Summary of Contents for Bosch REXROTH MS2E

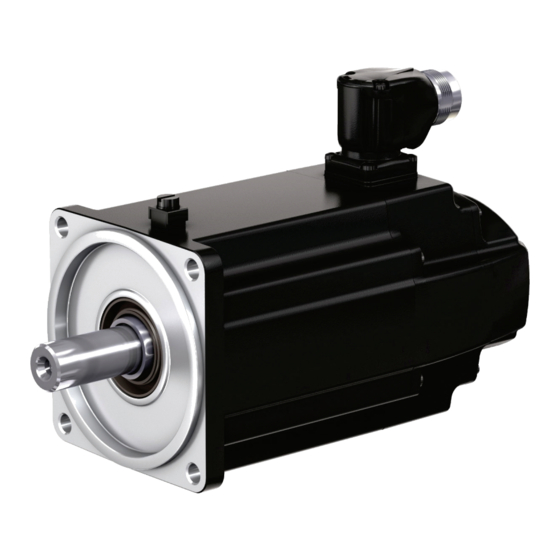

- Page 1 MS2E Synchronous Servomotors acc. to ATEX Directive 2014/34/EU Operating Instructions Edition 02 R911387136...

- Page 2 Edition 02, 2020-07 "Editions of this documentation" on page 1 Copyright © Bosch Rexroth AG 2020 All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial prop‐ erty rights.

- Page 3 Comply with the time required for the (p. ex. dissipateurs thermiques). Respectez le Kühlkörpern). Abkühlzeit der drive components to cool down (at least 15 délai de refroidissement des composants Antriebskomponenten einhalten minutes). d’entraînement (au moins 15 minutes). (mind. 15 Minuten). R911387136_Edition 02 Bosch Rexroth AG...

- Page 4 Antes de entrar ou aceder à área perigosa, Prima di accedere alla zona di pericolo, la zona de peligro, los accionamientos se imobilize os acionamentos de forma segura. arrestare e bloccare gli azionamenti. tienen que haber parado con seguridad. Bosch Rexroth AG R911387136_Edition 02...

- Page 5 Sørg for at koble spændingsforsyningen fra, aardleiding. arbete på drivkomponenter. inden du rører ved drive components. Schakel voor toegang tot Var medveten om kondensatorernas Overhold kondensatorernes afladningstider. aandrijvingscomponenten de urladdningstid. spanningsvoorziening uit. Neem de ontlaadtijden van condensatoren in acht. R911387136_Edition 02 Bosch Rexroth AG...

- Page 6 Batterierna får inte tas isär eller skadas. Undlad at skille batterier ad eller at Batterijen niet demonteren of beschadigen. Släng inte batterierna i elden. beskadige dem. Smid ikke batterier ind i Nooit batterijen in het vuur werpen. åben ild. Bosch Rexroth AG R911387136_Edition 02...

- Page 7 Unikać kontaktu z powierzchniami Nedotýkejte se kovových povrchů (např. jäähdytyslevyt). Noudata käyttölaitteen metalowymi (np. radiatorami). Przestrzegać chladicích těles). Dodržujte dobu ochlazení komponenttien jäähtymisaikoja (väh. 15 czasów schładzania podzespołów napędów komponent pohonu (min. 15 minut). minuuttia). (min. 15 minut). R911387136_Edition 02 Bosch Rexroth AG...

- Page 8 Pred prijemom ali dostopom v nevarno območje varno zaustavite vse gnane dele. Pred zásahom alebo prístupom do Înainte de intervenţia sau accesul în zona nebezpečnej oblasti uveďte pohony periculoasă, opriţi în siguranţă componentele bezpečne do zastavenia. de acţionare. Bosch Rexroth AG R911387136_Edition 02...

- Page 9 áramellátást. Pirms darba pie piedziņas komponentiem Преди работа по задвижващите atslēdziet elektroapgādi. Ügyeljen a kondenzátorok kisülési idejére! компоненти, изключете захранващото Ņemiet vērā kondensatoru izlādes laikus. напрежение. Обърнете внимание на времето за разреждане на кондензаторите. R911387136_Edition 02 Bosch Rexroth AG...

- Page 10 агресивен агент). Az akkumulátorokat ne szedje szét, és ne Neizjauciet un nesabojājiet baterijas. Не разглобявайте и не повреждайте rongálja meg! Az akkumulátort ne dobja Nemetiet baterijas ugunī. батерии. Не хвърляйте батерии в огън. tűzbe! Bosch Rexroth AG R911387136_Edition 02...

- Page 11 Venkite liesti metalinius paviršius (pvz., radiaatorid) puudutamist. Pidage kinni επιφάνειες (π.χ. μονάδες ψύξης). Λάβετε radiatorių). Išlaikykite pavaros komponentų ajamikomponentide mahajahtumisajast υπόψη το χρόνο ψύξης των στοιχείων atvėsimo trukmę (bent 15 minučių). (vähemalt 15 minutit). μετάδοσης κίνησης (τουλάχιστον 15 λεπτά). R911387136_Edition 02 Bosch Rexroth AG...

- Page 12 Μην απορρίπτετε τις μπαταρίες στη φωτιά. 中文 如果不按照下述指定的安全说明使用,将会导致人身伤害! 在没有阅读,理解随本产品附带的文件并熟知正当使用前,不要安装或使用本产品。 如果没有您所在国家官方语言文件说明,请与 Rexroth 销售伙伴联系。 只允许有资格人员对驱动器部件进行操作。 安全说明的详细解释在本文档的第一章。 高电压!电击导致生命危险! 只有在安装了永久良好的设备接地导线后才可以对驱动器的部件进行操作。 在接触驱动器部件前先将驱动器部件断电。 确保电容放电时间。 危险运动!生命危险! 保证设备的运动区域内和移动部件周围无障碍物。 防止人员意外进入设备运动区域内。 在接近或进入危险区域之前,确保传动设备安全停止。 电磁场/磁场!对佩戴心脏起搏器、金属植入物和助听器的人员会造成严重的人身伤害 ! 上述人员禁止进入安装及运行的驱动器区域,或者必须事先咨询医生。 热表面(大于 60 度)!灼伤风险! 不要触摸金属表面(例如散热器)。驱动器部件断电后需要时间进行冷却(至少 15 分钟)。 安装和运输不当导致受伤危险!当心受伤! 使用适当的运输和安装设备。 使用适合的工具及用适当的防护设备。 电池操作不当!受伤风险! 请勿对低电量电池重新激活或重新充电(爆炸和腐蚀的危险)。 请勿拆解或损坏电池。请勿将电池投入明火中。 Bosch Rexroth AG R911387136_Edition 02...

-

Page 13: Table Of Contents

Flange exactness..........................20 4.2.12 Vibration behavior ..........................21 4.2.13 Bearing.............................. 21 4.2.14 Frame size, installation type......................22 4.2.15 Coating ............................. 23 4.2.16 Noise emission ..........................23 Product identification ........................... 24 4.3.1 Type code ............................24 R911387136_Edition 02 Bosch Rexroth AG... - Page 14 MS2E connection technique......................44 7.2.4 Ground conductor..........................45 7.2.5 Protective cable glands for connectors....................45 7.2.6 Connect flange socket........................45 7.2.7 Plug connector protective cover ....................... 46 Shielding concept..........................48 Commissioning and operation..................49 Safety..............................49 Commissioning............................. 49 Bosch Rexroth AG R911387136_Edition 02...

- Page 15 Environmental protection and disposal ............... 56 Troubleshooting ......................58 12.1 Troubleshooting procedure ........................58 Technical data......................59 Appendix........................60 14.1 EU Declaration of Conformity....................... 60 14.2 China RoHS 2............................61 14.3 UL / CSA............................... 61 Index..........................63 R911387136_Edition 02 Bosch Rexroth AG...

- Page 16 MS2E Synchronous Servomotors acc. to ATEX Directive 2014/34/EU Bosch Rexroth AG R911387136_Edition 02...

-

Page 17: About This Documentation

Non-compliance with this safety instructions will result in death or severe per‐ sonal injury. WARNING Non-compliance with this safety instructions can result in death or severe personal injury. CAUTION Non-compliance with this safety instructions can result in moderate or minor personal injury. R911387136_Edition 02 Bosch Rexroth AG... - Page 18 ● Listings on the first level contain a bullet point – Listings on the second level contain a dash Handling instructions are specified in numbered lists. Please comply with the order of the handling instructions. Bosch Rexroth AG R911387136_Edition 02...

-

Page 19: Safety Instructions

Machine Directive 2006/42/EC and DIN EN 60204-1 (safety of machines). The electrical installation must comply with the protection requirements of EMC Directive 2014/30/EU. The plant manufacturer is responsible for appro‐ R911387136_Edition 02 Bosch Rexroth AG... -

Page 20: Unintended Use

In the case of damage due to non-observance of the safety notes, Bosch Rexroth assumes no liability. Applications for functional safety are only allowed if the motors have the SI- sign on the rating plate. -

Page 21: Protection From Electric Voltage

Electrostatic charges may be caused e.g. by the following processes: ● electrostatic painting ● pneumatically conveyed dust or bulk material ● hydraulically conveyed or flowing liquids and droplets R911387136_Edition 02 Bosch Rexroth AG... -

Page 22: Protection Against Ignitable Electrostatic Discharge

Only using the serially delivered motor holding brake or an external holding brake activated by the drive controller is not suitable for person‐ al protection! Rotating parts! Danger to life, risk of injury, heavy injury or material damage. Bosch Rexroth AG R911387136_Edition 02... -

Page 23: Protection Against Burns

● Allow the motors to cool down long enough before touching them. ● Temperature-sensitive components may not come into contact with the motor surface. Ensure appropriate mounting distance of connection ca‐ bles and other components. R911387136_Edition 02 Bosch Rexroth AG... -

Page 24: Scope Of Delivery

At delivery, immediately check if the supplied components match with the de‐ livery note. The carrier must be informed immediately, in the case of any damaged package and goods. Start-up of damaged goods is prohibited. Bosch Rexroth AG R911387136_Edition 02... -

Page 25: About This Product

4.2.1 Basic data Product 3~ PM motor Type MS2E Ambient temperature during opera‐ 0 … 40 °C (without de-rating) tion Protection class (EN 60034-5) IP65 with shaft sealing ring Cooling mode (EN 60034-6) IC410, Self-cooling R911387136_Edition 02 Bosch Rexroth AG... -

Page 26: Mechanical Interfaces

Non Drive End, B-Seite Left, links Right, rechts In the case of special design, details named in the operating in‐ structions can deviate. In this case, order the supplementary doc‐ umentation. 4.2.2 Mechanical interfaces ØG ØC ØF ☐A Bosch Rexroth AG R911387136_Edition 02... -

Page 27: Rotor Inertia

The threshold values for motor temperature monitoring are contained in the encoder data memory and are read in and monitored automatically during the operation with IndraDrive controllers. Threshold values for MS2E motors: ● Motor-warning temperature (125°C) ● Motor-disconnection temperature (130°C) R911387136_Edition 02 Bosch Rexroth AG... -

Page 28: Cooling Mode

ACURO®link-Protocol. The encoder fulfills the specifications for safety tech‐ nique according to SIL 3 and PL e. The motor temperature is transmitted digi‐ tally. Singleturn The singleturn design allows absolute, indirect position recording within one mechanical motor rotation. Bosch Rexroth AG R911387136_Edition 02... -

Page 29: Degree Of Protection

"DS" thread according to DIN 332-2. The standard design for a non-positive shaft-hub connection without play and excellent smooth running. Use clamping sets, pressure sleeves or clamping elements for coupling the machine elements to be driven. R911387136_Edition 02 Bosch Rexroth AG... - Page 30 We recommend regular visual inspections on shaft sealing rings. Depending on operating conditions, signs of wear may appear after 5,000 operating hours. If necessary, replace the shaft sealing rings. We recommend to have these repairs made by Bosch Rexroth Service. Winding MS2E motors with key are balanced with "half key".

- Page 31 Damage of the NDE bearing by exceeding the maximum permissible ax‐ ial force. It is recommended to use drive elements with integrated bearings and mount them on the motor shaft via axially compensating cou‐ plings. R911387136_Edition 02 Bosch Rexroth AG...

-

Page 32: Holding Brake

Ensure the functionality of the brake in normal operation, due to voltage con‐ trol, current monitoring, cyclic control of the brake holding torque, for exam‐ ple. Rated voltage The rated voltage to apply the brakes is 24 V DC (±10%). Bosch Rexroth AG R911387136_Edition 02... - Page 33 MS2E03-B____-____1-_____-__ 1.80 0.46 MS2E03-D____-____1-_____-__ 1.80 0.46 MS2E04-B____-____1-_____-__ 5.00 0.63 MS2E04-C____-____1-_____-__ 5.00 0.63 MS2E05-B____-____1-_____-__ 10.00 0.73 MS2E05-C____-____1-_____-__ 10.00 0.73 MS2E05-D____-____1-_____-__ 10.00 0.73 MS2E06-C____-____1-_____-__ 10.00 0.73 MS2E06-D____-____2-_____-__ 15.00 0.75 MS2E06-E____-____2-_____-__ 15.00 0.75 1) Tolerance ± 10% R911387136_Edition 02 Bosch Rexroth AG...

- Page 34 Safety and personal protection The permanent magnet brake of MS2E motors is no safety brake. This means, a torque reduction by non-influenceable disturbance factors can oc‐ cur. Especially for use in vertical axes. Bosch Rexroth AG R911387136_Edition 02...

- Page 35 2. Measure the transferable holding torque (M4) of the holding brake with a torque wrench. Check holding torque (M4) using the software function For Bosch Rexroth drive controller 1. Start the "P-0-0541, C2100 Command Holding system check" The effi‐ ciency of the holding brake and the opened state are checked by start‐...

-

Page 36: Flange Exactness

About this product If the holding torque (M4) is not achieved, the resurfacing routine can be used to reconstitute the holding torque. If you have any questions about grind in parameters, contact Bosch Rexroth service. 4.2.11 Flange exactness The properties concentricity, run-out and alignment are defined in the flange accuracy. -

Page 37: Vibration Behavior

● Horizontal installation ● Low vibration and impact loads ● No oscillating bearing movement < 180° ● Mean speed according to table : R911387136_Edition 02 Bosch Rexroth AG... -

Page 38: Frame Size, Installation Type

Frame size, installation type The motors can be installed horizontally and vertically with the shaft end pointing to the top or bottom. The installation variants correspond to IM-code according to EN 60034-7 for frame size and installation type. Bosch Rexroth AG R911387136_Edition 02... -

Page 39: Coating

The typical sound pressure level Lp(A) is specified for the speed range 0 rpm up to the rated speed, see chapter 4.2.1 "Basic data" on page 9. The instal‐ lation situation affects the noise emission. R911387136_Edition 02 Bosch Rexroth AG... -

Page 40: Product Identification

ATEX labeling explosion protection (gas) Use in systems for “integrated safety technique” prepared. ATEX labeling explosion protection (dust) Brake Holding brake data (optional) Tab. 4-13: Type plate specification MS2E The following marks of conformity are used. Bosch Rexroth AG R911387136_Edition 02... - Page 41 Motors labelled with the symbol EFUP 25 can be used for 25 as inten‐ ded before substances limited in their concentration according to China RoHS2 may leak and subsequently pose a risk to environment and health. Tab. 4-14: Meaning of marks of conformity R911387136_Edition 02 Bosch Rexroth AG...

-

Page 42: Explosion Protection

The Ex mark for MS2E motors, specified in the declaration of conformity and on the type plate, is labeled with an “X” at the end. Please observe the follow‐ ing special conditions for a safe operation of the motors in your construction: Bosch Rexroth AG R911387136_Edition 02... - Page 43 M17 Encoder tective cover SUP-M02-MS2E yes, with assembled plug connector pro‐ M23 Hybrid tective cover SUP-M01-MS2E M40 Power ● During machine construction avoid possible impacts onto the electric connections and plug connectors. R911387136_Edition 02 Bosch Rexroth AG...

-

Page 44: Atex Labeling For Ms2E Motors (Dust)

IP6X Protection class acc. to EN 60034-5 Labeling “Special conditions on use” Bosch Rexroth AG R911387136_Edition 02... -

Page 45: Special Conditions On Use "X" (Gas)

Possible risks due to a higher degree of endangerment can re‐ duce the mechanical protection of the plug connectors. The plug connectors fulfill the requirements about impact strength according to the following table. R911387136_Edition 02 Bosch Rexroth AG... - Page 46 Do a risk evaluation about occurance of highly charge-generating processes with the danger of propagating brush discharges. Avoid propagating brush discharges or provide measures to avoid propagat‐ ing brush discharges. See section chapter 2.4.4 "Protection against ignitable electrostatic dis‐ charge" on page 6 Bosch Rexroth AG R911387136_Edition 02...

-

Page 47: Conditions For Use Of Ms2E Motors In Equipment Group Ii, Category 3

5.3.6 Switch-off Energies stored in the intermediate circuit have to be reduced or insulated as soon as possible through the activation of the emergency stop device, so that R911387136_Edition 02 Bosch Rexroth AG... -

Page 48: Holding Brake

The failure of the single-channel temperature monitor in the device system may occur, as the result of an error, and might not be de‐ tected, even if the motor is operated within the normal temperature range and load cycle. Bosch Rexroth AG R911387136_Edition 02... -

Page 49: Operating Conditions And Handling

× f 0 red 0 60K 2. Pan the S1-characteristic curve M parallel to the speed axis to the junction of the S1-characteristic curve and to the calculated point M 0 red on the torque axis. R911387136_Edition 02 Bosch Rexroth AG... - Page 50 Operating conditions and handling 0 red S1 red n [1/min] Fig. 6-1: Determine S1-characteristic curve M with de-rating factor S1 red The determined characteristic curve M shows approximately the S1 red S1-characteristic curve with appropriate de-rating (standard values). Bosch Rexroth AG R911387136_Edition 02...

-

Page 51: Vibration Load During Operation

Permissible shock load for MS2E motors The specified limit values do not apply to half-sine-shaped single shock load acc. to EN 60068-2-27. The specifications do not apply to motor operation. Applications with continuous shock load require a case-by-case review. R911387136_Edition 02 Bosch Rexroth AG... -

Page 52: Transport (Shipping)

Use lifting sling belts or lifting eye bolts. Secure the lifting eye bolts before use. ● Never walk under hanging loads. ● Never lift the motor on the shaft. ● Use suitable protective equipment and protective cloth‐ ing during transport, and wear safety shoes. Bosch Rexroth AG R911387136_Edition 02... -

Page 53: Storage

Damage due to moisture and humidity! ● Protect the products from dampness and corrosion. ● Store them only in rainproof and dry rooms. Before storage, discharge the liquid coolant from liquid-cooled motors to avoid frost damage. R911387136_Edition 02 Bosch Rexroth AG... -

Page 54: Operation On Foreign Converters

Voltage load of the motor During converter operation, the motor underlies a higher voltage load (insula‐ tion system, bearing) than on a sinusoidal source voltage only. Standard values for peak voltage and rate of rise of voltage: Bosch Rexroth AG R911387136_Edition 02... - Page 55 Connect and operate MS2E motors only with origin connection accesso‐ ries. Use ready-made cables by Bosch Rexroth or with origin connectors ready-made connection cables. In the case of self-assembled cables, observe the notes about tensile load in "Special conditions on use"X"" in chapter 5 "Explosion protection"...

- Page 56 "Bearing service life" on page After maintenance and repair work, Bosch Rexroth always recommends to do a safety and functionality test on basis of the risk analysis provided by the customer (e.g. for thermal protection, holding brake).

-

Page 57: Assembly

NOTICE Motor damage due to strikes onto the motor shaft Do not strike the shaft end and do not exceed the allowed ax‐ ial and radial forces of the motor. R911387136_Edition 02 Bosch Rexroth AG... -

Page 58: Connecting The Electric Supply

The connection between the grounding conductor and the system ground must be made before any other connections. ● The junctions to or on the control device must be situated outside a haz‐ ardous area or be licensed for the use in hazardous areas. Bosch Rexroth AG R911387136_Edition 02... -

Page 59: Overview

(ESD). Observe ESD safety measures. 7.2.2 Overview Type Connection mode Type of connection/size Locking Output direction MS2Exx-xxxxx-xxS Single cable SpeedCon rotatable Power SpeedCon rotatable MS2Exx-xxxx-xxV Encoder SpeedCon rotatable Tab. 7-2: MS2E connection system overview R911387136_Edition 02 Bosch Rexroth AG... -

Page 60: Ms2E Connection Technique

MS2Exx-xxxxx-xxS Pin assignment Electrical connection "V" Device connector Power Encoder Connector size Output direction rotatable (max. 10x) Adjustment torque 12 … 18 Nm 2 … 6 Nm Locking (standard) SpeedCon SpeedCon Tab. 7-5: MS2Exx-xxxxx-xxVxx-xxxxx-xx Device connector Bosch Rexroth AG R911387136_Edition 02... -

Page 61: Ground Conductor

(e.g. storage, maintenance, ...). 7.2.6 Connect flange socket Observe when connecting the flange socket: ● Connect or disconnect plug connections only in de-energized, dry and clean state. ● Connect the motor with the ready-made connection cable. R911387136_Edition 02 Bosch Rexroth AG... -

Page 62: Plug Connector Protective Cover

The plug connector protective cover fulfills the required protection against im‐ pact onto the plug connector according to the ATEX directive. In the special conditions on use "X" we refer to the responsibility of the plant manufacturer to do a risk evaluation. Bosch Rexroth AG R911387136_Edition 02... - Page 63 The rotatable plug connector is set to a 90° position. 1. Position the connector protective cover onto the plug connector 2. Tighten (tightening torque 1.3 Nm) the fastening screws (0510) The connector protective cover is ready to use. R911387136_Edition 02 Bosch Rexroth AG...

-

Page 64: Shielding Concept

Ready-made cables of Bosch Rexroth are designed and tes‐ ted according to the requirements of installed motor components. This can no longer be ensured when using cables from other manufacturers. -

Page 65: Commissioning And Operation

● Check the proper function of the holding brake. ● Ensure that keys are protected against ejection. Commissioning For details on the commissioning order, please refer to the respective docu‐ mentation of the drive controller. R911387136_Edition 02 Bosch Rexroth AG... -

Page 66: Operation

Check the motor for cleanliness. ● Check increased vibration of the motor. ● Pay attention to exceptional noise. Decommission the drive when deviations from normal operation exist. For further procedure refer to chapter 12 "Troubleshooting " on page Bosch Rexroth AG R911387136_Edition 02... -

Page 67: Maintenance And Repair

An insufficient heat radiation may have undesired consequences. The bear‐ ing lifetime is reduced by operation at impermissibly high temperatures. Drive fault "motor overtemperature switch-off" despite operation on the basis of se‐ lected data, because the appropriate cooling is missing. R911387136_Edition 02 Bosch Rexroth AG... -

Page 68: Service Repair, Maintenance And Spare Parts

We recommend regular visual inspections on shaft sealing rings. Depending on operating conditions, signs of wear may appear after 5,000 operating hours. If necessary, replace the shaft sealing rings. We recommend to have these repairs made by Bosch Rexroth Service. 9.2.1 Service and support Our worldwide service network provides an optimized and efficient support. - Page 69 2014/34/EU Maintenance and repair ● Type plate specifications of the affected products, in particular type co‐ des and serial numbers ● Your contact data (phone and fax number as well as your e-mail ad‐ dress) R911387136_Edition 02 Bosch Rexroth AG...

-

Page 70: Disassembly And Exchange

(allowed soiling degree according to EN 50178: 2). 5. Replace the motor Observe the machine manufacturer's instructions when exchang‐ ing the motor mechanically. Bosch Rexroth AG R911387136_Edition 02... -

Page 71: Preparing Storage

When motors are liquid-cooled, completely discharge the coolant from the cooling tubes (e.g., via purging the coolant holes with pressure air). This will prevent frost damage at storage temperatures lower than 0 °C. R911387136_Edition 02 Bosch Rexroth AG... -

Page 72: Environmental Protection And Disposal

Most of the products can be recycled due to their high content of metal. In Recycling order to recycle the metal in the best possible way, the products must be dis‐ assembled into individual assemblies. Bosch Rexroth AG R911387136_Edition 02... - Page 73 Plastic parts of the products may contain flame retardants. These plastic parts are labeled according to EN ISO 1043. They have to be recycled sepa‐ rately or disposed of according to the applicable legal provisions. R911387136_Edition 02 Bosch Rexroth AG...

-

Page 74: Troubleshooting

Wrong or defective temperature display Temperature sensor not connected Connect temperature sensor Temperature sensor defective Stop the motor --> repair by manufacturer Connect the backup temperature sensor, if any is available. Tab. 12-1: Measure at malfunction an MS2E Bosch Rexroth AG R911387136_Edition 02... -

Page 75: Technical Data

Please, refer to the following docu‐ mentation for relevant information. Title Document type Document number MS2E Synchronous Servomotors for Hazardous Project planning DOK-MOTOR*-MS2E*******-PR··-··-P Areas acc. to ATEX Directive 2014/34/EU manual Tab. 13-1: Additional documentation R911387136_Edition 02 Bosch Rexroth AG... -

Page 76: Appendix

60/65 MS2E Synchronous Servomotors acc. to ATEX Directive 2014/34/EU Appendix Appendix 14.1 EU Declaration of Conformity Fig. 14-1: EU Declaration of Conformity original (page 1) Bosch Rexroth AG R911387136_Edition 02... -

Page 77: China Rohs 2

The UL/CSA conformity of MS2E motors can be found on the type plate of the motors. The following symbol is used for identification purposes: The list of MS2E motors is available under UL file number E335445 www.ul.com. R911387136_Edition 02 Bosch Rexroth AG... - Page 78 62/65 MS2E Synchronous Servomotors acc. to ATEX Directive 2014/34/EU Bosch Rexroth AG R911387136_Edition 02...

-

Page 79: Index

MS2E Synchronous Servomotors acc. to ATEX Directive 63/65 2014/34/EU Index Index Acceptance test..........32 Half key balancing..........14 Alignment............20 Hazardous substances........56 Ambient conditions..........33 Heat dissipation..........51 Ambient temperature........31, 33 Helical teeth............15 Attachments............14 Helpdesk............. 52 holding brake electrically-released........ - Page 80 64/65 MS2E Synchronous Servomotors acc. to ATEX Directive 2014/34/EU Index RoHS China RoHS 2..........61 Self-cooling IC410............. 12 Service..............52 Service hotline............ 52 Shaft..............11 smooth............13 with key way........... 14 Shaft length............11 Shield..............48 Shock..............35 Shutdown temperature........11 Sound pressure level..........

- Page 81 MS2E Synchronous Servomotors acc. to ATEX Directive 65/65 2014/34/EU Notes...

- Page 82 Bosch Rexroth AG P.O. Box 13 57 97803 Lohr a.Main, Germany Bgm.-Dr.-Nebel-Str. 2 97816 Lohr a.Main, Germany Phone +49 9352 18 0 Fax +49 9352 18 8400 www.boschrexroth.com/electrics *R911387136* R911387136 DOK-MOTOR*-MS2E*NN****-IT02-EN-P...