Siemens SITRANS F Operating Instructions Manual

Variable area flowmeter

Hide thumbs

Also See for SITRANS F:

- Function manual (350 pages) ,

- Instruction manual (306 pages) ,

- Operating instructions manual (278 pages)

Table of Contents

Advertisement

Quick Links

SITRANS FVA250

SITRANS F

Variable area flowmeter

SITRANS FVA250

Operating Instructions

___________________

Introduction

___________________

Safety notes

___________________

Description

___________________

Installing/Mounting

___________________

Connecting

___________________

Commissioning

___________________

Service and maintenance

___________________

Technical data

___________________

Dimensions and weight

1

2

3

4

5

6

7

8

9

Advertisement

Table of Contents

Summary of Contents for Siemens SITRANS F

- Page 1 ___________________ Introduction ___________________ Safety notes ___________________ SITRANS FVA250 Description ___________________ Installing/Mounting ___________________ Connecting SITRANS F ___________________ Commissioning Variable area flowmeter ___________________ Service and maintenance SITRANS FVA250 ___________________ Technical data Operating Instructions ___________________ Dimensions and weight...

- Page 2 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 3: Table Of Contents

Table of contents Introduction..............................5 Items supplied ..........................5 Scope of delivery ...........................5 Transportation and storage......................6 History ............................7 Further Information ........................7 Safety notes............................... 9 Hot surfaces resulting from hot process media ................9 Laws and directives ........................9 Installation in hazardous area ......................11 Certificates ...........................14 Description............................... - Page 4 Table of contents Output settings ..........................35 6.3.1 Measuring transducer HART with 4-20 mA output / pulse output / limit switches ...... 35 6.3.2 Measuring transducer PROFIBUS....................35 Configuring with HART........................ 35 6.4.1 Commissioning with PDM ......................35 6.4.2 Basic parameter settings......................36 6.4.3 HART parameters ........................

-

Page 5: Introduction

Introduction These instructions contain all the information you need for using the device. The instructions are aimed at persons mechanically installing the device, connecting it electrically, configuring the parameters and commissioning it, as well as service and maintenance engineers. Note It is the responsibility of the customer that the instructions and directions provided in the operating instructions are read, understood, and followed by the relevant personnel before installing the device. -

Page 6: Transportation And Storage

● Devices/replacement parts should be returned in their original packaging. ● If the original packaging is no longer available, ensure that all shipments are properly packaged to provide sufficient protection during transport. Siemens cannot assume liability for any costs associated with transportation damages. -

Page 7: History

Product information on the Internet The Operating Instructions are available on the CD-ROM shipped with the device, and on the Internet on the Siemens homepage, where further information on the range of SITRANS F flowmeters may also be found: Product information on the internet (http://www.siemens.com/flow) - Page 8 Introduction 1.5 Further Information SITRANS FVA250 Operating Instructions, 02/2013, A5E03821131-01...

-

Page 9: Safety Notes

Safety notes CAUTION Correct, reliable operation of the product requires proper transport, storage, positioning and assembly as well as careful operation and maintenance. Only qualified personnel should install or operate this instrument. Note Alterations to the product, including opening or improper modifications of the product, are not permitted. - Page 10 Material compatibility Siemens Flow Instruments can provide assistance with the selection of wetted sensor parts. However, the full responsibility for the selection rests with the customer and Siemens Flow Instruments can take no responsibility for any failure due to material incompatibility.

-

Page 11: Installation In Hazardous Area

Safety notes 2.3 Installation in hazardous area Installation in hazardous area WARNING Equipment used in hazardous areas must be Ex-approved and marked accordingly. It is required that the special conditions for safe use provided in the manual and in the Ex certificate are followed! Hazardous area approvals The device is approved for use in hazardous area zone 1 and has the following approval:... - Page 12 Safety notes 2.3 Installation in hazardous area WARNING With intrinsically safe circuits, use only certified sensors appropriate for the transmitter. If a non-conforming supply unit is used, the "fail-safe" type of protection will no longer be effective and the approval certification will be invalid. Temperature specifications for Ex use Table 2- 2 Maximum ambient temperature (Ta)

- Page 13 Safety notes 2.3 Installation in hazardous area ● Factor for heat input: F = 0.2 ● Temperature class: T4 ● Te = excess temperature ● Ta = ambient temperature at limiting value transmitter (limit switch SJ 3.5-N) Te = Tm − Tamb = 120°C − 40°C = 80°C Ta = (Te* F) + Tamb = (80°C* 0,2) + 40°C = 56°C Figure 2-1 Calculation of ambient temperature at limiting value transmitter (limit switch SJ 3.5-N)

-

Page 14: Certificates

Ex "d" and "nA", permanent cables must be laid. Certificates Certificates are posted on the Internet and on the documentation CD-ROM shipped with the device. See also Certificates on the Internet (http://www.siemens.com/processinstrumentation/certificates) SITRANS FVA250 Operating Instructions, 02/2013, A5E03821131-01... -

Page 15: Description

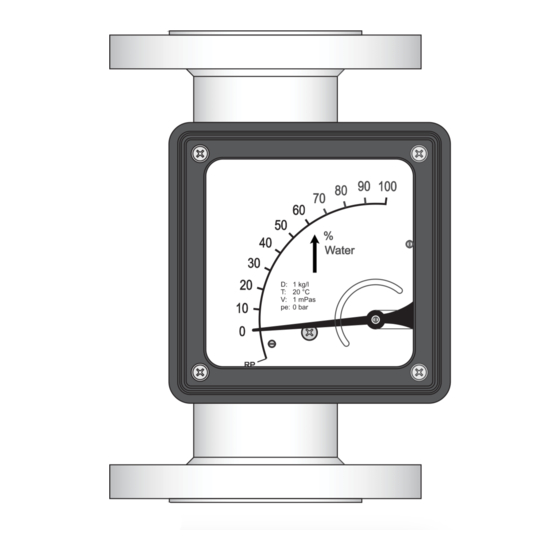

Description The SITRANS FVA250 is suitable for multipurpose measuring of fluids and gases in closed piping systems. The robust design also permits application under harsh conditions. Different flange connections, liners and rotameter materials meet the requirements in the pharmaceutical and chemical industry. System components ●... -

Page 16: Design

Description 3.2 Design Magneto-electrical measurement transducers (MEM) SITRANS FVA250 is optionally available with magneto-electrical measurement transducers for configuration with HART (MEM) or with PROFIBUS PA (MEM-PPA). Figure 3-2 Magneto-electrical measurement transducer (MEM) Design SITRANS FVA250 is an all-metal variable area flowmeter with a standard length of 250 mm (9.84 inch). -

Page 17: Theory Of Operation

Description 3.3 Theory of operation Theory of operation The FVA250 operates according to the principle of flotation. The flowing measuring substance raises the conical float in the measuring ring. In this way the annular gap widens until an equilibrium between the buoyancy of the measuring substance and the weight of the float is achieved. - Page 18 Description 3.3 Theory of operation SITRANS FVA250 Operating Instructions, 02/2013, A5E03821131-01...

-

Page 19: Installing/Mounting

Installing/Mounting SITRANS F flowmeters with minimum IP65/NEMA 4X enclosure rating are suitable for indoor and outdoor installations. ● Make sure that pressure and temperature specifications indicated on the device nameplate / label will not be exceeded. WARNING Installation in hazardous location Special requirements apply to the location and interconnection of sensor and transmitter. -

Page 20: Device Check

Installing/Mounting 4.2 Device check Device check Prior to installation check the functionality of the device: ● Remove the transport protection from the fitting. ● Verify the free mobility of the float. – The float must slide smoothly in the pipe without canting or deadlocking. –... -

Page 21: Mounting The Sensor

Installing/Mounting 4.4 Mounting the sensor Mounting the sensor Before mounting ● Verify that accessories such as spring stop, gas/fluid damping are still correctly seated in the flange. ● Check that the installation clearance between the flanges of the pipe correspond to the fitting dimension of the instrument and additionally 2 gaskets. -

Page 22: Damping

Installing/Mounting 4.5 Damping ● Align the flanges in order to achieve an installation free from strain. ● Use mounting screws and gaskets of the prescribed dimensions. The gaskets must be appropriate for the operating pressure, the temperature and the process media. CAUTION PTFE-lined devices For PTFE-lined instruments, use gaskets where the inner and outer dimensions conform... - Page 23 Installing/Mounting 4.5 Damping Installation and dismounting of the cone/float/damper/spring stop The instrument must be dismounted from the pipe before the float can be removed. After dismounting, clamp the instrument in a horizontal position, ensuring that the fitting is not damaged in the process. The dismounting procedure depends on the variable area flowmeter model.

-

Page 24: Retrofitting Mem Transducers

Installing/Mounting 4.6 Retrofitting MEM transducers Model with cone: Replacing floats for devices with cone (standard measuring ranges up to 5-50 l/h (gases: 0.15 – 1.5 m³/h) cannot be executed by the customer. For this purpose the device has to be returned to the manufacturer. -

Page 25: Connecting

Connecting Wiring MEM / MEM-PPA To connect the magneto-electrical measuring transducer proceed as follows: 1. Remove display cover. 2. Insert cable set via cable gland. 3. Guide signal leads under MEM / MEM-PPA from cable gland to terminal block of magneto-electrical measuring transducer. -

Page 26: Electrical Connection Schematics

Connecting 5.2 Electrical connection schematics Electrical connection schematics 5.2.1 Limit switches Figure 5-1 Terminal diagram for inductive limit switches Figure 5-2 Terminals - one limit switch SITRANS FVA250 Operating Instructions, 02/2013, A5E03821131-01... -

Page 27: Magneto-Electrical Measuring Transducer Hart

Connecting 5.2 Electrical connection schematics Figure 5-3 Terminals - two limit switches 5.2.2 Magneto-electrical measuring transducer HART Figure 5-4 Terminal diagram for magneto-electrical measuring transducer HART SITRANS FVA250 Operating Instructions, 02/2013, A5E03821131-01... -

Page 28: Measuring Transducer Hart With 4-20 Ma Output, Pulse Output And One Limit Switch

Connecting 5.2 Electrical connection schematics Figure 5-5 Terminals - transducer MEM with 4-20 mA output Table 5- 1 Supply current data (EEx ia IIC T6) 240 μH 30 V 16 nF 150 mA 70°C 1000 mW 5.2.3 Measuring transducer HART with 4-20 mA output, pulse output and one limit switch Figure 5-6 Terminal diagram for measuring transducer HART with 4-20 mA output, limit switch and... -

Page 29: Measuring Transducer Hart With 4-20 Ma Output And Two Limit Switches

Connecting 5.2 Electrical connection schematics Figure 5-7 Terminals - transducer MEM with 4-20mA output and binary outputs Table 5- 2 Supply current data (EEx ia IIC T6) 240 μH 3 0V 16 nF 150 mA 70°C 1000 mW Table 5- 3 Binary outputs (EEx ia IIC T6) 4 μH 30 V... -

Page 30: Magneto-Electrical Measuring Transducer Mem-Ppa

Connecting 5.2 Electrical connection schematics Figure 5-9 Terminals - transducer MEM with 4-20 mA output and binary outputs Table 5- 4 Supply current data (EEx ia IIC T6) 240 μH 30 V 16 nF 150 mA 70°C 1000 mW Table 5- 5 Binary outputs (EEx ia IIC T6) 4 μH 30 V... - Page 31 Connecting 5.2 Electrical connection schematics Figure 5-11 Terminals - transducer MEM-PPA Table 5- 6 Supply current data (EEx ia IIC T6) 10 μH 25 V 5 nF 280 mA 70°C 2000 mW SITRANS FVA250 Operating Instructions, 02/2013, A5E03821131-01...

- Page 32 Connecting 5.2 Electrical connection schematics SITRANS FVA250 Operating Instructions, 02/2013, A5E03821131-01...

-

Page 33: Commissioning

Commissioning When starting up the device, the following points must be observed: ● Ensure that the actual operation conditions (pressure, temperature) do not exceed the limits which are given on the nameplate of the device ● Avoid float impacts! Therefore it is recommended to start up with a closed shut-off valve and open it slowly. -

Page 34: Limit Signal Settings

Commissioning 6.2 Limit signal settings Limit signal settings Limit switches (inductive contact) The limit switches can be set over the entire measuring range by varying the position of the limit pointers. CAUTION Unless otherwise desired by the customer, the factory set value for the switching point is for version with one limit switch about 40% of URV (Upper Range Value) and for devices with two limit switches about 20%/80% of URV. -

Page 35: Output Settings

Measuring transducer PROFIBUS The PROFIBUS PA is designed with an interface to provide a digital communication electric circuit in compliance with the FISCO model. The configuration tool for the signal output is "SIMATIC PDM" from Siemens. Configuring with HART 6.4.1... -

Page 36: Basic Parameter Settings

– Type in a name for the field unit, e.g. FVA250. – Make sure that the field unit address is set to 0. – Click on "Assign" and assign the device to MEM (Sensors→Flow→Variable Area→SIEMENS→MEM) and click "OK". 6.4.2 Basic parameter settings... -

Page 37: Hart Parameters

Commissioning 6.4 Configuring with HART 2. Select: "Device->Download to device". 3. Select "Execute even if the device TAG does not match the project data TAG" and click "OK". 6.4.3 HART parameters The available parameters are grouped into the following blocks: Identification General information on devices that enable the clear definition of the device is deposited in this parameter block. - Page 38 Commissioning 6.4 Configuring with HART Input All parameters that are involved in the acceptance of the measured value in the MEM are included in this block. ● Unit The unit of the measured variable is defined via this parameter. The following units are available: –...

- Page 39 Commissioning 6.4 Configuring with HART Outputs This block comprises all parameters that define the behavior of the current output and the binary outputs. ● Power output – power in case of alarm An alarm status of the MEM (see description of self-test) can optionally be displayed at the current output.

-

Page 40: Configuring With Profibus Pa

Commissioning 6.5 Configuring with PROFIBUS PA The dimension unit of the totalizer pursues that of the flow rate (e.g. if the flow rate unit is l/h, the totalizer will measure in liters). Pulses are optionally displayed at binary output N1. It must be observed that the maximum impulse rate amounts to approx. - Page 41 This file is needed for the integration of the device into the PROFIBUS- PA network and will be copied into the subdirectory defined by the programmable controller software. The GSD file can be downloaded from the Siemens homepage (Support-Center). Name of file: PA139700.GSD Device address The device address is used for selecting the device in the system.

-

Page 42: Acyclic Communication

Commissioning 6.5 Configuring with PROFIBUS PA Cyclic communication The master can cyclically read out the "OUT" measured value from the MEM-PPA transmitter. The measured value is represented as a 32-bit floating-point number in accordance with IEEE-754; the corresponding status is represented as an 8-bit word. The unit of the measured value can be selected (see Acyclic communication/unit of measured value). - Page 43 Commissioning 6.5 Configuring with PROFIBUS PA Flow direction The flow direction can be indicated by a sign. If the sign is negative, reverse flow turns into forward flow. Device mode The MEM-PPA measures unidirectional (only forward flow). Filter type (Information field) Normal, strong.

- Page 44 Commissioning 6.5 Configuring with PROFIBUS PA Simulation Instead of the measured value and the status from the Transducer Block, a simulation value and a simulation status can be defined. Simulation can be switched on or off (1 = ON, 0 = OFF).

- Page 45 Commissioning 6.5 Configuring with PROFIBUS PA Here the value "OUT" can be read acyclically. Factory Reset (acyclic communication) The "factory reset" command resets several parameters to their default values. ● Device address: 126 ● Filter time constant: 3 seconds ● Low-flow cutoff: 0 ●...

- Page 46 Commissioning 6.5 Configuring with PROFIBUS PA SITRANS FVA250 Operating Instructions, 02/2013, A5E03821131-01...

-

Page 47: Service And Maintenance

Service and maintenance Maintenance The device is maintenance-free, however, a periodic inspection according pertinent directives and regulations must be carried out. An inspection can include check of: ● Ambient conditions ● Seal integrity of the process connections, cable entries, and cover screws ●... -

Page 48: Recalibration

On conclusion of the maintenance and cleaning work the instruments must be subjected to a function control before being put back into operation. Recalibration Siemens A/S Flow Instruments offers to recalibrate the sensor. The following calibration is offered as standard: ● Standard matched pair calibration Note For recalibration the memory unit must always be returned with the sensor. -

Page 49: Technical Support

● Information about field service, repairs, spare parts and lots more under "Services." Additional Support Please contact your local Siemens representative and offices if you have additional questions about the device. Find your local contact partner at: http://www.automation.siemens.com/partner (http://www.automation.siemens.com/partner) - Page 50 7.6 Return procedures Required forms ● Delivery Note ● Cover Note for Return Delivery with the following information Cover note (http://support.automation.siemens.com/WW/llisapi.dll?func=cslib.csinfo&lang=en&objid= 16604370&caller=view) – product (ordering number) – number of devices or spare parts returned – reason for the return ● Declaration of Decontamination Declaration of Decontamination (http://www.automation.siemens.com/w1/efiles/feldg/files/Service/declaration_of_deconta...

-

Page 51: Technical Data

Technical data Table 8- 1 General data Range of application Flow measurement of liquids and gases Measuring principle Flotation / Float measuring Orientation Vertical - flow direction from bottom to top Table 8- 2 Measuring accuracy Directive VDI / VDE 3513, sheet 2 (qG = 50%) Liquids G 1.6 (add. -

Page 52: Classification According To Pressure Equipment Directive (Ped 97/23/Ec)

Technical data 8.1 Classification according to pressure equipment directive (PED 97/23/EC) Min. operating pressure > 2 x pressure loss (see measuring ranges) Climate classification Weatherproof and/or non-heated locations Class C in accordance with DIN IEC 654 Section 1 Protection class (DIN EN 60529) Display unit Aluminum: IP65 Stainless steel: IP66... -

Page 53: Pressure Vs. Temperature (Stainless Steel)

Technical data 8.2 Pressure vs. temperature (stainless steel) Pressure vs. temperature (stainless steel) Limit switches Switching principle Inductive contact, single contact and twin contact, NAMUR NC Connection M20x1.5 Auxiliary power supply 8 V DC, Ri approx. 1 kOhm Self-inductance 250 μH Self-capacitance 50 nF Ambient temperature... -

Page 54: Mem Transducer Hart With 4-20 Ma

Technical data 8.4 MEM Transducer HART with 4-20 mA MEM Transducer HART with 4-20 mA Electric remote transmitter, signal output HART Connection 2-wire Auxiliary power supply 14 ... 30 V DC Output 4 ... 20 mA Ambient temperature -40 ... +70 °C (-40 ... +158 °F) When used in non-hazardous locations ... -

Page 55: Mem Transducer Profibus Pa

Technical data 8.6 MEM transducer PROFIBUS PA Function Limit signal transducer or pulse output Explosion protection II 2G EEX ia IIC T6 (-40 ... +70 °C [-40 ... +158 °F]) Ui = 30 V DC Ii = 20 mA Pi = 100 mW Li = 4 μH Ci = 16 nF BVS 07 ATEX E 033... - Page 56 Technical data 8.6 MEM transducer PROFIBUS PA SITRANS FVA250 Operating Instructions, 02/2013, A5E03821131-01...

-

Page 57: Dimensions And Weight

Dimensions and weight Figure 9-1 SITRANS FVA250, Standard version (aluminum display housing) Table 9- 1 Dimensions in mm (inch), SITRANS FVA250 standard version I. W. Weight [kg (lbs)] 15 (½") 40 (150 lbs) 26 (1.02) 74 (2.91) 3.0 (6.6) 20 (¾") 40 (150 lbs) 26 (1.02) 74 (2.91) - Page 58 Dimensions and weight Heating jacket version Figure 9-2 SITRANS FVA250, Heating jacket version Table 9- 2 Dimensions in mm (inch), heating jacket version B flange Weight [kg (lbs)] 15 (½") 110 (4.33) 150 (5.91) 4.7 (10.4) 20 (¾") 110 (4.33) 150 (5.91) 4.7 (10.4) 25 (1")

- Page 59 Dimensions and weight Stainless steel version Figure 9-3 SITRANS FVA250, Stainless steel version (stainless steel display housing) Table 9- 3 Dimensions in mm (inch), stainless steel version I. W. Weight [kg (lbs)] 15 (½") 40 (150 lbs) 26 (1.02) 103 (4.06) 3.1 (6.8) 20 (¾") 40 (150 lbs)

- Page 60 Dimensions and weight SITRANS FVA250 Operating Instructions, 02/2013, A5E03821131-01...

-

Page 61: Index

Index Support, 49 Intrinsically safe circuits, 11 Introduction, 5 Items supplied, 5 Applications, 15 Laws and directives, 9 Commissioning with PDM, 35 Communication network, 35 Maintenance, 47 Compliance, 9 Material compatibility, 10 Contact person, 7 Customer Support Hotline, 49 Commissioning, 35 Damping, 22 Pressure Decontamination, 49... - Page 62 Index...