Siemens SINAMICS S120 Equipment Manual

Chassis power units liquid cooled

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Summary of Contents for Siemens SINAMICS S120

- Page 1 Equipment Manual 04/2007 Edition SINAMICS S120 Chassis Power Units Liquid Cooled sinamics...

- Page 3 System Overview Line-Side Power Components SINAMICS S120 Power Modules Chassis Power Units Liquid Cooled Line Modules Equipment Manual Motor Modules Motor-Side Power Components Cabinet Design and EMC Cooling circuit and coolant properties Maintenance and servicing List of Abbreviations (GH7), Edition 04/2007...

- Page 4 Siemens. This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and operated and maintained as recommended.

- Page 5 All obligations entered into by Siemens result from the respective contract of sale that contains the complete and sole valid warranty arrangements. These contractual warranty provisions are neither extended nor curbed as a result of the statements made in this documentation.

- Page 6 Internet Address Up-to-date information about our products can be found on the Internet at the following address: http://www.siemens.com/motioncontrol You can find information on SINAMICS S120 at: http://www.siemens.com/sinamics Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 7 (via protective conductors, for example) or the measuring probe is briefly discharged before measurements are taken with an isolated measuring device (for example, touching a bare metal housing). Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 8 EC Certificate of Conformity. Caution Operating the equipment in the immediate vicinity (< 1.5 m) of mobile telephones with a transmitter power of > 1 W may lead to incorrect operation. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 9: Table Of Contents

The SINAMICS range of drives ....................1-1 SINAMICS S120 drive system...................... 1-3 Technical specifications........................ 1-7 Structure of a drive system with SINAMICS S120 chassis liquid cooled ........1-9 1.4.1 Structure of a drive system with SINAMICS S120 and Power Module ........1-9 1.4.2... - Page 10 Parallel switching of Motor Modules ................... 5-20 Motor-Side Power Components......................6-1 Sinusoidal Filter ..........................6-1 6.1.1 Description............................ 6-1 6.1.2 Safety Information......................... 6-2 6.1.3 Dimension Drawing........................6-3 6.1.4 Technical Specifications ....................... 6-4 Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 11 Coolant definition........................8-13 8.2.1 Inhibitors, anti-freeze, biocides....................8-14 Materials ............................. 8-16 Horizontal installation ......................... 8-17 Condensation protection......................8-19 Degrees of protection ......................... 8-20 Connection system ........................8-21 Commissioning, service......................8-21 Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 12 9.4.21 Replacing the Power Supply Board, Basic Line Module, frame size GBL ......... 9-45 Reforming the DC link capacitors ....................9-47 List of Abbreviations ..........................10-1 10.1 List of Abbreviations ........................10-1 References ............................11-1 11.1 References ..........................11-1 Chassis Power Units Liquid Cooled VIII SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 13: System Overview

The SINAMICS range of drives Application SINAMICS is the new range of converters from Siemens designed for industrial mechanical and plant engineering applications. SINAMICS offers solutions for all drive tasks: • Simple pump and fan applications in the process industry. - Page 14 The different SINAMICS versions can be easily combined with each other. SINAMICS is part of the Siemens "Totally Integrated Automation" concept. Integrated SINAMICS systems covering configuration, data storage, and communication at automation level ensure low-maintenance solutions with the SIMATIC, SIMOTION, and SINUMERIK control systems.

-

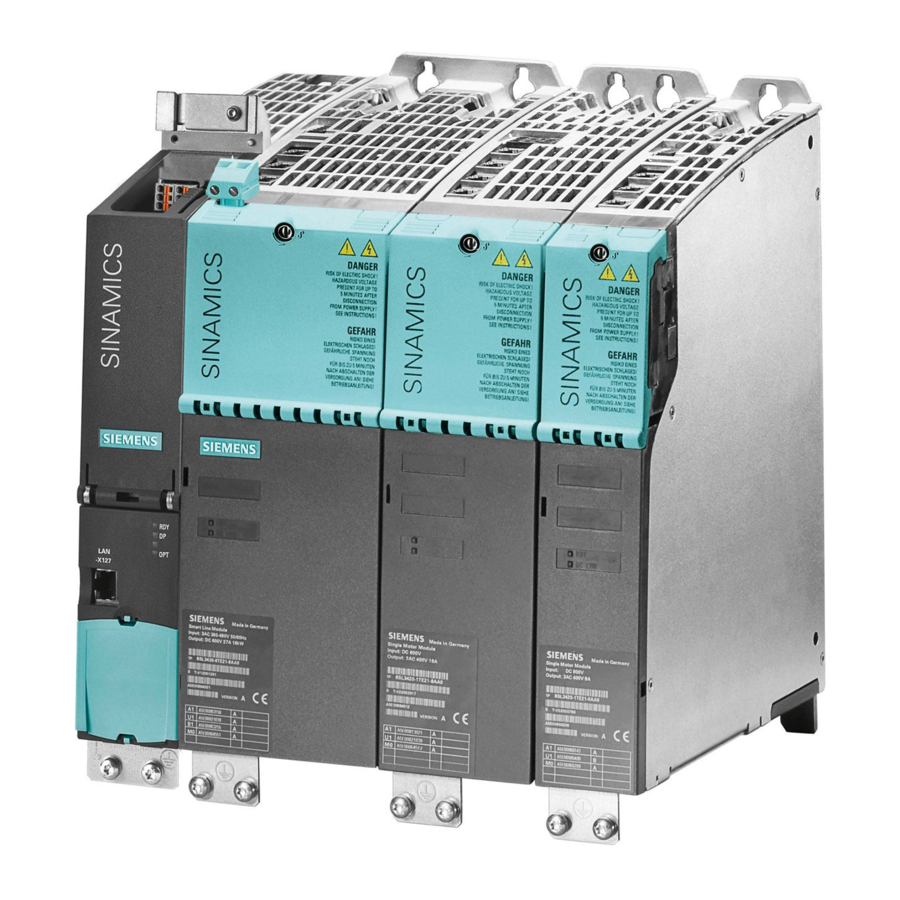

Page 15: Sinamics S120 Drive System

SINAMICS S120 drive system Modular system for sophisticated drive tasks SINAMICS S120 solves complex drive tasks for a wide range of industrial applications and is, therefore, designed as a modular system. Users can choose from many different harmonized components and functions to create a solution that best meets their requirements. - Page 16 Inter-axis connections can be established within a Control Unit and easily configured in the STARTER commissioning tool using a mouse. Simple technological tasks can be carried out by the SINAMICS S120 Control Unit itself. For complex numerical or motion-control tasks, high-performance SIMOTION D modules are used instead.

- Page 17 • Supplementary system components that enhance functionality and offer different interfaces for encoders and process signals. The SINAMICS S120 components were developed for installation in cabinets. They have the following features and characteristics: • Easy to handle, simple installation and wiring •...

- Page 18 The design of this liquid coolant circuit is an important factor in determining the operational reliability and service life of the equipment and the entire installation. The main criteria are described in the following chapters. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 19: Technical Specifications

1.3 Technical specifications Technical specifications Technical specifications Unless explicitly specified otherwise, the following technical specifications are valid for all the following components of the SINAMICS S120 Liquid Cooled drive system. Table 1-1 General technical specifications Electrical data Line connection voltage 380 V 3 AC –10 % to 490 V 3 AC +10 % (-15 % <... - Page 20 • Certificates Conformity CE (low-voltage and EMC Directives) Approvals cULus (File Nos.: E192450), some approvals in preparation (only up to 600 V 3 AC) in packaging for transportation Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 21: Structure Of A Drive System With Sinamics S120 Chassis Liquid Cooled

System Overview 1.4 Structure of a drive system with SINAMICS S120 chassis liquid cooled Structure of a drive system with SINAMICS S120 chassis liquid cooled 1.4.1 Structure of a drive system with SINAMICS S120 and Power Module Fig. 1-4 Basic structure of a drive system with SINAMICS S120 and Power Module... -

Page 22: Structure Of A Drive System With Sinamics S120 And Unregulated Infeed

System Overview 1.4 Structure of a drive system with SINAMICS S120 chassis liquid cooled 1.4.2 Structure of a drive system with SINAMICS S120 and unregulated infeed Fig. 1-5 Basic structure of a drive system with SINAMICS S120 (unregulated infeed) Chassis Power Units Liquid Cooled... -

Page 23: Line-Side Power Components

The connection lines to the Power Module must be kept as short as possible (max. 5 m). Caution Using line reactors not approved by SIEMENS for SINAMICS: - Can damage/destroy Power Module. - Line harmonics that may interfere with or damage other loads connected to the same line supply. -

Page 24: Dimension Drawing

Line-Side Power Components 2.1 Line reactors for Power Modules 2.1.3 Dimension drawing Fig. 2-1 Dimension drawing: Line reactor for Power Modules Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 25: Technical Specifications

0.236/0.267 0.323/0.365 Line supply/load connection connecting connecting connecting connecting lugs lugs lugs lugs Degree of protection IP00 IP00 IP00 IP00 Dimensions Width Height Depth 212.5 Weight 24.5 27.8 Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 26: Line Reactors For Basic Line Modules

The connection lines to the Line Module must be kept as short as possible (max. 5 m). Caution Using line reactors not approved by SIEMENS for SINAMICS: - Can damage/destroy Line Modules. - Line harmonics that may interfere with or damage other loads connected to the same line supply. -

Page 27: Dimension Drawing

Line-Side Power Components 2.2 Line reactors for Basic Line Modules 2.2.3 Dimension drawing Mounting hole Fig. 2-2 Dimension drawing: line reactor for Basic Line Modules Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 28 0CE41-0AA0 0CH33-4AA0 0CH36-0AA0 0CH41-2AA0 0CH41-6AA0 12.5 18 x 14 152.5 152.5 hmax 212.5 211.5 232.5 84.5 60.5 60.5 Dimensions n1 and n2 correspond to the drill hole spacing Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 29: Technical Specifications

0.693/0.783 0.865/0.977 Line supply/load connection connecting connecting connecting connecting lugs lugs lugs lugs Degree of protection IP00 IP00 IP00 IP00 Dimensions Width Height Depth 232.5 Weight 38.9 63.8 Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 30 Line-Side Power Components 2.2 Line reactors for Basic Line Modules Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 31: Power Modules

Power Module must be connected to a Control Unit via DRIVE-CLiQ. The open-loop and closed-loop control functions are stored in the Control Unit. Fig. 3-1 Overview of Power Modules in chassis format Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 32: Safety Information

Non-observance can cause lethal shock voltages. Caution The busbars and coolant connections which stick out of the module must never be used as handles or support surfaces when the units are transported. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 33: Interface Description

Power Modules 3.3 Interface description Interface description 3.3.1 Overview Fig. 3-2 Power Module, frame size FL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 34 Power Modules 3.3 Interface description Fig. 3-3 Power Module, frame size GL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 35: Connection Example

U2 V2 W2 PE DRIVE-CLiQ 24 V DC connecting cable for supplying a CU310 Control Unit integrated in the Power Module Fig. 3-4 Wiring diagram for the Power Module Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 36: Line/Dc Link/Motor Connection

When the STO (Safe Torque Off) or SS1 (Safe Stop 1) function is activated via terminals, a 24 V DC supply must be connected to terminal -X9:7 and terminal -X9:8 must be connected to ground. Upon removal, pulse suppression is activated. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 37: Terminal Block X41

Reserved, do not use Reserved, do not use Receive data - Reserved, do not use Reserved, do not use + (24 V) Power supply M (0 V) Electronic ground Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 38: Cooling Circuit Connections

The warning information on the components must be carefully observed! Cause and rectification of faults The following reference contains information about the cause and rectification of faults: Reference: /IH1/ SINAMICS S120 Commissioning Manual Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 39: Dimension Drawing

Dimension drawing, frame size FL The cooling clearances to be maintained are indicated by the dotted line. Front view Side view Fig. 3-5 Dimension drawing of Power Module, frame size FL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 40 Dimension drawing, frame size GL The cooling clearances to be maintained are indicated by the dotted line. Front view Side view Fig. 3-6 Dimension drawing of Power Module, frame size GL Chassis Power Units Liquid Cooled 3-10 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 41: Installation

Screw coupling points for mechanical support The Power Modules are provided with screw coupling points at the top and bottom so that they can be connected to modules mounted adjacently. Chassis Power Units Liquid Cooled 3-11 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 42: Electrical Connection

Removing the connection bracket for the interference-suppression capacitor Warning Failing to remove the connection bracket for the interference-suppression capacitor on a non-grounded system/IT system can cause significant damage to the unit. Chassis Power Units Liquid Cooled 3-12 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 43: Technical Specifications

This value applies to the water coolant option; for other coolant types, see Chapter 8. In order to build a UL-approved system, it is absolutely essential to use the specified fuses. Chassis Power Units Liquid Cooled 3-13 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 44: Overload Capability

The base load current for a high overload (IH) is based on a duty cycle of 150% for 60 s or 160% for 10 s. 10 s 1.6 * I 1.5 * I 60 s 300 s Fig. 3-10 High overload Chassis Power Units Liquid Cooled 3-14 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 45: Derating Factors

Derating factors 3.7.2.1 Derating factors as a function of coolant temperature SINAMICS S120 Liquid Cooled units are designed for cooling by H O or by an O / Antifrogen N mixture. An H O / Antifrogen N mixture must contain between 20 % and 45 % Antifrogen N. -

Page 46: Derating Factors As A Function Of Ambient Temperature

Maximum ambient temperature at 90 % current load Maximum ambient temperature at 100 % current load Fig. 3-13 Maximum ambient temperature as a function of installation altitude Chassis Power Units Liquid Cooled 3-16 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 47: Current Derating As A Function Of Pulse Frequency

1TE35-0AA0 78 % 50 % Note For pulse frequencies in the range between the specified fixed values, the relevant derating factors can be determined by linear interpolation. Chassis Power Units Liquid Cooled 3-17 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 48 Power Modules 3.7 Technical specifications Chassis Power Units Liquid Cooled 3-18 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 49: Line Modules

500 V 3 AC –10 % to 690 V 3 AC +10 % (-15 % < 1 min) (47 to 63 Hz) • Suitable for TN, TT, and IT supply systems • Operating status and error status via LEDs Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 50: Basic Line Modules

They are suitable for applications in which no regenerative energy is present or in which energy is exchanged between the motor-side and regenerative axes in the DC link. Fig. 4-1 Overview of Basic Line Modules Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 51: Safety Information

Caution The busbars and coolant connections which stick out of the module must never be used as handles or support surfaces when the units are transported. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 52: Interface Description

Line Modules 4.2 Basic Line Modules 4.2.3 Interface description 4.2.3.1 Overview Fig. 4-2 Basic Line Module, frame size FBL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 53 Line Modules 4.2 Basic Line Modules Fig. 4-3 Basic Line Module, frame size GBL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 54: Connection Example

675 V to 932 V DC • Connecting thread M12 / 50 for ring cable lugs to DIN 46234 PE connection Connecting thread M12 / 50 for ring cable lugs to DIN 46234 Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 55: Terminal Block X9

Max. connectable cross-section 1.5 mm Note A cable harness is used to connect terminals -X41:1 and -X41:2 to terminals -X9:8 and -X9:7. 4.2.3.6 Terminal block X42 Reserved, do not use! Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 56: Cooling Circuit Connections

The seals for the screwed connections can be used only once when the cooling circuit is first assembled. The seals must be replaced if the circuit is disassembled and assembled again. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 57: Meaning Of The Leds On The Control Interface Board In The Basic Line Module

The warning information on the components must be carefully observed! Cause and rectification of faults The following reference contains information about the cause and rectification of faults: Reference: /IH1/ SINAMICS S120 Commissioning Manual Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 58: Dimension Drawing

The cooling clearances to be maintained are indicated by the dotted line. Front view Side view Fig. 4-5 Dimension drawing of Basic Line Module, frame size FBL Chassis Power Units Liquid Cooled 4-10 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 59 The cooling clearances to be maintained are indicated by the dotted line. Front view Side view Fig. 4-6 Dimension drawing of Basic Line Module, frame size GBL Chassis Power Units Liquid Cooled 4-11 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 60: Installation

If several modules are mounted adjacent to one another, they can be interconnected via the screw coupling points. When a single module is installed, lateral support can be provided by means of reinforcing plates inserted between the module and the cabinet. Chassis Power Units Liquid Cooled 4-12 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 61: Electrical Connection

Removing the connection bracket for the interference-suppression capacitor Warning Failing to remove the connection bracket for the interference-suppression capacitor on a non-grounded system/IT system can cause significant damage to the unit. Chassis Power Units Liquid Cooled 4-13 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 62: Technical Specifications

This value applies to the water coolant option; for other coolant types, see Chapter 8. In order to build a UL-approved system, it is absolutely essential to use the specified fuses. Chassis Power Units Liquid Cooled 4-14 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 63 This value applies to the water coolant option; for other coolant types, see Chapter 8. In order to build a UL-approved system, it is absolutely essential to use the specified fuses. Chassis Power Units Liquid Cooled 4-15 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 64: Derating Factors

4.2.7.1 Derating factors Derating factors as a function of coolant temperature SINAMICS S120 Liquid Cooled units are designed for cooling by H O or by an O / Antifrogen N mixture. An H O / Antifrogen N mixture must contain between 20 % and 45 % Antifrogen N. - Page 65 Maximum ambient temperature at 90 % current load Maximum ambient temperature at 100 % current load Fig. 4-11 Maximum ambient temperature as a function of installation altitude Chassis Power Units Liquid Cooled 4-17 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 66 Line Modules 4.2 Basic Line Modules Chassis Power Units Liquid Cooled 4-18 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 67: Motor Modules

Module must be connected to a Control Unit via DRIVE-CLiQ. The open-loop and closed- loop control functions are stored in the Control Unit. Frame size GXL Frame size HXL Frame size JXL Fig. 5-1 Overview of Motor Modules (chassis) Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 68: Safety Information

Non-observance can cause lethal shock voltages. Caution The busbars and coolant connections which stick out of the module must never be used as handles or support surfaces when the units are transported. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 69: Interface Description

Motor Modules 5.3 Interface description Interface description 5.3.1 Overview Fig. 5-2 Motor Module, frame size GXL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 70 -X42 Control Interface Board -X402 Electronic fan -X401 -X400 Motor connection (U2, V2, W2) PE connection Ventilation hose Supply / return Fig. 5-3 Motor Module, frame size HXL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 71 Motor Modules 5.3 Interface description Fig. 5-4 Motor Module, frame size JXL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 72: Connection Example

Connection lugs: d = 13 mm (M12 / 50 Nm) for ring cable lugs to DIN 46234 PE connection Connection lugs: d = 13 mm (M12 / 50 Nm) for ring cable lugs to DIN 46234 Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 73: Terminal Block X9

The KTY temperature sensor must be connected with the correct polarity. Note A cable harness is used to connect terminals -X41:1 and -X41:2 to terminals -X9:8 and -X9:7. 5.3.6 Terminal block X42 Reserved, do not use! Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 74: Cooling Circuit Connections

The seals for the screwed connections can be used only once when the cooling circuit is first assembled. The seals must be replaced if the circuit is disassembled and assembled again. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 75: Meaning Of The Leds On The Control Interface Board In The Motor Module

Cause and rectification of faults The following reference contains information about the cause of the faults and how they can be resolved: Reference: /IH1/ SINAMICS S120 Commissioning Manual Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 76: Dimension Drawing

Dimension drawing, frame size GXL The cooling clearances to be maintained are indicated by the dotted line. Front view Side view Fig. 5-6 Dimension drawing of Motor Module, frame size GXL Chassis Power Units Liquid Cooled 5-10 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 77 Dimension drawing, frame size HXL The cooling clearances to be maintained are indicated by the dotted line. Front view Side view Fig. 5-7 Dimension drawing of Motor Module, frame size HXL Chassis Power Units Liquid Cooled 5-11 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 78 Dimension drawing, frame size JXL The cooling clearances to be maintained are indicated by the dotted line. Front view Side view Fig. 5-8 Dimension drawing of Motor Module, frame size JXL Chassis Power Units Liquid Cooled 5-12 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 79: Installation

Screw coupling points for mechanical support The Motor Modules are provided with screw coupling points at the top and bottom so that they can be connected to modules mounted adjacently. Chassis Power Units Liquid Cooled 5-13 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 80: Technical Specifications

This value applies to the water coolant option; for other coolant types, see Chapter 8. In order to build a UL-approved system, it is absolutely essential to use the specified fuses. Chassis Power Units Liquid Cooled 5-14 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 81 This value applies to the water coolant option; for other coolant types, see Chapter 8. In order to build a UL-approved system, it is absolutely essential to use the specified fuses. Chassis Power Units Liquid Cooled 5-15 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 82: Overload Capability

The base load current for a high overload (IH) is based on a duty cycle of 150% for 60 s or 160% for 10 s. 10 s 1.6 * I 1.5 * I 60 s 300 s Fig. 5-11 High overload Chassis Power Units Liquid Cooled 5-16 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 83: Derating Factors

Derating factors 5.6.2.1 Derating factors as a function of coolant temperature SINAMICS S120 Liquid Cooled units are designed for cooling by H O or by an O / Antifrogen N mixture. An H O / Antifrogen N mixture must contain between 20 % and 45 % Antifrogen N. -

Page 84: Derating Factors As A Function Of Ambient Temperature

Maximum ambient temperature at 90 % current load Maximum ambient temperature at 100 % current load Fig. 5-14 Maximum ambient temperature as a function of installation altitude Chassis Power Units Liquid Cooled 5-18 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 85: Current Derating As A Function Of Pulse Frequency

Maximum output frequencies achieved by increasing the pulse frequency Pulse frequency Maximum output frequency [kHz] [Hz] 1.25 Due to the closed-loop control, the maximum output frequency is limited to 300 Hz. Chassis Power Units Liquid Cooled 5-19 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 86: Parallel Switching Of Motor Modules

Motor Modules, 675 V - 1035 V DC Order number Power [kW] Output current [A] Minimum line length [m] 6SL3320-1TG35-8AA0 6SL3320-1TG38-1AA0 6SL3320-1TG41-0AA0 1000 1025 6SL3320-1TG41-3AA0 1200 1270 Chassis Power Units Liquid Cooled 5-20 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 87: Motor-Side Power Components

This reduces the output current of the Power Modules or Motor Modules (see section 3.7.2.4 or 5.6.2.4) When a sinusoidal filter is used, the available output voltage decreases by 15%. Fig. 6-1 Sinusoidal filter Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 88: Safety Information

- Outgoing cable to the load 1U2, 1V2, 1W2. Non-observance may damage the sinusoidal filter. Caution Using sinusoidal filters not approved by SIEMENS for SINAMICS can damage/destroy the Power Modules or Motor Modules. Caution The surface temperature of the sinusoidal filters may exceed 80°C. -

Page 89: Dimension Drawing

Motor-Side Power Components 6.1 Sinusoidal Filter 6.1.3 Dimension Drawing Installation hole Fig. 6-2 Dimension drawing of sinusoidal filter Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 90: Technical Specifications

Connection lugs M10 Max. motor cable length 300 (shielded) between sinusoidal filter and 450 (unshielded) motor Degree of protection IP00 IP00 IP00 IP00 Dimensions Width Height Depth Weight Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 91: Motor Reactors

The connecting cables to the Power Module or Motor Module must be kept as short as possible (max. 5 m). Caution When using motor reactors that SIEMENS has not approved for SINAMICS, then these can thermally damage the reactor. Caution The surface temperature of the motor reactors can exceed 80 °C. -

Page 92: Dimension Drawing

Motor-Side Power Components 6.2 Motor reactors 6.2.3 Dimension drawing Mounting hole Type 1 Type 2 Fig. 6-3 Dimension drawing of motor reactor Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 93 2AH38-1AA0 2AH41-1AA0 2AH41-3AA0 Connection type Type 1 Type 1 Type 1 Type 1 hmax 134.5 79.5 94.5 94.5 Dimensions n1 and n2 correspond to the drill hole spacing Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 94: Technical Specifications

- PE Max. permissible cable 300 (shielded) length between motor 450 (unshielded) reactor and motor Degree of protection IP00 IP00 IP00 IP00 Dimensions Width Height Depth Weight, approx. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 95: Dv/Dt Filter With Voltage Peak Limiter

Connection voltage: 510 – 720 V DC 6SL3315-1TE32-1AA0 4 kHz 6SL3315-1TE32-6AA0 4 kHz 6SL3315-1TE33-1AA0 4 kHz 6SL3325-1TE33-1AA0 4 kHz 6SL3315-1TE35-0AA0 4 kHz 6SL3325-1TE35-0AA0 4 kHz Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 96: Safety Information

• cable to the dv/dt reactor to 1U2, 1V2, 1W2. Failure to connect the terminals correctly could damage the voltage limiting network. Caution dv/dt filters with Voltage Peak Limiter that SIEMENS has not approved for SINAMICS might sustain thermal damage when used in a SINAMICS unit. Caution The surface temperature of the dv/dt reactors can exceed 80 °C. -

Page 97: Interface Description

Interface description Fig. 6-4 Overview of voltage limiting network interfaces, type 1 DCPS, DCNS 1U2, 1V2, 1W2 Fig. 6-5 Overview of voltage limiting network interfaces, type 2 Chassis Power Units Liquid Cooled 6-11 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 98 Motor-Side Power Components 6.3 dv/dt filter with Voltage Peak Limiter Fig. 6-6 Overview of voltage limiting network interfaces, type 3 Chassis Power Units Liquid Cooled 6-12 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 99: Connecting The Dv/Dt Filter With Voltage Peak Limiter

Motor Motor Module DC link DCPS DCNS Voltage limiting network Fig. 6-8 Connecting the dv/dt filter with Voltage Peak Limiter for versions with two dv/dt reactors Chassis Power Units Liquid Cooled 6-13 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 100 2 x 120 Note The connections should be kept as short as possible. The maximum cable length for the specified connections is 5 m in each case. Chassis Power Units Liquid Cooled 6-14 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 101: Dimension Drawing Of Dv/Dt Reactor

Motor-Side Power Components 6.3 dv/dt filter with Voltage Peak Limiter 6.3.5 Dimension drawing of dv/dt reactor Mounting hole Fig. 6-9 Dimension drawing of dv/dt reactor Chassis Power Units Liquid Cooled 6-15 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 102 M10 (12 x 18) M12 (15 x 22) M12 (15 x 22) M12 (15 x 22) M12 (15 x 22) Dimensions n1 and n2 correspond to the drill hole spacing Chassis Power Units Liquid Cooled 6-16 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 103: Dimension Drawing Of Voltage Limiting Network

6.3.6 Dimension drawing of voltage limiting network Fig. 6-10 Dimension drawing of voltage limiting network, type 1 Fig. 6-11 Dimension drawing of voltage limiting network, type 2 Chassis Power Units Liquid Cooled 6-17 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 104 Motor-Side Power Components 6.3 dv/dt filter with Voltage Peak Limiter Fig. 6-12 Dimension drawing of voltage limiting network, type 3 Chassis Power Units Liquid Cooled 6-18 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 105 Supply voltage: 380 V – 480 V 6SL3000-2DE32-6BA0 Type 1 6SL3000-2DE35-0BA0 Type 2 Supply voltage: 500 V – 690 V 6SL3000-2DH35-8BA0 Type 3 6SL3000-2DH38-1BA0 Type 3 6SL3000-2DH41-3BA0 Type 3 Chassis Power Units Liquid Cooled 6-19 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 106: Technical Specifications

Terminal 70 mm² Terminal 70 mm² - PE Terminal 35 mm² Terminal 35 mm² Degree of protection IP00 IP00 IP00 IP00 Dimensions Width Height Depth Weight, approx. Chassis Power Units Liquid Cooled 6-20 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 107 For versions with 2 dv/dt reactors, the cable lengths specified in the table must not be doubled. Two dv/dt reactors are required for these Motor Modules. The technical specifications provided apply to one dv/dt reactor. Chassis Power Units Liquid Cooled 6-21 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 108 Motor-Side Power Components 6.3 dv/dt filter with Voltage Peak Limiter Chassis Power Units Liquid Cooled 6-22 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 109: Cabinet Design And Emc

7.1.1 General The modular concept of SINAMICS S120 allows a wide range of potential device combinations. For this reason, it is impossible to describe each individual combination. This section instead aims to provide some basic information and general rules on the basis of which special device combinations can be physically constructed and to ensure electromagnetic compatibility. -

Page 110: Safety Information

Safety regulations governing shock protection must be observed. See also EN 60204-1. Caution To ensure that the entire system works properly, you are advised to use the original Siemens accessories from catalog D21.1. Before commissioning, check the tightening torque of all the terminal screws. -

Page 111: Standards And Guidelines

Degrees of protection provided by enclosures (IP code) EN 61800–3 Adjustable speed electrical power drive systems Part 3: EMC product standard including specific test methods UL 508C Power conversion equipment Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 112: Basic Information About Emc

It specifies requirements for converters with operating voltages of less than 1000 V. Different environments and categories are defined depending on where the system is installed. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 113 Rated voltage <1000 V; use in environment 2 only. • Category C4: Rated voltage ≥1000 V or for rated currents ≥400 A in complex systems in environment 2. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 114: Emc-Compliant Drive Installation

EMC planning The Basic Line Module infeeds when combined with the appropriate line reactor comply with the interference emission limits stipulated in EN 61800-3 for the second environment (industrial). Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 115 EMC measures address not only environmental influences outside the cabinet but also the effect of the devices within the cabinet. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 116: The Zone Concept

Unshielded cables can be used within a zone. All bus and signal cables that leave the cabinet must be shielded. Fig. 7-4 Dividing a drive system into zones Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 117: Wiring And Shielding

Connect to cabinet enclosure on both sides ensuring good conductivity and Shielding bus maximum contact area! Cable propping bar Fig. 7-5 Shield connection for motor cable at cabinet inlet Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 118 Shielding effects can also be achieved by grounding reserve cores at both ends. If the SINAMICS S120 chassis components are supplied externally with 230 V AC and 24 V DC, these supplies must not be used for multiple consumers that are physically separated from each other in different cabinets.

-

Page 119: Design

Contactors, relays, solenoid valves, electrical operating hour counters, and so on in the cabinet must be connected to anti-interference elements. RC elements, diodes, or varistors can be used for this purpose. They must be connected on the appropriate coil. Chassis Power Units Liquid Cooled 7-11 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 120: Overview Of Devices Required For Operation

The shielding between the motor and the Power Module or Motor Module must not be interrupted by additional components (e.g. fuses, contactors, reactors, or filters). Automation devices and SINAMICS S120 devices should be connected to different power supply networks. If only a joint supply is available, the automation devices used should be isolated from the supply by means of isolating transformers. -

Page 121: Arrangement Of Components And Equipment

If the mounting surface comprises more than one mounting plate, these must be connected conductively over the greatest possible surface area. If the components are installed individually, they must be grounded individually too. Chassis Power Units Liquid Cooled 7-13 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 122 Cabinet Design and EMC 7.5 Arrangement of components and equipment Chassis Power Units Liquid Cooled 7-14 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 123: Cooling Circuit And Coolant Properties

The materials used comply with the minimum requirements stipulated in Section 8.3. 3. Semi-open cooling circuit Oxygen can be transferred to the coolant only via the pressure compensator, otherwise as for 1. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 124 • To prevent blockages and corrosion, it is advisable to install an additional flushback filter in the circuit (so that residues can be rinsed out when the system is running). Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 125: Cooling Circuit For Aluminum Heatsink

T primary inlet T primary Inspection glass return Dirt trap, ≤ 100 µm Heat exchanger, copper T secondary Fig. 8-1 Recommendations for a closed cooling circuit Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 126 Ideally stainless steel, but a copper heat exchanger can be used as an alternative in closed circuits. 11. Bypass valve May be necessary to protect against condensation. 12. Coolant See Section 8.2 Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 127: Cooling Circuits For Stainless Steel Heatsinks

>3 m protected metals Hose Dirt trap, ≤ 100 µm Fig. 8-2 Recommendations for an open cooling circuit Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 128: Prevention Of Cavitation

DP SINAMICS with cover Höhe >3 m DP inlet/ Inspection glass return DP hose Dirt trap DP infeed DP return Fig. 8-3 Arrangement of pressure compensator, component pressure drops Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 129: Cooling Circuit Configuring Information

The maximum differential pressure across a heatsink is 200 kPa; higher differential pressures significantly increase the risk of cavitation and abrasion (Fig. 8-4). Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 130 • The risk of cavitation and abrasion increases as a result of the high total volumetric flow. • It is not possible to connect SINAMICS S120 in series because the total volumetric flow inherent to any constellation of series connection requires system pressures in the 600 kPa range or above.

- Page 131 Differential pressure as a function of volumetric flow for Basic Line Module, frame size FBL Fig. 8-6 Differential pressure as a function of volumetric flow for Basic Line Module, frame size GBL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 132 Differential pressure as a function of volumetric flow for Power Module frame size FL, and Motor Module frame size FXL Fig. 8-8 Differential pressure as a function of volumetric flow for Power Module frame size GL, and Motor Module, frame size GXL Chassis Power Units Liquid Cooled 8-10 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 133 Differential pressure as a function of volumetric flow for Motor Module, frame size HXL Fig. 8-10 Differential pressure as a function of volumetric flow for Motor Module, frame size JXL Chassis Power Units Liquid Cooled 8-11 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 134: Equipotential Bonding

This eliminates potential differences and thus the risk of electrochemical corrosion. A PE bar must be installed in every cabinet (including the recooling system) and the individual bars then interconnected. Chassis Power Units Liquid Cooled 8-12 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 135: Coolant Definition

This value is too high for the heatsinks which may sustain serious damage if inhibitors are not added! Note We recommend that use is made of Nalco's services (Manufacturer: Nalco) for analyzing the water quality at the plant site. Chassis Power Units Liquid Cooled 8-13 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 136: Inhibitors, Anti-Freeze, Biocides

Inhibitors can be used only in water with the properties defined in Section 8.2 which must not contain any magnesium carbonate. Control kits can be ordered from Nalco to check the inhibitor concentration. Chassis Power Units Liquid Cooled 8-14 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 137 Biocides and Antifrogen N must not be mixed. Antifrogen N has a biocidal effect even at the minimum required concentration of >20 %. Chassis Power Units Liquid Cooled 8-15 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 138: Materials

PE/EPDM supplied by Telle) Seals Pipes, valves Use of Viton, AFM34, EPDM is recommended. and fittings Hose connections Pipe-hose Secure with clips conforming to DIN2817, available, e.g. from Telle. transition Chassis Power Units Liquid Cooled 8-16 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 139: Horizontal Installation

Cooling circuit and coolant properties 8.4 Horizontal installation Horizontal installation SINAMICS S120 Liquid Cooled units can operate in a vertical position with the unit resting on its rear panel. To prevent heat concentrations inside the units in this mounting position, an external fan needs to be installed which is capable of removing heated air from the devices. - Page 140 Basic Line Module FBL, 1220 A (400 V), 730 A (690 V) Basic Line Module GBL Motor Module GXL Motor Module HXL Motor Module JXL Available at info2@de.ebmpapst.com Chassis Power Units Liquid Cooled 8-18 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 141: Condensation Protection

The dew points for low atmospheric pressure are lower than those at an altitude of 0 m, i.e. it is always acceptable to calculate the coolant supply temperature for an altitude of 0 m. Chassis Power Units Liquid Cooled 8-19 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 142: Degrees Of Protection

8.6 Degrees of protection Degrees of protection SINAMICS S120 Liquid Cooled units have degree of protection IP20 with the exception of the electrical connections (overall degree of protection IP00). The temperature ranges specified in Section 3.7.2 also apply to units mounted in a control cabinet. -

Page 143: Connection System

8.7 Connection system Connection system The electrical connections on the SINAMICS S120 Liquid Cooled units must be made with cables of the cross-section stipulated in the technical specifications for the relevant device. The coolant connection is made using 3/4'' couplings. - Page 144 Cooling circuit and coolant properties 8.8 Commissioning, service Chassis Power Units Liquid Cooled 8-22 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 145: Maintenance And Servicing

When the external power supply or the external 230 V AC auxiliary supply is connected, dangerous voltages are still present in the components even when the main circuit-breaker is open. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 146: Maintenance

The actual intervals at which maintenance procedures are to be performed depend on the installation conditions (cabinet environment) and the operating conditions. Siemens offers its customers support in the form of a service contract. For further details, contact your regional office or sales office. -

Page 147: Servicing

When securing connections for current-carrying parts (DC link, motor connections, busbars), you must observe the following tightening torques. Table 9-1 Tightening torques for connecting current-carrying parts Screw Torque 6 Nm 13 Nm 25 Nm 50 Nm Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 148: Replacing Components

Caution The busbars and coolant connections which stick out of the module must never be used as handles or support surfaces when the units are transported. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... -

Page 149: Replacing The Control Interface Board, Power Module, Frame Size Fl

9.4.1 Replacing the Control Interface Board, Power Module, frame size FL Replacing the Control Interface Board Fig. 9-1 Replacing the Control Interface Board, Power Module, frame size FL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 150 When dealing with connectors with a lock, make sure that the locking lever is securely engaged once connected. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 151: Replacing The Control Interface Board, Power Module, Frame Size Gl

9.4.2 Replacing the Control Interface Board, Power Module, frame size GL Replacing the Control Interface Board Fig. 9-2 Replacing the Control Interface Board, Power Module, frame size GL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 152 When dealing with connectors with a lock, make sure that the locking lever is securely engaged once connected. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 153: Replacing The Control Interface Board, Motor Module, Frame Size Gxl

9.4.3 Replacing the Control Interface Board, Motor Module, frame size GXL Replacing the Control Interface Board Fig. 9-3 Replacing the Control Interface Board, Motor Module, frame size GXL Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 154 When dealing with connectors with a lock, make sure that the locking lever is securely engaged once connected. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-10 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 155: Replacing The Control Interface Board, Motor Module, Frame Size Hxl

Replacing the Control Interface Board, Motor Module, frame size HXL Replacing the Control Interface Board Fig. 9-4 Replacing the Control Interface Board, Motor Module, frame size HXL Chassis Power Units Liquid Cooled 9-11 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 156 When dealing with connectors with a lock, make sure that the locking lever is securely engaged once connected. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-12 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 157: Replacing The Control Interface Board, Motor Module, Frame Size Jxl

Replacing the Control Interface Board, Motor Module, frame size JXL Replacing the Control Interface Board Fig. 9-5 Replacing the Control Interface Board, Motor Module, frame size JXL Chassis Power Units Liquid Cooled 9-13 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 158 When dealing with connectors with a lock, make sure that the locking lever is securely engaged once connected. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-14 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 159: Replacing The Control Interface Board, Basic Line Module, Frame Size Fbl

Replacing the Control Interface Board, Basic Line Module, frame size FBL Replacing the Control Interface Board Fig. 9-6 Replacing the Control Interface Board, Basic Line Module, frame size FBL Chassis Power Units Liquid Cooled 9-15 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 160 When dealing with connectors with a lock, make sure that the locking lever is securely engaged once connected. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-16 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 161: Replacing The Control Interface Board, Basic Line Module, Frame Size Gbl

Replacing the Control Interface Board, Basic Line Module, frame size GBL Replacing the Control Interface Board Fig. 9-7 Replacing the Control Interface Board, Basic Line Module, frame size GBL Chassis Power Units Liquid Cooled 9-17 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 162 When dealing with connectors with a lock, make sure that the locking lever is securely engaged once connected. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-18 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 163: Replacing The Fan, Power Module, Frame Size Fl

Maintenance and servicing 9.4 Replacing components 9.4.8 Replacing the fan, Power Module, frame size FL Replacing the fan Fig. 9-8 Replacing the fan, Power Module, frame size FL Chassis Power Units Liquid Cooled 9-19 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 164 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-20 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 165: Replacing The Fan, Power Module, Frame Size Gl

Maintenance and servicing 9.4 Replacing components 9.4.9 Replacing the fan, Power Module, frame size GL Replacing the fan Fig. 9-9 Replacing the fan, Power Module, frame size GL Chassis Power Units Liquid Cooled 9-21 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 166 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-22 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 167: Replacing The Fan, Motor Module, Frame Size Gxl

Maintenance and servicing 9.4 Replacing components 9.4.10 Replacing the fan, Motor Module, frame size GXL Replacing the fan Fig. 9-10 Replacing the fan, Motor Module, frame size GXL Chassis Power Units Liquid Cooled 9-23 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 168 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-24 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 169: Replacing The Fan, Motor Module, Frame Size Hxl

Maintenance and servicing 9.4 Replacing components 9.4.11 Replacing the fan, Motor Module, frame size HXL Replacing the fan Fig. 9-11 Replacing the fan, Motor Module, frame size HXL Chassis Power Units Liquid Cooled 9-25 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 170 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-26 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 171: Replacing The Fan, Motor Module, Frame Size Jxl

Maintenance and servicing 9.4 Replacing components 9.4.12 Replacing the fan, Motor Module, frame size JXL Replacing the fan Fig. 9-12 Replacing the fan, Motor Module, frame size JXL Chassis Power Units Liquid Cooled 9-27 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 172 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-28 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 173: Replacing The Fan, Basic Line Module, Frame Size Fbl

9.4 Replacing components 9.4.13 Replacing the fan, Basic Line Module, frame size FBL Replacing the fan Fig. 9-13 Replacing the fan, Basic Line Module, frame size FBL Chassis Power Units Liquid Cooled 9-29 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 174 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-30 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 175: Replacing The Fan, Basic Line Module, Frame Size Gbl

9.4 Replacing components 9.4.14 Replacing the fan, Basic Line Module, frame size GBL Replacing the fan Fig. 9-14 Replacing the fan, Basic Line Module, frame size GBL Chassis Power Units Liquid Cooled 9-31 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 176 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-32 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 177: Replacing The Power Supply Board, Power Module, Frame Size Fl

Replacing the Power Supply Board, Power Module, frame size FL Replacing the Power Supply Board Fig. 9-15 Replacing the Power Supply Board, Power Module, frame size FL Chassis Power Units Liquid Cooled 9-33 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 178 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-34 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 179: Replacing The Power Supply Board, Power Module, Frame Size Gl

Replacing the Power Supply Board, Power Module, frame size GL Replacing the Power Supply Board Fig. 9-16 Replacing the Power Supply Board, Power Module, frame size GL Chassis Power Units Liquid Cooled 9-35 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 180 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-36 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 181: Replacing The Power Supply Board, Motor Module, Frame Size Gxl

Replacing the Power Supply Board, Motor Module, frame size GXL Replacing the Power Supply Board Fig. 9-17 Replacing the Power Supply Board, Motor Module, frame size GXL Chassis Power Units Liquid Cooled 9-37 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 182 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-38 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 183: Replacing The Power Supply Board, Motor Module, Frame Size Hxl

Replacing the Power Supply Board, Motor Module, frame size HXL Replacing the Power Supply Board Fig. 9-18 Replacing the Power Supply Board, Motor Module, frame size HXL Chassis Power Units Liquid Cooled 9-39 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 184 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-40 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 185: Replacing The Power Supply Board, Motor Module, Frame Size Jxl

Replacing the Power Supply Board, Motor Module, frame size JXL Replacing the Power Supply Board Fig. 9-19 Replacing the Power Supply Board, Motor Module, frame size JXL Chassis Power Units Liquid Cooled 9-41 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 186 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-42 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 187: Replacing The Power Supply Board, Basic Line Module, Frame Size Fbl

Replacing the Power Supply Board, Basic Line Module, frame size FBL Replacing the Power Supply Board Fig. 9-20 Replacing the Power Supply Board, Basic Line Module, frame size FBL Chassis Power Units Liquid Cooled 9-43 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 188 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-44 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 189: Replacing The Power Supply Board, Basic Line Module, Frame Size Gbl

Replacing the Power Supply Board, Basic Line Module, frame size GBL Replacing the Power Supply Board Fig. 9-21 Replacing the Power Supply Board, Basic Line Module, frame size GBL Chassis Power Units Liquid Cooled 9-45 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 190 The tightening torques specified in Table 9-1 must be observed. Carefully re-establish the plug connections and ensure that they are secure. The screwed connections for the protective covers must only be tightened by hand. Chassis Power Units Liquid Cooled 9-46 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 191: Reforming The Dc Link Capacitors

The DC link capacitors are reformed by applying the rated voltage without load for at least 30 minutes at room temperature. Type plate Fig. 9-22 Type plate for an Motor Module Chassis Power Units Liquid Cooled 9-47 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 192 Table 9-2 Year and month of manufacture Character Year of manufacture Character Month of manufacture 2005 1 to 9 January to September 2006 October 2007 November 2008 December Chassis Power Units Liquid Cooled 9-48 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 193: List Of Abbreviations

Control Interface Board Computerunterstützte numerische Steuerung Computer Numerical Control Konnektorausgang Connector Output CO/BO Konnektor-/Binektorausgang Connector/Binector Output Mittelkontakt eines Wechselkontaktes Medium contact of a change-over contact Kommunikationsprozessor Communications Processor Chassis Power Units Liquid Cooled 10-1 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 194 Function diagram Firmware Firmware Global-Control-Telegramm (Broadcast- Global Control Telegram (Broadcast- Telegramm) Telegramm) Gerätestammdatei: beschreibt die Merkmale Device master file: describes the features of a eines PROFIBUS-Slaves PROFIBUS slave Chassis Power Units Liquid Cooled 10-2 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 195 National Electrical Manufacturers Association America) Nullmarke Zero Mark Schliesser Normaly Open contact Original Equipment Manufacturer Original Equipment Manufacturer Busstecker für Lichtleiter Optical Link Plug Option Module Interface Option Module Interface Chassis Power Units Liquid Cooled 10-3 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 196 Sensor Module Cabinet Sensor Module External Sensor Module External Speicherprogrammierbare Steuerung Programmable Logic Controller (PLC) PROFIBUS Steuerwort PROFIBUS controlword Terminal Board Terminal Board Totally Integrated Automation Totally Integrated Automation Chassis Power Units Liquid Cooled 10-4 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 197 Voltage Sensing Module Variables Drehmoment Variable Torque Werkzeugmaschine Machine tool Erweiterbare Auszeichnungssprache Extensible Markup Language (Standardsprache für Web-Publishing und Dokumentenmanagement) Zwischenkreis DC link PROFIBUS Zustandswort PROFIBUS statusword Chassis Power Units Liquid Cooled 10-5 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 198 List of Abbreviations 10.1 List of Abbreviations Chassis Power Units Liquid Cooled 10-6 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

-

Page 199: References

Order no.: E86060-K5511-A111-A2-7600, edition: 10/2005 /D11/ SINAMICS G130 Converter Chassis Units, SINAMICS G150 Converter Cabinet Units Order no.: E86060-K5511-A101-A3-7600, edition: 12/2005 /D21.1/ SINAMICS S120 Vector Control Drive System Order no.: E86060-K5521-A111-A2-7600, edition: 06/2006 /D21.3/ SINAMICS S150 Converter Cabinet Units Order no.: E86060-K5521-A131-A1-7600, edition: 05/2004... -

Page 200: References

Installation and Start-Up Manual CANopen Order no.: 6SL3097-2AA00-0BP2, edition: 03/2006 /FH1/ SINAMICS S120 Function Manual Order no.: 6SL3097-2AB00-0BP3, edition: 03/2007 /LH1/ SINAMICS S120 List Manual Order no.: 6SL3097-2AP00-0BP5, edition: 03/2007 Chassis Power Units Liquid Cooled 11-2 SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2... - Page 201 Voltage Peak Limiter.... 6-11 Current derating as a function of Interfaces pulse frequency ........3-17, 5-19 Basic Line Modules ........4-4 Dimension drawing Motor Modules ..........5-3 Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 202 Reforming the DC link capacitors ......9-47 Tightening torques..........9-3 Replacement Type plate............9-47 Control Interface Board, frame size FBL ..9-15 Voltage limiting network Control Interface Board, frame size FL...9-5 Dimension drawing........6-17 Chassis Power Units Liquid Cooled SINAMICS S120 Equipment Manual, Edition 04/2007, 6SL3097-2AM00-0BP2...

- Page 204 Siemens AG 6SL3097-2AM00-0BP2 Automation and Drives Large Drives P.O. Box 4848 D - 90437 NÜRNBERG GERMANY www.siemens.de/automation/ld...