Toro 30856 Groundsmaster 4500-D Operator's Manual

Traction unit

Hide thumbs

Also See for 30856 Groundsmaster 4500-D:

- Service manual (474 pages) ,

- Operator's manual (92 pages) ,

- Installation instructions manual (28 pages)

Summary of Contents for Toro 30856 Groundsmaster 4500-D

- Page 1 Form No. 3350–582 Groundsmaster 4500-D Groundsmaster Traction Unit Model No. 30856—Serial No. 230000701 and Up Operator’s Manual English (EN, GB)

-

Page 2: Table Of Contents

........The Toro General Commercial Products Warranty . -

Page 3: Introduction

Whenever you need service, genuine Toro parts, or Training additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and Read the operator’s manual and other training material serial numbers of your product ready. The numbers can be carefully. - Page 4 Preparation – machine speeds should be kept low on slopes and during tight turns; While mowing, always wear substantial footwear, long – stay alert for humps and hollows and other hidden trousers, hard hat, safety glasses, and hearing hazards; protection. Long hair, loose clothing, or jewelry may get tangled in moving parts.

-

Page 5: Toro Riding Mower Safety

The following list contains safety information specific to Maintenance and Storage Toro products or other safety information that you must know that is not included in the CEN, ISO, or ANSI Keep all nuts, bolts and screws tight to be sure the standard. -

Page 6: Sound Pressure Level

When operating a machine on slopes, by banks, or drop To ensure safety and accuracy, have an Authorized Toro offs, always have ROPS (roll–over protection system) Distributor check the maximum engine speed with a installed. -

Page 7: Vibration Level

Vibration Level Whole Body This unit does not exceed a vibration level of 0.5 m/s Hand-Arm the posterior based on measurements of identical machines per ISO 2631 procedures. This unit does not exceed a vibration level of 2.5 m/s the hands based on measurements of identical machines per ISO 5349 procedures. - Page 8 105-9223 (Affix over part no. 105–3890 for CE) 105-3888 1. Warning—read the Operator’s Manual. 1. Read the Operator’s Manual. 2. To start the engine (read the Operator’s Manual ), sit in the 2. To lock the parking brake, secure the brake pedals with the operator’s position, turn the ignition key to the Engine–run locking pin, press the brake pedals, and pull out the the parking position until the Engine–preheat light turns off, turn the ignition...

- Page 9 106-6754 1. Warning—do not touch the hot surface. 2. Cutting/dismemberment hazard, fan and entanglement hazard, belt—stay away from moving parts 105-9830 (Affix for CE) 1. Lock 2. Unlock 93-6686 2. Read the Operator’s 1. Hydraulic oil Manual. 105-9895...

- Page 10 105–3889 107-1983 (Affix over part no. 105–3889 for CE) 1. Warning—read the 3. Thrown object hazard—keep 4. Cutting hazard of hand or 5. Tipping hazard—do not drive Operator’s Manual. bystanders a safe distance foot—stay away from the machine on a slope from the machine.

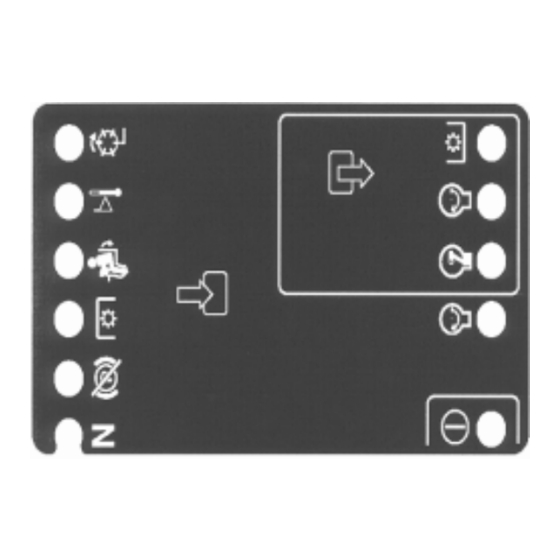

- Page 11 105-3890 1. Lower the cutting unit(s). 4. Center cutting units 7. Continuous variable setting 11. Power Take-off (PTO) 2. Raise the cutting unit(s). 5. Left cutting unit 8. Slow 12. High (GM 4700–D only) 3. Right cutting unit 9. Engage 13.

-

Page 12: Specifications

Specifications Traction Unit Specifications Kubota, four-cycle, four cylinder, 122 in. displacement, water-cooled turbo diesel Engine engine. Rated 58 hp @ 2600 RPM, 23:1 compression ratio. Low idle—1300 RPM, high idle—2800 RPM. Oil capacity is 8 qt. (7.6 l) with filter. Cooling system Capacity is 2-3/4 gallons (10.4 l) of 50/50 mixture of ethylene glycol anti-freeze. -

Page 13: Measurements

Measurements Width of cut 109 in. (2.8 m) Overall width cutting units down 112.8 in. (286 cm) cutting units up (transport) 88.25 in. (224 cm) Overall length 145.8 in. (370 cm) Height with ROPS 85 in. (216 cm) Ground clearance 6 in. -

Page 14: Setup

Read before operating the machine. Engine manual Operator Video View before operating machine Registration card Fill out and return to Toro Installing the Seat, Seat Belt, Greasing the Machine and Manual Tube Before the machine is operated, it must be greased to ensure proper lubrication. -

Page 15: Before Operating

Before Operating Caution If you leave the key in the ignition switch, someone could accidently start the engine and seriously injure you or other bystanders. Remove the key from the ignition before you do any maintenance. Figure 2 1. Oil fill cap Checking the Engine Oil 5. -

Page 16: Filling The Fuel Tank

Caution If the engine has been running, the pressurized, hot coolant can escape and cause burns. Do not open the radiator cap when the engine is running. Use a rag when opening the radiator cap, and open the cap slowly to allow steam to escape. 2. -

Page 17: Checking The Hydraulic Fluid

Checking the Hydraulic Fluid Mobil. Contact your local Toro Distributor for details. This oil is available in 5 gallon (19 l) containers from your Toro Distributor, order part no. 100–7674. The machines reservoir is filled at the factory with approximately 7.5 gallons of high quality hydraulic fluid. -

Page 18: Checking The Rear Axle Lubricant

Check Tire Pressure The tires are over-inflated for shipping. Therefore, release some of the air to reduce the pressure. The correct air pressure in the tires is 20 psi (138 kPa). Important Maintain the recommended pressure in all tires to ensure a good quality-of-cut and proper machine performance. -

Page 19: Operation

Operation Forward Speed Control Preset the forward speed control (Fig. 8) to limit the amount the traction pedal can be depressed in the forward Note: Determine the left and right sides of the machine direction to maintain a constant mowing speed. from the normal operating position. -

Page 20: Brake Pedals

Brake Pedals Engine Temperature Gauge Two foot pedals (Fig. 10) operate individual wheel brakes This gauge (Fig. 11) indicates the engine coolant for turning assistance, parking, and to aid in obtaining temperature. better side hill traction. A latch connects the pedals for parking brake operation and transport. -

Page 21: Starting And Stopping The Engine

2. Move the throttle control to the low idle position. 3. Turn the ignition key to the Run position. The glow indicator will light. 4. When the glow indicator dims, turn the ignition key to the Start position. Release the key immediately when the engine starts and allow it to return to the Run position. -

Page 22: Checking The Interlock Switches

Checking the Interlock Danger Switches Under certain conditions, diesel fuel and fuel Caution vapors are highly flammable and explosive. A fire or explosion from fuel can burn you and others and can cause property damage. If safety interlock switches are disconnected or Use a funnel and fill the fuel tank outdoors, in damaged the machine could operate unexpectedly an open area, when the engine is off and is cold. -

Page 23: Pushing Or Towing The Machine

Pushing or Towing the Machine Tie Downs In an emergency, the machine can be moved forward by On each side of the frame under the front steps actuating the bypass valve in the variable displacement The rear bumper hydraulic pump and pushing or towing the machine. Do not push or tow the machine for more than 1/4 mile (0.4 km). -

Page 24: Operating Tips

High Lift Parallel Sail Important Allow engine to idle for 5 minutes before shutting it off after a full load operation. This allows the The blade generally performs better in the higher heights of turbo charger to cool down before shutting the engine off. cut (2 to 4 inch). - Page 25 Optional Equipment Configuration High Lift Parallel Sail Blade Standard Angle Sail DO NOT USE Mulching Baffle Roller Scraper Blade WITH MULCHING BAFFLE Has been shown to Grass Cutting: .75 improve dispersion Recommended in May work well in to 1.75 inch Height and after cut perfor- most applications light or sparse turf...

-

Page 26: Standard Control Module (Scm)

Standard Control Module Output circuits are energized by an appropriate set of input conditions. The three outputs include PTO, ETR, and (SCM) START. Output LED’s monitor relay condition indicating the presence of voltage at one of three specific output The Standard Control Module is a ”potted” electronic terminals. - Page 27 Each row (across) in the logic chart below identifies input and output requirements for each specific product function. Product functions are listed in the left column. Symbols identify specific circuit condition including: energized to voltage, closed to ground, and open to ground. –...

-

Page 28: Maintenance

Maintenance Note: Determine the left and right sides of the machine from the normal operating position. Recommended Maintenance Schedule Maintenance Service Maintenance Procedure Interval Check the alternator belt tension. After first 10 hours Torque the wheel lug nuts. Change the engine oil and filter. After first 50 hours Check the engine RPM (at idle and full throttle). -

Page 29: Daily Maintenance Checklist

Daily Maintenance Checklist Duplicate this page for routine use. For the week of: Mon. Tues. Wed. Thurs. Fri. Sat. Sun. Maintenance Check Item Check the safety interlock operation. Check the brake operation. Check the engine oil and fuel level. Check the cooling system fluid level. Drain the water/fuel separator. -

Page 30: Service Interval Chart

Service Interval Chart Caution If you leave the key in the ignition switch, someone could accidently start the engine and seriously injure you or other bystanders. Remove the key from the ignition before you do any maintenance. -

Page 31: Greasing The Bearings And Bushings

Greasing the Bearings and Bushings The machine has grease fittings that must be lubricated regularly with No. 2 General Purpose Lithium Base Grease. If the machine is operated under normal conditions, lubricate all bearings and bushings after every 50 hours of operation or immediately after every washing. -

Page 32: Hood Removal

Hood Removal To gain additional access to engine compartment, the hood may be removed from traction unit. 1. Release hood latches (Fig. 21) and raise hood. Figure 19 Figure 21 1. Hood latch 2. Unhook lanyard from hood pin, remove pin and slide hood tubes rearward off guides (Fig. -

Page 33: Servicing The Air Cleaner

Servicing the Air Cleaner Check the air cleaner body for damage which could possibly cause an air leak. Replace a damaged air cleaner body. Service the air cleaner filters when the air cleaner indicator (Fig. 24) shows red or every 400 hours (more frequently in extremely dusty or dirty conditions). -

Page 34: Servicing The Engine Oil And Filter

5. Inspect the new filter for shipping damage. Check the sealing end of the filter. Do not install a damaged filter. 6. Insert the new filter properly into the air cleaner body. Make sure that the filter is sealed properly by applying pressure to the outer rim of the filter when installing it. -

Page 35: Bleeding Air From The Injectors

Fuel Lines and Connections 2. Loosen the hose clamps at both ends of the filter and pull the fuel lines off of the filter. Check the fuel lines and connections every 400 hours or yearly, whichever comes first. Inspect them for deterioration, damage, or loose connections. -

Page 36: Servicing The Engine Cooling System

5. Repeat the procedure on the remaining nozzles. Servicing the Engine Cooling System Remove debris from the engine area, oil cooler and radiator daily. Clean them more frequently in dirty conditions. 1. Unlatch and swing open rear screen (Fig. 32). Clean the screen thoroughly of all debris. -

Page 37: Adjusting The Throttle

800 operating hours, in normal conditions. 2. Start the engine. Plug the normal muffler exit with a Use Toro replacement filters Part No. 94-2621 for the rear block of wood or metal plate so that the exhaust flow (cutting unit) of the machine and 75-1310 for the front will be forced out of the clean-out port. -

Page 38: Checking The Hydraulic Lines And Hoses

Hydraulic System Test Ports The test ports are used to test the pressure in the hydraulic circuits. Contact your local Toro distributor for assistance. Test Port “A” (Fig. 39), located on rear of filter manifold, under right hand frame rail. Used to measure the traction system charge pressure. - Page 39 Test Port “B” (Fig. 40), located on side of counter balance Test Port “F” (Fig. 42), located on top of right hand deck manifold, under operators seat. Used to measure the manifold. Used to measure cutting unit circuit pressure for counter balance pressure applied to cutting units for cutting units 5, 2 and 3.

-

Page 40: Adjusting Counterbalance

Adjusting Counterbalance The counterbalance dial (Fig. 44) is used to adjust the pressure in the counterbalance circuit. Recommended counterbalance pressure is 620 psi. Rotate the adjusting dial (Fig. 44) clockwise to increase the pressure or counterclockwise to decrease the pressure. Adjust Length Figure 45... -

Page 41: Changing The Planetary Gear Drive Oil

Changing the Planetary Gear Drive Oil Change the oil initially after first 200 hours of operation. Thereafter change the oil every 800 hours, or yearly, whichever occurs first. Use a high quality SAE 85W-140 wt. gear lube. 1. With the machine on a level surface, position the wheel so that the check/drain plug (Fig. -

Page 42: Checking The Rear Wheel Toe-In

Checking the Rear Wheel Charging and Connecting the Toe-In Battery After every 800 operating hours or annually, check the rear Warning wheel toe-in. 1. Measure the center-to-center distance (at axle height) at CALIFORNIA the front and rear of the steering tires. The front measurement must be 1/8 in. -

Page 43: Battery Care

Wash hands after wash the entire case with a solution of baking soda and handling. water. Rinse with clear water. Coat the battery posts and cable connectors with Grafo 112X (skin-over) grease (Toro Part No. 505-47) or petroleum jelly to prevent corrosion. -

Page 44: Fuses

Fuses There are 4 fuses in the electrical system. They are located under the operators control panel (Fig. 53). 1. Rotate latches and remove control panel cover. Figure 53 1. Fuse block... -

Page 45: Electrical Schematic

Electrical Schematic... -

Page 46: Hydraulic Schematic

Hydraulic Schematic... -

Page 47: Preparing For Seasonal Storage

C. Coat the cable terminals and battery posts with area. Grafo 112X skin-over grease (Toro Part No. 505-47) or petroleum jelly to prevent corrosion. D. Slowly recharge the battery every 60 days for 24... -

Page 48: The Toro General Commercial Products Warranty

If for any reason you are dissatisfied with your Distributor’s service or have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.