Table of Contents

Advertisement

Save This Manual For

Future Reference

Dust CoBlection

System

Serial

Number

Model and serial number may be

found on the motor cover.

You should record both model and

serial number in a safe place for

future use.

FOR YOUR

SAFETY:

READ

ALL

INSTRUCTIONS

CAREFULLY.

\

DUST COLLECTION

S YS TEM

° assembmy

o operation

"parts

o repamr

Sold by SEARS, ROEBUCK

AND CO., Chicago,

IL. 60684 U.S.A.

Part No. SP5373

Printed in Taiwar_

Advertisement

Table of Contents

Summary of Contents for Craftsman SP5373

- Page 1 FOR YOUR SAFETY: READ INSTRUCTIONS CAREFULLY. Sold by SEARS, ROEBUCK Part No. SP5373 DUST COLLECTION S YS TEM ° assembmy o operation "parts o repamr AND CO., Chicago, IL. 60684 U.S.A.

-

Page 2: Warranty Information

FULL:ONEYEAR WARRANTY If within 0ne year from the date of purchase, thls Craftsman Dust Collection System falls due to a defect in maierlal0r workmanship; Sears wil! repair it, free of charge; WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE CENTER/ DEPARTMENTTHROUGHOUT THE UNITED STATES. - Page 3 CAUTION: if usingthts Dust Collection System to help keep airborne wood dust in heavy usage within acceptable limits, you must regularly monitor air borne dust andmaintain Dust Collection to avoid exceeding dust limits. Each application unique. Your maintenance schedule must, there- fore, be tailored to your specific use of this Dust Col- lection System.

- Page 4 AFETY KNOWYOUR TOOL Read and undersiarid owner's manual 3tt_xed to the tOOl [:.earn its appiicalion nuns as welt as its(specffic potenl.iat hazards uafiar tolhis tOoL 2, _ GROUND THE TOOL This Io01 is equipped with an approved cord and a 3prong grounding type plug to tit the proper grounding...

-

Page 5: Table Of Contents

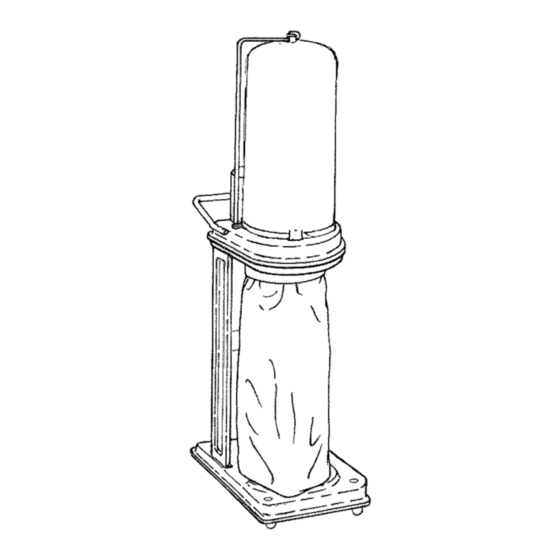

,i introduction The Craftsman Dust Collection System is specifically designed to capture sawdust and wood chips at the source. The fine dust is filtered by the upper bag while heavy particles settle in the lower bag for easy removal. -

Page 6: Unpacking And Checking Carton Contents

I_NPAC_KiR_ i_::_ _HECKING €ONTENTSI! CARTON CONTENTS LISTf Descrlptlon A _; FiltedDust Bag ... Fitter/Dust Bag Hanger Handle..Filtration Housing ... 1 inlet Guard ... F : ::Right Side Support Leg ... 1 Loose Parts Bag ... Rear Fixed Casters ... Base Plate ...:... -

Page 7: Mounting Front Pivoting Casters

assembmy MOUNTING FRONT PRVOTING CASTERS 1, Locate the following items from the loose parts bag: Description A Pivoting Casters ... 2 B Hex Nuts* (3/8 - 16) ... 2 C Flat Washers* (3/8 x 3/4) ... 4 D Acorn Nuts*, ... E Base Plate ... -

Page 8: Mounting Support Legs

4i Support the opposite side of Filtration Housingw_th a b[()ck of wood_ A;:Ptace:O÷Ring in relief of Inlet pipe (See page!8) 5.: Position Inlet Guardin tine with the threaded holes On the base of the Filtration Housing. NOTE: Makesureinlet Guard is pointing to rear of machine_ 6. -

Page 9: Mounting Inlet Bracket

MOUNTING INLET BRACKET 1, Locate the following items from the loose parts bag: Description Flat Washers* (5/16x 11/16xl/!6) B Hex Screws* (M8 x 1.25 - 12) ... 2 Flat Washers *(1/4 x 1/2) ... 2 D Hex Screws* (M6 x 1 - 12) ... 2 2, Insert Inlet Bracket between relief flange of Inlet Guard and against inside edge of angle flange on Support Leg. -

Page 10: Mounting Filter/Dust Bag Holder

AG HOLDER 1_ LoCate the foUowing items from the loose parts bag: Description ...A Hex Nut* (M6 X 1) ... B Lockwasher* (1/4) ... C Flat Washer* (1/4x 1/2) ... 2_ Attach hexnut to threaded portion of Filter/Dust Bag Holderand place lockwasher and flat washer on nut as shown. -

Page 11: Chip Bag Assembly

CHiP BAG ASSEMBLY LOWER FiLTRATiON HOUSING 1. Insert lower Chip Bag by tilting the Metal Reinforced Bandat an angle and position it through the hole inthe lower Filtration Housing. 2. Tuck one side of the Band under the Sawdust Chute Extension. 3. -

Page 12: Operation

ii:i;ii!ii!iiii!iiiiii i i!i !ii I'H iiii: : ThliS _Dust!i¢olie_ion System i!s designed to be corn netted directly t0:thewoodwOrking machines. Pieasel useoniythel_artS provided for maximum effJctency: 4!!IDiameterx :_4)" Hose_ PVC Vulcanized rubbe_ with wire reinforcement and 2- 4'_clamps_ • i•• • _I ii _-_ Bandsaws: Belt and Disk Sanders: arid Radial... -

Page 13: Onloff Switch

rlqplll i ... ON ! OFF SWITCH On the rear of the Motor Housing above the Handle, is the Switch Box. The ON!OFF Switch has the ability to be turned "ON" when the Red Key is properly installed. Switch to the "ON" position by moving the switch upward. -

Page 14: Grounding Instructions

'... " " "... TION: CONNECT TO _ A::120Vi 15"AMP, CIRCUIT AND USEA15=AMP,TIME CIRCUIT BREAKER; FAILURE TO CONNECT THIS WAY CAN RESULT IN INJURY FROI_I SHOCK OR FIRE, Your Dust Collection System must be properly grounded: Not all outlets are properly grounded, are not sure that your outlet is propedy have it checked by a qualified electrician WARNtNG:... -

Page 15: Chip Collecting Bag Removal

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH "OFF" AND REMOVE PLUG FROM POWER SOURCE OUTLET BEFORE MAINTAINING DUST COLLECTION SYSTEM ... WARNING: TO AVOID INJURY FROM ELEC- TRIC SHOCK OR SUDDENLY STARTING UNIT, AL- WAYS REMOVE SWITCH KEY AND KEEP UN- PLUGGED WHILE UNIT IS DISASSEMBLED tN ANY WAY. -

Page 16: Motor

MOTOR Excessive dust fin _tO_: could cause excessive heat: in motor. Every effort shou!d be imade _to: prevent foreign material fromenteting the motor:i When operated ur_ler condi- tions likely to permit accumtllations of dust, dirt;or waste within the motor, a visual inspection should be made at frequent intervals. - Page 17 PROBLEM PROBABLE Excessive noise. 1. Motor " Motor fails to devet- Circuit overloaded with op full power. NOTE: LOW VOL- lights, appliances and other motors. TAGE: (Power out- Undersize extension cord put of motor de- or extension cord too creases rapidly with decrease in voltage long.

- Page 18 PARTS!LIsT, FOR!; : CRAFTSMAN DUST COLLECTION SYSTEM MODEL 113.299780 ,'_"...

- Page 19 PARTS LiST FOR CRAFTSMAN Always order Item Part De _rlptton 819166 Filler/Dust 819172 1 H P 819187 Sw :ch 819302 Switch 819189 with Plug 819191 STD833025 ,Hex Hd M6x 1-25 819192 Plug, Plastic 819171 Housing, Upper STD551125 Lockwasher, STD840610...

-

Page 20: Repair Parts

Dust Collection System HOW TO ORDER REPAIR PARTS ill i i i Sold by SEARS. Part No. SP5373 DUST COLLECTmON SYSTEM Service is available nearest Sears Service Center/Department out the United States. Model and serial numbers Cover of your Dust Collection...