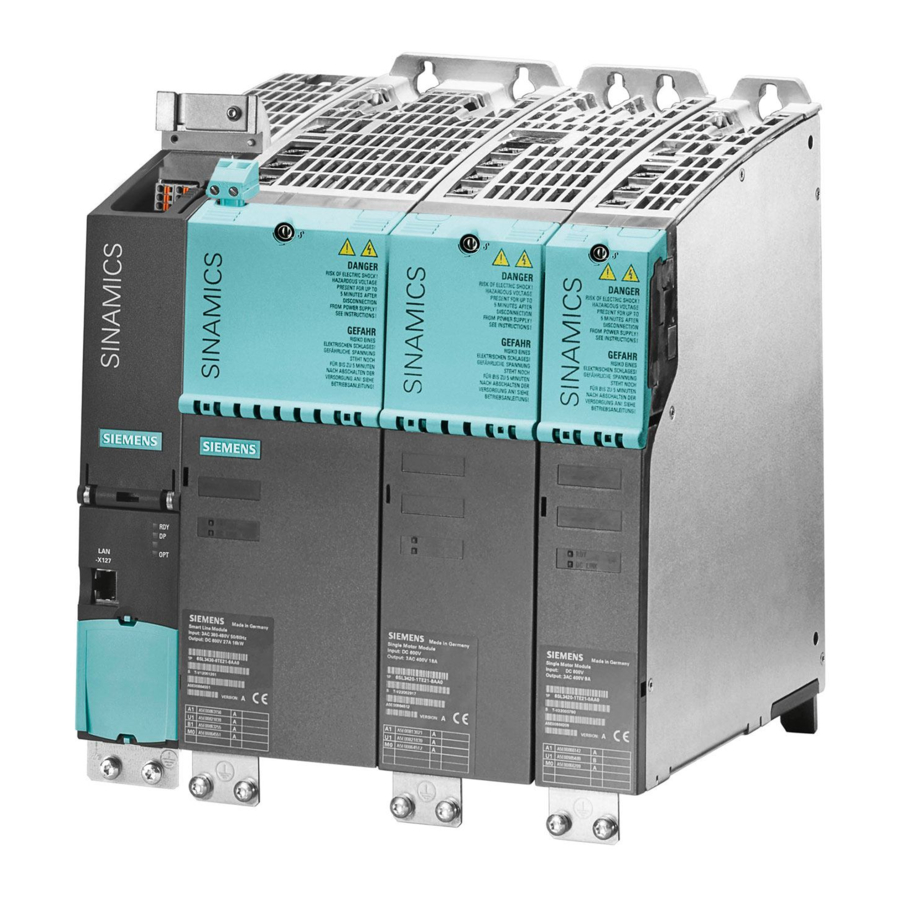

Siemens SINAMICS S120 Manual

Power units in booksize c/d-type format

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Siemens SINAMICS S120

- Page 3 ___________________ Preface ___________________ Fundamental safety instructions ___________________ SINAMICS System overview ___________________ Motor Modules in booksize C/D-type format S120 Power Units in Booksize C/D-Type ___________________ Motor connection, shield Format support and fabrication ___________________ Motor-side power components Manual ___________________ Cabinet design ___________________ Service and support for booksize C/D-type ___________________...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Preface

Preface Preface to the SINAMICS S120 Manual "Booksize C/D-Type Power Units" Based on the booksize design, SINAMICS S120 booksize C/D-type power units have been developed for full compatibility with the booksize series ● The C type power unit includes Single Motor Modules from 18 A to 60 A and the Double Motor Module 2 x 18 A. - Page 6 Siemens' content, and adapt it for your own machine documentation. Training At the following address (http://www.siemens.com/sitrain), you can find information about SITRAIN (Siemens training on products, systems and solutions for automation and drives). FAQs You can find Frequently Asked Questions in the Service&Support pages at Product Support (https://support.industry.siemens.com/cs/de/en/ps/faq).

- Page 7 Preface Usage phase Document/tool Installation/assembly SINAMICS S120 Equipment Manual for Control Units and Additional System Components • SINAMICS S120 Equipment Manual for Booksize Power Units • SINAMICS S120 Equipment Manual for Booksize Power Units C/D Type • SINAMICS S120 Equipment Manual for Chassis Power Units •...

- Page 8 Preface Software Manual Basic Functions SINAMICS S120 Function Manual Drive Functions Commissioning Of a simple SINAMICS S120 drive with Getting Started (up to Firmware V5.1 SP1) STARTER Commissioning With STARTER SINAMICS S120 Commissioning Manual (up to firmware V5.1 SP1) Commissioning Of a simple SINAMICS S120 drive with Getting Started (from Firmware V5.2)

- Page 9 Relevant directives and standards You can obtain an up-to-date list of currently certified components on request from your local Siemens office. If you have any questions relating to certifications that have not yet been completed, please ask your Siemens contact person.

- Page 10 ("Safety Integrated") on the Internet at the following address (https://support.industry.siemens.com/cs/ww/en/ps/13231/cert). The following directives and standards are relevant for SINAMICS S devices: ● European Low Voltage Directive SINAMICS S devices fulfil the requirements stipulated in the Low-Voltage Directive 2014/35/EU, insofar as they are covered by the application area of this directive.

- Page 11 SINAMICS S devices showing the test symbols fulfill the EMC requirements for Australia and New Zealand. ● Quality systems Siemens AG employs a quality management system that meets the requirements of ISO 9001 and ISO 14001. Not relevant standards China Compulsory Certification SINAMICS S devices do not fall in the area of validity of the China Compulsory Certification (CCC).

- Page 12 This document contains recommendations relating to third-party products. Siemens accepts the fundamental suitability of these third-party products. You can use equivalent products from other manufacturers. Siemens does not accept any warranty for the properties of third-party products. Ground symbols Table 1...

-

Page 13: Table Of Contents

System overview ........................... 25 Field of application ........................25 Platform Concept and Totally Integrated Automation ............. 26 Introduction ..........................28 SINAMICS S120 components ....................30 2.4.1 Advantages of Motor Modules in booksize C/D-type format ..........32 2.4.2 Overview of C/D-type Motor Modules ..................33 System data .......................... - Page 14 Electromagnetic fields in the workplace ................102 6.4.1 Preliminary remarks ......................102 6.4.2 Measurements/assessments for SINAMICS S120 Booksize Power Units ......103 Arrangement of components and equipment ............... 104 Electrical connection ......................105 6.6.1 Releasing the DC link protective cover ................105 6.6.2...

- Page 15 Table of contents 6.6.6 Connecting the 24 V terminal adapter .................. 113 6.6.7 Shield connection ........................114 6.6.7.1 Shield connection for X21/X22 on the Motor Module ............114 6.6.7.2 Shield connection for the motor holding brake ..............114 Connection system ....................... 114 6.7.1 Configuring the cable length ....................

- Page 16 Table of contents Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

-

Page 17: Fundamental Safety Instructions

Fundamental safety instructions General safety instructions WARNING Electric shock and danger to life due to other energy sources Touching live components can result in death or severe injury. • Only work on electrical devices when you are qualified for this job. •... - Page 18 Fundamental safety instructions 1.1 General safety instructions WARNING Risk of electric shock and fire from supply networks with an excessively low impedance Excessively high short-circuit currents can lead to the protective devices not being able to interrupt these short-circuit currents and being destroyed, and thus causing electric shock or a fire.

- Page 19 Fundamental safety instructions 1.1 General safety instructions WARNING Electric shock due to unconnected cable shield Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected cable shields. • As a minimum, connect cable shields and the conductors of power cables that are not used (e.g.

- Page 20 • If you come closer than around 2 m to such components, switch off any radios or mobile phones. • Use the "SIEMENS Industry Online Support app" only on equipment that has already been switched off. Power Units in Booksize C/D-Type Format...

- Page 21 Fundamental safety instructions 1.1 General safety instructions NOTICE Damage to motor insulation due to excessive voltages When operated on systems with grounded line conductor or in the event of a ground fault in the IT system, the motor insulation can be damaged by the higher voltage to ground. If you use motors that have insulation that is not designed for operation with grounded line conductors, you must perform the following measures: •...

- Page 22 Fundamental safety instructions 1.1 General safety instructions WARNING Unexpected movement of machines caused by inactive safety functions Inactive or non-adapted safety functions can trigger unexpected machine movements that may result in serious injury or death. • Observe the information in the appropriate product documentation before commissioning.

-

Page 23: Equipment Damage Due To Electric Fields Or Electrostatic Discharge

Fundamental safety instructions 1.2 Equipment damage due to electric fields or electrostatic discharge Equipment damage due to electric fields or electrostatic discharge Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules or devices that may be damaged by either electric fields or electrostatic discharge. NOTICE Equipment damage due to electric fields or electrostatic discharge Electric fields or electrostatic discharge can cause malfunctions through damaged... -

Page 24: Industrial Security

Siemens’ products and solutions undergo continuous development to make them more secure. Siemens strongly recommends that product updates are applied as soon as they are available and that the latest product versions are used. Use of product versions that are no longer supported, and failure to apply the latest updates may increase customer’s exposure... -

Page 25: Residual Risks Of Power Drive Systems

Fundamental safety instructions 1.5 Residual risks of power drive systems WARNING Unsafe operating states resulting from software manipulation Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe operating states in your system that may lead to death, serious injury, and property damage. - Page 26 Fundamental safety instructions 1.5 Residual risks of power drive systems 2. Unusually high temperatures, including open flames, as well as emissions of light, noise, particles, gases, etc., can occur inside and outside the components under fault conditions caused by, for example: –...

-

Page 27: System Overview

System overview Field of application SINAMICS is the family of drives from Siemens designed for machine and plant engineering applications. SINAMICS offers solutions for all drive tasks: ● Simple pump and fan applications in the process industry ● Complex single drives in centrifuges, presses, extruders, elevators, as well as conveyor and transport systems ●... -

Page 28: Platform Concept And Totally Integrated Automation

Communication via PROFINET This Ethernet-based bus enables control data to be exchanged at high speed via PROFINET IO with IRT or RT and makes SINAMICS S120 a suitable choice for integration in high-performance multi-axis applications. At the same time, PROFINET also uses standard IT mechanisms (TCP/IP) to transport information, e.g. - Page 29 ● HMI (operator control and monitoring) ● Control ● Drives and I/O Figure 2-2 SINAMICS as part of the Siemens modular automation system Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

-

Page 30: Introduction

System overview, SINAMICS S120 with S120M distributed servo drive technology Modular system for sophisticated drive tasks SINAMICS S120 solves complex drive tasks for a wide range of industrial applications and is, therefore, designed as a modular system. Select from many different harmonized components and functions to create the combination that best meets your requirements. - Page 31 Electronic rating plates in all components An important digital linkage element of the SINAMICS S120 drive system are the electronic type plates integrated in every component. They allow all drive components to be detected automatically via a DRIVE-CLiQ link. As a result, data does not have to be entered manually during commissioning or component replacement –...

-

Page 32: Sinamics S120 Components

System overview 2.4 SINAMICS S120 components SINAMICS S120 components Figure 2-4 SINAMICS S120 components Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0... - Page 33 ● Standardized design, side-by-side mounting Note Installation location in the cabinet As a general rule, SINAMICS S120 components must be mounted vertically in the control cabinet. If other mounting positions are permissible, these are specified in the descriptions for the individual components.

-

Page 34: Advantages Of Motor Modules In Booksize C/D-Type Format

Only components from the booksize C/D-type series plus the relevant connection components are described in this manual. Additional documentation containing system information and system component descriptions can be found in the SINAMICS S120 Manual "Booksize Power Units". This manual also contains all further information that is required to operate Motor Modules in booksize C/D-type format: ●... -

Page 35: Overview Of C/D-Type Motor Modules

System overview 2.4 SINAMICS S120 components 2.4.2 Overview of C/D-type Motor Modules The Motor Modules of the SINAMICS S system in booksize C-type and D-type format operate as inverters. They make the energy from the connected motors' DC link available at an adjusted voltage and with variable frequency. - Page 36 System overview 2.4 SINAMICS S120 components Table 2- 2 Overview of Motor Modules in booksize D-type format (with up to 3x overload) 50 mm modules 100 mm modules 6SL3120-1TE13-0AD. (3 A) 6SL3120-1TE23-0AD. (30 A) • • 6SL3120-1TE15-0AD. (5 A) 6SL3120-2TE21-8AD. (2 x 18 A) •...

-

Page 37: System Data

System overview 2.5 System data System data Unless explicitly specified otherwise, the following technical data is valid for components of the SINAMICS S120 booksize drive system described in this document. Table 2- 3 Electrical data Line connection voltage 380 … 480 V 3 AC ±10 % (-15 % < 1 min) Line frequency 47 …... - Page 38 System overview 2.5 System data Table 2- 5 Degree of protection / protection class Degree of protection IPXXB according to EN 60529, open type according to UL/CSA Protection class Power circuits I (with protective conductor connection) Electronic circuits safety extra-low voltage PELV/SELV Table 2- 6 Environmental conditions Chemically active substances...

- Page 39 System overview 2.5 System data Installation altitude Operation 0 ... 1000 m above sea level without derating > 1000 ... 4000 m Reduction of the output current by 10 % per 1000 meters, or • Reduction in the ambient temperature by 5 °C per 1000 meters •...

- Page 40 System overview 2.5 System data Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

-

Page 41: Motor Modules In Booksize C/D-Type Format

Motor Modules in booksize C/D-type format Description A Motor Module is an inverter that supplies AC voltage to the connected motor(s). The Motor Module is supplied with DC voltage from a Line Module via the DC link. Connect Motor Modules via DRIVE-CLiQ to a Control Unit in which the open-loop and closed-loop control functions for the Motor Module are implemented. -

Page 42: Safety Instructions For Motor Modules Of C/D-Type

This can result in serious injury or death. • Only use adapters (DC link adapters and DC link rectifier adapters) approved by Siemens for the connection to the DC link. WARNING Electric shock due to incorrectly installed DC link bridges Incorrectly installed DC link bridges at the left-hand end of the drive line-up can cause an electric shock. - Page 43 Motor Modules in booksize C/D-type format 3.2 Safety instructions for Motor Modules of C/D-type WARNING Electric shock due to missing DC link side covers There is a danger of an electric shock through contact when the side covers of the DC link are missing.

- Page 44 • Set the DC power supply to 26 V. This ensures that the supply voltage for the brake remains within the permissible range when the following conditions are fulfilled: – Siemens three-phase motors are used – Siemens MOTION-CONNECT power cables are used – Motor cable lengths, max. 100 m Power Units in Booksize C/D-Type Format...

- Page 45 Damage or malfunctions can occur on the devices or system when DRIVE-CLiQ cables are used that are either incorrect or have not been approved for this purpose. • Only use suitable DRIVE-CLiQ cables that have been approved by Siemens for the particular application.

-

Page 46: Interface Description

Motor Modules in booksize C/D-type format 3.3 Interface description Interface description 3.3.1 Overview Interfaces of the 50 mm modules and 100 mm modules (30 A and 2 x 18 A) The interface designations for Double Motor Modules are shown in parentheses. Figure 3-1 Overview of interfaces of Motor Modules in booksize C/D-type format (here: 100 mm) Power Units in Booksize C/D-Type Format... - Page 47 Motor Modules in booksize C/D-type format 3.3 Interface description Note Shield connection The shield connection plate is fitted to the Motor Module in the delivery state. The associated shield connection clamp can be found in the terminal kit. Note Protective conductor connection On the 100 mm module illustrated above, the protective conductor connection is located on the left next to the shield connection plate.

- Page 48 Motor Modules in booksize C/D-type format 3.3 Interface description Interfaces of the 100 mm modules (45 A / 60 A) Figure 3-2 Overview of interfaces of Motor Modules in booksize C-type format 45 A / 60 A Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

-

Page 49: Motor And Brake Connection

Motor Modules in booksize C/D-type format 3.3 Interface description ① Interface X11 to connect the motor holding brake ② Threaded socket M4 for attachment of the shield connection clamp (Page 114) Figure 3-3 Motor Module 45 A / 60 A (view from below) Additional data regarding connecting motor holding brakes is provided in Chapter "Control cabinet installation/electrical connection (Page 114)". - Page 50 Motor Modules in booksize C/D-type format 3.3 Interface description Note Motor connector For information about the motor connector, please refer to Chapter "Motor connector" (Page 73). Note Shielding Attach the motor cable shield to the shield connection plate on the Motor Module using the shield connection clamp supplied in the terminal kit.

- Page 51 Motor Modules in booksize C/D-type format 3.3 Interface description The following diagrams show the dependencies of motor cable length, motor holding brake current and cross-section of the motor holding brake cables: Module input voltage 24 V Module input voltage 26 V Note Protective circuit against overvoltages The Motor Modules have an integrated overvoltage protection circuit for the motor holding...

-

Page 52: Protective Conductor Connection

Motor Modules in booksize C/D-type format 3.3 Interface description NOTICE Faulty brake function due to inadmissible wear Inadmissible wear means that the braking function can no longer be guaranteed. • Comply with the defined Emergency Stop characteristics. • Avoid repeated brief acceleration of the motor against a holding brake that is still closed. Consider the operating times of the brakes and the relays in the drive control and/or enable circuit. - Page 53 Motor Modules in booksize C/D-type format 3.3 Interface description 50 mm modules: Protective 100 mm modules (30 A, 100 mm modules (45 A / 60 A): conductor connection behind 2 x 18 A): Protective conductor Protective conductor connection the shield connection plate connection to the left, adjacent at the motor connection block to the shield connection plate...

-

Page 54: X21/X22 Ep Terminals / Temperature Sensor

Motor Modules in booksize C/D-type format 3.3 Interface description 3.3.4 X21/X22 EP terminals / temperature sensor Table 3- 3 X21/X22: EP terminals / temperature sensor Terminal Function Technical data + Temp Temperature sensors: KTY84-130 / Pt1000 / PTC / bimetallic switch with - Temp NC contact EP +24 V (digital input... -

Page 55: X200-X203 Drive-Cliq Interface

Motor Modules in booksize C/D-type format 3.3 Interface description Temperature sensor connection WARNING Electric shock when the motor temperature sensor insulation fails When connecting temperature sensors, which have no safe protective separation with respect to the motor power circuit, then arcing to the signal electronics can occur. •... -

Page 56: Connection Examples

Motor Modules in booksize C/D-type format 3.4 Connection examples Connection examples Figure 3-4 Connection example for Motor Modules Book a room size format C/D type, 3 A ... 30 A, 2x3 A ... 2x18 A Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0... - Page 57 Motor Modules in booksize C/D-type format 3.4 Connection examples Figure 3-5 Connection examples for Motor Modules Booksize format C type, 45 A / 60 A Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

-

Page 58: Meaning Of The Leds

Motor Modules in booksize C/D-type format 3.5 Meaning of the LEDs Meaning of the LEDs Table 3- 5 Meaning of the LEDs on the Motor Module Status Description, cause Remedy DC LINK The electronics power supply is missing or outside the –... -

Page 59: Dimension Drawings

Motor Modules in booksize C/D-type format 3.6 Dimension drawings Dimension drawings Figure 3-6 Dimension drawing of 50 mm Motor Modules in booksize C/D-type format with internal air cooling, all dimensions in mm and (inches) Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0... - Page 60 Motor Modules in booksize C/D-type format 3.6 Dimension drawings Figure 3-7 Dimension drawing of 100 mm Motor Modules 30 A / 2 x 18 A in Booksize format C/D type with internal air cooling, all dimensions in mm and (inches) Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

- Page 61 Motor Modules in booksize C/D-type format 3.6 Dimension drawings Figure 3-8 Dimension drawing of 100 mm Motor Modules 45 A / 60 A in Booksize format C type with internal air cooling, all dimensions in mm and (inches) Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

-

Page 62: Installation

Motor Modules in booksize C/D-type format 3.7 Installation Installation Motor Modules are designed for installation in the control cabinet. They are fixed to the control cabinet wall or a mounting panel using M6 screws. Figure 3-9 Installing a Motor Module Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0... - Page 63 Motor Modules in booksize C/D-type format 3.7 Installation Drilling patterns Drilling pattern for 50 mm Motor Modules Drilling pattern for 100 mm Motor Modules Requirements placed on the electrical cabinet ● Housing: Sheet steel ● Panel thickness: 3 mm (0.12 in) ●...

-

Page 64: Technical Data

Motor Modules in booksize C/D-type format 3.8 Technical data Technical data 3.8.1 Single Motor Modules Table 3- 6 Technical data of Single Motor Modules in Booksize format C type (18 A to 60 A) C-type 6SL3120- 1TE21- 1TE22- 1TE23- 1TE24- 1TE26- 8AC. - Page 65 Motor Modules in booksize C/D-type format 3.8 Technical data C-type 6SL3120- 1TE21- 1TE22- 1TE23- 1TE24- 1TE26- 8AC. 4AC. 0AC. 5AC. 0AC. Ventilation clearances above/below ≥ 80 Weight Higher output frequencies up to a maximum of 3200 Hz are possible with an additional license. Default for 400 V line systems;...

-

Page 66: Double Motor Modules

Motor Modules in booksize C/D-type format 3.8 Technical data D-type 6SL3120 1TE13- 1TE15- 1TE21- 1TE21- 1TE22- 1TE23- 0AD. 0AD. 0AD. 8AD. 4AD. 0AD. Ventilation clearances above/below ≥ 80 Weight Higher output frequencies up to a maximum of 3200 Hz are possible with an additional license. Default for 400 V line systems;... - Page 67 Motor Modules in booksize C/D-type format 3.8 Technical data C-type 6SL3120- 2TE21-8AC. Current carrying capacity DC link busbars 24 V DC busbars Unit rating Based on I (600 V DC; 4 kHz) 2 x 9.7 Based on I 2 x 8.2 Typical power loss See also Power losses of the components (Page 134) Max.

-

Page 68: Motor Overload Protection According To 61800-5-1

The Motor Module has integrated motor overload protection according to 61800-5-1. The protection threshold is 115 % of the full load current of the Motor Module. It can be adapted using parameter p5453 (see SINAMICS S120/S150 List Manual). Power Units in Booksize C/D-Type Format... -

Page 69: Characteristics

Motor Modules in booksize C/D-type format 3.9 Characteristics Characteristics 3.9.1 Duty cycles Rated duty cycles of Motor Modules in booksize C-type format Figure 3-10 Duty cycle with initial load Figure 3-11 Duty cycle without initial load Figure 3-12 S6 duty cycle with initial load for a duty cycle duration of 600 s Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0... - Page 70 Motor Modules in booksize C/D-type format 3.9 Characteristics Figure 3-13 S6 duty cycle with initial load for a duty cycle duration of 60 s Figure 3-14 Duty cycle with 60 s overload for a duty cycle duration of 300 s Figure 3-15 Duty cycle with 30 s overload for a duty cycle duration of 300 s Rated duty cycles of Motor Modules in booksize D-type format...

- Page 71 Motor Modules in booksize C/D-type format 3.9 Characteristics Figure 3-17 Duty cycle with initial load Figure 3-18 Duty cycle without initial load for a duty cycle duration of 10 s Figure 3-19 Duty cycle without initial load for a duty cycle duration of 30 s Table 3- 10 Times I for the duty cycle...

- Page 72 Motor Modules in booksize C/D-type format 3.9 Characteristics Figure 3-20 S6 duty cycle with initial load for a duty cycle duration of 600 s Figure 3-21 S6 duty cycle with initial load for a duty cycle duration of 60 s Figure 3-22 Duty cycle with 60 s overload for a duty cycle duration of 300 s Figure 3-23...

-

Page 73: Derating Characteristics

Motor Modules in booksize C/D-type format 3.9 Characteristics 3.9.2 Derating characteristics Derating characteristics for Motor Modules in booksize C/D-type format Note For information about derating depending on ambient temperature and installation altitude, please refer to Chapter "System data" (Page 35). Figure 3-24 Output current as a function of the pulse frequency Note... - Page 74 Motor Modules in booksize C/D-type format 3.9 Characteristics Figure 3-25 Output current during operation at low frequencies Supplementary conditions applicable to operation at low frequencies ● Derating does not apply to acceleration from zero speed if an output frequency of >10 Hz is reached within 100 ms.

-

Page 75: Motor Connection, Shield Support And Fabrication

Motor connection, shield support and fabrication Motor plug connector for Motor Modules 3 A ... 30 A 4.1.1 Description Motor Modules up to 30 A are connected to motors using a motor plug connector (power connector). The motor plug connector is not included in the scope of supply. The motor connector must be ordered separately for power cables that do not have preassembled connectors. -

Page 76: Electrical Connection

Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A Note Using identical plug connector variants for Double Motor Modules Two connectors of identical type must be used on Double Motor Modules (both push-in connectors or both connectors with screw terminals). -

Page 77: Cable Cross-Sections And End Sleeves

Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A ③ BR- (white) ④ Motor protective conductor connection (PE) ⑤ U2, V2, W2 ⑥ Locking lever (for push-in connector only) Spring-loaded terminal Screw terminal (push-in) U2, V2, W2, pro-... - Page 78 Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A Table 4- 2 Connector with screw terminals 1.5 mm 2.5 mm 4 mm 6 mm Dimensions of the terminal AWG 16 AWG 14 AWG 12 AWG 10 openings...

-

Page 79: Crimping Conductor End Sleeves

Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A 4.1.2.2 Crimping conductor end sleeves The following crimping tool is available from Weidmüller to crimp conductor end sleeves (www.weidmueller.com). ● Type PZ 6/5 Article No. 9011460000 Figure 4-1 Crimp shape PZ 6/5 Note... - Page 80 Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A ① Conductors U-V-W ② Protective conductor core ③ Holding brake conductors ④ Protective braided shield ⑤ Shrink tubing Figure 4-2 Conductor and stripped insulation lengths Table 4- 3 Conductor and stripped insulation lengths as a function of the cable cross-section, data in mm and (inch) 1.5 mm...

-

Page 81: Connecting The Motor Cable

Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A Note Cables for UL applications For UL applications, only 60/75 °C copper cables may be used. 4.1.4 Connecting the motor cable Connecting conductors to the push-in connector The state of the push-in plug connector when it is Insert the conductors into the open terminals. - Page 82 Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A Opening the terminals/releasing the motor cables To release the terminals, press the individual locking levers up using a slot-head screwdriver (0.8 x 4 mm) until the lever snaps back into the motor connector casing. If it is difficult to withdraw the conductors from the open terminal, it may help to press the locking lever up as far as it will go while withdrawing the conductor.

-

Page 83: Installation

Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A 4.1.5 Installation 4.1.5.1 Installation Plug the motor connector into socket X1 for Single Motor Modules and into sockets X1 and X2 for Double Motor Modules. The motor connector has a catch, which snaps into the opening provided on the Motor Module. -

Page 84: Shielding

Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A Figure 4-4 Connecting the power cables to the Motor Module 4.1.5.2 Shielding Shield for 50 mm modules and 100 mm modules (30 A, 2 x 18 A) Shield connection The shield is connected through the shield connecting plate, which is screwed to the Motor Module, and a shield connecting terminal. - Page 85 Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A Shield support The power cable shield is attached to the shield connection plate of the Motor Module by means of the supplied shield connection clamp. 1.

-

Page 86: Coding

Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A 4.1.5.3 Coding Coding keys can be used to distinguish between different motor connectors, especially those for Double Motor Modules. The terminal kit contains 2 coding stars, each of which has 6 coding keys. -

Page 87: Pre-Assembled Power Cables

Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A Now insert coding keys into the matching slots on the motor connector terminal. In order to prevent the connector with ② coding key from being inserted into the left-hand connector terminal, a coding key must be inserted into the matching ③... - Page 88 Motor connection, shield support and fabrication 4.1 Motor plug connector for Motor Modules 3 A ... 30 A Detaching the preassembled power cable from the motor connector If the power cable needs to be routed through a confined space, the motor connector must be detached from the preassembled cable.

-

Page 89: Motor Connection Block For 45 A / 60 A Motor Modules

Motor connection, shield support and fabrication 4.2 Motor connection block for 45 A / 60 A Motor Modules Motor connection block for 45 A / 60 A Motor Modules 4.2.1 Description The motor connection block is used for the 45 and 60 A modules to connect phase conductors U2, V2, W2 and the protective conductor connection (PE) of the motor. - Page 90 Motor connection, shield support and fabrication 4.2 Motor connection block for 45 A / 60 A Motor Modules Figure 4-5 Dimension drawing of the motor connection block Table 4- 5 Dimensions of the motor connection block in mm (inch) Maximum dimensions 42 (1.65) 24.5 (0.96) 12 (0.47)

-

Page 91: Shield Connection Plate For 45 A / 60 A Motor Modules 100 Mm

Motor connection, shield support and fabrication 4.2 Motor connection block for 45 A / 60 A Motor Modules 4.2.2.2 Shield connection plate for 45 A / 60 A Motor Modules 100 mm Attach the shield connecting plate to the lower mounting points of the module. The shield connecting plate has several slots, which provide various options for connecting a shield: ●... -

Page 92: Prefabricating A Motor Connecting Cable

Motor connection, shield support and fabrication 4.2 Motor connection block for 45 A / 60 A Motor Modules Connection using a shield connection clamp Connection using a hose clamp at the shield connecting plate at the shield connecting plate The shield connecting plate, shield connecting terminals and hose clamps are not included in the scope of supply of the Motor Module. - Page 93 Motor connection, shield support and fabrication 4.2 Motor connection block for 45 A / 60 A Motor Modules 5. Shorten the individual conductors as indicated in the drawing and table below. 6. Use suitable ring or tubular cable lugs (see appendix). ①...

- Page 94 Motor connection, shield support and fabrication 4.2 Motor connection block for 45 A / 60 A Motor Modules Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

-

Page 95: Motor-Side Power Components

2 x rated current Control types Vector control and U/f control Further information such as safety instructions and dimension drawings can be found in the SINAMICS S120 Manual "Booksize Power Units". Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0... -

Page 96: Safety Instructions For Motor Reactors

NOTICE Damaged device due to use of incorrect motor reactors When using motor reactors that have not been approved by Siemens for SINAMICS, the motor reactors can be damaged. • Only use motor reactors that Siemens has approved for operation with SINAMICS. -

Page 97: Technical Data

Motor-side power components 5.1 Motor reactors 5.1.3 Technical data Table 5- 2 Technical data, motor reactors, part 1 Article No. 6SE7021- 6SL3000- 6SE7022- 0ES87-1FE0 2BE21-0AA0 6ES87-1FE0 Suitable for Motor Modules 6SL3120- 6SL3120- 6SL3120- booksize C/D type 1TE13-0AD. 1TE21-0AD. 1TE21-8AC. 2TE13-0AD. 2TE21-0AD. - Page 98 Motor-side power components 5.1 Motor reactors Table 5- 3 Technical data, motor reactors, part 2 Article No. 6SE7024- 6SE7027- 6SL3000- 7ES87-1FE0 2ES87-1FE0 2BE26-0AA0 Suitable for Motor Modules 6SL3120- 6SL3120- 6SL3120- 6SL3120- booksize C/D type 1TE22-4AC. 1TE23-0AC. 1TE24-5AC. 1TE26-0AC. 1TE22-4AD. 1TE23-0AD. Rated current Maximum current Inductance...

-

Page 99: Cabinet Design

Cabinet design General information SINAMICS S components are available as chassis units with degree of protection IP20 or IPXXB according to IEC 60529 and as open type devices to UL 50. This therefore ensures that fingers cannot come into contact with any active components. To ensure also protection against mechanical stress and climatic conditions, the components must always be operated in housings, cabinets or enclosed electrical operating areas/rooms that fulfill at least degree of protection IP54 according to European enclosure specifications,... -

Page 100: Safety Instructions With Respect To Control Cabinet Design

Cabinet design 6.2 Safety instructions with respect to control cabinet design Safety of machinery - electrical equipment of machines All information relating to device selection in this section applies to ● Operation on TN and TT line supply systems with grounded neutral point and grounded protective conductor as well as to IT line supply systems ●... -

Page 101: Classification Of Emc Behavior

● Operation on TN and TT line supply systems with grounded neutral point ● Observance of information about cable shielding and equipotential bonding ● Use of the recommended power and signal cables from Siemens. ● Only use Siemens cables for the DRIVE-CLiQ connections. -

Page 102: Drive System Applications

6.3.3 Drive system applications SINAMICS S120 units are designed for use in the second environment. They are to be used on a professional basis in trade, business and industry and are not sold to the general public. In order to satisfy the EMC requirements, the drive system must be installed by appropriately qualified personnel in compliance with EMC regulations and the installation notes provided in the manual. -

Page 103: Emitted Interference/Interference Immunity

Note Malfunctions when not using original Siemens accessories Malfunctions can occur if accessories are used that are not original. • For DRIVE-CLiQ connections, only use the genuine Siemens DRIVE-CLiQ wiring and DRIVE-CLiQ cabinet bushings. Power Units in Booksize C/D-Type Format... -

Page 104: Electromagnetic Fields In The Workplace

100 kHz (see system data or relevant technical specifications) 5. The routing of power cables has a significant impact on the electromagnetic fields that occur. You can find more detailed information in the "EMC installation guideline (https://support.industry.siemens.com/cs/ww/de/view/60612658)". Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0... -

Page 105: Measurements/Assessments For Sinamics S120 Booksize Power Units

Magnetic flux density For assessment, see the following Limits not exceeded table Table 6- 2 Minimum distances from SINAMICS S120 power units at 0 Hz ... 100 kHz in cm (inch) Line Module with Generally Individuals with active implants power rating... -

Page 106: Arrangement Of Components And Equipment

● EMC Note Further information about the arrangement of components and equipment For detailed information about the arrangement of components and equipment, please refer to the SINAMICS S120 Manual "Booksize Power Units". Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0... -

Page 107: Electrical Connection

6.6.1 Releasing the DC link protective cover The protective covers for the DC link on the SINAMICS S120 components have an interlocking mechanism, which must be opened using a flat bladed screwdriver (1 x 5.5 mm). This interlocking mechanism is identical for the power units of all series. -

Page 108: Connecting The Dc Link Busbars And 24 V Busbars To Components In The Booksize C/D Type Format

Cabinet design 6.6 Electrical connection 6.6.2 Connecting the DC link busbars and 24 V busbars to components in the Booksize C/D type format 6.6.2.1 Description The DC link busbars and 24 V busbars of the components must be connected in a drive line- up before commissioning. - Page 109 Motor Modules. It is not permissible that the maximum current carrying capacity of the DC link busbar is exceeded. For detailed information on this topic, see SINAMICS S120 Manual "Booksize Power Units ", Chapter "Current carrying capacity of DC links".

-

Page 110: Installation

Cabinet design 6.6 Electrical connection NOTICE Component damage caused by excessively low current load capability of the DC link busbars The DC link busbars of the individual components have different current carrying capacities (current ratings). If the current flowing through a DC link busbar is higher than the current specified for the busbar, the component will heat up and may sustain damage as a result of overheating. - Page 111 Cabinet design 6.6 Electrical connection Loosen the DC link screws at the right-hand end Always connect the lower DC link busbars first of the left module, and at the left-hand end of the and then the upper DC link busbars. To do this, adjacent module.

- Page 112 Cabinet design 6.6 Electrical connection Close the DC link protective covers until you hear them snap into place. WARNING Electric shock due to incorrectly installed DC link bridges Incorrectly installed DC link bridges at the left-hand end of the drive line-up can cause an electric shock.

-

Page 113: 24 V Connection

Cabinet design 6.6 Electrical connection NOTICE Material damage due to loose power connections Insufficient tightening torques or vibration can result in faulty electrical connections. This can cause fire damage or malfunctions. • Tighten all power connections with the specified tightening torques, e.g. line supply connection, motor connection, DC link connections. -

Page 114: Connection Of Booksize Components To Booksize C/D-Type Components

Description It is possible to combine components in booksize format with components in booksize C/D- type format with one another in the SINAMICS S120 drive line-up. They are mutually compatible in terms of both hardware design and software support. The following components in booksize format can also be used for components in booksize C/D-type format: ●... -

Page 115: Connecting The 24 V Terminal Adapter

Cabinet design 6.6 Electrical connection Further information can be found in the SINAMICS S120 Manual "Booksize Power Units". NOTICE DC link rectifier adapters for 45 A and 60 A modules burning No appropriate DC link rectifier adapters are available for 45 A and 60 A Motor Modules, Booksize C type. -

Page 116: Shield Connection

(Page 47)"). Connection system Note Information about the connection system and cables For detailed information about the connection system and cables, please refer to the SINAMICS S120 Manual "Booksize Power Units" Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0... -

Page 117: Configuring The Cable Length

Cabinet design 6.7 Connection system 6.7.1 Configuring the cable length To implement a longer motor cable, you can ● select a higher rating Motor Module or ● reduce the permissible continuous output current I in relation to the rated output continuous current I rated... -

Page 118: Current-Carrying Capacity And Derating Factors For Power Cables And Signal Cables

Cabinet design 6.7 Connection system 6.7.2 Current-carrying capacity and derating factors for power cables and signal cables The current carrying capacity of PVC/PUR-insulated copper cables is specified for routing types B1, B2 and C under continuous operating conditions in the table below with reference to an ambient air temperature of 40°... - Page 119 Cabinet design 6.7 Connection system Table 6- 8 Derating factors for deviating ambient temperatures Ambient air temperature [° C] Derating factor according to EN 60204-1, Table 1.15 1.08 1.00 0.91 0.82 0.71 0.58 WARNING Overheating of the motor cables when the permissible conductor cross-sections are fallen below Excessively thin motor cables can result in overheating.

-

Page 120: Connecting Terminals

Cabinet design 6.7 Connection system 6.7.3 Connecting terminals Table 6- 9 Connectable conductor cross-sections and tightening torques for screw terminals Screw terminal type Conductor Flexible 0.08 … 1.5 mm (AWG 28 ... AWG cross sections With end sleeve, without plastic sleeve that can be With end sleeve, with plastic sleeve 0.25 …... -

Page 121: Cable Lugs

Cabinet design 6.7 Connection system 6.7.4 Cable lugs Figure 6-4 Dimension drawing of cable lugs Table 6- 11 Dimensions of cable lugs Cable lug Bolt Cable cross-section [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] Ring 1 - 2.5 Ring 2.5 - 6 Ring 6 - 10... -

Page 122: Possible Functions Of The 24 V Supply

Note Grounding the 24 V electronics power supply In SINAMICS S120 components, the electronics ground is permanently connected to the protective conductor potential. The connection cannot be disconnected. WARNING... - Page 123 Set the DC power supply to at least 26 V. This ensures that the supply voltage for the brake remains within the permissible range when the following conditions are fulfilled: • Siemens three-phase motors are used • Siemens MOTION-CONNECT power cables are used • Motor cable lengths, max. 100 m Protective circuit against overvoltages The Motor Modules have an integrated overvoltage protection circuit for the motor holding brake.

- Page 124 External protective circuits are not required. Note More information Further information about conductor protection and the possible functions of the 24 V supply can be found in the SINAMICS S120 Manual "Booksize Power Units". Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

-

Page 125: Cable Shielding And Routing

Cabinet design 6.9 Cable shielding and routing Cable shielding and routing In order to comply with the EMC requirements, certain cables must be routed apart from other cables and from certain components. To satisfy EMC requirements, the following cables must be used with shields: ●... - Page 126 The cable shields must be connected as close to the conductor terminal connections as possible to ensure a low-impedance connection with cabinet ground. For power cables from Siemens in which the shield is connected to the connector shell (see relevant catalog), this is a sufficiently good shield support.

-

Page 127: Protective Connection And Equipotential Bonding

• Carefully comply with the applicable regulations for dimensioning the protective conductor (see below). Protective connection concept, SINAMICS S120 booksize power units Booksize power units should always be connected with a protective conductor to the central PE busbar or the conductive mounting plate in the control cabinet (see the following diagram). - Page 128 Additional details are provided in the following document "Dimensioning the protective conduc- tor for SINAMICS S120 Booksize (https://support.industry.siemens.com/cs/ww/en/view/109738572)". ④ Same cross-section as the line conductor of the motor cable. Figure 6-5 Protective connection concept, SINAMICS S120 booksize Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

- Page 129 Cabinet design 6.10 Protective connection and equipotential bonding Protective connection via the mounting plate Alternative to the described methods with protective conductors, it is also possible to establish the protective conductor connection of the electrical cabinet through the mounting plate, assuming that all of the following conditions are satisfied. As a consequence, the requirements placed on a protective conductor for an increased discharge current are satisfied.

- Page 130 Cabinet design 6.10 Protective connection and equipotential bonding Functional equipotential bonding For EMC reasons, the shield of the motor cable should be connected through a large surface area both at the Motor Module as well as at the motor. The drive line-up must be arranged on a single, bare metal mounting plate in order to comply with the EMC limit values.

-

Page 131: Notes On Control Cabinet Cooling

Cabinet design 6.11 Notes on control cabinet cooling 6.11 Notes on control cabinet cooling 6.11.1 Control cabinet cooling options The following options are available for cooling the control cabinet: ● Filter fan ● Heat exchanger ● Cooling unit ● Liquid cooling ●... -

Page 132: General Information On Ventilation

They switch themselves off with a small hysteresis as soon as the heat sink temperature drops below the stored temperature value and there is no pulse enable. The fan run-on time can be parameterized (see SINAMICS S120/S150 List Manual). Air guidance The cooling air must flow through the components vertically from bottom (cooler region) to top (region heated by operation). - Page 133 Cabinet design 6.11 Notes on control cabinet cooling ① Cooling unit ② Control cabinet Figure 6-6 Examples of cabinet ventilation NOTICE Component damage caused by condensation Condensation on the components can result in their failure. • Select the air circuit and arrangement of the cooling equipment in such a way that no condensation can form on the components.

-

Page 134: Ventilation Clearances

Note Ventilation clearances of the SINAMICS booksize drive line-up The ventilation clearances of other components in the booksize drive line-up can be found in the SINAMICS S120 Manual "Booksize Power Units". Drive line-up with internal air cooling Figure 6-7 Ventilation clearances for a drive line-up with internal air cooling... -

Page 135: Dimensioning Cooling Equipment

Cabinet design 6.11 Notes on control cabinet cooling 6.11.4 Dimensioning cooling equipment Manufacturers provide calculation programs for selecting cooling equipment. It is always necessary to know the power loss of the components and equipment installed in the cabinet. The physical relationship is shown in the following example. Formula to calculate the power loss: q = Q - k ·... -

Page 136: Power Losses Of The Components

Cabinet design 6.12 Power losses of the components 6.12 Power losses of the components 6.12.1 Typical power losses for Motor Modules The information on the power losses in the previous chapters are maximum values, which occur in the most unfavorable case. For typical applications, the losses are lower. The following applies as typical application: ●... -

Page 137: Maximum Power Losses In The Rated Load Range

Cabinet design 6.12 Power losses of the components Overview of typical power losses at the rated operating point Table 6- 16 Typical power losses in the control cabinet for operation at the rated operating point for internally cooled Motor Modules Motor Module internal air cooling Single Motor Module 3 A... -

Page 138: Maximum Power Losses In The Partial Load Range

Note Additional power loss values The power loss data for other components in the booksize drive line-up can be found in the SINAMICS S120 Manual "Booksize Power Units". 6.12.3 Maximum power losses in the partial load range Losses in the partial load range for Motor Modules... -

Page 139: Service And Support For Booksize C/D-Type

Service and support for booksize C/D-type Spare parts You can find spare parts in the Internet here (https://www.sow.siemens.com). Replacing the fan 7.2.1 Safety instructions when replacing a fan WARNING Electric shock when live parts are touched Before replacing the fan, you must switch off the power supplies (400 V AC and 24 V DC). -

Page 140: Replacing The Fan

Service and support for booksize C/D-type 7.2 Replacing the fan 7.2.2 Replacing the fan Note Service life and replacement intervals of the fan module The modules have an operating hours counter (p0251). When the maximum operating duration is reached, a corresponding message is output (A30042). The fan modules of the Motor Modules can be ordered as replacement parts. - Page 141 Service and support for booksize C/D-type 7.2 Replacing the fan Detach the protective conductor from Pull the fan module out forwards out of Motor Module with removed fan module the Motor Module. the Motor Module. (12 V or 24 V) Screwdriver: Torx 20 Installing a new fan module 1.

- Page 142 Service and support for booksize C/D-type 7.2 Replacing the fan Replacing the fan for 100 mm modules (45 A / 60 A) The fan assembly is integrated in the motor connection block. Use a slotted screwdriver to release the Open the cover. Remove the conductors of the motor terminal block cover on the left and connecting cable (von left: protective...

- Page 143 Service and support for booksize C/D-type 7.2 Replacing the fan Motor Module without fan Removed fan module Installing a new fan module 1. Insert a new fan assembly into the Motor Module. The power supply for the fan is automatically established. 2.

-

Page 144: Recycling And Disposal

Service and support for booksize C/D-type 7.3 Recycling and disposal Recycling and disposal For environmentally friendly recycling and disposal of your old device, please contact a company certified for the disposal of electrical and electronic waste and dispose of the device in accordance with the regulations in your country. -

Page 145: Appendix

Appendix List of abbreviations Note The following list of abbreviations includes all abbreviations and their meanings used in the entire SINAMICS family of drives. Abbreviation Source of abbreviation Meaning A… Alarm Warning Alternating Current Alternating current Analog Digital Converter Analog digital converter Analog Input Analog input Active Interface Module... - Page 146 Appendix A.1 List of abbreviations Abbreviation Source of abbreviation Meaning C… Safety message Controller Area Network Serial bus system Communication Board CAN Communication Board CAN Communication Board Ethernet PROFINET communication module (Ethernet) Compact Disc Compact disc Command Data Set Command data set CF Card CompactFlash Card CompactFlash card...

- Page 147 Appendix A.1 List of abbreviations Abbreviation Source of abbreviation Meaning DRIVE-CLiQ DRIVE-CLiQ DRAM Dynamic Random Access Memory Dynamic Random Access Memory DRIVE-CLiQ Drive Component Link with IQ Drive Component Link with IQ Dynamic Servo Control Dynamic Servo Control Doppelsubmodul Double submodule Digital Time Clock Timer EASC...

- Page 148 Appendix A.1 List of abbreviations Abbreviation Source of abbreviation Meaning FPGA Field Programmable Gate Array Field Programmable Gate Array Firmware Firmware Gigabyte Gigabyte Global Control Global control telegram (broadcast telegram) Ground Reference potential for all signal and operating voltages, usually defined as 0 V (also referred to as M) Gerätestammdatei Generic Station Description: Describes the fea-...

- Page 149 Appendix A.1 List of abbreviations Abbreviation Source of abbreviation Meaning Kreuzweiser Datenvergleich Data cross-check Know-how protection Know-how protection Kinetische Pufferung Kinetic buffering Proportional gain KTY84-130 Temperature sensor Symbol for inductance Light Emitting Diode Light emitting diode Linearmotor Linear motor Lageregler Position controller Least Significant Bit Least significant bit...

- Page 150 Appendix A.1 List of abbreviations Abbreviation Source of abbreviation Meaning Nullmarke Zero mark Normally Open (contact) NO contact Netzstromrichter Line-side converter Network Time Protocol Standard for synchronization of the time of day NVRAM Non-Volatile Random Access Memory Non-volatile read/write memory Open Architecture Software component which provides additional functions for the SINAMICS drive system...

- Page 151 Appendix A.1 List of abbreviations Abbreviation Source of abbreviation Meaning Power Supply Power supply Power Stack Adapter Power Stack Adapter PT1000 Temperature sensor Positive Temperature Coefficient Positive temperature coefficient Point To Point Point-to-point Pulse Width Modulation Pulse width modulation Prozessdaten Process data r…...

- Page 152 Safe stop Safety Integrated Safety Integrated Safety Info Channel Safety Info Channel Safety Integrity Level Safety Integrity Level SITOP Siemens power supply system Safely-Limited Acceleration Safely limited acceleration Smart Line Module Smart Line Module Safely-Limited Position Safely Limited Position Safely-Limited Speed...

- Page 153 Appendix A.1 List of abbreviations Abbreviation Source of abbreviation Meaning Terminal Board Terminal Board Technology Extension Software component which is installed as an addi- tional technology package and which expands the functionality of SINAMICS (previously OA applica- tion) Totally Integrated Automation Totally Integrated Automation Transport Layer Security Encryption protocol for secure data transfer (previ-...

- Page 154 Appendix A.1 List of abbreviations Abbreviation Source of abbreviation Meaning Extensible Markup Language Extensible markup language (standard language for Web publishing and document management) Zwischenkreis DC link Zero Mark Zero mark Zustandswort Status word Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

-

Page 155: Documentation Overview

Appendix A.2 Documentation overview Documentation overview Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0... - Page 156 Appendix A.2 Documentation overview Power Units in Booksize C/D-Type Format Manual, 12/2018, 6SL3097-5AC20-0BP0...

-

Page 157: Index

Shielding, 123 Field of application, 25 Communication PROFIBUS DP, 27 PROFINET, 26 Components Motor Module, 39 Heat dissipation SINAMICS S120, 30 Control cabinet, 129 Configuring, 115 Control cabinet design, 97 Electrical connection, 105 Heat dissipation, 129 Installation Protective connections, 125... - Page 158 Motor Module, 45, 114 Electrical connection, 74 Shield connection plate, 89 Installation, 81 Shielding, 82, 123 Shield connection, 82 SINAMICS S120, 30 Shield support, 83 System architecture, 29 Stripped lengths, 78 System data, 35 Motor holding brake, 48 Motor Module, 39...