Siemens SINAMICS S120 Equipment Manual

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Siemens SINAMICS S120

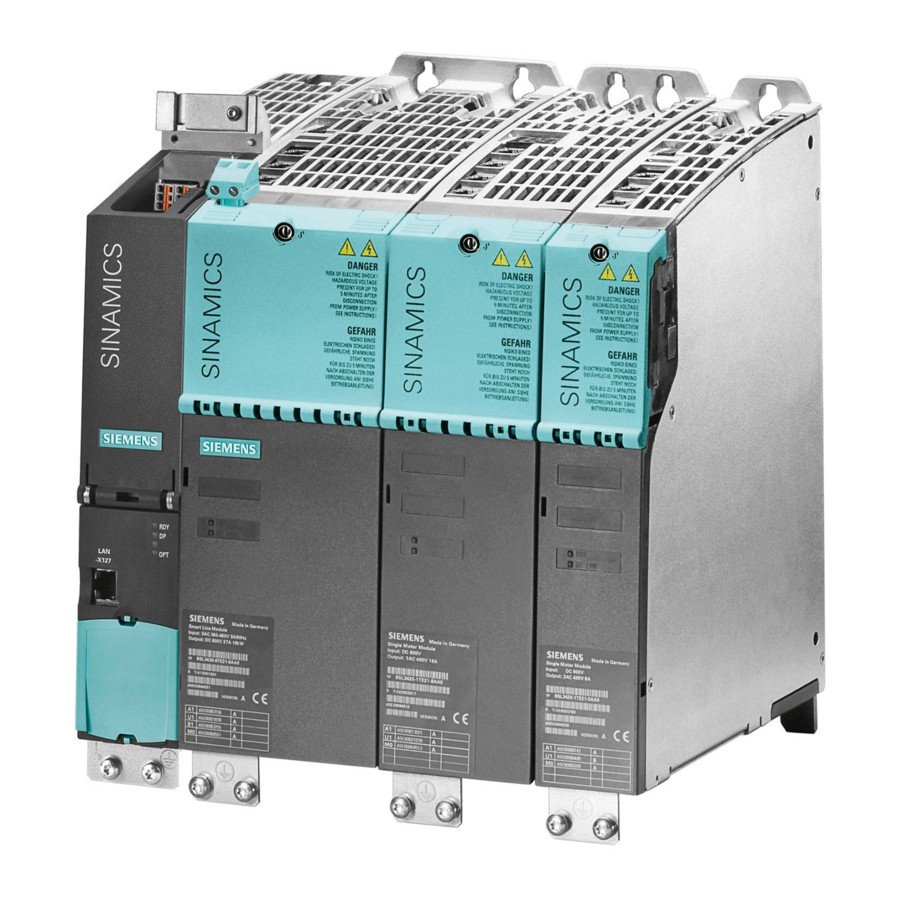

- Page 1 SINAMICS S120 Cabinet Modules Equipment Manual 10/2008 SINAMICS...

- Page 3 Preface Safety information System overview SINAMICS Mechanical installation S120 S120 Cabinet Modules Electrical installation Equipment Manual Cabinet Modules Manual Maintenance and servicing Diagnostics Options Appendix (GH5), 10/2008 A5E00427098A...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Preface

This documentation is aimed at machine manufacturers, plant engineers, commissioning engineers, and service personnel who use SINAMICS. Objective This manual describes the hardware components and design of the SINAMICS S120 Cabinet Modules. It provides information about installation, electrical connection, and cabinet design. - Page 6 "Calls are subject to charge (e.g. € 0.14/min from fixed lines within Germany). Tariffs of other telephone providers may differ." Internet address Up-to-date information about our products can be found on the Internet at: http://www.siemens.com For information about SINAMICS S120 Cabinet Modules, go to: http://www.siemens.com/sinamics-s120-cabinet-modules S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

-

Page 7: Table Of Contents

Table of contents Preface ..............................5 Safety information............................ 15 Requirements..........................15 Electrostatic sensitive devices (ESD) ..................16 Safety information ........................17 Residual risks..........................19 System overview............................21 Overview ............................21 Field of application ........................23 Benefits ............................23 Line Modules..........................24 2.4.1 Basic Line Modules........................24 2.4.2 Smart Line Modules ........................25 2.4.3 Active Line Modules........................26 DC link components........................27... - Page 8 Table of contents Introduction to EMC ........................49 EMC-compliant design ........................ 53 Connections ..........................56 4.5.1 PE busbar............................ 57 4.5.1.1 General information........................57 4.5.1.2 Connecting the PE busbar when cabinet units are installed side-by-side ........58 4.5.1.3 Connecting the PE busbar in accordance with the plant-side grounding concept...... 59 4.5.1.4 Connecting external cables to the PE busbar................

- Page 9 Table of contents 5.2.4 Technical data..........................129 5.2.5 Derating data..........................133 Smart Line Modules ........................135 5.3.1 General information ........................135 5.3.2 Description ..........................135 5.3.3 Options............................141 5.3.4 Technical data..........................142 5.3.5 Derating data..........................146 Active Line Modules........................148 5.4.1 General information ........................148 5.4.2 Description ..........................148 5.4.3 Options............................156 5.4.4 Technical data..........................157 5.4.5...

- Page 10 Table of contents 5.8.9 Derating data..........................231 Maintenance and servicing ........................233 Chapter content......................... 233 Cleaning the cabinet ......................... 233 Servicing the cabinet......................... 234 Replacing components......................235 6.4.1 General information........................235 6.4.2 Safety information ........................236 6.4.3 Installation device for power blocks ..................237 6.4.4 Replacing the filter mats......................

- Page 11 Table of contents 6.4.11 Replacing the fuses ........................298 6.4.11.1 Replacing the fuses for the auxiliary power supply..............298 6.4.11.2 Replacing fuses in the fuse switch disconnector for Booksize Cabinet Kit .......299 6.4.11.3 Replacing the fuses (F71 - F73) in the Line Connection Module ..........300 6.4.11.4 Replacing the DC fuses for Motor Module in chassis format, frame sizes FX and GX .....301 6.4.11.5 Replacing the DC fuses for Motor Module in chassis format, frame sizes HX and JX....302 6.4.11.6 Replacing the encapsulated fuses .....................304...

- Page 12 Table of contents 8.7.3 Interfaces........................... 339 8.7.4 Connection example ......................... 341 K50, SMC30 Sensor Module Cabinet-Mounted for TTL, HTL, and SSI encoders ....342 8.8.1 General information........................342 8.8.2 Safety information ........................346 8.8.3 Interfaces........................... 347 8.8.4 Connection example ......................... 350 K51, Voltage Sensing Module for determining the motor speed and the phase angle ....

- Page 13 Table of contents 8.22 L42/L43/L44, Line Connection Module for Active Line Modules/Basic Line Modules/Smart Line Modules..........................396 8.23 L45, EMERGENCY STOP pushbutton in the cabinet door ............397 8.24 L46/L47, grounding switch upstream/downstream of main breaker ..........398 8.24.1 Grounding switch upstream of main breaker (option L46)............398 8.24.2 Grounding switch downstream of main breaker (option L47) ............399 8.25...

-

Page 15: Safety Information

The operating instructions and the machine documentation are available in the languages specified in the supply contracts. Note We recommend engaging the support and services of your local Siemens service center for all planning, installation, commissioning, and maintenance work. S120 Cabinet Modules Equipment Manual... -

Page 16: Electrostatic Sensitive Devices (Esd)

Safety information 1.2 Electrostatic sensitive devices (ESD) Electrostatic sensitive devices (ESD) CAUTION The Cabinet Modules contain electrostatic sensitive devices. These components can be easily destroyed if not handled properly. Observe the following notes if you nevertheless have to work with electronic modules: •... -

Page 17: Safety Information

Commissioning must not start until you have ensured that the machine in which the components described here are to be installed complies with Directive 98/37/EC. SINAMICS S120 Cabinet Modules must only be commissioned by suitably qualified personnel. The personnel must take into account the information provided in the technical customer documentation for the product, and be familiar with and observe the specified danger and warning notices. - Page 18 1.3 Safety information CAUTION As part of routine tests, SINAMICS S120 Cabinet Modules undergo a voltage test in accordance with EN 61800-5-1. Prior to performing the voltage test for electrical equipment of industrial machines in accordance with EN 60204-1, Section 19.4, all connections of the Cabinet Modules must be disconnected/removed to prevent the units from being damaged.

-

Page 19: Residual Risks

Safety information 1.4 Residual risks Residual risks Residual risks of power drive systems When carrying out a risk assessment of the machine/plant in accordance with the EU Machinery Directive, the machine manufacturer/plant operator must consider the following residual risks associated with the control and drive components of a power drive system (PDS). - Page 20 Safety information 1.4 Residual risks WARNING Electromagnetic fields "electro smog" Electromagnetic fields are generated by the operation of electrical power engineering installations such as transformers, converters or motors. Electromagnetic fields can interfere with electronic devices, which could cause them to malfunction.

-

Page 21: System Overview

System overview Overview SINAMICS S120 Cabinet Modules are the components of a modular cabinet unit system for multi-axis drives with a central supply infeed and a common DC link busbar, as typically found in paper-making machines, roller mills, test stands, or hoisting gear. - Page 22 System overview 2.1 Overview Figure 2-1 Example of a drive line-up with SINAMICS S120 Cabinet Modules for a multi-motor drive The following table provides an overview of the voltage ranges and power ratings available for the SINAMICS S120 Cabinet Modules:...

-

Page 23: Field Of Application

System overview 2.2 Field of application Field of application The modular SINAMICS S120 Cabinet Modules drive system is used to coordinate multiple motors in a multi-axis drive system. Typical examples include: ● Paper-making machines ● Roller mills ● Hoisting gear ●... -

Page 24: Line Modules

System overview 2.4 Line Modules Line Modules Power is fed to the drive line-up via Line Modules, which generate a DC voltage from the line voltage and, therefore, supply energy to the Motor Modules connected to the DC link. They are suitable for connection to grounded (TN, TT) and non-grounded (IT) systems. -

Page 25: Smart Line Modules

System overview 2.4 Line Modules Line Connection Module Basic Line Module Circuit breaker Motor Module Figure 2-4 Line Connection Module with Basic Line Modules connected in parallel 2.4.2 Smart Line Modules Smart Line Modules can supply energy to the DC link and return regenerative energy to the supply system. -

Page 26: Active Line Modules

Interface Modules include the required pre-charging input circuit for the Active Line Module, in addition to a Clean Power Filter. These two components are considered to be an integral unit for SINAMICS S120 Cabinet Modules and are supplied together. For a compact configuration, Line Connection Modules up to input currents of 3,200 A are available. -

Page 27: Dc Link Components

System overview 2.5 DC link components Line Connection Module Active Active Line Interface Module Circuit breaker Module Motor Module Figure 2-9 Line Connection Module with Active Interface Module and Active Line Module > 800 A Line Connection Module Circuit breaker Motor Module Active... -

Page 28: Motor Modules

Auxiliary Power Supply Modules supply power to the auxiliary voltage busbar system of the SINAMICS S120 Cabinet Modules. The fans of the SINAMICS S120 devices installed in the Cabinet Modules are one of the devices connected to this auxiliary voltage busbar system. In addition, the auxiliary voltage busbar system supplies the electronics modules with external 24 V DC. -

Page 29: System Data

System overview 2.9 System data System data General technical data Electrical data Line voltages and power ranges 380 ... 480 V 3 AC, ±10 % (-15 % < 1 min), 1.6 ... 800 kW 500 ... 690 V 3 AC, ±10 % (-15 % < 1 min), 55 ... 1200 kW Line system configurations TN/TT supplies or isolated-neutral supplies (IT supplies) Line frequency... - Page 30 System overview 2.9 System data Ambient conditions In operation During storage During transport 0 °C Ambient temperature ... +40 °C -25 °C to +55 °C -25 °C to +70 °C -40 °C to +50 °C see derating data from for 24 hours 95 % ...

-

Page 31: Overview Of Options

System overview 2.10 Overview of options 2.10 Overview of options Table 2- 2 Overview of options Option code Brief description of option Customer documentation (circuit diagram, terminal diagram, layout diagram) in DXF format Draft of customer documentation Documentation language: English/French Documentation language: English/Spanish Documentation language: English/Italian Unit acceptance in presence of customer: Visual acceptance... - Page 32 System overview 2.10 Overview of options Option code Brief description of option 25/125 kW braking unit for line voltages of 500 to 600 V 50/250 kW braking unit for line voltages of 500 to 600 V Insulation monitoring Base 100 mm high, RAL 7022 Cable-marshaling compartment 200 mm high, RAL 7035 IP21 degree of protection IP23 degree of protection...

-

Page 33: Mechanical Installation

Mechanical installation Important notes Transport WARNING Please note the following when transporting the cabinet units: • The cabinet units are heavy. Their center of gravity is displaced, and they can be top heavy. • Ensure that the ground at the installation location is strong enough to bear the weight of the cabinet units. - Page 34 Note Notes regarding damage in transit: • Carry out a thorough visual inspection of the SINAMICS S120 Cabinet Modules before accepting the delivery from the shipping company. • Check that you have received all the items specified on the delivery note.

-

Page 35: Mechanical Installation: Checklist

Mechanical installation: Checklist Important safety precautions DANGER To ensure that the SINAMICS S120 Cabinet Modules operate safely and reliably, they must be properly installed and commissioned by qualified personnel, taking into account all the warning notices provided. In particular, the general and national installation and safety guidelines for high-voltage installations (e.g. - Page 36 Mechanical installation 3.2 Mechanical installation: Checklist Table 3- 1 Mechanical installation: Checklist Item Activity Applicable?/Completed? The ambient conditions must be permissible. (→ See general technical data in section "System data" in chapter "System overview") The load-carrying capacity and properties of the ground must fulfill the requirements for installation of the Cabinet Modules.

-

Page 37: Mechanical Installation

Mechanical installation 3.3 Mechanical installation Mechanical installation 3.3.1 Important safety precautions DANGER To ensure that the cabinet units operate safely and reliably, they must be properly installed and commissioned by qualified personnel, taking into account all the warning notices provided. In particular, the general and national installation and safety guidelines for high-voltage installations (e.g. - Page 38 Mechanical installation 3.3 Mechanical installation CAUTION Cabinet Modules do not fulfill the requirements for IP20 until they have been closed off by installing a side panel on the right (option M26) and a side panel on the left (option M27). The cabinet units are installed in accordance with the dimension drawings supplied.

- Page 39 Mechanical installation 3.3 Mechanical installation WARNING In a residential environment this product can cause high-frequency disturbances, which may make interference-suppression measures necessary. Unpacking the cabinets The packaging material must be discarded in accordance with the applicable country-specific guidelines and rules. Tools required To install the connections, you will need: ●...

-

Page 40: Lifting The Cabinet Units Off The Transport Pallet And Installing Them

Mechanical installation 3.3 Mechanical installation 3.3.3 Lifting the cabinet units off the transport pallet and installing them The applicable local guidelines regarding the transportation of the cabinet from the transport pallet to the installation location must be observed. A crane transport assembly (option M90) can also be fitted on the top of the cabinet. The fixing screws on the transport pallet can be removed from the pallet base without having to raise the cabinet unit. -

Page 41: Disassembling The Crane Transport Assembly

Mechanical installation 3.3 Mechanical installation 3.3.4 Disassembling the crane transport assembly With option M90 (crane transport assembly), the Cabinet Modules are equipped with either transport eyebolts or mounting rails. Dismantling The transport eyebolts can be unscrewed and removed. Depending on the length of the cabinet or transport unit, the support rails can have a varying number of fastening screws. -

Page 42: Connection For Side-By-Side Installation Of Cabinet Units

Mechanical installation 3.3 Mechanical installation 3.3.6 Connection for side-by-side installation of cabinet units Description An accessories kit is provided with each cabinet or transport unit for the connection of cabinet units in a side-by-side installation. The table below shows the content of this accessories kit and the fixing points for connecting the cabinet units. -

Page 43: Electrical Installation

Electrical installation Safety information Required safety precautions before installation work is carried out DANGER The Cabinet Modules are used in industrial high-voltage installations. During operation, this Cabinet Module contains rotating and live parts. For this reason, there is a risk of severe injury or significant material damage if the required covers are removed without authorization, if it is used or operated incorrectly, or if it has not been properly maintained. -

Page 44: Electrical Installation: Checklist

Electrical installation 4.2 Electrical installation: Checklist Electrical installation: Checklist Important safety precautions DANGER The cabinet units are operated with high voltages. All connection work must be carried out when the cabinet is de-energized. All work on the unit must be carried out by trained personnel only. Work on an open unit must be carried out with extreme caution because external supply voltages may be present. - Page 45 Electrical installation 4.2 Electrical installation: Checklist Table 4- 1 Electrical installation: Checklist Item Activity Applicable?/Completed? General information For strain relief, the cables must be clamped on the cable propping bar (C-type mounting bar). When EMC-shielded cables are used, screwed glands that connect the shield to ground with the greatest possible surface area must be provided on the motor terminal box.

- Page 46 Electrical installation 4.2 Electrical installation: Checklist Item Activity Applicable?/Completed? When connecting the braking resistor, the maximum permissible cable lengths between the Braking Module (options L61/L62, L64/L65) and the associated braking resistor must be observed. The resistor is connected at terminals R1 and R2 on the Braking Module. The thermal contact of the braking resistor must be wired up and its signal evaluated by the controller.

- Page 47 Electrical installation 4.2 Electrical installation: Checklist Item Activity Applicable?/Completed? Signal connections Cabinet operation by higher-level controller/control room. The control cables must be connected in accordance with the interface assignment and the shield applied. To prevent interference, the control cables must be laid separately from the power cables.

- Page 48 Electrical installation 4.2 Electrical installation: Checklist Item Activity Applicable?/Completed? K50, The SMC30 Sensor Module is used for detecting the SMC30 Sensor Module actual motor speed. The following encoders are supported by the SMC30 Sensor Module: TTL encoder • HTL encoder •...

-

Page 49: Introduction To Emc

Electrical installation 4.3 Introduction to EMC Introduction to EMC Description Electromagnetic compatibility (EMC) describes the capability of an electrical device to function satisfactorily in an electromagnetic environment without itself causing interference that is unacceptable for other devices in the environment. EMC therefore represents a quality feature for: ●... - Page 50 Electrical installation 4.3 Introduction to EMC Definition of environments 1 and 2 Figure 4-1 Definition of environments 1 and 2 ● Environment 1: Residential buildings or locations at which the drive system is connected to a low-voltage public network without a transformer. ●...

- Page 51 Electrical installation 4.3 Introduction to EMC ● Category C1: Rated voltage < 1000 V; unrestricted use in environment 1 ● Category C2: Rated voltage for stationary drive systems < 1000 V; for use in environment 2 For use in environment 1 only when sold and installed by skilled personnel. ●...

- Page 52 Electrical installation 4.3 Introduction to EMC The most important measures for reducing bearing currents: ● Insulated motor bearing at the non-drive end The insulated bearing is standard for all 1LA8 motors designated for converter operation. An insulated bearing at the non-drive end is available as an option for motors of the 1LG4/1LG6 series starting at frame size 280.

-

Page 53: Emc-Compliant Design

Electrical installation 4.4 EMC-compliant design EMC-compliant design The following section provides some basic information and guidelines that will help you comply with the EMC and CE guidelines. Cabinet installation ● Connect painted or anodized metal components using toothed self-locking screws or remove the insulating layer. - Page 54 Electrical installation 4.4 EMC-compliant design Using large cross sections ● Use underground and grounding cables with large cross sections or, better still, with litz wires or flexible cables. Use anti-interference elements ● If relays, contactors, and inductive or capacitive loads are connected, the switching relays or contactors must be fitted with anti-interference elements.

- Page 55 Electrical installation 4.4 EMC-compliant design Shield connection ● Shields must not be used to conduct electricity. In other words, they must not simultaneously act as neutral or PE conductors. ● Apply the shields so that they cover the greatest possible surface area. You can use ground clamps, ground terminals, or ground screw connections.

-

Page 56: Connections

Electrical installation 4.5 Connections Connections Connection overview The following connections must be established as standard connections for the Cabinet Modules: Table 4- 3 Connection overview for Cabinet Modules Connection Required connections for Cabinet Modules Line Basic Smart Active Motor Booksize Booksize Central Auxiliary... -

Page 57: Pe Busbar

Electrical installation 4.5 Connections 4.5.1 PE busbar 4.5.1.1 General information Availability PE busbars are included in the following S120 Cabinet Modules: ● Line Connection Module ● Basic Line Module ● Smart Line Module ● Active Line Module ● Motor Module in chassis format ●... -

Page 58: Connecting The Pe Busbar When Cabinet Units Are Installed Side-By-Side

Electrical installation 4.5 Connections 4.5.1.2 Connecting the PE busbar when cabinet units are installed side-by-side A connection jumper for the PE busbar is supplied with every cabinet. Preparatory steps ● Install and secure the cabinet units properly. ● Disconnect the cabinet units from the power supply. ●... -

Page 59: Connecting The Pe Busbar In Accordance With The Plant-Side Grounding Concept

Electrical installation 4.5 Connections 4.5.1.3 Connecting the PE busbar in accordance with the plant-side grounding concept DANGER Once you have established the connections to the PE busbar in the cabinet and/or established the connections to the PE busbar across more than one cabinet unit, you must establish a connection to the central ground of the entire system. -

Page 60: Dc Busbar

Electrical installation 4.5 Connections 4.5.2 DC busbar 4.5.2.1 General information Availability The DC busbar is included as a standard item in the following S120 Cabinet Modules: ● Basic Line Module ● Smart Line Module ● Active Line Module ● Motor Module in chassis format ●... - Page 61 Electrical installation 4.5 Connections Preparatory steps ● Verify that the cabinet units to be connected have been isolated from the supply. ● Install and secure the cabinet units properly. ● Observe the "five safety rules". ● Allow unimpeded access to the DC busbar (if necessary, remove the protective covers).

- Page 62 Electrical installation 4.5 Connections CAUTION The screws must only be loosened rather than removed because otherwise the nuts could fall into the device. The torque (50 Nm) must be observed to avoid excessive heating of the terminal contacts during operation. All jumpers of the DC busbar must always be connected in busbar systems.

-

Page 63: Connecting Dc Busbars To The Power Unit

Electrical installation 4.5 Connections 4.5.2.3 Connecting DC busbars to the power unit The components required for connecting the DC busbars to the power unit are included as standard parts. If any components are replaced, you may have to carry out the following steps to restore the connections. -

Page 64: Auxiliary Voltage Busbar System

Electrical installation 4.5 Connections 4.5.3 Auxiliary voltage busbar system 4.5.3.1 General information Availability The auxiliary voltage busbar system is included in the following S120 Cabinet Modules: ● Smart Line Module ● Active Line Module ● Motor Module in chassis format ●... -

Page 65: Connection Overview

Electrical installation 4.5 Connections Table 4- 4 Assignment of the auxiliary voltage busbar system Busbar Designation Voltage Line voltage (for fan supply via transformer): 380 to 480 V 2 AC or • 500 to 690 V 2 AC • 230 V 1 AC 24 V DC for electronics power supply The maximum load-carrying capacity of the auxiliary voltage busbar system is 100 A according to IEC (or 80 A according to UL). -

Page 66: Connecting The Auxiliary Voltage Busbar System When Cabinet Units Are Installed Side-By- Side

Electrical installation 4.5 Connections 4.5.3.3 Connecting the auxiliary voltage busbar system when cabinet units are installed side-by- side Description To connect the auxiliary voltage busbar system, 3 preassembled jumpers are provided for each cabinet. One jumper connects one busbar system. The procedure is described below. Figure 4-10 Connecting the auxiliary voltage busbar system when cabinet units are installed side-by- side... -

Page 67: Connecting To The Infeed

Electrical installation 4.5 Connections 4.5.3.4 Connecting to the infeed Description If an Auxiliary Power Supply Module is not available to supply power to the auxiliary voltage busbar system or if the Auxiliary Power Supply Module and the Cabinet Modules to be supplied are installed in different parts of the cabinet and require jumpering, an infeed Faston plug, for example, can be used to feed power to the auxiliary voltage busbar system. -

Page 68: Connecting The Motor Cables

Electrical installation 4.5 Connections 4.5.4 Connecting the motor cables Preparatory steps ● Install and secure the cabinet units properly. ● Disconnect the cabinet units from the power supply. ● Make sure that all the necessary safety measures have been taken at the installation location. - Page 69 Electrical installation 4.5 Connections Connecting the motor cables 1. Open the cabinet and remove the covers in front of the connection panel for motor cables (terminals U2/T1, V2/T2, W2/T3; X2). 2. Move or remove the base plate below the connection panel through which the motor cables are fed.

- Page 70 Electrical installation 4.5 Connections Connection cross sections Refer to the "Technical data" for the Motor Modules, "Cabinet Modules" chapter for the connection cross sections. Direction of motor rotation In the case of three-phase induction motors with a clockwise phase sequence (looking at the drive shaft), the motor must be connected to the cabinet unit as follows.

-

Page 71: Line/Power Connections

Electrical installation 4.5 Connections 4.5.5 Line/power connections Line Connection Modules Table 4- 6 Line/power connection of the Line Connection Modules Terminals Technical specifications U1/L1, V1/L2, W1/L3 Voltage: 3 AC power input 380 V AC, 3-phase –10% to 480 V AC, 3-phase +10% (-15% < 1 min) 500 V AC, 3-phase –10% to 690 V AC, 3-phase +10% (-15% <... -

Page 72: Adjusting The Fan Voltage

Electrical installation 4.5 Connections 4.5.6 Adjusting the fan voltage A transformer is incorporated in the Motor Module in chassis format (-T1-T10) and Basic Line Module/Active Line Module/Smart Line Module (-T2-T10) for setting the correct operating voltage for the 230 V fans. The locations of the transformers are indicated in the layout diagrams supplied. - Page 73 Electrical installation 4.5 Connections CAUTION If the terminals are not reconnected to the actual line voltage: • The required cooling capacity cannot be provided because the fan rotates too slowly; • The fan fuses may blow due to an overcurrent. Note With the fan transformer (500 to 690 V 2 AC), a jumper is inserted between terminal "600 V"...

-

Page 74: Operating Cabinet Modules On An Isolated-Neutral Supply System (It System)

Electrical installation 4.5 Connections 4.5.7 Operating Cabinet Modules on an isolated-neutral supply system (IT system) When the Cabinet Modules are operated on an isolated-neutral supply system (IT system), the integrated EMC filters are deactivated by unscrewing a connection clamp in the following Cabinet Modules. -

Page 75: Cable Routing

Electrical installation 4.5 Connections 4.5.10 Cable routing 4.5.10.1 General information DANGER The work described in this section is carried out in cabinets that are operated in industrial high-voltage installations. During operation, this cabinet contains rotating and live parts. For this reason, there is a risk of severe injury or significant material damage if the required covers are removed without authorization, if it is used or operated incorrectly, or if it has not been properly maintained. -

Page 76: Cable Routing For Line Connection Modules

Electrical installation 4.5 Connections 4.5.10.2 Cable routing for Line Connection Modules For the Line Connection Modules, the customer must carry out the following cabling or connection work: Table 4- 11 Checklist for cabling or connection work for Line Connection Modules Cable routing Completed? Cable for supply infeed... - Page 77 Electrical installation 4.5 Connections Cable routing for connecting to the supply infeed Frame size: GL/HL KL/LL 1. Feed the infeed cable into the cabinet from the bottom. 2. Feed the cable up through the cabinet to terminal block -X1. 3. Secure the cable at suitable points. 4.

- Page 78 Electrical installation 4.5 Connections Signal cables Frame size: GL/HL KL/LL 1. Feed the signal cables into the cabinet from the bottom left. 2. Feed the signal cables up through the cabinet to terminal blocks -X30, -X40, and -X50. 3. Fasten the signal cables at suitable points. 4.

-

Page 79: Cable Routing For Basic Line Modules

Electrical installation 4.5 Connections 4.5.10.3 Cable routing for Basic Line Modules For the Basic Line Modules, the customer must carry out the following cabling or connection work: Table 4- 12 Checklist for cabling or connection work for Basic Line Modules Cable routing Completed? PROFIBUS cables to the CU320 Control Unit... - Page 80 6. Use cable ties to secure the cable at suitable points. 7. Connect the cable to the CU320 Control Unit. (→ See SINAMICS S120 Equipment Manual GH1 Control Units) S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 81 Electrical installation 4.5 Connections Cable routing for DRIVE-CLiQ connections and signal cables Frame size: 1. Feed the DRIVE-CLiQ/signal cable into the cabinet from the bottom left. 2. Use cable ties to secure the cable at suitable points. 3. Feed the cable up through the cabinet and, when it reaches the Control Unit CU320, guide it up and to the right toward the CU320.

- Page 82 Electrical installation 4.5 Connections Cable routing to the customer terminal block -X55 Frame size: 1. Feed the cable for the customer terminal block into the cabinet from the bottom left. 2. Remove approx. 3 cm of the cable insulation at the level of the shield plate in the lower part of the cabinet and attach the cable.

-

Page 83: Cable Routing For Smart Line Modules

Electrical installation 4.5 Connections 4.5.10.4 Cable routing for Smart Line Modules For the Smart Line Modules, the customer must carry out the following cabling or connection work: Table 4- 13 Checklist for cabling or connection work for Smart Line Modules Cable routing Completed? PROFIBUS cables to the CU320 Control Unit... - Page 84 6. Use cable ties to secure the cable at suitable points. 7. Connect the cable to the CU320 Control Unit (→ See SINAMICS S120 Equipment Manual GH1 Control Units) S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 85 Electrical installation 4.5 Connections Cable routing for DRIVE-CLiQ connections and signal cables to the CU320 Control Unit Frame size: 1. Feed the DRIVE-CLiQ/signal cable into the cabinet from the bottom left. 2. Use cable ties to secure the cable at suitable points. 3.

- Page 86 Electrical installation 4.5 Connections Cable routing to the customer terminal block -X55 Frame size: 1. Feed the cable for the customer terminal block into the cabinet from the bottom left. 2. Use cable ties to secure the cable at suitable points. 3.

-

Page 87: Cable Routing For Active Line Modules

Electrical installation 4.5 Connections 4.5.10.5 Cable routing for Active Line Modules For the Active Line Modules, the customer must carry out the following cabling or connection work: Table 4- 14 Checklist for cabling or connection work for Active Line Modules Cable routing Completed? PROFIBUS cables to the CU320 Control Unit... - Page 88 6. Use cable ties to secure the cable at suitable points. 7. Connect the cable to the CU320 Control Unit (→ See SINAMICS S120 Equipment Manual GH1 Control Units) S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 89 6. Use cable ties to secure the cable at suitable points. 7. Connect the cable to the CU320 Control Unit (→ See SINAMICS S120 Equipment Manual GH1 Control Units) S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 90 Electrical installation 4.5 Connections Cable routing for DRIVE-CLiQ connections and signal cables, frame sizes FX+FI and GX+GI Frame size: FX+FI GX+GI 1. Feed the cable for the DRIVE-CLiQ/signal cables into the cabinet from the bottom left. 2. Use cable ties to secure the cable at suitable points. 3.

- Page 91 Electrical installation 4.5 Connections Cable routing for DRIVE-CLiQ connections and signal cables, frame sizes HX+HI and JX+JI Frame size: HX+HI JX+JI 1. Feed the cable for the DRIVE-CLiQ/signal cables into the cabinet from the bottom left. 2. Use cable ties to secure the cable at suitable points. 3.

- Page 92 Electrical installation 4.5 Connections Cable routing to customer terminal block -X55, frame sizes FX+FI and GX+GI Frame size: FX+FI GX+GI 1. Feed the cable for the customer terminal block into the cabinet from the bottom right (frame size FX+FI) or bottom left (frame size GX+GI). 2.

- Page 93 Electrical installation 4.5 Connections Cable routing for customer terminal block –X55, frame sizes HX+HI and JX+JI Frame size: HX+HI JX+JI 1. Feed the cable for the customer terminal block into the cabinet from the bottom left. 2. Use cable ties to secure the cable at suitable points. 3.

-

Page 94: Cable Routing For Booksize Base Cabinets + Booksize Cabinet Kit

Electrical installation 4.5 Connections 4.5.10.6 Cable routing for Booksize Base Cabinets + Booksize Cabinet Kit Note The procedure is the same as that for the Motor Module in chassis format Cabinet Modules. (→ See the section titled "Cable routing for Motor Modules in chassis format") Cable routing of motor cable Note The motor cables are easy to connect to terminals in the lower part of the customer... - Page 95 6. Use cable ties to secure the cable at suitable points. 7. Connect the cable to the CU320 Control Unit. (→ See SINAMICS S120 Equipment Manual GH1 Control Units) S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 96 Electrical installation 4.5 Connections Cable routing for DRIVE-CLiQ connections and signal cables to the CU320 Control Unit Frame size: FX+GX HX+JX 1. Feed the DRIVE-CLiQ/signal cable into the cabinet from the bottom left. 2. Use cable ties to secure the cable at suitable points. 3.

- Page 97 Electrical installation 4.5 Connections Cable routing of signal cables to the customer terminal block -X55 Frame size: FX+GX HX+JX 1. Feed the cable for the customer terminal block into the cabinet from the bottom left. 2. Use cable ties to secure the cable at suitable points. 3.

- Page 98 Electrical installation 4.5 Connections Cable routing of signal cables to SMC10/20/30 Sensor Module Frame size: FX+GX HX+JX 1. Feed the cable for the customer terminal block into the cabinet from the bottom left. 2. Remove approx. 3 cm of the insulation at the level of the shield plate in the lower part of the cabinet and attach the cable.

- Page 99 Electrical installation 4.5 Connections Cable routing for motor connection Frame size: FX+GX HX+JX 1. Feed the cable into the cabinet from below. 2. Feed the cable up through the cabinet to the motor connections -U2/-T1, -V2/-T2, -W2/-T3. 3. Connect the cable to the terminals. S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

-

Page 100: Cable Routing For Central Braking Modules

Electrical installation 4.5 Connections 4.5.10.8 Cable routing for Central Braking Modules Cable routing to the braking resistor Central Braking Module 1. Feed the cable into the cabinet from below. 2. Feed the cable up and behind the PE busbar to the braking resistor terminals. 3. - Page 101 Electrical installation 4.5 Connections Cable routing to terminal block -X2 Central Braking Module 1. Feed the cable into the cabinet from the bottom left. 2. Guide the cable up and, when it reaches the level of terminal -X2, guide it to the right. 3.

-

Page 102: Cable Routing For Auxiliary Power Supply Modules

Electrical installation 4.5 Connections 4.5.10.9 Cable routing for Auxiliary Power Supply Modules Cable routing for connecting to the supply infeed Auxiliary Power Supply Module 1. Feed the cable into the cabinet from the bottom right. 2. Guide the cable up and, when it reaches the level of the line connection, guide it to the left. - Page 103 Electrical installation 4.5 Connections Cable routing for signal cables to terminal blocks -X45, -X46, -X47 Auxiliary Power Supply Module 1. Feed the cable into the cabinet from the bottom left. 2. Guide the cable up and, when it reaches the terminal blocks, to the right. 3.

-

Page 104: 4.5.10.10 Safety And Emc

Electrical installation 4.5 Connections 4.5.10.10 Safety and EMC DANGER All covers removed while the cables were being routed must be replaced before the Cabinet Module is commissioned. NOTICE When routing cables, take care not to change the internal cabinet wiring. NOTICE The screening plates must be replaced before the cabinet is commissioned, in order to ensure that screening is EMC-compliant. -

Page 105: Cabinet Modules

Cabinet Modules Line Connection Modules 5.1.1 General information DANGER Hazardous voltages are present in certain parts of this equipment during operation of the cabinet unit. Only qualified personnel may work on the cabinet. Such personnel must be thoroughly familiar with all the warnings and maintenance procedures for the cabinet described in the documentation provided. - Page 106 Cabinet Modules 5.1 Line Connection Modules Line Connection Modules are available for the following voltages and currents: Input voltage Input current 380 to 480 V 3 AC 250 to 3200 A 500 to 690 V 3 AC 280 to 3200 A Table 5- 1 -X1 terminals for the supply infeed Terminals...

- Page 107 Cabinet Modules 5.1 Line Connection Modules C/L + D/L - -X50 -X40 - F1 - F2 - F3 -B101 -X60 -X60 -X120 -X240 -T110 -T111 -T Figure 5-1 Configuration example for Line Connection Modules (frame size FL) S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 108 Cabinet Modules 5.1 Line Connection Modules C/L + D/L - -T24 -X50 -X40 -T110 -X120 -X11 -Q10 - F71 - F72 - F73 -X60 -B101 -T112 -T110 -T111 -X240 -E240 Figure 5-2 Configuration example for Line Connection Modules (frame size JL) S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

-

Page 109: Fuse Switch Disconnector (Input Current ≤ 800 A)

Cabinet Modules 5.1 Line Connection Modules 5.1.2.1 Fuse switch disconnector (input current ≤ 800 A) Up to 800 A, a switch disconnector with integrated fuses is incorporated. Terminal block -X50 – "Fuse switch disconnector" checkback contact Table 5- 2 Terminal block -X50 – "Fuse switch disconnector" checkback contact Terminal Designation Technical specifications... - Page 110 Cabinet Modules 5.1 Line Connection Modules Table 5- 4 Factory setting of the overcurrent release on Line Connection Modules for Basic Line Modules Order number Order number Input current Overload trip Short-time Short-circuit Line Connection Basic Line Module Line Module delayed short- release delay Module...

-

Page 111: Terminal Block -X40 - External 230 V Ac Auxiliary Infeed

Cabinet Modules 5.1 Line Connection Modules Terminal block -X50 – "Circuit breaker" checkback contact Table 5- 6 Terminal block -X50 – "Circuit breaker" checkback contact Terminal Designation Technical specifications "Fuse switch disconnector" checkback contacts Max. load current: 3 A Max. switching voltage: 250 V AC NC: normally-closed contact, NO: normally-open contact, COM: mid-position contact, max. -

Page 112: Versions Of Line Connection Modules

Cabinet Modules 5.1 Line Connection Modules 5.1.3 Versions of Line Connection Modules Different versions to suit specific input currents are available: ● Units ≤ 800 A are equipped with a main breaker with fuse switch disconnector ● Units > 800 A are equipped with a fixed-mounted circuit breaker (draw-out circuit breaker is available as option) Line Connection Modules come in the following versions (specified by an option code) according to the type of the Line Module that is being fed:... -

Page 113: Version L43 For Basic Line Modules

Cabinet Modules 5.1 Line Connection Modules -Q10 Pre-charging 3WL1 -R 1 U1_1 U1/L1 V1_1 V1/L2 W1_1 W1/L3 -R 1.1 U1_2 V1_2 W1_2 Figure 5-5 Connection example: Line Connection Module ≥ 2,000 A for connection to Active Line Modules connected in parallel, options: L42 5.1.3.2 Version L43 for Basic Line Modules When Basic Line Modules are used, a line reactor is incorporated as a standard feature. - Page 114 Cabinet Modules 5.1 Line Connection Modules -Q10 Pre-charging 3WL1 U1/L1 U1/L1 V1/L2 V1/L2 W1/L3 W1/L3 Figure 5-8 Connection example: Line Connection Module > 1,800 A, < 2,000 A for connection to Basic Line Modules, options: L43 If Basic Line Modules that are fed via a common Line Connection Module are connected in parallel, line reactors are generally incorporated in the Line Connection Module.

-

Page 115: Version L44 For Smart Line Modules

Cabinet Modules 5.1 Line Connection Modules 5.1.3.3 Version L44 for Smart Line Modules U1/L1 U1/L1 V1/L2 V1/L2 W1/L3 W1/L3 Figure 5-10 Connection example: Line Connection Module ≤800 A for connection to Smart Line Modules, options: L44 -Q10 3WL1 U1/L1 U1/L1 V1/L2 V1/L2 W1/L3... -

Page 116: Options

Cabinet Modules 5.1 Line Connection Modules 5.1.4 Options Note The individual options are described in the chapter titled "Options". Electrical options Component Option Main contactor (for Line Connection Modules ≤ 800 A) No line reactor for Basic Line Modules Draw-out circuit breaker (for Line Connection Modules > 800 A) Line current transformer Line Connection Module for Active Line Modules Line Connection Module for Basic Line Modules... -

Page 117: Technical Data

Cabinet Modules 5.1 Line Connection Modules 5.1.5 Technical data Table 5- 9 Technical data for Line Connection Modules, 380 to 480 V 3 AC, part I Order no. 6SL3700- 0LE32- 0LE34- 0LE36- 0LE38- 0LE41- 5AA0 0AA0 3AA0 0AA0 0AA0 Infeed/regenerative feedback current - Rated current I 1000 Power demand 230 V AC... - Page 118 Cabinet Modules 5.1 Line Connection Modules Table 5- 10 Technical data for Line Connection Modules, 380 to 480 V 3 AC, part II Order no. 6SL3700- 0LE41- 0LE41- 0LE42- 0LE42- 0LE42- 0LE43- 3AA0 6AA0 0AA0 0BA0 5BA0 2BA0 Infeed/regenerative feedback current - Rated current I 1250 1600...

- Page 119 Cabinet Modules 5.1 Line Connection Modules Table 5- 11 Technical data for Line Connection Modules, 500 to 690 V 3 AC, part I Order no. 6SL3700- 0LG32- 0LG34- 0LG36- 0LG38- 0LG41- 8AA0 0AA0 3AA0 0AA0 0AA0 Infeed/regenerative feedback current - Rated current I 1000 Power demand 230 V AC - Starting current...

- Page 120 Cabinet Modules 5.1 Line Connection Modules Table 5- 12 Technical data for Line Connection Modules, 500 to 690 V 3 AC, part II Order no. 6SL3700- 0LG41- 0LG41- 0LG42- 0LG42- 0LG42- 3AA0 6AA0 0BA0 2BA0 5BA0 Infeed/regenerative feedback current - Rated current I 1250 1600 2000...

-

Page 121: Derating Data

Cabinet Modules 5.1 Line Connection Modules 5.1.6 Derating data Current derating as a function of the installation altitude and ambient temperature If the cabinet units are operated at an installation altitude > 2000 m above sea level, the maximum permissible output current can be calculated using the following table. The installation altitude and ambient temperature are compensated here. - Page 122 Cabinet Modules 5.1 Line Connection Modules Voltage derating as a function of the installation altitude In addition to current derating, voltage derating must also be considered at installation altitudes > 2000 m above sea level. Table 5- 15 Voltage derating as a function of the installation altitude (380 to 480 V 3 AC) Installation altitude Rated converter input voltage above sea level in m...

-

Page 123: Basic Line Modules

Cabinet Modules 5.2 Basic Line Modules Basic Line Modules 5.2.1 General information DANGER Hazardous voltages are present in certain parts of this equipment during operation of the cabinet unit. Only qualified personnel may work on the cabinet. Such personnel must be thoroughly familiar with all the warnings and maintenance procedures for the cabinet described in the documentation provided. - Page 124 Cabinet Modules 5.2 Basic Line Modules Integration Figure 5-13 Connection example for Basic Line Modules S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 125 Cabinet Modules 5.2 Basic Line Modules Configuration In Basic Line Modules of frame sizes FB and GB, a fully-controlled thyristor bridge is used to pre-charge the Basic Line Module and the connected DC link. The thyristors normally operate with a trigger delay angle of 0°. Basic Line Modules of frame size GD for 900 kW (400 V) or 1.500 kW (690 V) have a diode jumper, and the DC link is pre-charged via a separate line-side pre-charging device.

- Page 126 Cabinet Modules 5.2 Basic Line Modules - F19 -F 19 C /L + C /L + F _Schienen _G 600 -Q 50 - F21 -F 21 - X50 - F 20 - F 20 - F23 - F 22 D /L - D /L - - F 22 - F 24...

- Page 127 Cabinet Modules 5.2 Basic Line Modules Parallel connection of Basic Line Modules to increase power rating A pair of Basic Line Modules is available for creating drive line-ups with more power. These modules can be operated on a common Line Connection Module and are arranged to the right and left of the Line Connection Module.

-

Page 128: Options

Cabinet Modules 5.2 Basic Line Modules 5.2.3 Options Note The individual options are described in the chapter titled "Options". Electrical options Component Option CBC10 Communication Board CBE20 Communication Board AOP30 operator panel CU320 Control Unit with CompactFlash card without/with performance enhancement K90/K91 Cabinet anti-condensation heating 25/125 kW braking unit... -

Page 129: Technical Data

Cabinet Modules 5.2 Basic Line Modules 5.2.4 Technical data Table 5- 17 Technical data for Basic Line Modules, 380 ... 480 V 3 AC Order no. 6SL3730- 1TE34- 1TE35- 1TE38- 1TE41- 1TE41- 1TE41- 2AA0 3AA0 2AA0 2AA0 5AA0 8AA0 for parallel connection, - attached to Line Connection Module ...-2BA0 ...-5BA0... - Page 130 Cabinet Modules 5.2 Basic Line Modules Order no. 6SL3730- 1TE34- 1TE35- 1TE38- 1TE41- 1TE41- 1TE41- 2AA0 3AA0 2AA0 2AA0 5AA0 8AA0 Weight (standard version) 320/440/480 Frame size The base load current I is based on a duty cycle of 150 % for 60 s or I for 5 s with a duty cycle duration of 300 s.

- Page 131 Cabinet Modules 5.2 Basic Line Modules Table 5- 18 Technical data for Basic Line Modules, 500 ... 690 V 3 AC Order no. 6SL3730- 1TH33- 1TH34- 1TH36- 1TH41- 1TH41- 1TH41- 0AA0 3AA0 8AA0 1AA0 4AA0 8AA0 for parallel connection, - attached to Line Connection Module ...-2BA0 ...-4BA0 ...-8BA0...

- Page 132 Cabinet Modules 5.2 Basic Line Modules Order no. 6SL3730- 1TH33- 1TH34- 1TH36- 1TH41- 1TH41- 1TH41- 0AA0 3AA0 8AA0 1AA0 4AA0 8AA0 Weight (standard version) 320/440/480 Frame size The base load current I is based on a duty cycle of 150 % for 60 s or I for 5 s with a duty cycle duration of 300 s.

-

Page 133: Derating Data

Cabinet Modules 5.2 Basic Line Modules 5.2.5 Derating data Current derating as a function of the installation altitude and ambient temperature If the cabinet units are operated at an installation altitude > 2000 m above sea level, the maximum permissible output current can be calculated using the following table. The installation altitude and ambient temperature are compensated here. - Page 134 Cabinet Modules 5.2 Basic Line Modules Voltage derating as a function of the installation altitude In addition to current derating, voltage derating must also be considered at installation altitudes > 2000 m above sea level. Table 5- 21 Voltage derating as a function of the installation altitude (380 to 480 V 3 AC) Installation altitude Rated converter input voltage above sea level in m...

-

Page 135: Smart Line Modules

Cabinet Modules 5.3 Smart Line Modules Smart Line Modules 5.3.1 General information DANGER Hazardous voltages are present in certain parts of this equipment during operation of the cabinet unit. Only qualified personnel may work on the cabinet. Such personnel must be thoroughly familiar with all the warnings and maintenance procedures for the cabinet described in the documentation provided. - Page 136 Cabinet Modules 5.3 Smart Line Modules Integration Cabinet Module DC busbar X400 X401 X402 X500 Smart Line -X41 Module READY +24 V Cabinet Module EP M Voltage Sensing Module Line Connection Module P24 V Bypass 230 V AC Internal contactor control power supply Checkback signal...

- Page 137 Cabinet Modules 5.3 Smart Line Modules Configuration IGBTs (fundamental frequency-switched) are used as power semiconductors of the Smart Line Modules. Because this reduces switching losses, high current utilization of the power units can be achieved. The current flows in the direction of the infeed via the freewheeling diodes of the IGBTs. While a diode is conducting, the anti-parallel IGBT is also activated.

- Page 138 Cabinet Modules 5.3 Smart Line Modules C /L + D /L - -T 30 .X 21 - T 2 - F 1 - F 2 - X126 - E1 -F 24 - X9 - T 10 - E240 - X55 -W100 24 V Figure 5-16...

- Page 139 Cabinet Modules 5.3 Smart Line Modules C /L + D /L - -T 30 .X 21 -F 1 -F 3 -F 2 -F 4 - X126 - E2 -E 3 - E4 - F 24 -X 9 -T 20 - T 10 - R1 - X55 - E241...

- Page 140 Cabinet Modules 5.3 Smart Line Modules Parallel connection of Smart Line Modules to increase power rating Up to four Smart Line Modules with the same power rating can be connected in parallel in order to increase power. Smart Line Modules with "mirror-image" power connections enable the parallel connection of these modules in a compact configuration.

-

Page 141: Options

Cabinet Modules 5.3 Smart Line Modules 5.3.3 Options Note The individual options are described in the chapter titled "Options". Electrical options Component Option CBC10 Communication Board CBE20 Communication Board AOP30 operator panel CU320 Control Unit with CompactFlash card without/with performance enhancement K90/K91 Without line reactor Cabinet anti-condensation heating... -

Page 142: Technical Data

Cabinet Modules 5.3 Smart Line Modules 5.3.4 Technical data Table 5- 23 Technical data for Smart Line Modules, 380 ... 480 V 3 AC Order no. 6SL3730- 6TE35- 6TE37- 6TE41- 6TE41- 6TE41- 5AA0 3AA0 1AA0 3AA0 7AA0 for parallel connection, - attached to Line Connection Module ...-1BA0 ...-3BA0... - Page 143 Cabinet Modules 5.3 Smart Line Modules Order no. 6SL3730- 6TE35- 6TE37- 6TE41- 6TE41- 6TE41- 5AA0 3AA0 1AA0 3AA0 7AA0 Weight (standard version) Frame size The base load current I is based on a duty cycle of 150 % for 60 s or I for 5 s with a duty cycle duration of 300 s.

- Page 144 Cabinet Modules 5.3 Smart Line Modules Table 5- 24 Technical data for Smart Line Modules, 500 ... 690 V 3 AC Order no. 6SL3730- 6TG35- 6TG38 6TG41 6TG41 5AA0 -8AA0 -2AA0 -7AA0 for parallel connection, - attached to Line Connection Module ...-8BA0 ...-2BA0 ...-7BA0...

- Page 145 Cabinet Modules 5.3 Smart Line Modules Order no. 6SL3730- 6TG35- 6TG38 6TG41 6TG41 5AA0 -8AA0 -2AA0 -7AA0 Weight (standard version) Frame size The base load current I is based on a duty cycle of 150 % for 60 s or I for 5 s with a duty cycle duration of 300 s.

-

Page 146: Derating Data

Cabinet Modules 5.3 Smart Line Modules 5.3.5 Derating data Current derating as a function of the installation altitude and ambient temperature If the cabinet units are operated at an installation altitude > 2000 m above sea level, the maximum permissible output current can be calculated using the following table. The installation altitude and ambient temperature are compensated here. - Page 147 Cabinet Modules 5.3 Smart Line Modules Voltage derating as a function of the installation altitude In addition to current derating, voltage derating must also be considered at installation altitudes > 2000 m above sea level. Table 5- 27 Voltage derating as a function of the installation altitude (380 to 480 V 3 AC) Installation altitude Rated converter input voltage above sea level in m...

-

Page 148: Active Line Modules

Cabinet Modules 5.4 Active Line Modules Active Line Modules 5.4.1 General information DANGER Hazardous voltages are present in certain parts of this equipment during operation of the cabinet unit. Only qualified personnel may work on the cabinet. Such personnel must be thoroughly familiar with all the warnings and maintenance procedures for the cabinet described in the documentation provided. - Page 149 Cabinet Modules 5.4 Active Line Modules Integration Figure 5-18 Connection example for Active Line Modules (frame size FI/FX and GI/GX) S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 150 Cabinet Modules 5.4 Active Line Modules Figure 5-19 Connection example for Active Line Modules (frame size HI/HX and JI/JX) S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 151 Cabinet Modules 5.4 Active Line Modules Configuration Active Line Modules are always operated together with an Active Interface Module, which contains the associated Clean Power Filter and pre-charging circuit. The included line filter enables compliance with the EMC requirements for the "second environment". Note The configuration examples of the individual Active Line Modules are used to illustrate the positioning of the factory-fitted components.

- Page 152 Cabinet Modules 5.4 Active Line Modules C /L + D /L - - T 30. X21 - G 1 - R 2 - F1 - F 2 -X 630 - E 10 - K4 - X126 - X609 - E1 - B51 -Q 2 - T10...

- Page 153 Cabinet Modules 5.4 Active Line Modules C /L + D /L - - R 2 -K 4 - K101 - E10 Figure 5-21 Configuration examples for Active Interface Modules (frame size JI) S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 154 Cabinet Modules 5.4 Active Line Modules C /L + D /L - -T 30 .X 21 - G 1 -F 1 /3 -F 2 /4 - X126 -E 2 - E3 - E4 - T 20 -T 10 - E240 - E241 -W100 Figure 5-22...

- Page 155 Cabinet Modules 5.4 Active Line Modules Parallel connection of Active Line Modules to increase power rating Active Line Modules are available for creating drive line-ups with more power. These modules can be operated in parallel on a common Line Connection Module and are arranged to the right and left of the Line Connection Module.

-

Page 156: Options

Cabinet Modules 5.4 Active Line Modules 5.4.3 Options Note The individual options are described in the chapter titled "Options". Electrical options Component Option CBC10 Communication Board CBE20 Communication Board AOP30 operator panel CU320 Control Unit with CompactFlash card without/with performance enhancement K90/K91 Cabinet anti-condensation heating 25/125 kW braking unit... -

Page 157: Technical Data

Cabinet Modules 5.4 Active Line Modules 5.4.4 Technical data Table 5- 29 Technical data for Active Line Modules (including Active Interface Module), 380 to 480 V 3 AC, part I Order no. 6SL3730- 7TE32- 7TE32- 7TE33- 7TE35- 1BA0 6BA0 8BA0 0BA0 for parallel connection, - attached to Line Connection Module on left side... - Page 158 Cabinet Modules 5.4 Active Line Modules Order no. 6SL3730- 7TE32- 7TE32- 7TE33- 7TE35- 1BA0 6BA0 8BA0 0BA0 Weight (standard version) Frame size FX + FI FX + FI GX + GI GX + GI The base load current I is based on a duty cycle of 150 % for 60 s or I for 5 s with a duty cycle duration of 300 s.

- Page 159 Cabinet Modules 5.4 Active Line Modules Table 5- 30 Technical data for Active Line Modules (including Active Interface Module), 380 to 480 V 3 AC, part II Order no. 6SL3730- 7TE36- 7TE38- 7TE41- 7TE41- 1BA0 4BA0 0BA0 4BA0 for parallel connection, - attached to Line Connection Module on left side ...-0BC0 ...-4BC0...

- Page 160 Cabinet Modules 5.4 Active Line Modules Table 5- 31 Technical data for Active Line Modules (including Active Interface Module), 500 to 690 V 3 AC Order no. 6SL3730- 7TG35- 7TG37- 7TG41- 7TG41- 8BA0 4BA0 0BA0 3BA0 for parallel connection, - attached to Line Connection Module on left side ...-4BC0 ...-0BC0 ...-3BC0...

- Page 161 Cabinet Modules 5.4 Active Line Modules Order no. 6SL3730- 7TG35- 7TG37- 7TG41- 7TG41- 8BA0 4BA0 0BA0 3BA0 Weight (standard version) 1360 1360 1360 Frame size HX + HI JX + JI JX + JI JX + JI The base load current I is based on a duty cycle of 150 % for 60 s or I for 5 s with a duty cycle duration of 300 s.

-

Page 162: Derating Data

Cabinet Modules 5.4 Active Line Modules 5.4.5 Derating data Current derating as a function of the installation altitude and ambient temperature If the cabinet units are operated at an installation altitude > 2000 m above sea level, the maximum permissible output current can be calculated using the following table. The installation altitude and ambient temperature are compensated here. - Page 163 Cabinet Modules 5.4 Active Line Modules Voltage derating as a function of the installation altitude In addition to current derating, voltage derating must also be considered at installation altitudes > 2000 m above sea level. Table 5- 34 Voltage derating as a function of the installation altitude (380 to 480 V 3 AC) Installation altitude Rated converter input voltage above sea level in m...

-

Page 164: Motor Modules In Booksize Format

Cabinet Modules 5.5 Motor Modules in booksize format Motor Modules in booksize format 5.5.1 General information DANGER Hazardous voltages are present in certain parts of this equipment during operation of the cabinet unit. Only qualified personnel may work on the cabinet. Such personnel must be thoroughly familiar with all the warnings and maintenance procedures for the cabinet described in the documentation provided. - Page 165 Cabinet Modules 5.5 Motor Modules in booksize format Integration Figure 5-23 Connection example for Single Motor Modules in Booksize Cabinet Kit format S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 166 Cabinet Modules 5.5 Motor Modules in booksize format Figure 5-24 Connection example for Double Motor Modules in Booksize Cabinet Kit format S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 167 Cabinet Modules 5.5 Motor Modules in booksize format Configuration Motor Modules in booksize format are factory-installed as "Booksize Cabinet Kits" in Booksize Base Cabinets and delivered as a complete unit including cabinet-side connection components. Multiple Booksize Cabinet Kits can be installed in one Base Cabinet, depending on the mounting width requirements, which in turn depend on the power.

- Page 168 Cabinet Modules 5.5 Motor Modules in booksize format C /L + blech -Q 7 D /L - -X 38 - R18 - R 17 - Q2 - Q4 -T 24 - T 1 -A10 C U bl - X55 - X1 - W100 Figure 5-25 Configuration example for Motor Modules in Booksize Cabinet Kit format...

- Page 169 Cabinet Modules 5.5 Motor Modules in booksize format Mounting grid arrangement in the cabinet The area for connecting the Motor Modules in the cabinet is divided into three grid widths: ● 100 mm ● 200 mm ● 300 mm The table below shows the grid width assigned to the various Motor Modules. Table 5- 36 The assignment of the Motor Modules according to grid width Grid width...

-

Page 170: Options

Cabinet Modules 5.5 Motor Modules in booksize format 5.5.3 Options Note The individual options are described in the chapter titled "Options". Electrical options for Booksize Base Cabinets Component Option Second auxiliary voltage busbar system Cabinet anti-condensation heating Mechanical options for Booksize Base Cabinets Component Option Base 100 mm high... -

Page 171: Customer Interface -X55.1

Cabinet Modules 5.5 Motor Modules in booksize format 5.5.4 Customer interface -X55.1 Description The customer terminal block (-X55.1) is mounted as standard in the cabinet for each Booksize Cabinet Kit. It provides the function-related inputs/outputs for temperature monitoring and for the "Safe Torque Off" and "Safe Stop 1" functions. Note All other cabinet interfaces and connections are explained in the circuit and terminal diagrams on the customer CD supplied. -

Page 172: Technical Data

Cabinet Modules 5.5 Motor Modules in booksize format 5.5.5 Technical data Table 5- 38 Technical data for Booksize Base Cabinet Order no. 6SL3720- 1TX38-0AA0 1TX41-2AA0 Usable installation width 1000 Weight (standard version) Dimensions (standard version, IP20) - width 1200 - height 2200 2200 - depth... - Page 173 Cabinet Modules 5.5 Motor Modules in booksize format Table 5- 39 Technical data for Motor Modules in Booksize Cabinet Kit format, Double Motor Modules, line voltage 380 ... 480 V 3 AC, DC link voltage 510 ... 720 V DC Order no.

- Page 174 Cabinet Modules 5.5 Motor Modules in booksize format Table 5- 40 Technical data for Motor Modules in Booksize Cabinet Kit format, Single Motor Modules, line voltage 380 ... 480 V 3 AC, DC link voltage 510 ... 720 V DC, part I Order no.

- Page 175 Cabinet Modules 5.5 Motor Modules in booksize format Table 5- 41 Technical data for Motor Modules in Booksize Cabinet Kit format, Single Motor Modules, line voltage 380 ... 480 V 3 AC, DC link voltage 510 ... 720 V DC, part II Order no.

-

Page 176: Overload Capability

Cabinet Modules 5.5 Motor Modules in booksize format 5.5.6 Overload capability Duty cycle with 30 s and 60 s overload with a duty cycle duration of 300 s Figure 5-26 Duty cycle with 30 s and 60 s overload with a duty cycle duration of 300 s S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A... -

Page 177: Derating Data

Cabinet Modules 5.5 Motor Modules in booksize format 5.5.7 Derating data Current derating as a function of the installation altitude and ambient temperature If the cabinet units are operated at an installation altitude > 2000 m above sea level, the maximum permissible output current can be calculated using the following table. -

Page 178: Motor Modules In Chassis Format

Cabinet Modules 5.6 Motor Modules in chassis format Motor Modules in chassis format 5.6.1 General information DANGER Hazardous voltages are present in certain parts of this equipment during operation of the cabinet unit. Only qualified personnel may work on the cabinet. Such personnel must be thoroughly familiar with all the warnings and maintenance procedures for the cabinet described in the documentation provided. - Page 179 Cabinet Modules 5.6 Motor Modules in chassis format Integration Figure 5-27 Connection example for Motor Modules in chassis format S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 180 Cabinet Modules 5.6 Motor Modules in chassis format Configuration Motor Modules contain the following components as standard: ● Retaining device for the DC busbar, including the interface to the DC connections of the Motor Module. ● The required DC busbar must be obtained separately (options M80 to M87). ●...

- Page 181 Cabinet Modules 5.6 Motor Modules in chassis format C /L + -Q 7 - F 5 - F 1 - F 2 D /L - -R 17-R 18 -T 30 .X 21 -T 1 - X126 -E 1 -X 9 - T 10 - X55 H utschiene _ M oM o_ F...

- Page 182 Cabinet Modules 5.6 Motor Modules in chassis format - R17 ,- R18 C /L + - R 19 , -R 20 - Q 7 - F5 D /L - - F 1 - F 3 -F 2 - F 4 -T 30 .X 21 -T 1 - X126...

- Page 183 Cabinet Modules 5.6 Motor Modules in chassis format Parallel connection of Motor Modules to increase power rating The following rules must be observed when connecting Motor Modules in parallel: ● Up to 4 identical Motor Modules can be connected in parallel. ●...

- Page 184 Cabinet Modules 5.6 Motor Modules in chassis format Minimum cable lengths for parallel connection and connection to a motor with a single-winding system NOTICE The minimum motor cable lengths specified in the table below must be observed when two or more Motor Modules are connected in parallel and there is a connection to a motor with a single-winding system.

-

Page 185: Options

Cabinet Modules 5.6 Motor Modules in chassis format 5.6.3 Options Note The individual options are described in the chapter titled "Options". Electrical options Component Option CBC10 Communication Board CBE20 Communication Board AOP30 operator panel SMC 10/20/30 Sensor Modules K46, K48, K50 Second auxiliary voltage busbar system Terminal module for activating "Safe Torque Off"... -

Page 186: Customer Interface -X55

Cabinet Modules 5.6 Motor Modules in chassis format 5.6.4 Customer interface -X55 This chapter describes only those interfaces in the cabinet unit that require additional connection work by the customer. All other interfaces are pre-wired at the factory and are not designed for customer connections. - Page 187 Cabinet Modules 5.6 Motor Modules in chassis format -X4: Terminal block Table 5- 47 -X4: Terminal block Terminal Designation Technical specifications Assigned only if the CU320 Control Unit is present (option K90/K91). EP M1 Supply voltage: 24 V DC (20.4 V - 28.8 V) (Enable Pulses) Current consumption: 10 mA EP +24 V...

-

Page 188: Technical Data

Cabinet Modules 5.6 Motor Modules in chassis format 5.6.5 Technical data Table 5- 48 Technical data for Motor Modules in chassis format, line voltage 380 ... 480 V 3 AC, DC link voltage 510 ... 720 V DC, part I Order no. - Page 189 Cabinet Modules 5.6 Motor Modules in chassis format Order no. 6SL3720- 1TE32- 1TE32- 1TE33- 1TE33- 1TE35- 1TE36- 1AA0 6AA0 1AA0 8AA0 0AA0 1AA0 Dimensions (standard version, IP20) - width - height 2200 2200 2200 2200 2200 2200 - depth Weight, approx. (standard version) Frame size Rated output of a typ.

- Page 190 Cabinet Modules 5.6 Motor Modules in chassis format Table 5- 49 Technical data for Motor Modules in chassis format, line voltage 380 ... 480 V 3 AC, DC link voltage 510 ... 720 V DC, part II Order no. 6SL3720- 1TE37- 1TE38- 1TE41-...

- Page 191 Cabinet Modules 5.6 Motor Modules in chassis format Order no. 6SL3720- 1TE37- 1TE38- 1TE41- 1TE41- 1TE41- 5AA0 4AA0 0AA0 2AA0 4AA0 Weight, approx. (standard version) Frame size Rated output of a typ. 6-pole standard induction motor based on I or I at 400 V 3 AC 50 Hz.

- Page 192 Cabinet Modules 5.6 Motor Modules in chassis format Table 5- 50 Technical data for Motor Modules in chassis format, line voltage 500 ... 690 V 3 AC, DC link voltage 675 ... 1035 V DC; part I Order no. 6SL3720- 1TG28- 1TG31- 1TG31-...

- Page 193 Cabinet Modules 5.6 Motor Modules in chassis format Order no. 6SL3720- 1TG28- 1TG31- 1TG31- 1TG31- 1TG31- 1TG32- 5AA0 0AA0 2AA0 5AA0 8AA0 2AA0 Dimensions (standard version, IP20) - width - height 2200 2200 2200 2200 2200 2200 - depth Weight, approx. (standard version) Frame size Rated output of a typ.

- Page 194 Cabinet Modules 5.6 Motor Modules in chassis format Table 5- 51 Technical data for Motor Modules in chassis format, line voltage 500 ... 690 V 3 AC, DC link voltage 675 ... 1035 V DC; part II Order no. 6SL3720- 1TG32- 1TG33- 1TG34-...

- Page 195 Cabinet Modules 5.6 Motor Modules in chassis format Order no. 6SL3720- 1TG32- 1TG33- 1TG34- 1TG34- 1TG35- 6AA0 3AA0 1AA0 7AA0 8AA0 Dimensions (standard version, IP20) - width - height 2200 2200 2200 2200 2200 - depth Weight, approx. (standard version) Frame size Rated output of a typ.

- Page 196 Cabinet Modules 5.6 Motor Modules in chassis format Table 5- 52 Technical data for Motor Modules in chassis format, line voltage 500 ... 690 V 3 AC, DC link voltage 675 ... 1035 V DC; part III Order no. 6SL3720- 1TG37- 1TG38- 1TG38-...

- Page 197 Cabinet Modules 5.6 Motor Modules in chassis format Order no. 6SL3720- 1TG37- 1TG38- 1TG38- 1TG41- 1TG41- 4AA0 1AA0 8AA0 0AA0 3AA0 Dimensions (standard version, IP20) - width - height 2200 2200 2200 2200 2200 - depth Weight, approx. (standard version) Frame size Rated output of a typ.

-

Page 198: Overload Capability

Cabinet Modules 5.6 Motor Modules in chassis format 5.6.6 Overload capability The Motor Modules in chassis format are equipped with an overload reserve to handle breakaway torques, for example. In the case of drives with overload requirements, the appropriate base load current must, therefore, be used as a basis for the required load. -

Page 199: Derating Data

Cabinet Modules 5.6 Motor Modules in chassis format 5.6.7 Derating data Current derating as a function of the installation altitude and ambient temperature If the cabinet units are operated at an installation altitude > 2000 m above sea level, the maximum permissible output current can be calculated using the following table. - Page 200 Cabinet Modules 5.6 Motor Modules in chassis format Voltage derating as a function of the installation altitude In addition to current derating, voltage derating must also be considered at installation altitudes > 2000 m above sea level. Table 5- 55 Voltage derating as a function of the installation altitude (380 to 480 V 3 AC) Installation altitude Rated converter input voltage...

- Page 201 Cabinet Modules 5.6 Motor Modules in chassis format Derating factors when the pulse frequency is increased The following table shows the derating factors for the output current when the pulse frequency is increased. The derating factors must be applied to the currents specified in the technical data.

-

Page 202: Central Braking Modules

Cabinet Modules 5.7 Central Braking Modules Central Braking Modules 5.7.1 General information DANGER Hazardous voltages are present in certain parts of this equipment during operation of the cabinet unit. Only qualified personnel may work on the cabinet. Such personnel must be thoroughly familiar with all the warnings and maintenance procedures for the cabinet described in the documentation provided. - Page 203 Cabinet Modules 5.7 Central Braking Modules WARNING The fan is switched on and off by means of a temperature control, which prevents it from running unnecessarily. The fan can start up on its own. WARNING The Braking Module incorporated into the Central Braking Module is able to support a higher braking power than standard braking resistors.

- Page 204 Cabinet Modules 5.7 Central Braking Modules Integration Cabinet Module DC busbar C -X1 G -X5 Central Braking Module Overcurrent Overload Inhibit/ Overtemp reset Ready Relay Ready Fault Auxiliary power supply: 380 to 480 V 2 AC or 500 to 690 V 2 AC 230 V AC 24 V DC to drive control...

- Page 205 Cabinet Modules 5.7 Central Braking Modules Configuration Central Braking Modules are designed in a 400 mm wide Cabinet Module. The Central Braking Modules are connected to the overhead DC busbar using fuses. The Central Braking Module comprises: ● Braking Module ●...

- Page 206 Cabinet Modules 5.7 Central Braking Modules -F 19 -F 21 C /L + -F 20 D /L - - F22 D C _C hop - Sich -C 68 -C 69 - R 68 - R 69 -T 10 - F23 - X240 -E 10 -X 5.1...

-

Page 207: Options

Cabinet Modules 5.7 Central Braking Modules Parallel connection of Central Braking Modules To increase the braking power, it is permissible for Central Braking Modules to be connected in parallel under the following conditions: ● A separate braking resistor must be connected to each Central Braking Module. ●... -

Page 208: Interfaces

Cabinet Modules 5.7 Central Braking Modules 5.7.4 Interfaces Description The Central Braking Module has the following interfaces: ● Control terminals (Disable/Reset, Ready, Fault) ● Braking resistor connection ● Reset key ● Threshold switch ● Braking resistor monitoring ● Switch-on ratio of the braking resistor S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A... - Page 209 Cabinet Modules 5.7 Central Braking Modules Interface overview Figure 5-34 Interface overview for the Central Braking Module S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 210 Cabinet Modules 5.7 Central Braking Modules -X2, control terminals Terminal Function Meaning Technical specifications DI 24V 0 = Normal operation 24 V AC/V DC, input load approximately 10 mA ground 1 = Disable, reset (connection not required) Ground Ground DO.COM Mid-position contact Centralized fault indication for: No DC link voltage, overtemperature, overload, short...

- Page 211 Cabinet Modules 5.7 Central Braking Modules Table 5- 58 Response thresholds of the Braking Module Rated voltage Response Switch Comments threshold position 380 ... 480 V 774 V 774 V is the default factory setting. With line voltages of between 380 and 400 V, the response threshold can be set to 673 V to reduce the voltage stress on 673 V the motor and converter.

- Page 212 Cabinet Modules 5.7 Central Braking Modules PD, switch-on ratio of the braking resistor The braking resistor's switch-on ratio (ratio between ON time and OFF time) is set via potentiometer PD. The setting made is only evaluated when activated via the S3 switch. The adjustable values for the switch-on ratio at potentiometer PD correspond to the graphic below.

-

Page 213: Technical Data

Cabinet Modules 5.7 Central Braking Modules 5.7.5 Technical data Table 5- 59 Technical data for Central Braking Modules Order no. 6SL3700- 1AE35- 1AE41- 1AF35- 1AF41- 1AH36- 1AH41- 0AA1 0AA1 5AA1 1AA1 3AA1 2AA1 Line voltage 380 ... 480 500 ... 600 660 ... - Page 214 Cabinet Modules 5.7 Central Braking Modules Order no. 6SL3700- 1AE35- 1AE41- 1AF35- 1AF41- 1AH36- 1AH41- 0AA1 0AA1 5AA1 1AA1 3AA1 2AA1 Weight, approx. (standard version) Frame size Power demand of fans. The specified power loss equals the maximum value at 100 % capacity utilization. The value in normal operation is lower.

-

Page 215: Braking Resistor

Cabinet Modules 5.7 Central Braking Modules 5.7.6 Braking resistor 5.7.6.1 Description The regenerative energy of the drive line-up is dissipated via the braking resistor. The braking resistor is connected to a Braking Module. The braking resistor is positioned outside the cabinet or switchgear room. This enables the resulting heat loss to be dissipated, thereby reducing the amount of air conditioning required. -

Page 216: Duty Cycle

Cabinet Modules 5.7 Central Braking Modules Note Sufficient space must be available for dissipating the energy converted by the braking resistor. A sufficient distance from flammable objects must be ensured. The braking resistor must be installed as a free-standing unit. Objects must not be placed on or anywhere above the braking resistor. -

Page 217: Interfaces On The Braking Resistor

Cabinet Modules 5.7 Central Braking Modules 5.7.6.4 Interfaces on the braking resistor Power connections on the braking resistor Table 5- 60 Power connections on the braking resistor Terminal Function Connection to the Central Braking Module: -X5 Connection to the Central Braking Module: -X5 PE connection max. -

Page 218: Technical Data

Cabinet Modules 5.7 Central Braking Modules 5.7.6.6 Technical data Table 5- 62 Technical data of the braking resistors Order no. 6SL3000- 1BE35- 1BE41- 1BF35- 1BF41- 1BH36- 1BH41- 0AA0 0AA0 5AA0 1AA0 3AA0 2AA0 Line voltage 380 ... 480 500 ... 600 600 ... - Page 219 Cabinet Modules 5.7 Central Braking Modules Figure 5-38 Dimension drawing type 1 Figure 5-39 Dimension drawing type 2 S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 220 Cabinet Modules 5.7 Central Braking Modules Figure 5-40 Dimension drawing type 3 S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

-

Page 221: Auxiliary Power Supply Modules

SINAMICS S120 Cabinet Modules as well as to other external loads. Among other things, the fans of the SINAMICS S120 devices installed in the Cabinet Modules are connected to this busbar system. In addition, the auxiliary voltage busbar system supplies the electronics modules with external 24 V DC. - Page 222 Cabinet Modules 5.8 Auxiliary Power Supply Modules Integration Figure 5-41 Connection example for Auxiliary Power Supply Modules S120 Cabinet Modules Equipment Manual Manual, (GH5), 10/2008, A5E00427098A...

- Page 223 Cabinet Modules 5.8 Auxiliary Power Supply Modules Configuration The Auxiliary Power Supply Module is connected on the plant side to a voltage corresponding to the respective rated device voltage. The standard version contains the following components: ● Fuse switch disconnector with fuse monitoring for external evaluation ●...

- Page 224 Cabinet Modules 5.8 Auxiliary Power Supply Modules C/ L + D/ L - - T15 - T 14 - X40 - Q 4 -Q 3 - Q 2 Auxblech - Q 1 -X 47 - F 1 - F 2 - F 3 - X45 - X46 - E240...

-

Page 225: Options