Siemens SINAMICS S120 Equipment Manual

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Siemens SINAMICS S120

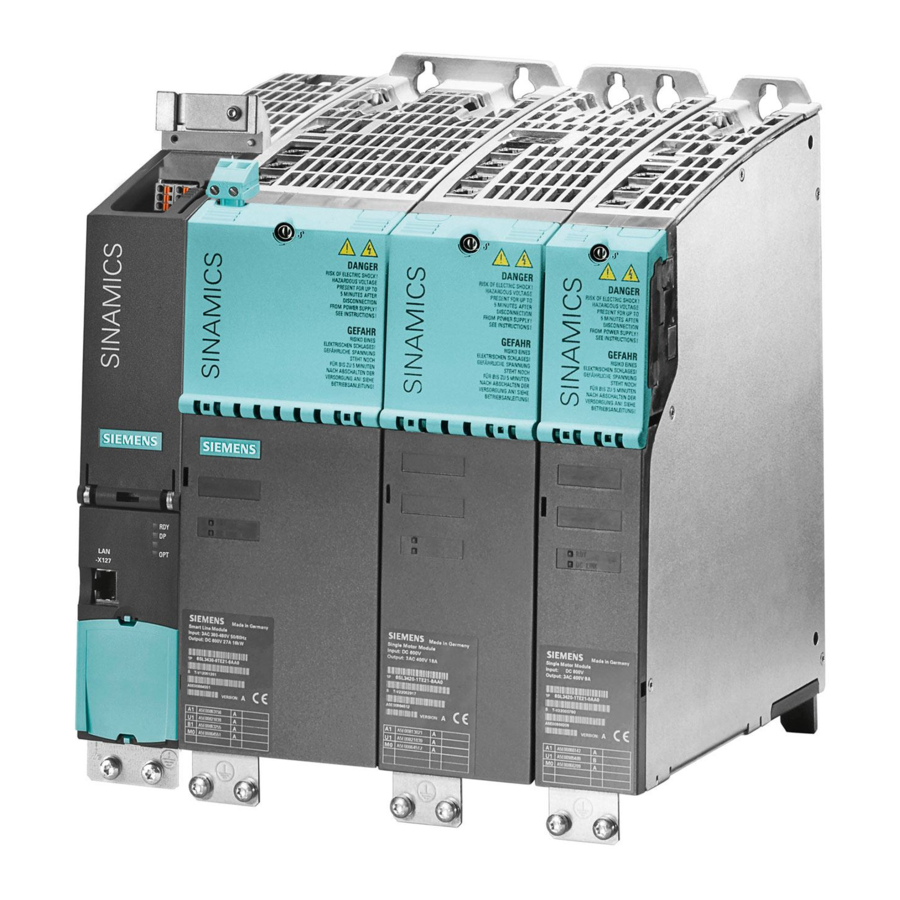

- Page 1 SINAMICS SINAMICS S120 Equipment Manual AC Drive...

- Page 3 Foreword System overview Line-side power components SINAMICS Power Modules SINAMICS S120 Equipment Manual AC Drive DC link components Motor-side power components Manual Control Units Supplementary system components and encoder system integration Accessories Cabinet design and EMC for components, Blocksize format...

- Page 4 Trademarks All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

- Page 5 Orientation SINAMICS S Sales Documentation Planning/configuration SIZER Configuration tool Decision/ordering SINAMICS S Catalogs SINAMICS S120 Equipment Manual for Control Units and Installation/assembly • Supplementary System Components SINAMICS S120 Equipment Manual Power Modules Booksize • SINAMICS S120 Equipment Manual Power Modules Chassis •...

- Page 6 Foreword Usage phase Tools SINAMICS S120 Commissioning Manual Maintenance/servicing • SINAMICS S List Manual • SINAMICS S150 Operating Manual • Target group This Manual addresses planners, installation technicians, design engineers. Benefits This manual provides information on the components and functions of devices so that the target group is capable of installing, setting up, testing, operating, and troubleshooting the devices safely and correctly.

- Page 7 European and African time zones A&D Technical Support Tel.: +49 (0) 180 / 5050 - 222 Fax: +49 (0) 180 / 5050 - 223 Internet: www.siemens.com/automation/support-request E-mail: adsupport@siemens.com Asian and Australian time zones A&D Technical Support Tel.: +86 1064 719 990...

- Page 8 The EC Declaration of Conformity for the EMC Directive can be found/obtained from: • in the Internet: www.ad.siemens.de/csinfo under Product/Order No. 15257461 • with the responsible branch office of the A&D MC Business Division of Siemens AG. ESD information Caution Electrostatic sensitive devices (ESDs) are individual components, integrated circuits, or boards that may be damaged by either electrostatic fields or electrostatic discharge.

- Page 9 Foreword Safety information Danger Commissioning shall not start until you have ensured that the machine in which the components described here are to be installed complies with Directive 98/37/EC. SINAMICS S equipment must only be commissioned by suitably qualified personnel. The personnel must take into account the information provided in the technical customer documentation for the product, and be familiar with and observe the specified danger and warning notices.

- Page 10 Foreword Note When operated in dry areas, SINAMICS equipment conforms to the Low-Voltage Directive 73/23/EEC. Note SINAMICS equipment fulfills, in the configuration specified in the associated EC Declaration of Conformance and when the EMC Mounting Guidelines is consequently implemented, Order No. 6FC 5297-⃞AD30-0AP⃞, EMC Directive 89/336/EEC. Warning Operating the equipment in the immediate vicinity (<...

-

Page 11: Table Of Contents

Field of application ........................1-1 Versions ............................. 1-2 Platform concept and Totally Integrated Automation..............1-2 Overview, SINAMICS S120 AC Drive..................1-3 Components, SINAMICS S120 AC Drive .................. 1-5 System data ..........................1-6 Standards........................... 1-8 Line-side power components ........................2-1 Introduction ..........................2-1 Line connection variants ...................... - Page 12 Table of contents Power Modules ............................3-1 Power Modules Blocksize (PM340) ................... 3-1 3.1.1 Description ..........................3-1 3.1.2 Safety information ........................3-4 3.1.3 Interface description........................3-7 3.1.3.1 Overview ............................ 3-7 3.1.3.2 Line supply connection......................3-16 3.1.3.3 Motor connection........................3-17 3.1.3.4 Connection to the option module, brake control ..............

- Page 13 Table of contents 4.2.2 Braking resistors ........................4-20 4.2.2.1 Description ..........................4-20 4.2.2.2 Safety information ........................4-20 4.2.2.3 Dimension drawing ........................4-21 4.2.2.4 Technical data.......................... 4-22 Motor-side power components........................ 5-1 Motor reactors ..........................5-1 5.1.1 Blocksize ............................ 5-1 5.1.1.1 Description ..........................5-1 5.1.1.2 Safety information ........................

- Page 14 Table of contents 6.2.4 Dimension drawing........................6-17 6.2.5 Mounting the CU310 on the Power Module Blocksize............. 6-18 6.2.6 Mounting the CU310 in the Power Module Chassis ..............6-20 6.2.7 Technical data.......................... 6-21 Control Unit CU310 PN (PROFINET) ..................6-22 6.3.1 Description ..........................

- Page 15 Table of contents 7.2.3.11 X541 bidirectional digital inputs/outputs .................. 7-14 7.2.3.12 Relay outputs X542........................7-15 7.2.3.13 Description of the LEDs on the Terminal Module 31 (TM31) ..........7-15 7.2.4 Dimension drawing ........................7-16 7.2.5 Mounting ..........................7-17 7.2.6 Electrical Connection ....................... 7-18 7.2.7 Technical data..........................

- Page 16 Table of contents DRIVE-CLiQ coupling ........................ 8-6 8.2.1 Description ..........................8-6 8.2.2 Safety Information ........................8-6 8.2.3 Interface description........................8-7 8.2.3.1 Overview ............................ 8-7 8.2.4 Dimension drawing........................8-8 8.2.5 Installation ..........................8-9 8.2.6 Technical data..........................8-9 Screening Kit..........................8-10 8.3.1 Dimension drawings.........................

- Page 17 Table of contents 10.3 Service and maintenance for Chassis format components ............. 10-7 10.3.1 Maintenance..........................10-8 10.3.2 Installation equipment ......................10-9 10.3.3 Replacing components ......................10-10 10.3.3.1 Safety information ........................10-10 10.3.3.2 Replacing the Powerblock, Power Module, frame size FX............ 10-11 10.3.3.3 Replacing the Powerblock, Power Module, frame size GX ...........

- Page 18 Table of contents Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 19: System Overview

System overview Field of application SINAMICS is the new family of drives from Siemens for industrial machines and plant construction. SINAMICS offers solutions for all drive tasks: • Simple pump and fan applications in the process industry. • Complex individual drives in centrifuges, presses, extruders, elevators, as well as conveyor and transport systems. -

Page 20: Versions

The different SINAMICS versions can be easily combined with each other. SINAMICS is a part of the Siemens "Totally Integrated Automation" concept. Integrated SINAMICS systems covering configuration, data storage, and communication at automation level ensure low-maintenance solutions with SIMATIC, SIMOTION, and SINUMERIK. -

Page 21: Overview, Sinamics S120 Ac Drive

System overview 1.4 Overview, SINAMICS S120 AC Drive Overview, SINAMICS S120 AC Drive SINAMICS S120 AC Drive is a modular drive system for individual axes and addresses sophisticated drive tasks for an extremely wide range of industrial applications. Applications include: •... - Page 22 System overview 1.4 Overview, SINAMICS S120 AC Drive Configuration example Figure 1-3 Configuration with multi-axis and single-axis drives Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 23: Components, Sinamics S120 Ac Drive

System overview 1.5 Components, SINAMICS S120 AC Drive Components, SINAMICS S120 AC Drive This overview includes components from SINAMICS S120 AC Drive. Figure 1-4 Component overview, SINAMICS S120 AC Drive Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 24: System Data

• Power Modules, either with or without integrated line filter as well as integrated braking chopper to provide power to the connected motor To address the required functions, SINAMICS S120 AC Drive is equipped with: • Control Units that provide the drive and technological functions. -

Page 25: Power Modules

System overview 1.6 System data Electrical data Chassis format units • Category C3 acc. to EN 61800-3. Standard – Category C2 acc. to EN 61800-3. With line filter – Overvoltage category III acc. to EN 60664-1 Mechanical data Vibratory load Long-term storage •... -

Page 26: Standards

System overview 1.7 Standards Electrical data Installation altitude Blocksize format units • Up to 1000 m above sea level without de-rating. Above 1000 m with current de-rating, linear to 80 % up to 4000 m. Above 2000 m with voltage de-rating, linear to 77 % up to 4000 m. Chassis format units Up to 2000 m above sea level NN without de-rating, •... - Page 27 System overview 1.7 Standards Standards Title EN 60664-X Insulation coordination for equipment within low-voltage systems Part 1: Principles, requirements and tests Part 3: Use of coating, potting or moulding for protection against pollution EN 60721-3-X Classification of environmental conditions Part 3-0: Classification of environmental parameters and their severities; Introduction Part 3-1: Classification of environmental parameters and their severities;...

- Page 28 System overview 1.7 Standards Equipment Manual AC Drive 1-10 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 29: Line-Side Power Components

Line-side power components Introduction The line connection for a SINAMICS Blocksize drive line-up comprises an optional line reactor and an optional line filter: • Line supply voltages: – 1-ph. 200 V to 1-ph. 240 V AC +/- 10%. – 3-ph. 380 V to 3-ph. 480 V AC +/- 10%. •... - Page 30 Caution The following can occur if line reactors/line filters are used, which have not been approved for SINAMICS by SIEMENS: - the Power Modules could be damaged/destroyed. - Line reactions can occur that can damage or interfere with other loads powered from the same network.

-

Page 31: Line Connection Variants

Line-side power components 2.2 Line connection variants Line connection variants 2.2.1 Methods of line connection A distinction is made between: • Direct operation of the line connection components on the supply • Operation of the Line Connection Components via an Autotransformer •... -

Page 32: Operation Of The Line Connection Components On The Supply Network

Line-side power components 2.2 Line connection variants 2.2.2 Operation of the Line Connection Components on the Supply Network The SINAMICS S Blocksize drive system is designed to be directly connected to TN, TT line supply systems with grounded neutral conductor or grounded phase conductor as well as to IT line systems with rated voltages from 3-ph. -

Page 33: Operation Of The Line Connection Components Via An Autotransformer

Line-side power components 2.2 Line connection variants 2.2.3 Operation of the Line Connection Components via an Autotransformer An autotransformer can be used for voltage adaptation in the range up to 3-ph. 480 V AC +10% or 1-ph. 240 V AC +10%. Caution To ensure protective separation, an isolating transformer must be used for voltages greater than 3-ph. -

Page 34: Operation Of The Line Connection Components Via An Isolating Transformer

Line-side power components 2.2 Line connection variants 2.2.4 Operation of the Line Connection Components via an Isolating Transformer The isolating transformer converts the type of the line supply type in the plant (e.g. IT/TT line supply) to a TN line supply. Additional voltage adaptation to the permissible voltage tolerance range is possible. -

Page 35: Line Connection Via A Residual-Current Circuit-Breaker

Line-side power components 2.2 Line connection variants Figure 2-6 Isolating transformer 2.2.5 Line Connection via a Residual-Current Circuit-Breaker In preparation Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 36: Line Filter

• Outgoing cable to the line reactor to LOAD/LAST L1', L2', L3' Non-observance may damage the line filter Caution Using line filters not released by Siemens AG for SINAMICS can lead to line reactions that can damage or destroy other loads powered from the network. Equipment Manual AC Drive... -

Page 37: Dimension Drawing, Blocksize

Line-side power components 2.3 Line filter 2.3.3 Dimension drawing, Blocksize Figure 2-7 Dimension drawing: Line filter, frame size A Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 38: Dimension Drawing, Chassis

Line-side power components 2.3 Line filter 2.3.4 Dimension drawing, Chassis Figure 2-8 Dimension drawing, line filter Table 2-1 Dimensions of the line filter, all data in mm and (inches) 6SL3000- 0BE32-5AA0 0BE34-4AA0 0BE36-0AA0 330 (12.99) 360 (14.17) 400 (15.74) 240 (9.44) 240 (9.44) 265 (10.43) 116 (4.56) -

Page 39: Installation

Line-side power components 2.3 Line filter 6SL3000- 0BE32-5AA0 0BE34-4AA0 0BE36-0AA0 2 (0.07) 2 (0.07) 2.5 (0.09) 78.2 (3.07) 78.2 (3.07) 90 (3.54) 220 (8.66) 220 (8.66) 240 (9.44) 210 (8.26) 210 (8.26) 250 (9.84) 330 (12.99) 330 (12.99) 370 (14.56) 9 (0.35) 9 (0.35) 12 (0.47) - Page 40 Line-side power components 2.3 Line filter Figure 2-10 Mounting: Power Module with motor reactor, line filter and line reactor Equipment Manual AC Drive 2-12 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 41: Electrical Connection

Line-side power components 2.3 Line filter 2.3.6 Electrical Connection Figure 2-11 Shielding: Line filter, frame size A Equipment Manual AC Drive 2-13 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 42: Technical Data, Blocksize Line Filter

Line-side power components 2.3 Line filter 2.3.7 Technical data, Blocksize line filter Table 2-2 Technical data, Blocksize line filter Line supply voltage 3-ph. 380...480 V AC Line filter 6SE6400-2FA00-6AD0 Suitable for Power Module 6SL3210-1SE11-3UA0, 6SL3210-1SE11-7UA0 6SL3210-1SE12-2UA0, 6SL3210-1SE13-1UA0 6SL3210-1SE14-1UA0 Rated current Power loss <... -

Page 43: Line Reactors

- Outgoing cable to the load 1U2, 1V2, 1W2. Non-observance may damage the line reactor. Caution When using line reactors that have not been approved by SIEMENS for SINAMICS, the following can occur: - the Power Modules could be damaged/destroyed. -

Page 44: Dimension Drawings, Blocksize Line Reactors

Line-side power components 2.4 Line reactors 2.4.3 Dimension drawings, Blocksize line reactors Figure 2-12 Dimension drawing: Line reactor, frame sizes A, B and C Table 2-4 Total and retaining dimensions, line reactors, Part 1 Line reactor 6SE6400- 3CC00-4AB3 3CC01-0AB3 3CC00-2AD3 3CC00-2AD3 3CC00-4AD3 Suitable for Power Module... - Page 45 Line-side power components 2.4 Line reactors Table 2-5 Total and retaining dimensions, line reactors, Part 2 Line reactor 6SE6400- 6SE6400-3CC00- 6SL3203-0CD21- 6SL3203-0CD21- 6SL3203-0CD21- 3CC00-4AD3 6AD3 0AA0 0AA0 4AA0 Suitable for Power Module 6SL3210- 1SE13-1UA0 1SE14-1UA0 1SE16-0UA0 1SE17-7UA0 1SE21-0UA0 Frame size Dimension A in mm and (inches) 200 (7.87) 270 (10, 62)

- Page 46 Line-side power components 2.4 Line reactors Figure 2-13 Dimension drawing: Line reactor frame sizes D and E Table 2-7 Total and retaining dimensions, line reactor Line reactor 6SL3203- 0CJ24-5AA0 0CJ24-5AA0 0CD25-3AA0 0CJ28-6AA0 0CJ28-6AA0 Suitable for Power Module 6SL3210- 1SE23-8UA0 1SE24-5UA0 1SE26-0UA0 1SE27-5UA0 1SE31-0UA0...

- Page 47 Line-side power components 2.4 Line reactors Figure 2-14 Dimension drawing: Line reactor, frame size F Table 2-8 Total and retaining dimensions, line reactor Line reactor 6SE6400- 3CC11-2FD0 3CC11-2FD0 3CC11-7FD0 Suitable for Power Module 1SE31-1UA0 1SE31-5UA0 1SE31-8UA0 6SL3210- Frame size Dimension A in mm and (inches) 240 (9.44) Dimension B in mm and (inches) 141 (5.55)

-

Page 48: Dimension Drawing, Chassis Line Reactor

Line-side power components 2.4 Line reactors 2.4.4 Dimension drawing, Chassis line reactor Dimension drawing of the line reactors Figure 2-15 Dimension drawing, line reactors Equipment Manual AC Drive 2-20 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... - Page 49 Line-side power components 2.4 Line reactors Table 2-9 Dimensions of the line reactors, all data in mm and (inches) 6SL3000- 0CE32-3AA0 0CE32-8AA0 0CE33-3AA0 0CE35-1AA0 25 (0.98) 25 (0.98) 25 (0.98) 30 (1.18) 5 (0.19) 5 (0.19) 5 (0.19) 6 (0.23) 12.5 (0.49) 12.5 (0.49) 12.5 (0.49)

-

Page 50: Installation

Line-side power components 2.4 Line reactors 2.4.5 Installation Figure 2-16 Mounting: Line reactor, frame size A Table 2-10 Total and retaining dimensions, line reactor, Part 1, all data in mm and (inches) Line reactor 3CC00-4AB3 3CC01-0AB3 3CC00-2AD3 6SE6400- 3CC00-4AD3 3CC00-6AD3 Suitable for 1SB11-0UA0 1SB14-0UA0... - Page 51 Line-side power components 2.4 Line reactors Figure 2-17 Mounting: Line reactors, frame sizes B and C Table 2-11 Total and retaining dimensions, line reactor, Part 2, all data in mm and (inches) Line reactor 0CD21-0AA0 0CD21-4AA0 0CD22-2AA0 0CD22-2AA0 0CD23-5AA0 6SL3203- Suitable for Power Module 1SE16-0UA0 1SE21-0UA0...

- Page 52 Line-side power components 2.4 Line reactors Figure 2-18 Mounting: PM340 and line reactor, frame size B Equipment Manual AC Drive 2-24 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 53 Line-side power components 2.4 Line reactors Figure 2-19 Side mounting: Line reactors, frame sizes B and C The line reactors for Power Modules, frame sizes A - E, are designed as sub-chassis components. The line reactor is retained on the mounting surface and the Power Module is mounted on the line reactor in a space-saving fashion.

-

Page 54: Electrical Connection

Line-side power components 2.4 Line reactors 2.4.6 Electrical Connection Line supply/load connection Figure 2-20 Power Module with line filter Figure 2-21 Power Module Blocksize with line reactor and line filter Equipment Manual AC Drive 2-26 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 55: Technical Data, Blocksize

Line-side power components 2.4 Line reactors 2.4.7 Technical data, Blocksize Table 2-12 Technical data, Blocksize line reactors, Part 1 Line supply voltage 1-ph 200 V AC -10 % to 240 V AC+10% Order No. 6SE6400- 3CC00-4AB3 3CC01-0AB3 Suitable for Power 1SB11-0UA0 1SB14-0UA0 Module 6SL3210-... - Page 56 Line-side power components 2.4 Line reactors Table 2-14 Technical data, Blocksize line reactors, Part 3 Line supply voltage 3-ph 380 V AC -10 % to 480 V AC +10% Order No. 6SL3203- 0CD21-4AA0 0CD22-2AA0 0CD23-5AA0 0CJ24-5AA0 Suitable for 1SE17-7UA0 1SE21-8UA0 1SE23-2UA0 1SE23-8UA0 Power Module...

-

Page 57: Technical Data, Chassis

Line-side power components 2.4 Line reactors 2.4.8 Technical data, Chassis Table 2-16 Technical data, Chassis line reactors Order No. 6SL3000- 0CE32-3AA0 0CE32-8AA0 0CE33-3AA0 0CE35-1AA0 0CE35-1AA0 Suitable for 6SL3310- 1TE32-1AA0 1TE32-6AA0 1TE33-1AA0 1TE33-8AA0 1TE35-0AA0 Power Module Rated current of the Power Module Rated voltage 3-ph. - Page 58 Line-side power components 2.4 Line reactors Equipment Manual AC Drive 2-30 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 59: Power Modules

Power Modules Power Modules Blocksize (PM340) 3.1.1 Description The Power Modules, Blocksize format are designed as follows: • Line side diode rectifier • DC link electrolytic capacitors with pre-charging circuit • Output inverter • Chopper transistor for (external) braking resistor •... - Page 60 Power Modules 3.1 Power Modules Blocksize (PM340) Table 3-1 Overview, Power Modules 340 (selection) Power Module (230 V) frame size A, with and without Power Module frame size B, with and without integrated line integrated line filter filter Power Module (400 V) frame size A, without integrated line filter Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 61 Power Modules 3.1 Power Modules Blocksize (PM340) Power Module frame size C, with and without integrated Power Module frame size D, without line filter line filter Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 62: Safety Information

Power Modules 3.1 Power Modules Blocksize (PM340) Power Module frame size E, without line filter Power Module frame size F, without line filter 3.1.2 Safety information Caution During transport and during storage, Power Modules must be protected against mechanical shock and vibration. It is also important to protect the unit against water (rain) and against excessively high/excessively low temperatures. - Page 63 Power Modules 3.1 Power Modules Blocksize (PM340) Danger It must be checked as to whether the Power Module is designed for the correct power supply voltage - higher supply voltages may not be connected to the Power Module. Danger After connecting the line and motor feeder cables to the appropriate terminals, it must be checked that the front covers (only frame sizes D and F) are closed and latched.

- Page 64 Power Modules 3.1 Power Modules Blocksize (PM340) Caution Power Modules must be mounted in the vertical position. For the Power Modules, the following cooling clearances must be maintained above and below the component: - frame sizes A and B: 100 mm (3.93 inch), - frame size C: 125 mm (4.92 inches), - frame sizes D and E 300 mm (11.81 inches) and - frame size F: 350 mm (13.77 inches).

-

Page 65: Interface Description

Power Modules 3.1 Power Modules Blocksize (PM340) 3.1.3 Interface description 3.1.3.1 Overview Figure 3-1 PM340, frame size A Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... - Page 66 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-2 PM340, frame size B Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 67 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-3 PM340, frame size C Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 68 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-4 PM340, frame size D Equipment Manual AC Drive 3-10 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 69 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-5 PM340, frame size E Equipment Manual AC Drive 3-11 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 70 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-6 PM340, frame size F Equipment Manual AC Drive 3-12 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 71 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-7 Connection example PM340, 1-ph. 200 V - 240 V AC Equipment Manual AC Drive 3-13 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 72 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-8 Connection example PM340, 3-ph. 380 V - 480 V AC Equipment Manual AC Drive 3-14 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 73 Power Modules 3.1 Power Modules Blocksize (PM340) Arrangement of the line supply and motor terminals. The arrangement of the line supply and motor terminals for frame sizes A to F of the Power Module 340 are shown in the following diagram. The diagram also shows the tightening torques for the terminals.

-

Page 74: Line Supply Connection

Power Modules 3.1 Power Modules Blocksize (PM340) 3.1.3.2 Line supply connection Table 3-2 Terminal strip, line supply connection 1-ph. 200 V - 240 V AC Terminal Signal name Technical specifications Line phase L Line phase N Max. conductor cross-section: 2.5 mm² Table 3-3 Terminal strip, line supply connection 3-ph. -

Page 75: Motor Connection

Power Modules 3.1 Power Modules Blocksize (PM340) 3.1.3.3 Motor connection Table 3-4 Terminal strip, motor connection 1-ph. 200 V - 240 V AC and 3-ph. 380 V - 480 V AC Terminal Designation Technical specifications DC link negative DCP/R1 DC link positive and position connection of the braking resistor Negative connection for the braking resistor PE connection Motor phase U... -

Page 76: Dimension Drawings

Power Modules 3.1 Power Modules Blocksize (PM340) 3.1.4 Dimension drawings Figure 3-10 Dimension drawings, Power module PM340 Frame size C Frame size B Frame size A Equipment Manual AC Drive 3-18 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... - Page 77 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-11 Dimension drawing: Power Module 340, frame size D Equipment Manual AC Drive 3-19 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 78 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-12 Dimension drawing: Power Module 340, with integrated line filter, frame size D Equipment Manual AC Drive 3-20 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 79 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-13 Dimension drawing: Power Module 340, frame size E Equipment Manual AC Drive 3-21 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 80 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-14 Dimension drawing: Power Module 340, with integrated line filter, frame size E Equipment Manual AC Drive 3-22 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 81 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-15 Dimension drawing: Power Module 340, frame size F Equipment Manual AC Drive 3-23 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 82 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-16 Dimension drawing: Power Module PM340, with integrated line filter, frame size F Equipment Manual AC Drive 3-24 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 83: Mounting

Power Modules 3.1 Power Modules Blocksize (PM340) 3.1.5 Mounting Drilling templates for frame sizes A to C Figure 3-17 Drilling templates for frame sizes A to C Equipment Manual AC Drive 3-25 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... - Page 84 Power Modules 3.1 Power Modules Blocksize (PM340) Drilling templates for frame sizes D to F Figure 3-18 Drilling templates for frame sizes D to F - with and without line filter Equipment Manual AC Drive 3-26 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 85 Power Modules 3.1 Power Modules Blocksize (PM340) The dimensions and the tightening torques when retaining the Power Modules are specified in the following table. Table 3-7 PM340, dimensions and tightening torques when mounting Frame size Height, width, depth Dimensions Retaining type Tightening torques (with Control Unit) HxWxD...

- Page 86 Power Modules 3.1 Power Modules Blocksize (PM340) Table 3-8 PM340, load terminals - tightening torques Frame size Tightening torques 2.25 For frame sizes D to F, the terminals are accessed by releasing the tongue at the side of the terminal covers using a suitable flat screwdriver. The cover can then be pushed upwards and engaged in this position as shown in the following diagram.

- Page 87 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-19 Access to the line and motor terminals for frame sizes D to F Equipment Manual AC Drive 3-29 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 88: Electrical Installation

Power Modules 3.1 Power Modules Blocksize (PM340) 3.1.6 Electrical installation Operation on non-grounded line supply systems (IT) It is not permissible to use Power Modules with series line filter in IT line supply systems. In order that the Power Modules remain functional when ground faults occur, a line reactor must be connected in series. - Page 89 Power Modules 3.1 Power Modules Blocksize (PM340) Line supply voltage 1-ph. 230 V AC ± 10 % PM340 6SL3210– 1SB11-0UA0 1SB12-3UA0 1SB14-0UA0 PM340 with integrated line filter 6SL3210– 1SB11-0AA0 1SB12-3AA0 1SB14-0AA0 Max. motor cable length 50 (shielded) 50 (shielded) 50 (shielded) (without external options) 75 (non-shielded) 75 (non-shielded)

- Page 90 Power Modules 3.1 Power Modules Blocksize (PM340) Line voltage 3-ph. 380 V to 480 V AC PM340 6SL3210- 1SE11-3UA0 1SE11-7UA0 1SE12-2UA0 1SE13-1UA0 1SE14-1UA0 PM340 with integrated 6SL3210- 1SE11-3AA0 1SE11-7AA0 1SE12-2AA0 1SE13-1AA0 1SE14-1AA0 line filter Line supply connection Screw terminals Screw terminals Screw terminals Screw terminals Screw terminals...

- Page 91 Power Modules 3.1 Power Modules Blocksize (PM340) Line voltage 3-ph. 380 V to 480 V AC PM340 6SL3210- 1SE16-0UA0 1SE17-7UA0 1SE21-0UA0 1SE21-8AA0 1SE22-5UA0 PM340 with integrated 6SL3210- 1SE16-0AA0 1SE17-7AA0 1SE21-0AA0 1SE21-8UA0 1SE22-5AA0 line filter Power loss 0.139 0.158 0.183 0.240 0.297 Cooling air requirement 0.009...

- Page 92 Power Modules 3.1 Power Modules Blocksize (PM340) Table 3-12 Technical data PM340, Part 4 Line voltage 3-ph. 380 V to 480 V AC PM340 6SL3210- 1SE23-2UA0 1SE23-8UA0 1SE24-5UA0 1SE26-0UA0 1SE27-5UA0 PM340 with integrated 6SL3210- 1SE23-2AA0 1SE23-8AA0 1SE24-5AA0 1SE26-0AA0 1SE27-5AA0 line filter Rated output current I Base load current I Output current for S6...

- Page 93 Power Modules 3.1 Power Modules Blocksize (PM340) Line voltage 3-ph. 380 V to 480 V AC PM340 6SL3210- 1SE23-2UA0 1SE23-8UA0 1SE24-5UA0 1SE26-0UA0 1SE27-5UA0 PM340 with integrated 6SL3210- 1SE23-2AA0 1SE23-8AA0 1SE24-5AA0 1SE26-0AA0 1SE27-5AA0 line filter Max. motor cable 50 (shielded) 75 (shielded) 75 (shielded) 75 (shielded) 75 (shielded)

- Page 94 Power Modules 3.1 Power Modules Blocksize (PM340) Line voltage 3-ph. 380 V to 480 V AC PM340 6SL3210- 1SE31-0UA0 1SE31-1UA0 1SE31-5UA0 1SE31-8UA0 PM340 with integrated line 6SL3210- 1SE31-0AA0 1SE31-1AA0 1SE31-5AA0 1SE31-8AA0 filter Rated input current with line reactor - without line reactor Resistance value of the ≥...

- Page 95 Power Modules 3.1 Power Modules Blocksize (PM340) Table 3-14 Cooling air requirement Frame size Required cooling air quantity 17.3 86.4 197.6 197.6 Interrelationship between the pulse frequency and current de-rating Table 3-15 Current de-rating depending on the pulse frequency Order Line Rated Power...

- Page 96 Power Modules 3.1 Power Modules Blocksize (PM340) Order Line Rated Power Output current in A at a switching frequency of: voltage output (high current overload) 6SL3210 [kW] 4 kHz 6 kHz 8 kHz 10 kHz 12 kHz 14 kHz 16 kHz 1SE23- 15.0 32.0...

- Page 97 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-21 Load cycle without pre-load condition Figure 3-22 S6 load cycle with pre-load condition Figure 3-23 S6 load cycle with pre-load condition Equipment Manual AC Drive 3-39 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 98 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-24 Load cycle with 60 s overload with a load cycle period of 300 s 30 s 300 s Figure 3-25 Load cycle with 30 s overload with a load cycle period of 300 s Derating characteristic for Power Modules in Blocksize format Frame sizes A - C Figure 3-26...

- Page 99 Power Modules 3.1 Power Modules Blocksize (PM340) Figure 3-27 Output power as a function of ambient temperature Figure 3-28 Output power as a function of installation altitude Equipment Manual AC Drive 3-41 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 100: Power Modules Chassis

Power Modules 3.2 Power Modules Chassis Figure 3-29 Voltage correction factor as a function of installation altitude Power Modules Chassis 3.2.1 Description A Power Module is a power unit (frequency inverter) that provides the power supply for the connected motor. A Power Module must be connected to a Control Unit via DRIVE-CLiQ. The open-loop and closed-loop control functions are stored in the Control Unit. -

Page 101: Safety Information

Power Modules 3.2 Power Modules Chassis 3.2.2 Safety information Danger After disconnecting all the supply voltages, a hazardous voltage will be present at all Power Modules for another 5 minutes. Work cannot be carried out until this time has elapsed. Danger The DC link discharge voltage hazard warning in the local language must be attached to all of the components. -

Page 102: Interface Description

Power Modules 3.2 Power Modules Chassis 3.2.3 Interface description 3.2.3.1 Overview Figure 3-30 Power Module, frame size FX Equipment Manual AC Drive 3-44 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... - Page 103 Power Modules 3.2 Power Modules Chassis Figure 3-31 Power Module, frame size GX Equipment Manual AC Drive 3-45 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 104: Sample Connection

Power Modules 3.2 Power Modules Chassis 3.2.3.2 Sample connection Figure 3-32 Connection example: Power Module Chassis Equipment Manual AC Drive 3-46 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 105: Terminal Block X9

Power Modules 3.2 Power Modules Chassis 3.2.3.3 Terminal Block X9 Table 3-16 Terminal strip X9 Terminal Signal name Technical specifications P24V Voltage: 24 V DC (20.4 V - 28.8 V) Current consumption: max 1.4 A Reserved, do not use Reserved, do not use Reserved, do not use Reserved, do not use EP +24 V (Enable Pulses) -

Page 106: X41 Ep Terminal / Temperature Sensor Connection

Power Modules 3.2 Power Modules Chassis 3.2.3.5 X41 EP terminal / temperature sensor connection Table 3-18 Terminal strip X41 Terminal Function Technical specifications +Temp Temperature sensor connection KTY84-1C130 -Temp are assigned are assigned Max. cross-section that can be connected: 1.5 mm² (AWG 14) Notice The KTY temperature sensor must be connected with the correct polarity. -

Page 107: Meaning Of The Leds On The Power Module

The warning information on the components must be carefully observed! Cause and rectification of faults The following reference contains information about the cause of the faults and how they can be resolved: Reference: /IH1/ SINAMICS S120 Commissioning Manual. Equipment Manual AC Drive 3-49 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 108: Dimension Drawings

Power Modules 3.2 Power Modules Chassis 3.2.4 Dimension drawings Dimension drawing frame size FX The cooling clearances to be maintained are indicated by the dotted line. Figure 3-33 Dimension drawing Power Module, frame size FX Equipment Manual AC Drive 3-50 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... - Page 109 Power Modules 3.2 Power Modules Chassis Dimension drawing frame size GX The cooling clearances to be maintained are indicated by the dotted line. Figure 3-34 Dimension drawing Power Module, frame size GX Equipment Manual AC Drive 3-51 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 110: Mounting The Cu310 In The Power Module Chassis

Power Modules 3.2 Power Modules Chassis 3.2.5 Mounting the CU310 in the Power Module Chassis Figure 3-35 Mounting the CU310 in the Power Module Chassis, frame size FX The DRIVE-CLiQ cable and the cable for the 24 V power supply must be correctly routed so that the front flap can close. -

Page 111: Electrical Connection

Power Modules 3.2 Power Modules Chassis 3.2.6 Electrical connection Adjusting the fan voltage (-T10) The power supply for the device fans (1-ph. 230 V AC) in the Power Module (-T10) is taken from the line supply using transformers. The locations of the transformers are indicated in the interface descriptions. -

Page 112: Technical Data

Power Modules 3.2 Power Modules Chassis 3.2.7 Technical data Table 3-22 Technical data, Power Modules Chassis Line supply voltage 3-ph. 380 V to 480 V AC ± 10 % (-15 % < 1 min) Order No. 6SL3310– 1TE32-1AA0 1TE32-6AA0 1TE33–1AA0 1TE33-8AA0 1TE35-0AA0 Rated output current I Base load current I... - Page 113 Power Modules 3.2 Power Modules Chassis Line supply voltage 3-ph. 380 V to 480 V AC ± 10 % (-15 % < 1 min) Order No. 6SL3310– 1TE32-1AA0 1TE32-6AA0 1TE33–1AA0 1TE33-8AA0 1TE35-0AA0 PE connection Flat connector for M10 cable lug, max. connection cross section 2 x 185 mm Max.

-

Page 114: Characteristics

Power Modules 3.2 Power Modules Chassis 3.2.7.1 Characteristics Overload capability The Power Modules are equipped with an overload reserve e.g. to handle breakaway torques. In drives with overload requirements, the appropriate base load current must, therefore, be used as a basis for the required load. The criterion for overload is that the drive is operated with its base load current before and after the overload occurs (a load duration of 300 s is used as a basis here). -

Page 115: Current De-Rating As A Function Of The Pulse Frequency

Power Modules 3.2 Power Modules Chassis High overload The base load current for high overload IH is based on a load duty cycle of 150% for 60 s or 160% for 10 s with a load duty duration of 300 s. Figure 3-38 High overload 3.2.7.2... - Page 116 Power Modules 3.2 Power Modules Chassis Maximum output frequencies achieved by increasing the pulse frequency By multiplying the rated pulse frequency with a multiple integer, the following output frequencies can be achieved taking into account the derating factors: Table 3-24 Maximum output frequencies achieved by increasing the pulse frequency Pulse frequency [kHz] Maximum output frequency [Hz]...

- Page 117 Power Modules 3.2 Power Modules Chassis Figure 3-41 Voltage correction factor as a function of installation altitude Equipment Manual AC Drive 3-59 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 118 Power Modules 3.2 Power Modules Chassis Equipment Manual AC Drive 3-60 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 119: Dc Link Components

DC link components Blocksize 4.1.1 Braking resistors 4.1.1.1 Description The PM340 Power Modules cannot regenerate into the line supply. For the regenerative operation, e.g. the braking of a rotating mass, a braking resistor must be connected to convert the resulting energy into heat. The braking resistor is connected at terminals DCP/R1 and R2. - Page 120 DC link components 4.1 Blocksize Protecting the resistance The power supply to the Power Modules must be established through a contactor which can then shut down the power supply when the resistor overheats. A temperature protection switch handles the protective function (this is supplied with each break resistor).

-

Page 121: Dimension Drawings

DC link components 4.1 Blocksize 4.1.1.3 Dimension drawings Figure 4-2 Dimension drawing: Braking resistor, frame sizes A and B Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... - Page 122 DC link components 4.1 Blocksize Figure 4-3 Dimension drawing: Braking resistors, frame sizes C, D, E, F Table 4-1 Dimension data: Braking resistor, all data in mm and (inches), Part 1 Order No. 4BC05-0AA0 4BD11-0AA0 4BD12-0BA0 4BD16-5CA0 6SE6400- Frame size 230 (9.05) 230 (9.05) 239 (9.40)

-

Page 123: Mounting

DC link components 4.1 Blocksize Order No. 4BC05-0AA0 4BD11-0AA0 4BD12-0BA0 4BD16-5CA0 6SE6400- Frame size 185 (7.28) 72 (2.83) 72 (2.83) 149 (5.86) 185 (7.28) 56 (2.20) 56 (2.20) 138 (5.43) 230 (9.05) Table 4-2 Dimension data: Braking resistor, all data in mm and (inches), Part 2 Order No. -

Page 124: Technical Data

DC link components 4.1 Blocksize 4.1.1.5 Technical data Table 4-3 Technical data, braking resistors, Part 1 Order No. 6SE6400-4BC05- 6SE6400-4BD11- 6SL3201-0BE12- 6SE6400-4BD16- 0AA0 0AA0 0AA0 5CA0 Resistance Rated power P 0.05 0.65 Peak power P Load duration for peak power T 27.6 13.8 12.6... - Page 125 DC link components 4.1 Blocksize Figure 4-4 Load diagram for the braking resistor, Blocksize format T [s] period duration of braking duty cycle [s] load duration for peak power [W] rated power of the braking resistor [W] peak braking power of the braking resistor Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 126: Chassis

DC link components 4.2 Chassis Chassis 4.2.1 Braking Modules 4.2.1.1 Description A Braking Module (and an external braking resistor) is required in certain cases when the drive is to be braked or brought to a standstill (e.g. EMERGENCY SWITCHING-OFF Category 1). The Braking Module contains the power electronics and the associated control. The supply voltage for the electronics is taken from the DC link. -

Page 127: Safety Information

Danger The connection to the braking resistors must be short-circuit/ground-fault proof. Warning If braking resistors are used that have not been released by SIEMENS for SINAMICS, then the braking resistors could be destroyed. Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 128: Braking Module For Frame Size Fx

DC link components 4.2 Chassis 4.2.1.3 Braking Module for frame size FX Figure 4-5 Braking Module for Power Module, frame size FX Equipment Manual AC Drive 4-10 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 129: Braking Module For Type Gx

DC link components 4.2 Chassis 4.2.1.4 Braking Module for type GX Figure 4-6 Braking Module for Power Module, frame size GX Equipment Manual AC Drive 4-11 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 130: Sample Connection

DC link components 4.2 Chassis 4.2.1.5 Sample connection Figure 4-7 Example connection of Braking Module 4.2.1.6 Braking resistor connection X1 Table 4-5 Braking resistor connection Terminal Designation Braking resistor connection R+ Break resistor connection R- Max. cross-section that can be connected: 50 mm Equipment Manual AC Drive 4-12 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 131: X21 Digital Inputs/Outputs

DC link components 4.2 Chassis 4.2.1.7 X21 digital inputs/outputs Table 4-6 Terminal block X21 Terminal Designation Technical specifications +24 V Voltage: +18 V to 30 V Typical current consumption (own current consumption): 10 mA at 24 V DC DO fault output Voltage: 24 V DC Load current: 0.5 mA to 0.6 mA DI inhibit input... -

Page 132: Installing A Braking Module In A Power Module, Frame Size Fx

DC link components 4.2 Chassis 4.2.1.9 Installing a Braking Module in a Power Module, frame size FX Figure 4-8 Installing a Braking Module in a Power Module, frame size FX – steps 1 - 3 Equipment Manual AC Drive 4-14 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... - Page 133 DC link components 4.2 Chassis Figure 4-9 Installing a Braking Module in a Power Module, frame size FX – steps 4 - 6 Installing the Braking Module The steps for the installation procedure are numbered in accordance with the diagrams in front of them.

- Page 134 DC link components 4.2 Chassis 6. Secure the connection cable to the DC link with 2 screws (Braking Module connection) and 2 nuts (DC link connection). Carry out the subsequent steps in reverse order from steps 1 – 3. An opening above the connections for the braking resistor (R1, R2) is provided in the cover for connecting the cable to the braking resistor.

-

Page 135: Installing A Braking Module In A Power Module, Frame Size Gx

DC link components 4.2 Chassis 4.2.1.10 Installing a Braking Module in a Power Module, frame size GX Figure 4-10 Installing a Braking Module in a Power Module, frame size GX – steps 1 - 3 Equipment Manual AC Drive 4-17 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... - Page 136 DC link components 4.2 Chassis Figure 4-11 Installing a Braking Module in a Power Module, frame size GX – steps 4 - 6 Installing the Braking Module The steps for the installation procedure are numbered in accordance with the diagrams in front of them.

-

Page 137: Technical Data

DC link components 4.2 Chassis Carry out the subsequent steps in reverse order from steps 1 – 3. An opening above the connections for the braking resistor (R1, R2) is provided in the cover for connecting the cable to the braking resistor. Note You must observe the specified tightening torques. -

Page 138: Braking Resistors

DC link components 4.2 Chassis 4.2.2 Braking resistors 4.2.2.1 Description The braking resistor is used to reduce the excess DC link energy in regenerative operation. The braking resistor is connected to the Braking Module. The braking resistor is mounted outside the cabinet or switchgear room. This means that the resulting heat loss around the Power Module can be dissipated - and cooling costs/equipment reduced. -

Page 139: Dimension Drawing

DC link components 4.2 Chassis Danger The braking resistors are only suitable for mounting in a vertical position. They are not suitable for mounting on a wall. Sufficient space must be available for dissipating the energy converted by the braking resistor. -

Page 140: Technical Data

DC link components 4.2 Chassis Figure 4-13 Dimension drawing, 50 kW/250 kW resistor 4.2.2.4 Technical data Table 4-9 What are the technical data of the braking resistors Order No. Units 6SL3000–1BE31-3AA0 6SL3000–1BE32-5AA0 power (rated power) power (peak power) Max. current Cable entry Via cable gland M50 Via cable gland M50... - Page 141 DC link components 4.2 Chassis Duty cycle Figure 4-14 Duty cycle for braking resistors Equipment Manual AC Drive 4-23 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 142 DC link components 4.2 Chassis Equipment Manual AC Drive 4-24 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 143 Note The connecting cables to the Power Module must be kept as short as possible (max. 5 m). Caution When using motor reactors that SIEMENS has not approved for SINAMICS, then these can thermally damage the reactor. Caution The surface temperature of the motor reactors can exceed 80 °C.

-

Page 144: Dimension Drawings

Motor-side power components 5.1 Motor reactors 5.1.1.3 Dimension drawings Figure 5-1 Dimension drawing: Motor reactor, frame size A Table 5-1 Total dimensions: Motor reactor, frame size A, all data in mm and (inches) Motor reactor 3TC00-4AD3 3TC00-4AD2 6SE6400- Frame size Dimension A in mm and (inches) 200 (7.87) 200 (7.87) - Page 145 Motor-side power components 5.1 Motor reactors Figure 5-2 Dimension drawing: Motor reactor, frame sizes B and C Table 5-2 Total dimensions: Motor reactor, frame sizes B and C Motor reactor 0AE21-0CA0 0AJ23-2CA0 6SL3202- Frame size Dimension A in mm and (inches) 270 (10.62) 334 (13.14) Dimension B in mm and (inches)

- Page 146 Motor-side power components 5.1 Motor reactors Figure 5-3 Dimension drawing: Motor reactor, frame size D Figure 5-4 Dimension drawing: Motor reactor, frame size E Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 147: Motor-Side Power Components

Motor-side power components 5.1 Motor reactors Figure 5-5 Dimension drawing: Motor reactor, frame size F Table 5-3 Total dimensions: Motor reactor, frame size D, E, all data in mm and (inches) Motor reactor 3TC05-4DD0 3TC03-8DD0 3TC07-5ED0 3TC08-0ED0 6SE6400- Frame size 70 (2.75) 94 (3.70) 101 (3.97) - Page 148 Motor-side power components 5.1 Motor reactors Table 5-4 Total dimensions: Motor reactor, frame size F, all data in mm and (inches) Motor reactor 3TC06-2FE0 3TC08-8FE0 3TC14-5FD0 3TC15-4FD0 6SE6400- Frame size 118 (4.64) 138 (5.43) 138 (5.43) 101 (3.97) 138 (5.43) 158 (6.22) 169 (6.65) 121 (4.76)

-

Page 149: Mounting

Motor-side power components 5.1 Motor reactors 5.1.1.4 Mounting The motor reactor must be installed as close as possible to the Power Module. Figure 5-6 Mounting: Motor reactor, frame size A Table 5-5 Mounting: Motor reactor, frame size A, all data in mm and (inches) Motor reactor 3TC00-4AD3 3TC00-4AD2... - Page 150 Motor-side power components 5.1 Motor reactors Figure 5-7 Mounting: Motor reactor, frame sizes B and C Table 5-6 Mounting: Motor reactor, frame size B and C, all data in mm and (inches) Motor reactor 6SL3202- 0AE21-0CA0 0AJ23-2CA0 Suitable 6SL3210- 1SE16-0UA0 1SE21-8UA0 for Power Module 1SE17-7UA0...

- Page 151 Motor-side power components 5.1 Motor reactors Cable cross-section and terminal tightening torques Terminals for wiring on site Frame size Tightening torque [Nm] 2.25 Recommended minimum conductor cross-section [mm Highest conductor cross-section [mm Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 152 Motor-side power components 5.1 Motor reactors Figure 5-8 Mounting: Motor reactor, frame sizes D, E, F Table 5-7 Mounting: Motor reactor, frame sizes D, E, all data in mm and (inches) Motor reactor 6SE6400- 3TC05-4DD0 3TC03-8DD0 3TC05-4DD0 3TC07-5ED0 3TC08-0ED0 Suitable for 6SL3210- 1SE23-8UA0 1SE24-5UA0...

- Page 153 Motor-side power components 5.1 Motor reactors Mounting Power Modules and motor reactors Figure 5-9 Mounting Power Modules and motor reactors, frame sizes B and C Table 5-9 Total dimensions, Power Module 340 and motor reactor, frame sizes A, B and C, all data in mm and (inches) Motor reactor 6SE6400-3TC00-4AD3 6SE6400-3TC00-4AD2...

-

Page 154: Electrical Connection

Motor-side power components 5.1 Motor reactors 5.1.1.5 Electrical connection Figure 5-10 Electrical connection Equipment Manual AC Drive 5-12 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 155: Technical Data

Motor-side power components 5.1 Motor reactors 5.1.1.6 Technical data Table 5-10 Motor reactors for Power Modules 3-ph. 380 V to 480 V AC, Part 1 Motor reactor (for a 4 kHz pulse frequency) 6SE6400-3TC00-4AD2 6SL3202- 0AE21-0CA0 Rated current Power loss 0.005 0.02 Connection to the... - Page 156 Motor-side power components 5.1 Motor reactors Table 5-11 Motor reactors for Power Modules 3-ph. 380 V to 480 V AC, Part 2 Motor reactor (for a 4 kHz pulse frequency) 6SL3202-0AE21-0CA0 6SL3202-0AJ23-2CA0 6SE6400- 3TC05-4DD0 Rated current Power loss 0.02 0.06 Connection to the Cable 4 x AWG14 (1.5 mm Cable 4 x AWG14 (1.5 mm...

- Page 157 Motor-side power components 5.1 Motor reactors Table 5-12 Motor reactors for Power Modules 3-ph. 380 V to 480 V AC, Part 3 Motor reactor (for a 4 kHz pulse frequency) 6SE6400- 6SE6400- 6SE6400- 6SE6400- 6SE6400- 6SE6400- 3TC03-8DD0 3TC05-4DD0 3TC08-0ED0 3TC07-5ED0 3TC14-5FD0 3TC15-4FD0 Rated current...

-

Page 158: Chassis

Note The connecting cables to the Power Module must be kept as short as possible (max. 5 m). Caution When using motor reactors that SIEMENS has not approved for SINAMICS, then these can thermally damage the reactor. Caution The surface temperature of the motor reactors can exceed 80 °C. -

Page 159: Dimension Drawing

Motor-side power components 5.1 Motor reactors 5.1.2.3 Dimension drawing Mounting hole Type 2 Type 1 Figure 5-11 Dimension drawing, motor reactor Equipment Manual AC Drive 5-17 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 160: Technical Data

Motor-side power components 5.1 Motor reactors Table 5-14 Dimensions of motor reactors, all data in mm and (inches) 6SL3000- 2BE32-1AA0 2BE32-6AA0 2BE33-2AA0 2BE33-8AA0 2BE35-0AA0 Connection type 25 (0.98) 25 (0.98) 25 (0.98) 25 (0.98) 30 (1.18) 5 (0.19) 5 (0.19) 5 (0.19) 5 (0.19) 6 (0.23) -

Page 161: Sinusoidal Filter

The connecting cables to the Power Module must be kept as short as possible (max. 5 m). Caution Using sinusoidal filters that have not been approved by SIEMENS for SINAMICS can: • damage/destroy the Power Modules • cause line harmonics that may interfere with or damage other loads connected to the same line supply. -

Page 162: Dimension Drawing

Motor-side power components 5.2 Sinusoidal filter 5.2.1.3 Dimension drawing Figure 5-12 Dimension drawing, sinusoidal filter Equipment Manual AC Drive 5-20 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 163: Technical Data

Motor-side power components 5.2 Sinusoidal filter Table 5-16 Dimensions of the sinusoidal filters, all data in mm and (inches) 6SL3000- 2CE32-3AA0 2CE32-8AA0 2CE33-3AA0 2CE34-1AA0 620 (24.40) 620 (24.40) 620 (24.40) 620 (24.40) 320 (12.59) 320 (12.59) 360 (14.17) 360 (14.17) 300 (11.81) 300 (11.81) 370 (14.56) -

Page 164: Dv/Dt Filter

Motor-side power components 5.3 dv/dt filter dv/dt filter 5.3.1 Chassis 5.3.1.1 Description The dv/dt filter plus VPL (Voltage Peak Limiter) consists of two components: the dv/dt reactor and the voltage limiting network (Voltage Peak Limiter), which limits voltage peaks and returns the energy to the DC link. The dv/dt filter plus VPL is to be used for motors for which the voltage strength of the insulation system is unknown or insufficient. - Page 165 If this is not observed, then there is a danger of damage to the dv/dt reactor and the voltage limiting network. Caution When using dv/dt filters that SIEMENS has not approved for SINAMICS, then these dv/dt filters can be thermally damaged. Caution The surface temperature of the dv/dt reactors may exceed 80 °C.

-

Page 166: Interface Description

Motor-side power components 5.3 dv/dt filter 5.3.1.3 Interface description Figure 5-13 Interface overview, voltage limiting network, type 1 Figure 5-14 Interface overview, voltage limiting network, type 2 Equipment Manual AC Drive 5-24 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 167: Connection Of The Dv/Dt Filter

Motor-side power components 5.3 dv/dt filter 5.3.1.4 Connection of the dv/dt filter Figure 5-15 Connection of the dv/dt filter Cable cross-sections Table 5-19 Cable cross-sections for connected between a dv/dt filter and Power Module dv/dt filter plus VPL Connection to the DC link Connection between a dv/dt reactor and voltage limiting network (DCPS / DCNS) -

Page 168: Dimension Drawing, Dv/Dt Reactor

Motor-side power components 5.3 dv/dt filter 5.3.1.5 Dimension drawing, dv/dt reactor Figure 5-16 Dimension drawing, dv/dt reactor Equipment Manual AC Drive 5-26 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... - Page 169 Motor-side power components 5.3 dv/dt filter Table 5-20 Dimensions dv/dt reactor, 3-ph. 380 V – 480 V AC, all data in mm and (inches) 6SL3000- 2DE32-6CA0 2DE35-0CA0 25 (0.98) 30 (1.18) 5 (0.19) 6 (0.23) 14 (0.55) 17 (0.66) 10.5 x 14 (0.41 x 0.55) 14 x 18 (0.55 x 0.70) 7 (0.27) 9 (0.35)

-

Page 170: Dimension Drawing, Limiting Network

Motor-side power components 5.3 dv/dt filter 5.3.1.6 Dimension drawing, limiting network Figure 5-17 Dimension drawing, voltage limiting network, type 1 Figure 5-18 Dimension drawing, voltage limiting network, type 2 Equipment Manual AC Drive 5-28 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 171: Technical Data

Motor-side power components 5.3 dv/dt filter Table 5-21 Assigning voltage limiting networks to dimension drawings Voltage limiting network Dimension drawing, type 6SL3000-2DE32-6BA0 Type 1 6SL3000-2DE35-0BA0 Type 2 5.3.1.7 Technical data Table 5-22 Technical data, dv/dt filter plus VPL, 3-ph. 380 V – 480 V AC, Part 1 Order No. - Page 172 Motor-side power components 5.3 dv/dt filter Table 5-23 Technical data, dv/dt filter plus VPL, 3-ph. 380 V – 480 V AC, Part 2 Order No. 6SL3000- 2DE35-0AA0 2DE35-0AA0 2DE35-0AA0 Suitable for Motor Module 6SL3310- 1TE33-8AA0 1TE35-0AA0 1TE35-0AA0 Rated power of Motor Module dv/dt reactor thmax Power loss, typical...

-

Page 173: Control Units

Control Units Introduction Description The Control Units of SINAMICS S120 AC Drive are designed for use with Blocksize format or Chassis format Power Modules. Advantages 1. The control module CU310 DP provides the external communications interface PROFIBUS and a TTL/HTL encoder evaluation. - Page 174 Control Units 6.1 Introduction Control Unit 310 DP Control Unit 310 PN Control Unit Adapter 31 (CUA31) Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 175 Control Units 6.1 Introduction Figure 6-1 Overview, Control Unit 310 DP (CU310 DP) Note The Control Unit and the CompactFlash card must be ordered separately. Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

- Page 176 Control Units 6.1 Introduction Figure 6-2 Overview, Control Unit Adapter 31 (CUA31) Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 177: Control Unit Cu310 Dp (Profibus)

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) Control Unit CU310 DP (PROFIBUS) 6.2.1 Description The Control Unit 310 DP (PROFIBUS) is the component in which the open-loop and closed- loop control functions of a drive are implemented. The CU310 DP has the following interfaces (ports): Table 6-1 Overview of the CU310 interfaces Type... -

Page 178: Safety Information

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.2 Safety information Note The CompactFlash card may only be inserted and removed from the Control Unit when in the no-voltage condition. Caution The cooling clearances of 50 mm above and below the components must be observed. It is not permissible that the connecting cables cover the cooling openings. -

Page 179: Interface Description

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.3 Interface description 6.2.3.1 Overview Figure 6-3 Description of the CU310 DP interfaces (ports) Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 180: Sample Connection

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.3.2 Sample connection Figure 6-4 Connection example CU310 DP Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 181: X100 Drive-Cliq Interface

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.3.3 X100 DRIVE-CLiQ interface Table 6-2 DRIVE-CLiQ interface Signal name Technical specifications Transmit data + Transmit data - Receive data + Reserved, do not use Reserved, do not use Receive data - Reserved, do not use Reserved, do not use + (24 V) -

Page 182: X121 Digital Inputs/Outputs

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.3.5 X121 digital inputs/outputs Table 6-4 Terminal strip X121 Terminal Designation Technical specifications DI 0 Voltage: -3 V to 30 V Typical current consumption: 10 mA at 24 V DC DI 1 Isolation: The reference potential is terminal M1 DI 2 Level (incl. -

Page 183: Electronics Power Supply X124

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.3.6 Electronics power supply X124 Table 6-5 Terminal block X124 Terminal Function Technical specifications Electronics power supply Voltage: 24 V DC (20.4 V - 28.8 V) Current consumption: max. 0.8 A Electronics power supply (without DRIVE-CLiQ or digital outputs) Electronic ground Max. -

Page 184: X23 Htl/ Ttl Encoder Interface

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) Note A teleservice adapter can be connected to the PROFIBUS interface (X21) for remote diagnosis purposes. The power supply for the teleservice terminals 2 and 7 withstands a max. load and continued short-circuit current of 150 mA. -

Page 185: Profibus Address Switches

The address switch is behind the blanking plate. The blanking plate is part of the scope of supply. Setting the PROFIBUS address The following reference contains further information about setting the PROFIBUS address: Reference: /IH1/ SINAMICS S120 Commissioning Manual. Equipment Manual AC Drive 6-13 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 186: X22 Serial Interface (Rs232)

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.3.10 X22 serial interface (RS232) Table 6-9 Serial interface (RS-232-C) X140 Designation Technical data Receive data Transmit data Ground Ground reference Type: 9-pin SUB D connector 6.2.3.11 Measurement sockets T0, T1, and T2 Table 6-10 Measurement sockets T0, T1, and T2 Socket... -

Page 187: Slot For The Compactflash Card

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.3.12 Slot for the CompactFlash card Figure 6-5 Slot for CompactFlash card Caution The CompactFlash card may only be inserted as shown in the figure (arrow top right). The CompactFlash card may only be inserted or removed when the Control Unit is in a no-voltage condition. -

Page 188: Description Of The Leds On The Control Unit 310 Dp

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.3.13 Description of the LEDs on the Control Unit 310 DP Table 6-11 Description of the LEDs on the Control Unit Color State Description Electronics power supply outside permissible tolerance range Steady light The component is ready for operation and cyclic DRIVE-CLiQ Green communication is taking place. -

Page 189: Dimension Drawing

6.2 Control Unit CU310 DP (PROFIBUS) Cause and rectification of faults The following reference contains information about the cause and rectification of faults: Reference: /IH1/ SINAMICS S120 Commissioning Manual. RESET button The RESET button is located behind the blanking plate. -

Page 190: Mounting The Cu310 On The Power Module Blocksize

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.5 Mounting the CU310 on the Power Module Blocksize As soon as the Power Module has been been correctly installed, the Control Unit can be attached to the Power Module. Snap the CU310 onto the Power Module 340 Power Module 340 (frame size D) with CU310 (frame size D) The procedure when mounting the Control Unit on the Power Module is independent of the... - Page 191 Control Units 6.2 Control Unit CU310 DP (PROFIBUS) Removing the Control Unit Removing the CU310 from the Power Module 340 (frame size D) In order to remove the Control Unit from the Power Module, the blue release lever, as shown in the diagram, must be pressed downwards and the Control Unit swung-out to the front.

-

Page 192: Mounting The Cu310 In The Power Module Chassis

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.6 Mounting the CU310 in the Power Module Chassis Figure 6-7 Mounting the CU310 in the Power Module Chassis, frame size FX The DRIVE-CLiQ cable and the cable for the 24 V power supply must be correctly routed so that the front flap can close. -

Page 193: Technical Data

Control Units 6.2 Control Unit CU310 DP (PROFIBUS) 6.2.7 Technical data Table 6-12 Technical data CU310 DP Unit Value Electronics power supply Voltage DC 24 (20.4 – 28.8) Current (without DRIVE-CLiQ and digital outputs) Power loss <20 PE/ground connection At the housing with M4/3 Nm screw Response time The response time of digital inputs/outputs depends on the evaluation (refer to the function diagram). -

Page 194: Control Unit Cu310 Pn (Profinet)

Control Units 6.3 Control Unit CU310 PN (PROFINET) Control Unit CU310 PN (PROFINET) 6.3.1 Description The Control Unit 310 PN (PROFINET) is the control module in which the open-loop and closed-loop control functions of a drive are implemented. The CU310 PN has the following interfaces (ports): Table 6-13 Overview of the CU310 PN interfaces (ports) Type... -

Page 195: Interface Description

Control Units 6.3 Control Unit CU310 PN (PROFINET) 6.3.3 Interface description 6.3.3.1 Overview Figure 6-8 Description of the CU310 PN interfaces Note The PROFIBUS address switch is present for the CU310 PN, however it has not function. Equipment Manual AC Drive 6-23 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 196: Sample Connection

Control Units 6.3 Control Unit CU310 PN (PROFINET) 6.3.3.2 Sample connection Figure 6-9 Connection example CU310 PN Equipment Manual AC Drive 6-24 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 197: X100 Drive-Cliq Interface

Control Units 6.3 Control Unit CU310 PN (PROFINET) 6.3.3.3 X100 DRIVE-CLiQ interface Table 6-14 DRIVE-CLiQ interface Signal name Technical specifications Transmit data + Transmit data - Receive data + Reserved, do not use Reserved, do not use Receive data - Reserved, do not use Reserved, do not use + (24 V) -

Page 198: X121 Digital Inputs/Outputs

Control Units 6.3 Control Unit CU310 PN (PROFINET) 6.3.3.5 X121 digital inputs/outputs Table 6-16 Terminal strip X121 Terminal Designation Technical specifications DI 0 Voltage: -3 V to 30 V Typical current consumption: 10 mA at 24 V DC DI 1 Isolation: The reference potential is terminal M1 DI 2 Level (incl. -

Page 199: Electronics Power Supply X124

Control Units 6.3 Control Unit CU310 PN (PROFINET) 6.3.3.6 Electronics power supply X124 Table 6-17 Terminal block X124 Terminal Function Technical specifications Electronics power supply Voltage: 24 V DC (20.4 V - 28.8 V) Current consumption: max. 0.8 A (without DRIVE-CLiQ Electronics power supply or digital outputs) Electronic ground... -

Page 200: X23 Htl/ Ttl Encoder Interface

Control Units 6.3 Control Unit CU310 PN (PROFINET) 6.3.3.8 X23 HTL/ TTL encoder interface Table 6-19 Encoder connection X23 Signal name Technical specifications Reserved, do not use SSI_CLK SSI clock, positive SSI_XCLK SSI clock, negative PENC Encoder power supply PENC Encoder power supply PSENSE Remote sense encoder power supply (P) -

Page 201: Measurement Sockets T0, T1, And T2

Control Units 6.3 Control Unit CU310 PN (PROFINET) 6.3.3.10 Measurement sockets T0, T1, and T2 Table 6-21 Measurement sockets T0, T1, and T2 Socket Function Technical specifications Measurement socket 0 Voltage: 0 V to 5 V Resolution: 8 bits Measurement socket 1 Load current: max. -

Page 202: Description Of The Leds On The Control Unit 310 Pn

Control Units 6.3 Control Unit CU310 PN (PROFINET) 6.3.3.11 Description of the LEDs on the Control Unit 310 PN Table 6-22 Description of the LEDs on the Control Unit Color State Description Electronics power supply outside permissible tolerance range Steady light The component is ready for operation and cyclic DRIVE-CLiQ Green communication is taking place. -

Page 203: Dimension Drawing

6.3 Control Unit CU310 PN (PROFINET) Cause and rectification of faults The following reference contains information about the cause and rectification of faults: Reference: /IH1/ SINAMICS S120 Commissioning Manual. RESET button The RESET button is located behind the blanking plate. -

Page 204: Mounting The Cu310 On The Power Module Blocksize

Control Units 6.3 Control Unit CU310 PN (PROFINET) 6.3.5 Mounting the CU310 on the Power Module Blocksize As soon as the Power Module has been been correctly installed, the Control Unit can be attached to the Power Module. Snap the CU310 onto the Power Module 340 Power Module 340 (frame size D) with CU310 (frame size D) The procedure when mounting the Control Unit on the Power Module is independent of the... -

Page 205: Technical Data

Control Units 6.3 Control Unit CU310 PN (PROFINET) Removing the Control Unit Removing the CU310 from the Power Module 340 (frame size D) In order to remove the Control Unit from the Power Module, the blue release lever, as shown in the diagram, must be pressed downwards and the Control Unit swung-out to the front. -

Page 206: Control Unit Adapter 31 (Cua31)

Control Units 6.4 Control Unit Adapter 31 (CUA31) Control Unit Adapter 31 (CUA31) 6.4.1 Description The Control Unit Adapter 31 (CUA31), combined with a modular power unit is used to extend an existing DC/AC drive line-up e.g. with CU320 by one drive. The closed-loop control is externally implemented. -

Page 207: Interface Description

Control Units 6.4 Control Unit Adapter 31 (CUA31) 6.4.3 Interface description 6.4.3.1 Overview Figure 6-11 Interface description CUA31 Equipment Manual AC Drive 6-35 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 208: X200 - X202 Drive-Cliq Interface

Control Units 6.4 Control Unit Adapter 31 (CUA31) Figure 6-12 Connection example, CUA31 6.4.3.2 X200 - X202 DRIVE-CLiQ interface Table 6-25 DRIVE-CLiQ interface Signal name Technical specifications Transmit data + Transmit data - Receive data + Reserved, do not use Reserved, do not use Receive data - Reserved, do not use... -

Page 209: X224 Electronics Power Supply

Control Units 6.4 Control Unit Adapter 31 (CUA31) 6.4.3.3 X224 electronics power supply Table 6-26 Terminal strip X224 Terminal Function Technical specifications Electronics power supply Voltage: 24 V DC (20.4 V - 28.8 V) Current consumption: max. 0.8 A (without DRIVE-CLiQ Electronics power supply or digital outputs) Electronic ground... -

Page 210: Description Of The Leds At The Control Unit Adapter 31

The component is ready for operation and cyclic DRIVE-CLiQ communication is taking place. Cause and rectification of faults The following reference contains information about the cause and rectification of faults: Reference: /IH1/ SINAMICS S120 Commissioning Manual. 6.4.4 Dimension drawing Figure 6-13... -

Page 211: Mounting

Control Units 6.4 Control Unit Adapter 31 (CUA31) 6.4.5 Mounting Snapping the CUA31 onto the Power Module 340 Power Module 340 (frame size D) and CUA31 (frame size D) Equipment Manual AC Drive 6-39 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 212: Technical Data

Control Units 6.4 Control Unit Adapter 31 (CUA31) Removing the Control Unit Adapters 31 Removing the CUA31 from the Power Module 340 (frame size D) In order to remove the Control Unit Adapter 31 from the Power Module, the blue release lever, as shown in the diagram, must be pressed downwards and the Control Unit Adapter 31 is swung-out to the front. -

Page 213: Description

Supplementary system components and encoder system integration Basic Operator Panel 20 (BOP20) 7.1.1 Description The Basic Operator Panel 20 (BOP20) is a basic operator panel with six keys and a display unit with background lighting. The BOP20 can be inserted on the SINAMICS Control Unit CU310 DP / PN and operated. - Page 214 Supplementary system components and encoder system integration 7.1 Basic Operator Panel 20 (BOP20) Overview of displays and keys Figure 7-2 Overview of displays and keys Table 7-1 Displays Display Meaning top left The active drive object of the BOP is displayed here. 2 positions The displays and key operations always refer to this drive object.

- Page 215 The keys are dependent on the actual display and are used to raise or lower values. Lower Displays and operating the BOP20 Information about the displays and using the BOP20 is provided in the following reference: Reference: /IH1/ SINAMICS S120 Commissioning Manual. Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0...

-

Page 216: Mounting

Supplementary system components and encoder system integration 7.1 Basic Operator Panel 20 (BOP20) 7.1.3 Mounting Table 7-3 Mounting 1. CU310 and BOP20 2. Press the bars of the dummy cover together 3. Remove the dummy cover 4. Locate the BOP20 Note The Basic Operator Panel 20 (BOP20) may be inserted and withdrawn while the Control Unit is operational. -

Page 217: Technical Data

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.1.4 Technical data Table 7-4 Technical data Basic Operator Panel 20 (BOP20) Weight, approx. 0.02 Terminal Module 31 (TM31) 7.2.1 Description The Terminal Module 31 (TM31) is a terminal expansion module for snapping on to a DIN 50022 mounting rail. -

Page 218: Interface Description

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.3 Interface description 7.2.3.1 Overview X500 DRIVE-CliQ interfaces X501 X524 Electronics power supply X540 Auxiliary voltage for X520 digital inputs Digital inputs X530 X541 Voltage/current Digital measurement inputs/outputs X521 Analog inputs X522... -

Page 219: Sample Connection

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.3.2 Sample connection Figure 7-4 Example connection of TM31 Equipment Manual AC Drive Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 220: X500 And X501 Drive-Cliq Interface

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.3.3 X500 and X501 DRIVE-CLiQ interface Table 7-6 DRIVE-CLiQ interface X500 Signal name Technical specifications Transmit data + Transmit data - Receive data + Reserved, do not use Reserved, do not use Receive data - Reserved, do not use... -

Page 221: Digital Inputs X520

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.3.5 Digital inputs X520 Table 7-8 Screw terminal X520 Terminal Designation Technical specifications DI 0 Voltage: - 3 V to +30 V Typical current consumption: 10 mA at 24 V DC DI 1 Isolation: The reference potential DI 2... -

Page 222: Digital Inputs X530

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.3.6 Digital inputs X530 Table 7-9 Screw terminal X530 Terminal Designation Technical specifications DI 4 Voltage: -3 V to 30 V Typical current consumption: 10 mA at 24 V DC DI 5 Isolation: The reference potential is terminal M2 DI 6... -

Page 223: Auxiliary Voltage For The Digital Inputs X540

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.3.7 Auxiliary voltage for the digital inputs X540 Table 7-10 Screw terminal X540 Terminal Designation Technical specifications +24 V Voltage: +24 V DC Max. total load current: 150 mA +24 V +24 V +24 V... -

Page 224: Analog Inputs X521

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.3.8 Analog inputs X521 Table 7-11 Terminal block X521 Terminal Name Technical specifications AI 0+ You can set the following input signals using the appropriate parameters: AI 0- Voltage: -10 V to 10 V;... -

Page 225: Analog Outputs/Temperature Sensor Connection X522

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.3.10 Analog outputs/temperature sensor connection X522 Table 7-13 Terminal block X522 Terminal Designation Technical specifications AO 0V+ You can set the following output signals using parameters: Voltage: -10 V to 10 V (max. 3 mA) AO 0- AO 0C+ Current 1: 4 mA to 20 mA (max. -

Page 226: X541 Bidirectional Digital Inputs/Outputs

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.3.11 X541 bidirectional digital inputs/outputs Table 7-14 Terminals for bidirectional digital inputs/outputs Terminal Designation Technical specifications As input: Voltage: -3 V to 30 V DI/DO 8 Typical current consumption: 10 mA at 24 V DC DI/DO 9 Signal propagation times: DI/DO 10... -

Page 227: Relay Outputs X542

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.3.12 Relay outputs X542 Table 7-15 Terminal block X542 Terminal Designation Technical specifications DO 0.NC Contact type: Two-way contact max. load current: 8 A Max. switching voltage: 250 V , 30 V DO 0.COM Max. -

Page 228: Dimension Drawing

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.4 Dimension drawing Figure 7-5 Dimension drawing of the TM31 Equipment Manual AC Drive 7-16 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 229: Mounting

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.5 Mounting Installation 1. Place the component on the DIN rail. 2. Snap the component on to the DIN rail. Make sure that the mounting slides at the rear latch into place. -

Page 230: Electrical Connection

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.6 Electrical Connection It is always advisable to shield the digital I/O wiring. The following pictures show two typical shield contacts from Weidmüller. Figure 7-7 Shield contacts Internet address of the company: Weidmüller: www.weidmueller.com Danger... - Page 231 Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) Connector codes To ensure that identical connectors are assigned correctly on the TM31, the connecters are encoded as shown in the following diagram. Figure 7-8 Connector codes of the TM31 The bending radii of the cables must be taken into account (see description of MOTION- CONNECT).

-

Page 232: Technical Data

Supplementary system components and encoder system integration 7.2 Terminal Module 31 (TM31) 7.2.7 Technical data Table 7-17 Technical data Unit Value Electronics power supply Voltage 24 DC (20.4 – 28.8) Current (without DRIVE-CLiQ or digital outputs) Power loss <10 PE/ground connection At the housing with M4/1.8 Nm screw Response time The response time for the digital inputs/outputs and the analog inputs/outputs... -

Page 233: Sensor Module Cabinet 10 (Smc10)

Supplementary system components and encoder system integration 7.3 Sensor Module Cabinet 10 (SMC10) Sensor Module Cabinet 10 (SMC10) 7.3.1 Description The Sensor Module Cabinet-Mounted 10 (SMC10) evaluates encoder signals and transmits the speed, actual position value, rotor position and, if necessary, the motor temperature via DRIVE-CLiQ to the Control Unit. -

Page 234: Safety Information

Supplementary system components and encoder system integration 7.3 Sensor Module Cabinet 10 (SMC10) 7.3.2 Safety information Caution The cooling clearances of 50 mm above and below the components must be observed. Notice Only one measuring system can be connected to each Sensor Module. Note There may be no electrical connection between the measuring system housing and the measuring system electronics (this requirement is fulfilled for most encoder systems). -

Page 235: Interface Description

Supplementary system components and encoder system integration 7.3 Sensor Module Cabinet 10 (SMC10) 7.3.3 Interface description 7.3.3.1 Overview X500 DRIVE-CLiQ interface X524 Electronics power supply X520 Encoder system connector Protective conductor connection M4 / 1.8 Nm Figure 7-10 Interface description of the SMC10 Equipment Manual AC Drive 7-23 Manual, (GH6), 03/2006 Edition, 6SL3097-2AL00-0BP0... -

Page 236: Drive-Cliq Interface X500