Summary of Contents for Toro Greenmaster Flex 1820

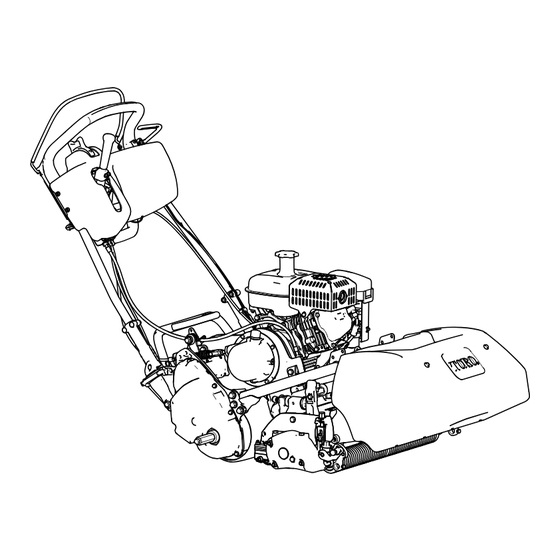

- Page 1 Form No. 3418-623 Rev B Greensmaster ® Flex ™ 1820/2120 Traction Unit Model No. 04044—Serial No. 401381001 and Up Model No. 04045—Serial No. 401400001 and Up *3418-623* B Register at www.Toro.com. Original Instructions (EN)

- Page 2 See your authorized Toro distributor. and training materials, go to www.Toro.com. Whenever you need service, genuine Toro parts, or additional information, contact an authorized Toro distributor and have the model and serial numbers of your product ready.

-

Page 3: Table Of Contents

Contents Servicing the Traction-Interlock Switch ..............33 Servicing the Brake-Interlock Switch....33 Safety ............... 4 Brake Maintenance ..........34 General Safety ........... 4 Adjusting the Service/Parking Brake....34 Safety and Instructional Decals ......4 Belt Maintenance ..........34 Setup ................ 7 Inspecting the Reel-Drive Belt...... -

Page 4: Safety

Safety • Keep clear of any discharge opening. Keep bystanders a safe distance away from the machine. This machine has been designed in accordance with • Keep children out of the operating area. Never EN ISO 5395:2013 and ANSI B71.4-2017. allow children to operate the machine. - Page 5 decal120-2769 120-2769 1. Toxic gas inhalation 4. Warning—disconnect hazard—do not operate the spark plug wire and indoors. read the Operator’s Manual before servicing or performing maintenance. decal120-9598 2. Explosion hazard—shut 5. Hot surface/burn 120-9598 off the engine and keep hazard—do not touch away from open flames hot surfaces.

- Page 6 decal133-2335 133-2335 3. Thrown object hazard—keep 5. Do not tow the machine. 1. Warning—read the Operator’s Manual; do not operate the machine unless you bystanders a safe distance away from are trained. the machine. 2. Warning—wear hearing protection. 4. Warning—stay away from moving parts;...

-

Page 7: Setup

Setup Loose Parts Use the chart below to verify that all parts have been shipped. Procedure Description Qty. – No parts required Prepare the traction unit (optional). Bolt (3/8 x 3/4 inch) Install the cutting unit to the traction unit. Handle retainer Install the handle retainers. -

Page 8: Preparing The Traction Unit

Preparing the Traction Unit Installing the Cutting Unit to the Traction Unit Optional—Cutting Unit Models 04251, 02452, 04253, or 04254 Parts needed for this procedure: Bolt (3/8 x 3/4 inch) No Parts Required Procedure Procedure Note: To install the weight rod onto your machine, If you are installing cutting unit Models 04251, 02452, refer to the installation instructions in your cutting unit 04253, or 04254 on this traction unit, complete the... -

Page 9: Installing The Handle Retainers

Installing the Handle Retainers Parts needed for this procedure: Handle retainer Hairpin cotter g000483 Figure 6 1. Transmission coupling Procedure While supporting the handle, remove the cable Maneuver the machine frame forward until it ties that secure the handle clamps to the side engages the cutting unit pivot arms Figure plates... -

Page 10: Installing The Transport Wheels

Installing the Transport Wheels Optional Parts needed for this procedure: Transport wheels—Transport Wheel Kit (Model No. 04123 [Optional]) Procedure g000475 Use your foot to push the center of the kickstand Figure 10 down and pull up on the lower handle support 1. -

Page 11: Installing The Production-Year Decal

Installing the Production-Year Decal CE Machines Only Parts needed for this procedure: g032407 Production-year decal Figure 12 1. Basket hooks Procedure Install the basket hooks over the frame loop If you use this machine in a country that complies to (Figure 12). -

Page 12: Breaking In The Machine

Product Overview Breaking in the Machine No Parts Required Procedure Only 8 hours of mowing operation is required for the break-in period. The first several hours of operation are critical to future dependability of the machine. You must monitor the machine performance closely so that minor difficulties, which could lead to major problems, are noted and g032409... -

Page 13: Throttle Control

Throttle Control The throttle control (Figure 15 Figure 16) is located on the right, rear side of the control panel. Rotate the throttle to regulate the engine speed. g027738 Figure 16 g000494 Figure 17 1. Full speed 2. Slow speed 1. -

Page 14: Choke Lever

Service Brake Choke Lever The service brake (Figure 18) is located on the left The choke lever (Figure 19) is located on the left front front side of the handle. Pulling back the lever applies of the engine. The lever has 2 positions: R the service brake. - Page 15 Fuel-Shutoff Valve Recoil-Starter Handle The fuel-shutoff valve (Figure 19 Figure 20) is Pull the recoil-starter handle (Figure 21) to start the located on the left front of the engine near the choke engine. lever. The valve has 2 positions: C and O LOSED Move the lever up to the C...

- Page 16 Kickstand The kickstand (Figure 23) is mounted to the rear of the machine. Use the kickstand when you install or remove the transport wheels or the cutting unit. • To use the kickstand to install the transport wheels, lower the kickstand to the ground and step down on the loop while pulling up and back on the lower-center handle (Figure...

-

Page 17: Specifications

Extinguish all cigarettes, cigars, pipes, and other Authorized Service Dealer or Distributor or go to sources of ignition. www.Toro.com for a list of all approved attachments • Do not remove the fuel cap or fill the fuel tank and accessories. -

Page 18: Checking The Engine-Oil Level

Checking the Engine-Oil Filling the Fuel Tank Level DANGER Check the engine-oil level before each use or every In certain conditions, fuel is extremely 8 operating hours, refer to Checking the Engine-Oil flammable and highly explosive. A fire or Level (page 30). - Page 19 WARNING Fuel is harmful or fatal if swallowed. Long-term exposure to vapors can cause serious injury and illness. • Avoid prolonged breathing of vapors. • Keep your face away from the nozzle and fuel tank or conditioner bottle opening. • Avoid contact with skin; wash off spills with soap and water.

-

Page 20: Setting The Machine To Match Turf Conditions

Setting the Machine to Match Turf Conditions Use the following table to set the machine to match turf conditions. Bedbars: Standard and Optional (Flex/eFlex 2120 Machines) Part Number Description Aggressiveness Comments 106-2468-01 Non-Aggressive Less Red, Standard 99-3794-03 Aggressive More Black Bedbars: Standard and Optional (Flex/eFlex 1820 Machines) 110-2282-01 Non-Aggressive... -

Page 21: Adjusting The Handle Height

Adjusting the Handle Height Note: The machine is shipped with the handle adjusted to the lowest position. The machine is normally operated with the handle telescoped out to its maximum height. Loosen the 3 carriage bolts and nuts securing each side of the handle in the handle clamps (Figure 26). -

Page 22: Checking The Operation Of The Interlock Switches

Checking the Operation of lever does not disengage, the interlock system needs service. Correct the problem before the Interlock Switches operating the machine; refer to Servicing the Traction-Interlock Switch (page 33). Service Interval: Before each use or daily With the OPC pressed and the shift lever moved to the left, engage the traction and reel CAUTION drive and release the OPC... -

Page 23: Transporting The Machine To A Job Site

• Ensure that the grass basket is in place while mowing. Shut off the engine before emptying the Note: The Toro Trans Pro trailer can be used to basket. transport the machine. For instructions on loading the • trailer, refer to your trailer Operator’s Manual. -

Page 24: Starting The Engine

E position. NGAGED • Use accessories and attachments approved by Ensure that the fuel-shutoff valve is open. The Toro® Company only. Move the On/Off switch to the O position. Slope Safety Move the throttle control to the F position. -

Page 25: Releasing The Transmission

Light Conditions Carefully rotate the lever. Use the LED Light Kit when you operate the machine Move the machine as necessary. in low light conditions; contact your authorized Toro distributor. Important: If possible, do not tow the machine. If towing the machine is absolutely... -

Page 26: After Operation

After Operation After Operation Safety General Safety • Reduce the throttle setting before shutting off the engine and, if the engine has a fuel-shutoff valve, turn off the valve after mowing. • Clean grass and debris from the machine to help prevent fires. -

Page 27: Maintenance

• Replace the paper air filter element (more often in dirty or dusty conditions). • Check the spark plug. Every 100 hours • Clean the fuel-tank screen. • Replace the clutch oil with Mobil ATF D/M Automatic Transmission Fluid (Toro Part Every 500 hours No. 505-136). • Replace the fuel line. -

Page 28: Daily Maintenance Checklist

Daily Maintenance Checklist Important: Duplicate this page for routine use. Maintenance For the week of: Check Item Mon. Tues. Wed. Thurs. Fri. Sat. Sun. Check the safety interlock operation. Check the parking brake operation. Check that pivot joints operate freely. Check the fuel level. -

Page 29: Pre-Maintenance Procedures

• Replace faulty silencers. • If major repairs are ever needed or if assistance is desired, contact an authorized Toro distributor. • To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. -

Page 30: Engine Maintenance

Engine Maintenance for the day. If you have already ran the engine, allow the oil to drain back down to the sump for at least 10 minutes before you check the engine-oil level. Engine Safety Remove the transport wheels (if installed). •... -

Page 31: Servicing The Air Cleaner

Changing the Engine Oil Wash the foam element in a solution of liquid soap and warm water. Squeeze the Service Interval: After the first 20 hours element to remove the dirt, but do not twist it, as the foam may tear. Every 50 hours Dry the foam element by wrapping it in a Start and run the engine for a few minutes to... -

Page 32: Servicing The Spark Plug

Servicing the Spark Plug Fuel System Maintenance Service Interval: Every 100 hours Use an NGK BR6HS spark plug or equivalent. The correct air gap is 0.6 to 0.7 mm (0.024 to 0.028 inch). Cleaning the Fuel-Tank Pull the molded wire off the spark plug (Figure Screen 38). -

Page 33: Electrical System Maintenance

Servicing the Electrical System Brake-Interlock Switch Maintenance Ensure that the engine is off. Servicing the Remove the control panel. Engage the service-brake lever and engage the Traction-Interlock Switch parking-brake latch. Use the following procedure if the traction-interlock Loosen and remove the interlock-switch switch needs adjustment or replacement. -

Page 34: Brake Maintenance

Brake Maintenance Belt Maintenance Adjusting the Inspecting the Reel-Drive Service/Parking Brake Belt If the service/parking brake slips when operated, Service Interval: Every 1,000 hours adjust the cable as follows: Shut off the engine and remove the key. Move the service/parking brake lever to the O Loosen the flange bolt that secures the belt position. -

Page 35: Visually Inspecting The Reel Clutch

Engaging/Disengaging Clean any debris from inside the belt compartment and from around the the Transmission-Belt compression spring (Figure 45). Ensure that the compression spring is Tensioner applying the proper tension on the belt. The transmission belt is tensioned by a spring-loaded Tighten the bearing housing mounting nut. -

Page 36: Controls System Maintenance

Controls System Move the traction control to the E NGAGED position. Maintenance Measure the distance from the pin on either end of the traction-control spring (Figure 48); repeat steps through until it is Adjusting the Traction within 7.3 to 7.6 cm (2-7/8 to 3 inches). Control Adjusting the Reel Control If the traction control does not engage or if it slips... -

Page 37: Storage

Repair or replace any part that is worn or damaged. Paint all scratched or bare metal surfaces. Paint is available from your authorized Toro distributor. Store the machine in a clean, dry garage or storage area. Cover the machine to protect it... - Page 38 Notes:...

- Page 39 The Way Toro Uses Information Toro may use your personal information to process warranty claims, to contact you in the event of a product recall and for any other purpose which we tell you about. Toro may share your information with Toro's affiliates, dealers or other business partners in connection with any of these activities. We will not sell your personal information to any other company.

- Page 40 Countries Other than the United States or Canada Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor's service or have difficulty obtaining guarantee information, contact the Toro importer.