoder). -

Page 136: Function Diagrams And Parameters

SI TM54F - Extended Functions Safe State selection • 2906 SI TM54F - Extended Functions assignment (F-DO 0 ... F-DO 3) • 2907 Overview of important parameters (see SINAMICS S120/S150 List Manual) Reverse the output phase sequence • p1820[0...n] Direction of rotation •... -

Page 137: Safely Limited Acceleration (Sla)

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.11 Safely Limited Acceleration (SLA) Function "Safely-Limited Acceleration" (SLA) monitors that the motor does not violate the defined acceleration limit (e.g. in the setup mode). SLA detects early on whether the speed is increasing at an inadmissible rate (the drive accelerates uncontrollably) and initiates the stop response. - Page 138 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Filter time If the determination of the acceleration leads to very noisy signals, the drive cannot reasonably monitor the acceleration. Remedy ● In this case, increase the "SLA filter time" (p9576). Note that SLA reacts with a delay when you increase the filter time.

- Page 139 (Page 251)"). You will find this status word in telegrams 700 and 701. Function diagrams (see SINAMICS S120/S150 List Manual) SLA (Safely-Limited Acceleration) • 2838 Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion enable safety functions (Control Unit) • p9501 SI Motion SLA filter time (CU) •...

-

Page 140: Safe Brake Test (Sbt)

● The parameters of the "SBT" function are protected by the safety password, and can only be changed in the safety commissioning mode. ● Using this function, brakes can be tested that are directly connected to SINAMICS S120 (integrated brake control), but also externally controlled brakes (e.g. via a PLC). - Page 141 2 brakes in a Category 3 application, a Performance Level of up to Category PL d can be achieved with an adequate test rate. You will find an application example of the calculation at this address (https://support.industry.siemens.com/cs/ww/en/view/69870640). Preconditions The following preconditions must be satisfied when using the "Safe Brake Test" function: ●...

- Page 142 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Enabling the SBT function To enable the Safe Brake Test function, proceed as follows: 1. Enable the Safe Brake Control (SBC) function: p9602 = 1. 2. Select the SBT selection type with parameter p10203: –...

- Page 143 ("motor holding brake closing time"). Further information can be found in the SINAMICS S120 Function Manual Drive Functions. – Note that you must set the times p1216 and p1217 exactly according to the physical behavior of the brake.

- Page 144 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Note SBT and EPOS If EPOS is activated, you must activate "follow-up mode" (r2683.0) before you perform the brake test so that the position monitoring does not react during the brake test. Note SBT and DSC If you use SBT with SIMOTION, evaluate parameter r10234 (S_ZSW3B) and activate Safety...

- Page 145 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Starting SBT 1. Selection You have the following options for the selection of the Safe Brake Test: – Selection via BICO using a 0/1 signal edge at DI for p10230[0] –...

- Page 146 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4. Start brake test Start the brake test sequence using a 0/1 edge at the DI for p10230[1] or in S_STW3B bit 1. 5. Exit brake test Note Observe the sequence when exiting When you exit the brake test, you must observe the following sequence.

- Page 147 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Sequence SBT has the following basic sequence: Figure 4-20 SBT: Time sequence ● After you have selected the brake test (0/1 edge in r10231.0), the drive determines the static suspended load. This is the reason that all brakes must be open and the pulses enabled when the brake test is selected.

- Page 148 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions ● At the end of the test sequence, the brake is opened or there is a prompt to open the brake. ● After deselection of the test sequence (test sequence is switched off), another test sequence can be started, e.g.

-

Page 149: Communication Via Sic/Scc

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.12.1 Communication via SIC/SCC Test of a motor holding brake The following figure shows the communication via SIC and SCC during the test of a motor holding brake: Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1... - Page 150 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Test of an external brake The following figure shows the communication via SIC and SCC during the test of an external brake: Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

-

Page 151: Function Diagrams And Parameters

SI Extended Functions - SBT (Safe Brake Test) • 2836 SI Extended Functions – Selection of active control word • 2837 Overview of important parameters (see SINAMICS S120/S150 List Manual) Motor holding brake configuration • p1215 Motor holding brake opening time •... -

Page 152: Safe Acceleration Monitor (Sam)

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.13 Safe Acceleration Monitor (SAM) The "Safe Acceleration Monitor" (SAM) function is used to safety monitor braking along the OFF3 ramp. The function is active for SS1, SS2 or STOP B and STOP C. Features As long as the speed is less, the converter continuously adds the adjustable tolerance p9548 to the actual speed so that the monitoring tracks the speed. - Page 153 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Calculating the SAM tolerance of the actual speed ● The following applies when parameterizing the SAM tolerance: – The maximum speed increase after SS1 or SS2 is triggered results from the effective acceleration (a) and the duration of the acceleration phase.

-

Page 154: Safe Brake Ramp (Sbr)

● System fault: – STOP F with subsequent STOP A – Safety message C01711 Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion SSM (SGA n < nx) speed limit (CU) • p9546 SI Motion SAM actual speed tolerance (Control Unit) •... - Page 155 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Additional specific functions (e.g. STO, new SLS speed limit) are activated at this point, depending on the Safety Integrated function used. Figure 4-21 Safe Brake Ramp without encoder (for SLS) Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

- Page 156 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Parameterization of the brake ramp p9581 (SI Motion braking ramp reference value) and p9583 (SI Motion brake ramp monitoring time) are used to set the gradient of the brake ramp. Parameter p9581 determine the reference speed and parameter p9583 define the ramp-down time.

-

Page 157: Safe Actual Value Acquisition

The following encoder systems can in principle be used for safety-relevant speed/position acquisition: ● Single-encoder systems ● 2-encoder systems Note Rules for connecting an encoder Note when connecting an encoder the valid rules: See SINAMICS S120 Drive Functions Function Manual. Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1... - Page 158 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Single-encoder system In a single-encoder system, only the motor encoder is used to safely acquire the drive actual values. This motor encoder must be appropriately suitable (see encoder types). The actual values are generated in a safety-relevant fashion either directly in the encoder or in the Sensor Module and are transferred to the Control Unit via DRIVE-CLiQ.

- Page 159 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Special feature in the case of linear motors The motor encoder (linear scale) of linear motors also acts as load measuring system. Only one measuring system is required for this reason. The system is connected by means of a Sensor Module or directly via DRIVE-CLiQ.

- Page 160 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Figure 4-24 Example of a 2-encoder system on a rotary axis When parameterizing a 2-encoder system with Safety Integrated, you must align parameters p9315 to p9329 with parameters r0401 to r0474. Note Assignment of the encoder parameters Parameters p95xx are assigned to the 1st encoder;...

- Page 161 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Table 4- 3 Encoder parameters and corresponding safety parameters for 2-encoder systems Safety parameters Designation Encoder parameters p9315/p9515 SI Motion coarse position value configuration p9315.0/p9515.0 Up-counter r0474[x].0 p9315.1/p9515.1 Encoder CRC, least significant byte first r0474[x].1 p9315.2/p9515.2 Redundant coarse position value, most significant bit left-...

- Page 162 U310-2, CUA32, SINAMICS HLA or SINAMICS S120 Combi. – An HTL/TTL encoder connected to the onboard interface of CU310-2, CUA32, SINAMICS HLA or SINAMICS S120 Combi must not be operated as first encoder. – Note the lowest possible velocity resolution (r9732[1]) for an HTL/TTL encoder system.

- Page 163 Information on the internal realization of the encoder must come from the encoder manufacturer. The FMEA must be created by the machine manufacturer. Siemens motors with and without DRIVE-CLiQ connection, which can be used for Safety Integrated functions, are listed under: Siemens motors for Safety Integrated (https://support.industry.siemens.com/cs/ww/en/view/33512621)

- Page 164 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Actual value synchronization This deviation cannot be larger than the position difference that can arise at maximum slip (p9549) during a cross-check cycle (r9724). Figure 4-25 Example diagram of actual value synchronization The mean value of the actual values of both channels is calculated cyclically after actual value synchronization (p9501.3 = 1) has been activated, for example, for systems or machines with slip.

- Page 165 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Safe motion monitoring The properties of the actual value acquisition determine not only the encoders used, but also the values for safe motion monitoring that can be achieved in the best case. ●...

- Page 166 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion enable safety-related functions Enable actual value synchroni- • p9501.3 zation SI Motion axis type (Control Unit) • p9502 SI Motion actual value acquisition clock (Control Unit) •...

-

Page 167: Notes Regarding Setting Parameters For Safe Actual Value Sensing Without Encoder

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.15.2 Notes regarding setting parameters for safe actual value sensing without encoder Parameters p9585, p9586, p9588 and p9589 are available to guarantee safe motion monitoring for Safety Extended Functions without encoder depending on the situation in your specific application. - Page 168 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions ● Using parameter Fault tolerance actual value acquisition encoderless (p9585), you can set the tolerance of the plausibility monitoring of current and voltage angle. – For synchronous motors, p9585 = 4 must be parameterized. –...

- Page 169 = 375 µs, 312.5 µs, 218.75 µs, 200 µs, 187.5 µs, 175 µs, 156.25 µs, 150 µs or 137.5 µs Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion actual value acquisition without encoder fault tolerance (CU) •...

-

Page 170: Safe Gearbox Stage Switchover

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions 4.2.16 Safe gearbox stage switchover "Safe gearbox switchover" allows you to switch between 8 gearbox ratios in operation. Switchover between gearbox ratios is only possible via PROFIsafe (p9601.3 = 1). Parameterization Before you can use "Safe gearbox switchover", you must parameterize the following values: ●... - Page 171 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Gearbox switchover without increased position tolerance In order to switch over the gearbox stage, where no increased tolerance is required for the crosswise comparison of the actual positions, proceed as follows: 1.

- Page 172 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Gearbox switchover with increased position tolerance In order to switch over the gearbox stage, where increased tolerance is required for the crosswise comparison of the actual positions, proceed as follows: Note Maximum duration of the increased position tolerance It is not permissible that the increased position tolerance is set for longer than 2 min.

- Page 173 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Figure 4-27 Gearbox switchover with increased position tolerance Diagnostics The selected gearbox stage is displayed for diagnostic purposes in parameter r9720, bits 24 to 26. The selected gearbox stage is displayed for diagnostic purposes in parameter r9720, bit 27. "Safe gearbox switchover"...

-

Page 174: Forced Checking Procedure (Test Stop)

Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion enable safety functions (Control Unit): Enable reliable gearbox • p9501.26 switchover SI Motion gearbox encoder (motor)/load denominator (Control Unit) •... - Page 175 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Executing a forced checking procedure (test stop) Forced checking procedure (test stop) can be executed at the following points in time: 1. Forced checking procedure (test stop) can be initiated application-specifically and can therefore be executed at a time that suits application requirements.

- Page 176 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Safety devices When the appropriate safety devices are implemented (e.g. protective doors), it can be assumed that running machinery will not pose any risk to personnel. The user is therefore only informed that the forced checking procedure (test stop) is due in the form of an alarm, which requests the user to perform forced checking procedure (test stop) at the next possible opportunity.

- Page 177 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions Figure 4-28 Connection example for TM54F Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

- Page 178 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions The F-DIs must be registered for the test stop using p10041. Note F-DI not operational during the test The F-DI states are frozen for the duration of the test! • Ensure that the states of the F-DIs are not evaluated during the test. The associated F-DOs must be registered for the test stop using p10046.

- Page 179 Description of Safety Integrated functions 4.2 Safety Integrated Extended Functions ● Forced checking procedure (test stop) can be automatically executed at POWER ON. – If an automatic test stop of F-DI and F-DO of the TM54F is to be executed, then set p10048 = 1.

-

Page 180: Safety Integrated Advanced Functions

● A trial license is available for test purposes; this allows you to use Safety Integrated functions for a specific time without having a valid license. Details on the trial license can be found in the "SINAMICS S120 Function Manual Drive Functions", Chapter "Licensing". - Page 181 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions Preconditions For the Safely-Limited Position function, the following requirements must be met: ● The use of one or two suitable encoders for the extended safety functions with encoder (see also Section "Notes regarding safe actual value sensing using an encoder system (Page 155)").

- Page 182 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions Control and status signals from the SLP Selecting SLP and switching over between the position ranges is realized via an F-DI or a PROFIsafe control bit. SLP selection can be checked using parameter r9720.6. The selected position range can be checked using parameter r9720.19.

- Page 183 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions Note Restrictions for PROFIsafe telegram 30 The use of PROFIsafe telegram 30 (with the 16-bit words S_STW1 and S_ZSW1) has the following restrictions: • Only position range 1 is available. •...

-

Page 184: Retraction

– Activate this program for retraction, for example, using an F-DI of the F-CPU Note FAQ retraction You will find a description of how retraction can be implemented via a fail-safe control and PROFIsafe communication in the Internet at: Retraction (https://support.industry.siemens.com/cs/ww/en/view/65128501) Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1... - Page 185 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions Control via F-DI (TM54F or onboard terminals) 1. Using parameters p10009, parameterize an F-DI, with which you can select/deselect the internal retract logic function. 2. Parameterize two F-DIs for the selection/deselection of the SDI positive and SDI negative functions in an independent acceptance test.

-

Page 186: Function Diagrams And Parameters

SI functions - CU310-2 safe state selection • 2876 SI functions, CU310-2 assignment (F-DO 0) • 2877 Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion enable safety functions (Control Unit) • p9501 SI Motion SLP (SE) upper limit values (Control Unit) •... -

Page 187: Transferring Safe Position Values (Sp)

Its use for safe position monitoring is only permissible if the reference to the absolute position was established at the controller level. In this case, the "safely referenced" bit of SINAMICS S120 (r9722.23) cannot be used. Enabling the "Transfer safe position values" function The following steps are required to enable the "Transfer safe position values"... - Page 188 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions Principle of operation After parameter assignment, release and POWER ON, the function is automatically selected and the values transferred. Please observe the following: ● Transfer of safe absolute position values –...

- Page 189 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions the actual position value does not exceed the 16-bit format. If the actual position value exceeds the range that can be displayed with 16 bits (±32767), a STOP F is initiated and message C01711 is output with fault value 7001.

-

Page 190: Synchronous Transfer Of Safe Position Values

Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions 4.3.4.2 Synchronous transfer of safe position values For axes that have to transfer their position values synchronously due to their application, proceed as follows: Selection and enabling 1. For all axes that must transfer their position synchronously at the same time, parameterize the following: –... -

Page 191: Function Diagrams And Parameters

Function diagrams (see SINAMICS S120/S150 List Manual) SI Motion drive-integrated control signals / status signals • 2840 Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion enable safety functions (Control Unit) • p9501 SI Motion SP modulo value (Control Unit) •... -

Page 192: Safe Referencing

Safety Integrated indicates the position of the drive in diagnostic parameters r9708 and r9713. Bit r9722.23 is set when the axis is safely referenced. Function diagrams (see SINAMICS S120/S150 List Manual) SI functions - safe referencing • 2821... - Page 193 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions Referencing types SINAMICS distinguishes between 2 types of referencing: ● Initial referencing For initial safe referencing, or in the event of a fault during a subsequent referencing, the following steps are necessary: –...

-

Page 194: Safe Cam (Sca)

Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion reference position (Control Unit) • p9572 Accept SI Motion reference position (Control Unit) • p9573 SI Motion diagnostics safe position •... - Page 195 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions Defining the output cam positions ● You define the output cam positions to be monitored using the parameters p9536[x] and p9537[x] (where x = 0 ... 29). Note that the defined output cams must have a certain minimum length: p9536[x] - p9537[x] ≥...

- Page 196 SCA (Safe Cam) • 2826 S_ZSW_CAM1 Safety status word Safe Cam 1 • 2844 Overview of important parameters (see SINAMICS S120/S150 List Manual) SI Motion enable safety functions (Control Unit) • p9501 SI Motion SCA (SN) enable (Control Unit) • p9503 SI Motion SP modulo value (Control Unit) •...

-

Page 197: Forced Checking Procedure (Test Stop)

Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions 4.3.7 Forced checking procedure (test stop) Forced checking procedure (test stop) and function test The functions and switch-off signal paths must be tested at least once within a defined period to establish whether they are working properly in order to meet the requirements of EN ISO 13849-1 and IEC 61508 in terms of timely error detection. - Page 198 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions Executing a forced checking procedure (test stop) Forced checking procedure (test stop) can be executed at the following points in time: 1. Forced checking procedure (test stop) can be initiated application-specifically and can therefore be executed at a time that suits application requirements.

- Page 199 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions Safety devices When the appropriate safety devices are implemented (e.g. protective doors), it can be assumed that running machinery will not pose any risk to personnel. The user is therefore only informed that the forced checking procedure (test stop) is due in the form of an alarm, which requests the user to perform forced checking procedure (test stop) at the next possible opportunity.

- Page 200 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions Figure 4-31 Connection example for TM54F Safety Integrated Function Manual, 12/2018, 6SL3097-5AR00-0BP1...

- Page 201 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions The F-DIs must be registered for the test stop using p10041. Note F-DI not operational during the test The F-DI states are frozen for the duration of the test! • Ensure that the states of the F-DIs are not evaluated during the test. The associated F-DOs must be registered for the test stop using p10046.

- Page 202 Description of Safety Integrated functions 4.3 Safety Integrated Advanced Functions ● Forced checking procedure (test stop) can be automatically executed at POWER ON. – If an automatic test stop of F-DI and F-DO of the TM54F is to be executed, then set p10048 = 1.

-

Page 203: Control Of The Safety Functions

The safety-oriented input and output terminals (F-DI and F-DO) act as an interface between the SINAMICS S120 Safety Integrated functionality and the process. A dual-channel signal applied to an F-DI (Fail-safe Digital Input, safety-oriented digital input = safe input terminal pair) controls the active monitoring of the activation/deactivation of safety functions. -

Page 204: Control Signals By Way Of Terminals On The Control Unit And Motor / Power Module

Control of the safety functions 5.2 Control signals by way of terminals on the Control Unit and Motor / Power Module Control signals by way of terminals on the Control Unit and Motor / Power Module Features ● Only for the Basic Functions ●... - Page 205 5.2 Control signals by way of terminals on the Control Unit and Motor / Power Module Overview of the safety function terminals for SINAMICS S120 The different power unit formats of SINAMICS S120 have different terminal designations for the inputs of the safety functions. These are shown in the following table.

- Page 206 Control of the safety functions 5.2 Control signals by way of terminals on the Control Unit and Motor / Power Module Description of the two-channel structure The functions are separately selected/deselected for each drive using two terminals. ● Switch-off signal path, Control Unit (CU310-2/CU320-2) The desired input terminal is selected via BICO interconnection (BI: p9620[0]).

- Page 207 Control of the safety functions 5.2 Control signals by way of terminals on the Control Unit and Motor / Power Module Note Parameterization of the grouping The grouping must be configured (DI on Control Unit) and wired (EP terminals) identically in both monitoring channels.

-

Page 208: Simultaneity And Tolerance Time Of The Two Monitoring Channels

Control of the safety functions 5.2 Control signals by way of terminals on the Control Unit and Motor / Power Module 5.2.1 Simultaneity and tolerance time of the two monitoring channels The monitoring functions must be selected/deselected simultaneously in both monitoring channels via the input terminals and only have an effect on the associated drive. - Page 209 (p9650 and p9658). Otherwise, the drive will coast down after the time p9650 + p9658 has elapsed. Further notes for setting the discrepancy time (also see the following diagram "Discrepancy time") are provided in the "SINAMICS S120/S150 List Manual" for the following message: ● F01611 (Basic Functions) ● C01770 (Extended/Advanced Functions)

-

Page 210: Bit Pattern Test

Extended/Advanced Functions). To do this, a value must be entered in p9651 or p10017 that is greater than the duration of a test pulse. Overview of important parameters (see SINAMICS S120/S150 List Manual) SI STO/SBC/SS1 debounce time (Control Unit) •... -

Page 211: Sto Via Terminals Of The Power Modules Blocksize (Cu310-2)