Siemens SINAMICS S120 Function Manual

Safety integrated

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Summary of Contents for Siemens SINAMICS S120

- Page 1 Function Manual 07/2007 SINAMICS S120 Safety Integrated Safety Integrated SINAMICS S120 sinamics...

- Page 3 Preface General information about SINAMICS Safety Integrated System features SINAMICS Basic Functions S120 Safety Integrated Extended Functions Control of the safety functions Function Manual Commissioning Application examples Acceptance test and acceptance report Appendix A Applies for: Firmware Version FW2.5 SP1 (FHS), 07/2007 6SL3097-2AR00-0BP0...

- Page 4 Trademarks All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

-

Page 5: Preface

SIZER configuration tool Planning/configuration • Configuration Manuals, Motors • Decision/ordering SINAMICS S Catalogs SINAMICS S120 Equipment Manual for Control Units and Installation/assembly • Additional System Components SINAMICS S120 Equipment Manual for Booksize Power • Units SINAMICS S120 Equipment Manual for Chassis Power •... - Page 6 SINAMICS S drive system. Benefits The Safety Integrated Function Manual covers all information, procedures and operations required for commissioning safety functions and servicing of SINAMICS S120. Search guides The following guides are provided to help you locate information in this manual: 1.

- Page 7 European and African time zones A&D Technical Support Tel.: +49 (0) 180 5050 - 222 Fax: +49 (0) 180 5050 - 223 Internet: http://www.siemens.de/automation/support-request America time zone A&D Technical Support Tel: +1 423 262 2522 Fax: +1 423 262 2289 Internet: http://www.siemens.de/automation/support-request...

- Page 8 ● Internet http://www.ad.siemens.de/csinfo Product/Order no: 15257461 ● Branch offices For the responsible regional offices of the A&D MC business division of Siemens AG. Notation The following notation and abbreviations are used in this documentation: Notation for parameters (examples): ● p0918 Adjustable parameter 918 ●...

- Page 9 Preface ESD Notes CAUTION Electrostatic sensitive devices (ESD) are single components, integrated circuits or devices that can be damaged by electrostatic fields or electrostatic discharges. Regulations for the ESD handling: During the handling of electronic components, pay attention to the grounding of the person, workplace and packaging! Electronic components may be touched by persons only when •...

- Page 10 Preface Safety instructions DANGER • Commissioning must not start until you have ensured that the machine in which the components described here are to be installed complies with Directive 98/37/EC. • SINAMICS devices and AC motors must only be commissioned by suitably qualified personnel.

- Page 11 Preface CAUTION • As part of routine tests, SINAMICS devices with AC motors undergo a voltage test in accordance with EN 50178. Before the voltage test is performed on the electrical equipment of industrial machines to EN 60204-1, Section 19.4, all connectors of SINAMICS equipment must be disconnected/unplugged to prevent the equipment from being damaged.

-

Page 13: Table Of Contents

Table of contents Preface ..............................5 General information about SINAMICS Safety Integrated ................. 15 Introduction ..........................15 Supported functions ........................16 Parameter, Checksum, Version, Password .................18 DRIVE-CLiQ rules for Safety Integrated Functions ..............21 System features............................23 Certification ..........................23 Probability of failure of the safety functions (PFH value).............23 Safety instructions........................24 Residual risk..........................25 Response times ...........................28... - Page 14 Table of contents Configuring PROFIsafe ....................... 66 5.4.1 PROFIsafe user data ........................66 Commissioning ............................69 General commissioning information.................... 69 6.1.1 Introduction ..........................69 6.1.2 Setting the sampling times ......................69 Commissioning TM54F by means of STARTER/SCOUT............70 6.2.1 Basic sequence of commissioning....................70 6.2.2 Configuration start screen ......................

-

Page 15: General Information About Sinamics Safety Integrated

General information about SINAMICS Safety Integrated Introduction Safety Integrated The "Safety Integrated" functions enable the implementation of highly effective application- oriented functions for man and machine protection. This innovate safety technology offers the following benefits: ● Increased safety ● Increased profitability ●... -

Page 16: Supported Functions

Adjustable-speed electrical power drive systems Part 5-2: Safety requirements - Functional Note In conjunction with certified components, the safety functions of the SINAMICS S120 drive system fulfill the following requirements: • Category 3 to EN 954-1. • Safety integrity level 2 (SIL 2) to IEC 61508. - Page 17 Per single Control Unit, either control via PROFIsafe or TM54F is permitted. Mixed operation is not permitted. ● SINAMICS S120: FW version from 2.5 SP1 ● SIMOTION D4x5: FW version from V4.1.1 (SINAMICS S120 with FW version from V2.5 SP1 integrated) ● Safe actual value acquisition (see chapter "Safe actual value acquisition") ●...

-

Page 18: Parameter, Checksum, Version, Password

General information about SINAMICS Safety Integrated 1.3 Parameter, Checksum, Version, Password Parameter, Checksum, Version, Password Properties of Safety Integrated parameters The following applies to Safety Integrated parameters: ● They are kept separate for each monitoring channel. ● During startup, a checksum (Cyclic Redundancy Check, CRC) over the safety parameters is generated and checked. - Page 19 General information about SINAMICS Safety Integrated 1.3 Parameter, Checksum, Version, Password ● r9728[0...1] SI Motion actual checksum SI parameters ● r9729[0...1] SI Motion specified checksum SI parameters During each ramp-up procedure, the actual checksum is calculated via the safety parameters and then compared with the specified checksum. If the actual and specified checksums are different, fault F01650/F30650 or F01680/F30680 is output and an acceptance test requested.

- Page 20 General information about SINAMICS Safety Integrated 1.3 Parameter, Checksum, Version, Password ● Change password for the drives – p0010 = 95 Commissioning mode – p9761 = Enter "old safety password". – p9762 = Enter "new password". – p9763 = Confirm "new password". –...

-

Page 21: Drive-Cliq Rules For Safety Integrated Functions

The Safety Integrated Functions (Basic and Extended Functions) are generally governed by the same DRIVE-CLiQ rules as specified in the chapter "Rules for wiring with DRIVE-CLiQ" References: /FH1/ SINAMICS S120 Function Manual. This specification also lists the exceptions for Safety Integrated components depending on the firmware version. -

Page 23: System Features

PFH values of other components used for this safety function. Corresponding PFH values are provided for the SINAMICS S120 drive system, depending on the hardware configuration (number of drives, control type, number of encoders used, ...). -

Page 24: Safety Instructions

System features 2.3 Safety instructions Safety instructions WARNING The Safety Integrated functions cannot be activated until the startup is completed. System startup is a critical operating state with increased risk. No personnel may be present in the immediate danger zone in this phase. The drives of vertical axes must be in torque state. -

Page 25: Residual Risk

System features 2.4 Residual risk WARNING • Encoder faults within a single-encoder system are detected by means of various HW and SW monitoring functions. It is not allowed to disable these monitoring functions and they must be parameterized carefully. Depending on the fault type and on the responding monitoring function, either the Category 0 or the Category 1 stop function to EN 60204-1 is activated (fault reaction function STOP A or STOP B according to Safety Integrated). - Page 26 System features 2.4 Residual risk WARNING • Faults in the absolute track (C-D track), cyclic interchange of the drive phases (V-W-U instead of U-V-W) and reversal of the control direction may cause acceleration of the drive. However, the fault prevents activation of the category 1 and 2 stop functions to IEC 60204-1 (fault reaction functions STOP B to E according to Safety Integrated).

- Page 27 System features 2.4 Residual risk WARNING Within a single-encoder system: a) a single electrical fault in the encoder b) a break of the encoder shaft (or loose encoder shaft coupling), or a loose encoder housing will cause a static state of the encoder signals (that is, they no longer follow a movement while still returning a correct level), and prevent fault detection while the drive is in stop state (for example, drive in SOS state).

-

Page 28: Response Times

System features 2.5 Response times Response times Control signals by way of terminals on the Control Unit and Motor Module Table 2-1 Response times with control signals by way of terminals on the Control Unit and Motor Module Function Standard Worst case 2 x r9780 + p0799 4 x r9780 + p0799... -

Page 29: Basic Functions

Basic Functions Note The Basic Functions are also described in the following manual: Reference: /FH1/SINAMICS S120 Function Manual Drive Functions Safe Torque Off (STO) General description In conjunction with a machine function or in the event of a fault, the "Safe Torque Off (STO)"... - Page 30 Basic Functions 3.1 Safe Torque Off (STO) CAUTION If two power transistors in the power unit (one in the upper and one offset in the lower inverter bridge) fail at the same time, this can cause a momentary movement. The maximum movement can be: Synchronous rotary motors: max.

- Page 31 Basic Functions 3.1 Safe Torque Off (STO) Restart after the "Safe Torque Off" function has been selected 1. Deselect the function in each monitoring channel via the input terminals. 2. Issue drive enable signals. 3. Revoke the closing lockout and switch the drive back on. –...

-

Page 32: Safe Stop 1 (Ss1, Time Controlled)

Basic Functions 3.2 Safe Stop 1 (SS1, time controlled) Parameter overview (see List Manual) ● p0799 CU inputs/outputs sampling times ● r9780 SI monitoring clock cycle (Control Unit) ● r9880 SI monitoring clock cycle (Motor Module) Safe Stop 1 (SS1, time controlled) General description The "Safe Stop 1"... -

Page 33: Safe Brake Control (Sbc)

Basic Functions 3.3 Safe Brake Control (SBC) Status for "Safe Stop 1" The status of the "Safe Stop 1" function is displayed using the following parameters: ● r9772 CO/BO: SI status (Control Unit) ● r9773 CO/BO: SI status (Control Unit + Motor Module) ●... - Page 34 Basic Functions 3.3 Safe Brake Control (SBC) WARNING "Safe Brake Control" does not detect faults in the brake itself, such as brake winding short- circuit, worn brakes, etc. If a cable breaks, this is only recognized by the "Safe Brake Control" function when the status changes, i.e.

- Page 35 Basic Functions 3.3 Safe Brake Control (SBC) Figure 3-1 Two-channel brake control, booksize The Motor Module carries out a check to ensure that the "Safe Brake Control" function is working properly and ensures that, if the Control Unit fails or is faulty, the brake current is interrupted and the brake applied.

-

Page 36: Forced Dormant Error Detection

Basic Functions 3.4 Forced dormant error detection Parameter overview (see SINAMICS S List Manual) ● p0799 CU inputs/outputs sampling times ● r9780 SI monitoring clock cycle (Control Unit) ● r9880 SI monitoring clock cycle (Motor Module) Forced dormant error detection Forced dormant error detection or test for the switch-off signal paths The forced dormant error detection function at the switch-off signal paths is used to detect software/hardware faults at both monitoring channels in time and is automated by means of... - Page 37 Basic Functions 3.4 Forced dormant error detection NOTICE The timer of the Basic Functions will be reset if the associated forced dormant error detection is executed and the Extended Functions are used simultaneously. The corresponding alarm of the Basic Functions is not triggered. Discrepancy is not checked at the terminals used to select the Basic Functions as long as STO is set by the Extended Functions.

-

Page 39: Extended Functions

Extended Functions Safe Stop 1 (SS1, time and acceleration controlled) General description The "Safe Stop 1" function can be implemented to stop the drive in accordance with IEC 60204-1, stop category 1. After "Safe Stop 1" is set at the OFF3 ramp (p1135), the drive brakes and changes to the Safe Torque Off (STO) status on expiration of the delay time (p9356/p9556), or after having reached the shutdown speed (p9360/p9560). - Page 40 Extended Functions 4.1 Safe Stop 1 (SS1, time and acceleration controlled) ● The Safe Acceleration Monitor (SBR) function is active in the ramp down phase (refer to the chapter "Safe Acceleration Monitor"). Commissioning The function is activated by entering the delay time in p9356 and p9556, or the shutdown speed in p9360 and p9560.

-

Page 41: Safe Stop 2 (Ss2)

Extended Functions 4.2 Safe Stop 2 (SS2) ● p9560 SI motion pulse cancelation shutdown speed (Control Unit) ● r9722 CO/BO: SI motion, status signals Safe Stop 2 (SS2) Description The Safe Stop 2 (SS2) function is used to safely brake down the drive along the OFF3 ramp (p1135), with transition to the SOS state (refer to the chapter Safe Operational Stop) on expiration of the delay time (p9352/p9552). -

Page 42: Safe Operational Stop (Sos)

Extended Functions 4.3 Safe Operational Stop (SOS) ● Safety message C01711/C30711 Overview of important parameters (refer to the List Manual) ● p1135 OFF3 ramp-down time ● p9301 SI motion enable safety functions (Motor Module) ● p9501 SI motion enable safety functions (Control Unit) ●... -

Page 43: Safely Limited Speed (Sls)

Extended Functions 4.4 Safely Limited Speed (SLS) ● Safety message C01707/C30707 System errors: ● STOP F ● Safety message C01711/C30711 Features ● The drive remains in the closed-loop control mode ● A programmable standstill tolerance window is available ● STOP B is the stop response after SOS has responded Note The range of the tolerance window should be oriented on the default standstill monitoring limit and be slightly higher than this limit. - Page 44 Extended Functions 4.4 Safely Limited Speed (SLS) delay time if a lower speed limit is selected. A delay time is not set if a higher speed limit is selected. Delay time Figure 4-4 Delay time SLS phase changeover A speed setpoint limit can be set as percentage in p9533. This value is used to calculate a speed setpoint limit r9733, depending on the selected speed limit p9531[x].

- Page 45 Extended Functions 4.4 Safely Limited Speed (SLS) Table 4-1 Changeover of speed limits: F-DI for bit 0 (r9720.9) F-DI for bit 1 (r9729.10) Speed limit p9331[0]/p9531[0] p9331[1]/p9531[1] p9331[2]/p9531[2] p9331[3]/p9531[3] The changeover from a lower to a higher speed limit takes effect without any delay. The changeover from a higher to a lower limit triggers a delay time which can be set at the corresponding parameter (p9351 and p9551).

-

Page 46: Safe Speed Monitor (Ssm)

Extended Functions 4.5 Safe Speed Monitor (SSM) Safe Speed Monitor (SSM) Description The SSM function is used to safely indicate undershoot of a speed limit (example: for standstill detection) in both rotary directions. A failsafe output signal is available for further processing. - Page 47 Extended Functions 4.6 Safe Acceleration Monitor (SBR) NOTICE The speed limit set at the SSM function (p9346/p9546) is also used as shutdown limit for the SBR function (safe acceleration monitoring). The SBR is deactivated if the speed is below this limit. The effect of the SSM safety function is therefore heavily limited if a relatively high SSM/SBR speed limit is set and the SS1 and SS2 stop functions are activated.

-

Page 48: Response To Fault/Limit Value Violation

Extended Functions 4.7 Response to fault/limit value violation Responses Speed limit violated (SBR): ● STOP A ● Safety message C01706/C30706 System errors: ● STOP F with subsequent STOP A ● Safety message C01711/C30711 Features ● Element of the SS1 (time and acceleration controlled) and SS2 functions ●... - Page 49 Extended Functions 4.7 Response to fault/limit value violation Stop response Action Effect STOP E (in preparation, current behavior similar to (in preparation, current behavior similar to STOP D) STOP D) (in preparation) STOP F Timer t (Basic Functions) or t (Extended If a safety function (SOS, SLS) is active, transition to Functions)

-

Page 50: Safe Actual Value Acquisition

Extended Functions 4.8 Safe actual value acquisition Safe actual value acquisition Supported encoder systems Safety functions used to monitor movements (e.g. SS2, SOS, SLS and SSM) require safe actual value acquisition. This function is required for safe acquisition of the actual speed. The following encoder type is supported: ●... - Page 51 Extended Functions 4.8 Safe actual value acquisition Two-encoder system The failsafe actual values for a drive are provided by two separate encoders. The safety- relevant actual values are generated either directly in the encoders or in the Sensor Modules and are transferred without retroaction to the Control Unit by way of failsafe communication via DRIVE-CLiQ.

- Page 52 Extended Functions 4.8 Safe actual value acquisition Actual value synchronization Figure 4-9 Example diagram of actual value synchronization The mean value of the actual values of both encoders is calculated cyclically after actual value synchronization (p9301.3 = p9501.3 = 1) was activated. The maximum slip defined in p9349/p9549 is monitored within the crosswise comparison clock cycle (r9724).

-

Page 53: Forced Dormant Error Detection

Extended Functions 4.9 Forced dormant error detection ● p9326 SI motion encoder assignment (Motor Module) ● p9526 SI motion encoder assignment second channel ● p9342 SI motion actual value comparison tolerance (crosswise) (Motor Module) ● p9542 SI motion actual value comparison tolerance (crosswise) (Control Unit) ●... - Page 54 In order to be able to utilize the TM54F test stop function, all F-DIs used must be interconnected as shown in the wiring example in the SINAMICS S120 GH1 Equipment Manual. The digital inputs of F-DI 0 to F -DI 4 must be connected to the "L1+" power supply.

- Page 55 Extended Functions 4.9 Forced dormant error detection Figure 4-10 Example of the TM54F wiring The F-DIs must be registered for the test stop by means p10041. Safety Integrated Function Manual, (FHS) , 07/2007 Edition, 6SL3097-2AR00-0BP0...

- Page 56 In order to be able to use the test stop function, interconnect the F-DO used in accordance with the example of the wiring in the SINAMICS S120 GH1 Equipment Manual and wire the forced feedback signals of the two relays to the corresponding digital input (DI 20 to DI 23).

-

Page 57: Control Of The Safety Functions

Control of the safety functions Overview of F-DI/F-DOs and of their structure Description The failsafe input and output signals (F-DI and F-DO) interface the internal Safety Integrated functionality with the process. F-DI signals (Failsafe Digital Inputs) control active monitoring of the activation/deactivation of safety functions. -

Page 58: Control Via Terminals On The Control Unit And The Power Unit

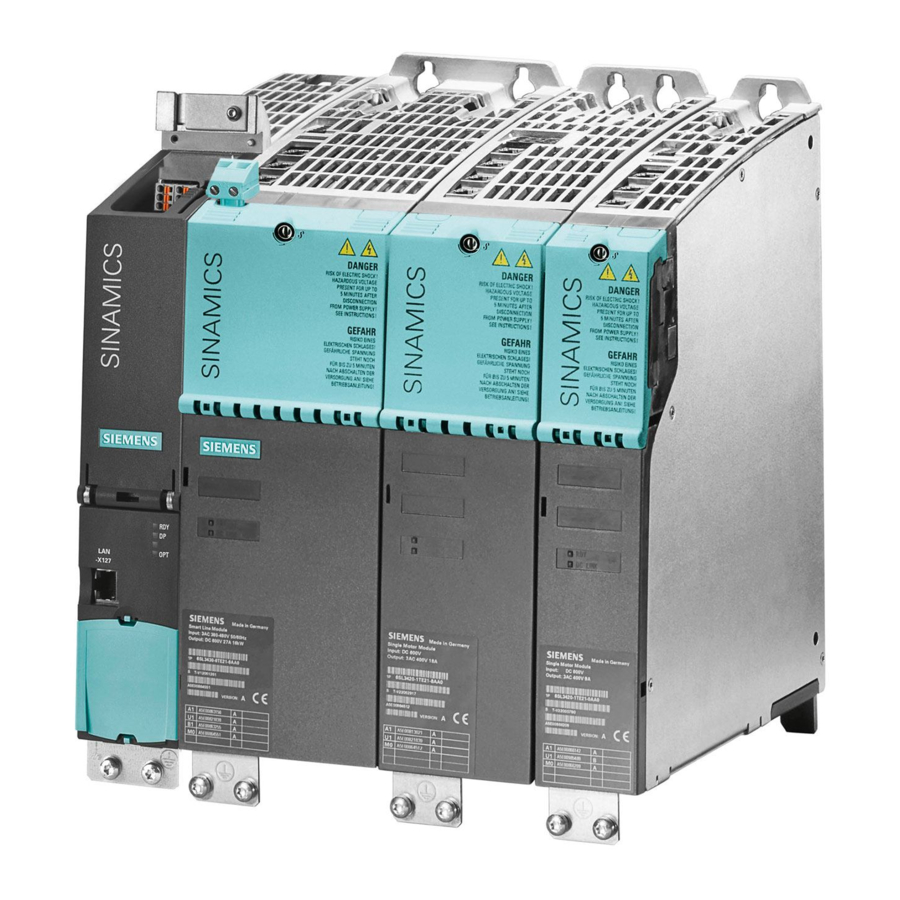

Overview of the safety function terminals for SINAMICS S120 The different power unit formats of SINAMICS S120 have different terminal designations for the inputs of the safety functions. These are shown in the following table. - Page 59 Control of the safety functions 5.2 Control via terminals on the Control Unit and the power unit Figure 5-1 Terminals for "Safe Torque Off", example for Motor Modules Booksize and CU320 Grouping drives (not for CU310) To ensure that the function works for more than one drive at the same time, the terminals for the corresponding drives must be grouped together as follows: ●...

- Page 60 Control of the safety functions 5.2 Control via terminals on the Control Unit and the power unit Figure 5-2 Grouping terminals with Motor Modules Booksize and CU320 Information on the parallel connection of chassis type Motor Modules When Motor Modules of chassis type are connected in parallel, a safe AND element is created on the parallel drive object.

-

Page 61: Control By Way Of Tm54F Terminals

Control of the safety functions 5.3 Control by way of TM54F terminals Control by way of TM54F terminals 5.3.1 General information Description Terminal Module TM54F is a terminal expansion module for snap-on rail mounting to DIN EN 60715. The TM54F features failsafe digital I/O for controlling the Safety Integrated functions. Each Control Unit can be assigned only one TM54F which is connected via DRIVE-CLiQ. -

Page 62: Overview Of The F-Dis

Control of the safety functions 5.3 Control by way of TM54F terminals 5.3.2 Overview of the F-DIs Description Failsafe digital inputs (F-DI) consist of two digital inputs. The cathode of the optocoupler is routed to the second digital input in order to allow the connection of an M-switching F-DO output (the anode must be wired to 24 V DC). - Page 63 Control of the safety functions 5.3 Control by way of TM54F terminals p10002 X531.1 r10051.5 (SL) F35151 X531.2 DI 10 p10040.5 r10051.5 (MA) F-DI 5 & X531.3 DI 11+ X531.6 DI 11- r10051.6 (SL) F35151 X531.4 DI 12 p10040.6 r10051.6 (MA) F-DI 6 &...

-

Page 64: Overview Of The F-Dos

Control of the safety functions 5.3 Control by way of TM54F terminals 5.3.3 Overview of the F-DOs Description Failsafe digital outputs (F-DO) consist of two digital outputs plus one digital input that checks the switching state for forced dormant error detection. The first digital input switches 24 V DC, and the second switches M of the X514 voltage supply. - Page 65 Control of the safety functions 5.3 Control by way of TM54F terminals ● SSM feedback active ● Safe state The following signals can be requested by means of p10039[0...3] for each drive group (index 0 corresponds with drive group 1 etc.): –...

-

Page 66: Configuring Profisafe

Control of the safety functions 5.4 Configuring PROFIsafe Overview of important parameters (refer to the List Manual) ● p10042[0..5] SI F-DO 0 signal sources ● ... ● p10045[0..5] SI F-DO 3 signal sources ● r10052 CO/BO: SI status of digital outputs ●... - Page 67 Control of the safety functions 5.4 Configuring PROFIsafe Meaning Remarks BICO SS2 activation SOS deactivation r9720.3 SOS activation SLS deactivation r9720.4 SLS activation Reserved Reserved Internal Event ACK Acknowledgment r9720.7 No acknowledgment Reserved SLS limit select bit 0 Selection of the speed limit for SLS r9720.9 (2-bit counter) SLS limit select bit 1...

- Page 68 Control of the safety functions 5.4 Configuring PROFIsafe Meaning Remarks BICO 12...14 Reserved SSM (n below limit) r9722.15 SSM (n higher than/equal to limit) Safety Integrated Function Manual, (FHS) , 07/2007 Edition, 6SL3097-2AR00-0BP0...

-

Page 69: Commissioning

Commissioning General commissioning information 6.1.1 Introduction The safety functions are commissioned using the screen forms in the STARTER. These functions are available for each drive at "Functions" -> "Safety Integrated". The password "0" is set by default. Information pertaining to operation with isochronous PROFIBUS NOTICE Always set parameter p9510 = 1 if a PROFIdrive controller exchanges isochronous process data with the Control Unit. -

Page 70: Commissioning Tm54F By Means Of Starter/Scout

Commissioning 6.2 Commissioning TM54F by means of STARTER/SCOUT ● The communication clock cycle must be executed at least with factor 4 to the current controller clock cycle (with isochronous PROFIBUS) or 1 ms (with non-isochronous PROFIBUS). ● The monitoring clock cycle can be set within the limits from 4 ms to 25 ms. However, the calculation time required for the Extended Functions in the Control Unit depends on the monitoring clock cycle, that is, shorter clock cycles extend the calculation time. -

Page 71: Configuration Start Screen

Commissioning 6.2 Commissioning TM54F by means of STARTER/SCOUT Step Execution Execute POWER ON Acceptance test 6.2.2 Configuration start screen Description The following functions can be selected in the start screen: ● Configuration Opens the "Configuration" screen ● Inputs Opens the "Inputs" screen ●... - Page 72 Commissioning 6.2 Commissioning TM54F by means of STARTER/SCOUT Figure 6-1 Configuration start screen TM54F Safety Integrated Function Manual, (FHS) , 07/2007 Edition, 6SL3097-2AR00-0BP0...

-

Page 73: Tm54F Configuration

Commissioning 6.2 Commissioning TM54F by means of STARTER/SCOUT 6.2.3 TM54F configuration Configuration screen of TM54F for Safety Integrated Figure 6-2 TM54F configuration Functions of this screen: ● Drive objects assignment (p10010) Selection of a drive object to be assigned to a drive group. ●... -

Page 74: F-Di/F-Do Configuration

Commissioning 6.2 Commissioning TM54F by means of STARTER/SCOUT detection (e.g. switch the L1+ and L2+ sensor power supply). Each selection triggers a timer in order to monitor the test cycle. An alarm is set on expiration of the monitored time. ●... - Page 75 Commissioning 6.2 Commissioning TM54F by means of STARTER/SCOUT Activate test mode (p10041) A check mark at an F-DI defines whether the pair of digital inputs is to be integrated in the forced dormant error detection test of the assigned power supply (L1+ or L2+) (for additional information, refer to the chapter "Forced dormant error detection", under Extended Functions).

-

Page 76: Control Interface

Commissioning 6.2 Commissioning TM54F by means of STARTER/SCOUT LED in the F-DO screen The LED downstream of the AND element indicates the logical state (inactive: gray, active: green). The LED of the digital inputs DI20 to DI23 indicate the status of the digital input (inactive: gray, active: green). -

Page 77: Profisafe Network Transition With Simotion D

PROFIsafe network transition with SIMOTION D The next sections deal with the configuration of PROFIsafe communication via PROFIBUS between the integrated drive unit SINAMICS S120 of a SIMOTION D or CX32 and a higher- level SIMATIC F-CPU. The configuration and operation of failsafe communication (named F-communication in the... - Page 78 1. Create an F-CPU or a CPU 317F-2 and a SIMOTION-D4x5 PLC (with integrated SINAMICS S120) in HW Config in accordance with the hardware installed. 2. Define a SIMOTION CPU for operation as DP slave and the F-CPU as associated DP master.

- Page 79 Commissioning 6.3 PROFIsafe network transition with SIMOTION D 4. Create a PROFIsafe slot in the "Configuration" dialog box of the SINAMICS drive unit. Select the PROFIBUS message frame tab, select the drive object which is to communicate with the SIMATIC F-CPU via PROFIsafe, click "Insert line" and then select "PROFIsafe".

- Page 80 Commissioning 6.3 PROFIsafe network transition with SIMOTION D DP partner (F I/O): Properties of the SINAMICS drive. local: Properties of the SIMOTION CPU. Enter the logical start address for F-communication of the SIMOTION CPU in the "Address" row. The send and receive safety message frames are assigned an address space of 6 bytes which must be located outside the process image of the SIMOTION-CPU ( >= 64).

- Page 81 Commissioning 6.3 PROFIsafe network transition with SIMOTION D Figure 6-10 SIMOTION D configuration 9. Double-click the icon of the SINAMICS drive unit and select the "Details" tab in the "Configuration" tab. Figure 6-11 PROFIsafe configuration for SINAMICS drive unit 10. Click "PROFIsafe…" and then define the F parameters which are important to F-communication.

- Page 82 Commissioning 6.3 PROFIsafe network transition with SIMOTION D Figure 6-12 Setting F parameters Setting F parameters: The top five failsafe parameters in this list are configured by default and cannot be edited. The following range of values is valid for the two remaining parameters: F_Dest_Add: 1-65534 F_Dest_Add determines the PROFIsafe destination address of the drive object.

- Page 83 Commissioning 6.3 PROFIsafe network transition with SIMOTION D Note For information about the creation of a safety program and access to PROFIsafe user data (e. g STW and ZSW) within the safety program, refer to the "SIMATIC, S7 Distributed Safety - Configuring and Programming"...

- Page 84 Commissioning 6.3 PROFIsafe network transition with SIMOTION D Figure 6-14 Activating PROFIsafe settings 3. Enable the SOS and SLS functions, click the "Configuration" button and then enter the PROFIsafe address of the drive in hexadecimal notation at the already defined parameter F_Dest_Add in the configuration screen (refer to the chapter "Configuring PROFIsafe communication", item 10).

- Page 85 Commissioning 6.3 PROFIsafe network transition with SIMOTION D Figure 6-16 Copying PROFIsafe parameters Figure 6-17 Activating PROFIsafe settings and saving the entire project 5. The following settings have to be made in the drive expert list and additional steps have to be taken in order to transfer the safety parameters: ●...

-

Page 86: Commissioning Profisafe By Means Of Starter/Hw Config

Procedure for configuring PROFIsafe communication Example configuration The next sections deal with a sample configuration of PROFIsafe communication between a SINAMICS S120 drive unit and higher-level SIMATIC F-CPU operating as PROFIBUS master. The configuration and operation of failsafe communication (F-communication) is based on... - Page 87 Create an F-CPU such as CPU 317F-2 and a SINAMICS S120 in HW Config in accordance with the hardware installed. 1. Set up the SINAMICS S120 for operation as a DP slave and the connected F-CPU as associated DP master.

- Page 88 Commissioning 6.4 Commissioning PROFIsafe by means of STARTER/HW Config Figure 6-19 Example: PROFIsafe configuration (HW Config) 4. Double-click the icon of the SINAMICS drive unit and select the "Details" tab in the "Configuration" tab. 5. Click "PROFIsafe…" and then define the F parameters which are important to F- communication.

-

Page 89: Commissioning A Linear/Rotary Axis

Commissioning 6.5 Commissioning a linear/rotary axis F_Dest_Add: 1-65534 F_Dest_Add determines the PROFIsafe destination address of the drive object. Any value within the range is allowed, however, it must be entered once again in the safety configuration of the drive in the SINAMICS drive unit. The F_Dest_Add value must be set in p9610 (Control Unit) and in p9810 (Motor Module). - Page 90 Commissioning 6.5 Commissioning a linear/rotary axis Figure 6-22 Safety commissioning of a linear/rotary axis 2. Select "Motion monitoring via TM54F" from the "Control selection" drop-down list box. 3. Enable the SOS, SLS function (p9501) by selecting it from the "Enables SOS, SLS" drop- down list box.

-

Page 91: Information Pertaining To Component Replacements

Information pertaining to component replacements Replacing components For information about component replacements, refer to the chapter "Example of component replacements" in the SINAMICS S120 Function Manual FH1. WARNING Observe the instructions with regard to changes to software components or to changes to these in the chapter "Safety instructions"! -

Page 92: Information Pertaining To Series Commissioning

Commissioning 6.7 Information pertaining to series commissioning component replacement in plus and minus direction (+/-) with activated safety monitoring function (SLS, if parameterized) in order to verify proper functionality. Information pertaining to series commissioning A commissioned project which has been uploaded to STARTER can be transferred to another drive unit including the existing safety parameterization. -

Page 93: Application Examples

Application examples Safe Stop 1 (SS1, time-controlled) when protective door is locked, emergency stop switch-off Figure 7-1 Application example Safety Integrated Function Manual, (FHS) , 07/2007 Edition, 6SL3097-2AR00-0BP0... - Page 94 Application examples 7.1 Safe Stop 1 (SS1, time-controlled) when protective door is locked, emergency stop switch-off Figure 7-2 Safety Integrated signal flow application example Note This example illustrates implementation options. The solution required for the machine must be suitable for the machine function, which means that parameters and control commands are defined individually.

- Page 95 Application examples 7.1 Safe Stop 1 (SS1, time-controlled) when protective door is locked, emergency stop switch-off Description of functions With two SIGUARD safety combinations for emergency stop and the protective door, as well as a standard PLC, the system can be configured according to EN 954-1, category 3, and EN1037.

- Page 96 Application examples 7.1 Safe Stop 1 (SS1, time-controlled) when protective door is locked, emergency stop switch-off Behavior when the protective door is opened To issue a request to open the protective door, press the S2 button ("OFF"). The drive is brought to a standstill in accordance with stop category 1 of EN 60204-1.

-

Page 97: Acceptance Test And Acceptance Report

Acceptance test and acceptance report General information Requirements for acceptance tests are derived from the EC Machinery Directive. IEC 22G WG 10 is currently working on a "Functional safety" standard which includes a detailed description of acceptance test requirements. The machine manufacturer (OEM) is committed accordingly ●... - Page 98 Acceptance test and acceptance report 8.1 General information Note • Observe the information in the chapter "Procedures for initial commissioning". • The acceptance report presented below is both an example and recommendation. • An acceptance report template in electronic format is available at your local sales office. Necessity of an acceptance test A complete acceptance test (as described in this chapter) is required after initial commissioning of Safety Integrated functionality on a machine.

- Page 99 Acceptance test and acceptance report 8.1 General information Content of the complete acceptance test Documentation Documentation of the machine and of safety functions 1. Machine description (with overview) 2. Specification of the controller (if this exists) 3. Configuration diagram 4. Function table Active monitoring functions depending on the operating mode, the protective doors and other sensors.

- Page 100 Acceptance test and acceptance report 8.1 General information Appendix Effect of the acceptance test on specific measures Table 8-1 Scope of the acceptance test depending on specific measures Measure Documentation Function test Part 1 Function test Part 2 Conclusion of the report Replacement of the Test of failsafe actual...

-

Page 101: Acceptance Test Procedure

Acceptance test and acceptance report 8.2 Acceptance test procedure Acceptance test procedure Note The acceptance test is used to check that the safety functions have been correctly parameterized. The measured values (e.g. distance, time) and system behavior identified (e.g. initiation of a specific stop) within the acceptance test are used to validate configured safety functions. - Page 102 Acceptance test and acceptance report 8.3 Acceptance report Drive number FW version SI version r9590 = r9770 = Parameter r0128 = r9390 = Motor Modules r9870 = r0128 = r9390 = r9870 = r0128 = r9390 = r9870 = r0128 = r9390 = r9870 = r0128 =...

-

Page 103: Description Of Safety Functions - Documentation Part 2

Acceptance test and acceptance report 8.3 Acceptance report 8.3.2 Description of safety functions - Documentation Part 2 8.3.2.1 Introduction This example contains the description of a plant; the settings for a specific plant must be adapted accordingly. 8.3.2.2 Function table Table 8-4 Example table: Active monitoring functions depending on the operating mode, the protective doors or other sensors... -

Page 104: Control Of The Si Functions By Way Of Tm54F

Acceptance test and acceptance report 8.3 Acceptance report Drive-specific data Table 8-6 Drive-specific data SI function Parameters Value Enable p9601 p9801 PROFIsafe address SLS1 (limit 1) SLS2 (limit 2) STOP F -> STOP A delay time 8.3.2.4 Control of the SI functions by way of TM54F Documentation of the parameters Table 8-7 Parameters for control by way of TM54F... -

Page 105: Safety Equipment

Acceptance test and acceptance report 8.4 Acceptance tests 8.3.2.6 Safety equipment Protective door The protective door is unlocked by means of single-channel request key Protective door switch The protective door is equipped with a safety door switch. The safety door switch returns the dual- channel signal "Door closed and locked". -

Page 106: Acceptance Test For Safe Stop 1, Time Controlled (Ss1)

Acceptance test and acceptance report 8.4 Acceptance tests Description Status Ensure that the correct drive is running Select STO when issuing the traversing command Note: The acceptance test must be carried out for each configured control, which may be via terminals, via the TM54F or via PROFIsafe. - Page 107 Acceptance test and acceptance report 8.4 Acceptance tests Table 8-10 "Safe Stop 1" function (SS1) Description Status Initial state Drive in "Ready" status (p0010 = 0) STO function enabled (p9601.0 = 1, p9801.0 = 1) Enable SS1 function (p9652 > 0, p9852 > 0) No safety faults and alarms (r0945, r2122, r2132) r9772.0 = r9772.1 = 0 (STO de-selected and inactive –...

-

Page 108: Acceptance Test For "Safe Brake Control" (Sbc)

Acceptance test and acceptance report 8.4 Acceptance tests Description Status Ensure that the correct drive is running The following is tested: Correct parameterization of the SS1 function • 8.4.3 Acceptance test for "Safe Brake Control" (SBC) "Safe Brake Control" function (SBC) This test comprises the following steps: Table 8-11 "Safe brake control"... -

Page 109: Acceptance Test For Safe Stop 1, Time And Acceleration Controlled

Acceptance test and acceptance report 8.4 Acceptance tests Description Status Check the following: Drive is braked and stopped by the mechanical brake. • No safety faults or alarms (r0945, r2122) • r9772.0 = r9772.1 = 1 (STO selected and active – CU) •... - Page 110 Acceptance test and acceptance report 8.4 Acceptance tests Description Status Move the drive Check whether the expected drive is moving Start Trace (trigger r9720.1 = 0) Trace recording of the following values: Safe actual speed (r9714) • SS1 deactivation (r9720.1) •...

-

Page 111: Acceptance Test For Safe Stop 2 (Ss2)

Acceptance test and acceptance report 8.4 Acceptance tests 8.4.5 Acceptance test for Safe Stop 2 (SS2) "Safe Stop 2" function (SS2) The functional test must be carried out separately for each drive (as far as the machine allows). The test comprises the following steps: Table 8-13 "Safe Stop 2"... -

Page 112: Acceptance Test For Safe Operational Stop (Sos)

Acceptance test and acceptance report 8.4 Acceptance tests Example of the Trace Figure 8-2 Example Trace SS2 8.4.6 Acceptance test for Safe Operational Stop (SOS) "Safe Operational Stop" (SOS) function The functional test must be carried out separately for each drive (as far as the machine allows). -

Page 113: Acceptance Test For Safely Limited Speed (Sls)

Acceptance test and acceptance report 8.4 Acceptance tests Description Status Start Trace (trigger actual position r9713 > 0) Trace recording of the following values: Safe actual position value (r9713[0/1]) • STOP A or B active (r9721.12) • STO active (r9721.0) •... - Page 114 Acceptance test and acceptance report 8.4 Acceptance tests Table 8-15 "Safely Limited Speed" (SLS) function Description Status Initial state Drive in "Ready" state (p0010 = 0) • Safety Integrated Extended Functions enabled (p9601.2 = 1) • SOS/SLS function enabled (p9501.0 = 1) •...

-

Page 115: Acceptance Test For Safe Speed Monitoring (Ssm)

Acceptance test and acceptance report 8.4 Acceptance tests 8.4.8 Acceptance test for Safe Speed Monitoring (SSM) "Safe Speed Monitor" (SSM) function The functional test must be carried out separately for each drive (as far as the machine allows). The test comprises the following steps: Table 8-16 "Safe Speed Monitor"... - Page 116 Acceptance test and acceptance report 8.4 Acceptance tests Example of the Trace Figure 8-5 Example Trace SSM Safety Integrated Function Manual, (FHS) , 07/2007 Edition, 6SL3097-2AR00-0BP0...

-

Page 117: List Of Abbreviations

Appendix A List of abbreviations Note The following list of abbreviations includes all abbreviations and their meanings used in the entire SINAMICS user documentation. Abbreviation Meaning, German Meaning, English A... Warnung Alarm Wechselstrom Alternating Current Analog-Digital-Konverter Analog Digital Converter Analogeingang Analog Input Active Interface Module Active Interface Module... - Page 118 Appendix A A.1 List of abbreviations Abbreviation Meaning, German Meaning, English Serielles Bussystem Controller Area Network Kommunikationsbaugruppe CAN Communication Board CAN Compact Disc Compact Disc Befehlsdatensatz Command Data Set CompactFlash CompactFlash Konnektoreingang Connector Input Computerunterstützte numerische Steuerung Computer Numerical Control Konnektorausgang Connector Output CO/BO...

- Page 119 Appendix A A.1 List of abbreviations Abbreviation Meaning, German Meaning, English Europäische Norm European Standard EnDat Geber-Schnittstelle Encoder-Data-Interface Impulsfreigabe Enable Pulses EPOS Einfachpositionierer Basic positioner Engineering System Engineering System Ersatzschaltbild Equivalent circuit diagram Erweitertes Stillsetzen und Rückziehen Extended Stop and Retract F...

- Page 120 Appendix A A.1 List of abbreviations Abbreviation Meaning, German Meaning, English Identifizierung Identifier Internationale Norm in der Elektrotechnik International Electrotechnical Commission Interface Interface IGBT Bipolartransistor mit isolierter Steuerelektrode Insulated Gate Bipolar Transistor Impulslöschung Pulse suppression Interpolatortakt Interpolator clock Drehstromversorgungsnetz ungeerdet Insulated three-phase supply network Interner Spannungsschutz Internal Voltage Protection...

- Page 121 Appendix A A.1 List of abbreviations Abbreviation Meaning, German Meaning, English NEMA Normengremium in USA (United States of America) National Electrical Manufacturers Association Nullmarke Zero Mark Schließer Normally Open (contact) Netzstromrichter Line power converter Open Architecture Open Architecture Original Equipment Manufacturer Original Equipment Manufacturer Busstecker für Lichtleiter Optical Link Plug...

- Page 122 Appendix A A.1 List of abbreviations Abbreviation Meaning, German Meaning, English RPDO Receive Process Data Object Receive Process Data Object RS232 Serielle Schnittstelle Serial Interface RS485 Norm. Beschreibt die Physik einer digitalen seriellen Standard. Describes the physical characteristics of a Schnittstelle.

- Page 123 Appendix A A.1 List of abbreviations Abbreviation Meaning, German Meaning, English Terminal Board Terminal Board Totally Integrated Automation Totally Integrated Automation Terminal Module Terminal Module Drehstromversorgungsnetz geerdet Grounded three-phase supply network Nachstellzeit Integral time TPDO Transmit Process Data Object Transmit Process Data Object Drehstromversorgungsnetz geerdet Grounded three-phase supply network Transistor-Transistor-Logik...

- Page 125 Overview of SINAMICS Documentation (07/2007) General Documentation/Catalogs SINAMICS SINAMICS SINAMICS SINAMICS G110 G130 S120 S150 G120 G150 G120D D11.1 D21.1 D21.3 G110/G120 Drive Converter Drive System Drive Converter Inverter chassis units Chassis Units 0.12 kW to 1200 kW Cabinet Units G120D Drive Converter 75 kW to 1200 kW...

- Page 127 If you come across any misprints in this document, please let us know using this form. We would also be grateful for any suggestions and recommendations for improvement. Safety Integrated Function Manual, (FHS) , 07/2007 Edition, 6SL3097-2AR00-0BP0...

-

Page 129: Index

Index Fault response, 48 F-DI, 57 F-DO, 57 Forced dormant error detection, 36, 53 Acceptance test Function test, 53 SBC, 108 Functions SLS, 113 Overview, 16 SOS, 112 Safe brake control (SBC), 33 SS1, 106, 109 Safe Torque Off, 29 SS2, 111 SSM, 115 STO, 105... - Page 130 Index Safe actual value acquisition, 50 Supported functions, 16 Safe Operational Stop SOS, 42 Safe Speed Monitor SSM, 46 Test of shutdown paths, 36 Safe Stop 1, 32 Test stop, 53 Time and acceleration controlled, 39 TM54F, 57 Safe Stop 2 Change password, 71 SS2, 41 Commissioning, 70...

- Page 132 Siemens AG 6SL3097-2AR00-0BP0 Automation and Drives Motion Control Systems PO Box 3180 91050 ERLANGEN GERMANY www.siemens.com/motioncontrol...