Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Toro Titan MX4800

- Page 1 Form No. 3394-246 Rev A TITAN ® MX4800, MX5400, or MX6000 Zero-Turn-Radius Riding Mower Model No. 74891—Serial No. 315000001 and Up Model No. 74892—Serial No. 315000001 and Up Model No. 74893—Serial No. 315000001 and Up *3394-246* A Register at www.Toro.com. Original Instructions (EN)

-

Page 2: Figure

California to cause cancer, birth defects, product properly and safely. or other reproductive harm. You may contact Toro directly at www.Toro.com for product Important: This engine is not equipped with a spark and accessory information, help finding a dealer, or to register arrester muffler. -

Page 3: Table Of Contents

Safety ................4 if you do not follow the recommended precautions. Safe Operating Practices........... 4 Toro Riding Mower Safety ........6 Slope Indicator ............7 Safety and Instructional Decals ......... 8 Product Overview ............13 Figure 2 Controls ...............14... -

Page 4: Safety

Safety Leveling the Mower Deck ........43 Inspecting the Belts ..........44 Replacing the Mower Belt ........45 Improper use or maintenance by the operator or owner can Removing the Mower..........46 result in injury. To reduce the potential for injury, comply with Installing the Mower Deck........47 these safety instructions and always pay attention to the safety Replacing the Grass Deflector ........47 alert symbol, which means CAUTION, WARNING, or... -

Page 5: Maintenance And Storage

Operation • Be certain that the seat belt can be released quickly in the event of an emergency. • Lightning can cause severe injury or death. If lightning is seen or thunder is heard in the area, do not operate •... -

Page 6: Toro Riding Mower Safety

• Keep hands and feet away from moving parts. If possible, of the machine. Failure to use original Toro parts could do not make adjustments with the engine running. cause serious injury or death. Making unauthorized •... -

Page 7: Slope Indicator

Slope Indicator G011841 Figure 3 This page may be copied for personal use. 1. The maximum slope you can safely operate the machine on is 15 degrees. Use the slope chart to determine the degree of slope of hills before operating. Do not operate this machine on a slope greater than 15 degrees. Fold along the appropriate line to match the recommended slope. -

Page 8: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. 1-653558 110-6691 1. Thrown object hazard—keep bystanders a safe distance from the machine. - Page 9 115-9632 1. Power take-off (PTO), 5. Fast Blade control switch on some models 2. Blade control switch—On 6. Continuous variable 117-1194 setting 3. Blade control switch—Off 7. Slow 1. Engine 4. Choke Battery Symbols Some or all of these symbols are on your battery 1.

- Page 10 130-0765 1. Read the Operator's 3. Remove the key from Manual. the ignition and read the Operator's Manual before performing maintenance. 2. Height-of-cut selection 130-0655 1. Fuel tank 3. Half 2. Full 4. Empty 130-0731 1. Warning—thrown object 2. Cutting hazard of hand or hazard;...

- Page 11 130-6996 1. Read the Operator's 4. Check the hydraulic oil Manual for information on every 25 hours maintenance. 2. Check the engine oil every 5. Check the caster wheel 8 hours tire pressure every 25 hours 3. Check the drive wheel tire 6.

- Page 12 132–0871 1. Warning—read the Operator’s Manual; do not operate this 4. Ramp hazard—when loading onto a trailer, do not use dual vehicle unless you are trained; wear hearing protection. ramps; only use a singular ramp wide enough for the machine; back up the ramp (in reverse) and drive forward off the ramp.

-

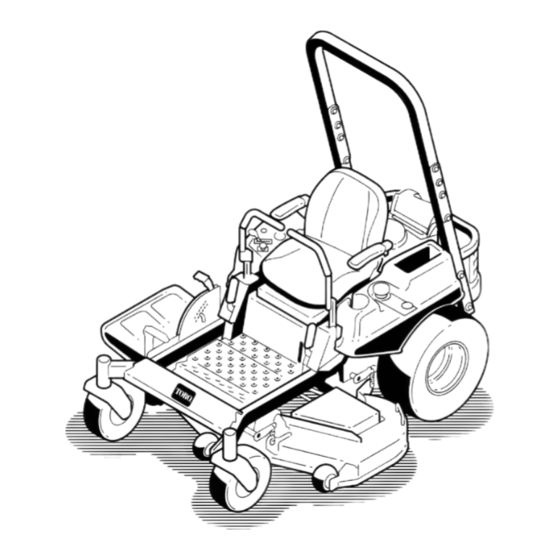

Page 13: Product Overview

Product Overview Figure 4 1. Drive wheel 4. Motion-control levers 7. Front caster wheel 10. Deflector 2. Operator seat 5. Parking brake 8. Anti-scalp roller 3. Rollover protection system 6. Footrest 9. Foot pedal deck lift and (ROPS) height-of-cut... -

Page 14: Controls

Push down on the choke knob to disengage it. its capabilities. Contact your Authorized Service Dealer or Distributor or go to www.Toro.com for a list of all approved Blade-Control Switch (Power Take-Off) attachments and accessories. -

Page 15: Operation

Operation DANGER In certain conditions during fueling, static Note: Determine the left and right sides of the machine electricity can be released causing a spark which from the normal operating position. can ignite the gasoline vapors. A fire or explosion from gasoline can burn you and others and can Adding Fuel damage property. -

Page 16: Checking The Engine-Oil Level

Using the Fuel Gauge Use the fuel window below the operator to verify the level of gasoline before filling the tank (Figure G020318 Figure 6 1. Fuel gauge window g027637 Figure 7 Filling the Fuel Tank Make sure the engine is shut off and the motion controls are 3. -

Page 17: Think Safety First

Think Safety First Using the Rollover Protection System (ROPS) Please carefully read all of the safety instructions and decals in the safety section. Knowing this information could help you, your family, pets or bystanders avoid injury. WARNING To avoid injury or death from rollover: keep the roll DANGER bar installed and use the seat belt. -

Page 18: Operating The Throttle

Operating the Throttle Failure to follow these instructions can burn out the starter motor. The throttle control can be moved between Fast and Slow Note: Additional starting cycles may be required positions (Figure 11). when starting the engine for the first time after the fuel Always use the fast position when turning on the mower deck system has been without fuel completely. -

Page 19: Operating The Mower Blade-Control Switch (Pto)

g028224 Figure 15 g028223 Figure 14 Operating the Mower Blade-Control Switch (PTO) The blade-control switch (PTO) starts and stops the mower Stopping the Engine blades and any powered attachments. CAUTION Engaging the Blade-Control Switch Children or bystanders can be injured if they (PTO) move or attempt to operate the machine while it is unattended. -

Page 20: The Safety-Interlock System

Disengaging the Blade-Control Switch Testing the Safety-Interlock System (PTO) Test the safety-interlock system before you use the machine each time. If the safety system does not operate as described below, have an Authorized Service Dealer repair the safety system immediately. 1. - Page 21 Using the Motion-Control Levers G008952 Figure 19 Driving Backward Figure 18 1. Motion-control 4. Backward 1. Move the levers to the center, unlocked position. lever—neutral-lock 2. To go backward, slowly pull the motion-control levers position rearward (Figure 20). 2. Center, unlocked position 5.

-

Page 22: Stopping The Machine

Stopping the Machine To stop the machine, move the traction control levers to neutral and move to locked position, disengage the blade-control switch (PTO), and turn the ignition key to off. Set the parking brake when you leave the machine; refer to Operating the Parking Brake (page 17). -

Page 23: Adjusting The Anti-Scalp Rollers

Positioning the Seat The seat can move forward and backward. Position the seat where you have the best control of the machine and are most comfortable. g024410 Figure 22 1. Deck lift pedal 3. Height-of-cut positions 2. Handle 4. Pin Figure 24 Adjusting the Anti-Scalp Rollers... -

Page 24: Adjusting The Motion-Control Levers

Adjusting the Motion-Control Note: Ensure that the left and right bypass levers are rearward and locked before moving the machine. Levers 6. Disengage the parking brake. Adjusting the Height The machine is now able to be pushed by hand. Note: Repeat the adjustment for the opposite control lever. The motion-control levers can be adjusted higher or lower for maximum operator comfort (Figure... -

Page 25: Using The Side Discharge

Using the Side Discharge The mower has a hinged grass deflector that disperses clippings to the side and down toward the turf. DANGER Without a grass deflector, discharge cover, or complete grass catcher assembly mounted in place, you and others are exposed to blade contact Figure 28 and thrown debris. - Page 26 WARNING Loading a machine onto a trailer or truck increases the possibility of tip-over and could cause serious injury or death. • Use extreme caution when operating a machine on a ramp. • Ensure that the ROPS is in the up position and use the seat belt when loading or unloading the machine.

-

Page 27: Operating Tips

If a blade is damaged or worn, replace it it is late fall when grass grows more slowly. immediately with a genuine Toro replacement blade. Alternating the Mowing Direction Alternate mowing direction to keep the grass standing straight. -

Page 28: Maintenance

Maintenance Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Change the hydraulic system filter and oil. After the first 50 hours • Check the safety-interlock system. • Check the air cleaner for dirty, loose or damaged parts. • Check the engine-oil level. Before each use or daily •... -

Page 29: Premaintenance Procedures

Figure 31 1. Read the Operator's Manual for information on maintenance. 4. Check the hydraulic oil every 25 hours. 2. Check the engine oil every 8 hours. 5. Check the caster wheel tire pressure every 25 hours. 3. Check the drive wheel tire pressure every 25 hours. 6. -

Page 30: Engine Maintenance

Engine Maintenance WARNING Contact with hot surfaces may cause personal injury. Keep hands, feet, face, clothing and other body parts away the muffler and other hot surfaces. Servicing the Air Cleaner Service Interval: Before each use or daily—Check the air cleaner for dirty, loose or damaged parts. -

Page 31: Servicing The Engine Oil

4. Remove the foam element from the paper element (Figure 34). SAE 30 g017552 Figure 35 Figure 34 1. Air-cleaner cover 3. Paper element 2. Foam element Checking the Engine-Oil Level Service Interval: Before each use or daily—Check the Servicing the Foam Element engine-oil level. - Page 32 Changing the Engine Oil and the Engine-Oil Filter Service Interval: Every 100 hours—Change the engine oil and the engine-oil filter. Note: The drain plug is attached to the drain hose. Note: Dispose of the used oil at a recycling center. Fill with oil as specified in the “Viscosity Grades”...

-

Page 33: Servicing The Spark Plug

g027478 Figure 40 Checking the Spark Plug Important: Do not clean the spark plug(s). Always replace the spark plug(s) when it has: a black coating, worn electrodes, an oily film, or cracks. Note: If you see light brown or gray on the insulator, the engine is operating properly. -

Page 34: Cleaning The Blower Housing

Installing the Spark Plug Fuel System Tighten the spark plug to 27 N-m (20 ft-lb). Maintenance DANGER In certain conditions, gasoline is extremely flammable and highly explosive. A fire or explosion from gasoline can burn you and others and can damage property. -

Page 35: Electrical System Maintenance

Electrical System Maintenance Servicing the Battery g0281 10 Service Interval: Monthly WARNING CALIFORNIA Proposition 65 Warning Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling. -

Page 36: Servicing The Fuses

Charging the Battery 1. Disengage the blade-control switch (PTO), move the motion-control levers to the neutral-lock position and set the parking brake. WARNING 2. Stop the engine, remove the key, and wait for all moving Charging the battery produces gasses that can parts to stop before leaving the operating position. -

Page 37: Drive System Maintenance

Drive System Maintenance Checking the Tire Pressure Service Interval: Every 25 hours—Check tire pressure. Maintain the air pressure in the front and rear tires as specified. Uneven tire pressure can cause uneven cut. Check the pressure at the valve stem (Figure 48). -

Page 38: Hydraulic System Maintenance

Hydraulic System 2. Remove the key and engage the parking brake. 3. Locate the filter and guards on each transaxle drive Maintenance system (Figure 50). Oil Type: 20w-50 engine oil. G010254 System Capacity: approximately 4.495 liter (152 oz) with a filter change. - Page 39 Installing the Hydraulic System Filters Service Interval: After the first 50 hours Every 400 hours 1. Apply a thin coat of oil on the surface of the rubber seal of each filter (Figure 51). 2. Turn the filter clockwise until rubber seal contacts the filter adapter then tighten the filter an additional 3/4 to 1 full turn (Figure...

-

Page 40: Mower Deck Maintenance

Check the cutter blades daily for sharpness, and for any wear or damage. File down any nicks and sharpen the blades as necessary. If a blade is damaged or worn, replace it immediately with a genuine Toro replacement blade. For convenient sharpening and replacement, you may want to G010333 keep extra blades on hand. - Page 41 3. Measure from the tip of the blade to the flat surface here. Figure 53 1. Cutting Edge 3. Wear/slot Forming G014973 2. Curved Area 4. Crack Figure 55 Checking for Bent Blades 1. Blade, in position for measuring Note: The machine must be on a level surface for the 2.

-

Page 42: Removing The Blades

(1/8 inch), the blade spindle could be bent. from both cutting edges. Contact an Authorized Toro Dealer for service. B. If the variance is within constraints, move to the next blade.. -

Page 43: Leveling The Mower Deck

Figure 60 1. Blade 2. Balancer Installing the Blades 1. Install the blade onto the spindle shaft (Figure 58). Figure 61 Important: The curved part of the blade must be pointing upward toward the inside of the mower to 1. Blades side to side 3. -

Page 44: Inspecting The Belts

Figure 62 1. Blades front to rear 3. Measure from the tip of the blade to the flat surface here 2. Outside cutting edges Figure 64 Leveling the Mower Deck 3. Hook 1. Deck lift arm 2. Chain 4. Adjustment bolt 1. -

Page 45: Replacing The Mower Belt

1. Install the new belt around the mower pulleys and the clutch pulley under the engine (Figure 66). 2. Using a spring removal tool (Toro part no. 92-5771), install the idler spring over the deck post and place tension on the idler pulley and mower belt (Figure 66). -

Page 46: Removing The Mower

Figure 68 1. Link pin 3. Hair pin cotter 2. Washer 2. Lift up on the mower deck to relieve tension from the mower deck. 3. Remove the chains from the hooks on the deck lift Figure 67 arms (Figure 69). -

Page 47: Installing The Mower Deck

Installing the Mower Deck Replacing the Grass Deflector 1. Park the machine on a level surface and disengage the Service Interval: Before each use or daily—Inspect the grass blade-control switch. deflector for damage. 2. Move the motion-control levers outward to the WARNING neutral-lock position, stop the engine, remove the key, set the parking brake and wait for all moving parts to... -

Page 48: Cleaning

Cleaning the bend and going over the rod as it returns from the bend. 5. Lift the loop end of the spring and place it into the Washing the Underside of the notch on the deflector assembly bracket (Figure 71). Mower Service Interval: After each use—Clean the mower housing. -

Page 49: Disposing Of Waste

Storage 6. Disengage the blade-control switch, stop the engine, and remove the ignition key. Wait for all moving parts to stop. Cleaning and Storage 7. Turn the water off and remove the coupling from the 1. Disengage the blade-control switch (PTO), set the washout fitting. - Page 50 D. Restart the engine and run it until it stops. E. Dispose of fuel properly. Recycle as per local codes. Important: Do not store stabilizer/conditioned fuel over 90 days. 13. Check and tighten all bolts, nuts, and screws. Repair or replace any part that is damaged.

-

Page 51: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The starter does not crank. 1. The blade-control switch (PTO) is 1. Move blade-control switch (PTO) to engaged. disengaged. 2. The parking brake is not on. 2. Set the parking brake. 3. The drive levers are not in neutral-lock 3. - Page 52 Problem Possible Cause Corrective Action The machine does not drive. 1. The by pass valves are not closed 1. Tighten the by pass valves. tight. 2. The pump belt is worn, loose or broken. 2. Change the belt. 3. The pump belt is off a pulley. 3.

-

Page 53: Schematics

Schematics Wire Diagram (Rev. A) - Page 54 Notes:...

- Page 55 Notes:...

- Page 56 Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company. Australian Consumer Law: Australian customers will find details relating to the Australian Consumer Law either inside the box or at your local Toro Dealer.