Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Husqvarna 917.29939

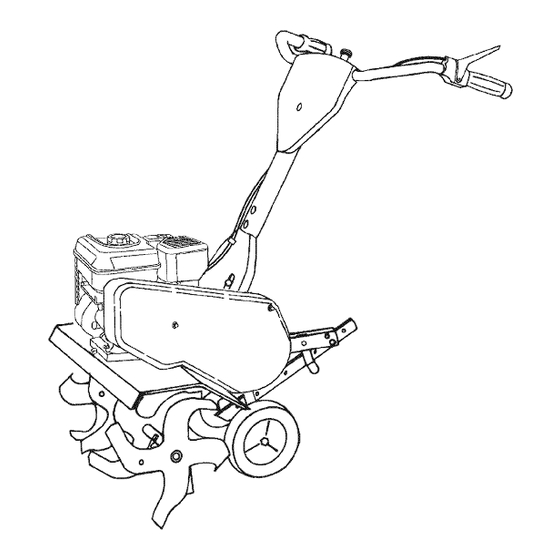

- Page 1 ® Owner's Manual 532 43 58-47...

-

Page 2: Safety Rules

• Always refer to the operator's guide instructions for while the important details if the tiller is to be stored for an ex- tended period. CAUTIONS, IMPORTANTS, AND NOTES ARE A MEANS OF ATTRACTING ATTENTION TO IMPORTANT OR CRITICAL INFORMATION IN THIS MANUAL. -

Page 3: Specifications

We have competent, well-trained technicians and the proper tools to service or repair this unit. Please read and retain this manual. The instructions will enable you to assemble and maintain your tiller properly. Always observe the "SAFETY RULES". TABLE OF CONTENTS SAFETY RULES ... -

Page 4: Tools Required For Assembly

Your new tiller has been assembled at the factory with exception of those parts left unassembled for shipping purposes. To ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to insure proper tightness. -

Page 5: Assembly ................................................................. 4

Route tine control cable(s) through plastic cable clip on handle mount. NOTE: Cables must not touch the muffler. Cut cable ties securing tiller to skid. Remove tiller from skid by pulling backwards. Remove screws securing depth stake to skid and dis- card the screws. -

Page 6: Operation

KNOW YOUR TILLER READ THIS OWNER'S MANUAL Compare the illustrations with your tiller to familiarize yourself with the location of various controls and adjustments. Save this manual for future reference. These symbols may appear on your Tiller or in literature meaning. - Page 7 • For normal tilling, set wheels at the second or third hole from the top. THROTTLE CONTROL (See Fig. 5) It serves as a brake to slow the tiller's forward HAIRPIN CLiP AND CLEVIS PIN WHEEL Fig. 6 Replace the...

-

Page 8: Before Starting Engine

AROUND THE YARD • Tip depth stake forward until it is held by the stake spring. Push tiller handles down, raising tines off the ground. Push or pull tiller to desired location. AROUND TOWN Disconnect spark plug wire. Drain fuel tank. - Page 9 To slow down the tiller, press down on handles. If you are straining or tiller is shaking, the wheels and depth stake are not set properly in the soil being tilled. The proper setting of the wheels and depth stake is through trial and error and depends upon the soil condition.

-

Page 10: Maintenance Schedule

2 - Service more often when operating in dirty or dusty conditions, GENERAL RECOMMENDATIONS The warranty on this tiller does not cover items that have been subjected to operator abuse or negligence. To receive full value from the warranty, operator must maintain tiller as instructed in this manual. -

Page 11: Air Cleaner

Change the oil after every 50 hours of operation or at least once a year if the tiller is not used for 50 hours in one year. Check the crankcase oil level before starting the engine and after each five (5) hours of continuous use. - Page 12 FINS MUFFLER Fig. 14 MUFFLER Do not operate tiller without muffler. Do not tamper with exhaust system. Damaged mufflers or spark arresters could create a fire hazard. Inspect periodically necessary. If your engine is equipped with a spark arrester screen assembly, remove every 50 hours for cleaning and inspection.

-

Page 13: Service And Adjustments

HEIGHT Factory assembly has provided lowest handle height. Select handle height best suited for your tilling conditions. Handle height will be different when tiller digs into soil. • If a higher handle height is desired, loosen the four nuts securing handle panel to engine brackets. - Page 14 SERVICE AND ADJUSTMENTS TO REMOVE BELT GUARD • Remove two (2) cap nuts and washers from side of belt guard. • Loosen (do not remove) tine shield nut on underside of tine shield. Pull belt guard out and away from unit. Replace belt guard by reversing above procedure.

- Page 15 SERVICE AND ADJUSTMENTS CHECK TINE OPERATION • See "TINE OPERATION CHECK" in this section of manual. REPLACE BELT GUARD FORWARD MOTION (iNSiDE) V-BELT ENGINE PULLEY / I _ \ BELT GUIDE REVERSE IDLER PULLEY BELT GUIDE FORWARD IDLER PULLEY REVERSE (OUTSIDE) V-BELT REVERSE IDLER PULLEY...

-

Page 16: Storage

Immediately prepare your tiller for storage at the end of the season or if the unit will not be used for 30 days or more. WARNING: Never store the tiller with gasoline in the tank inside a building where fumes may reach an open flame or spark. -

Page 17: Troubleshooting

1. Ground too dry and hard. difficult handling 2. Wheels and depth stake incorrectly adjusted. 1. Ground too wet. Soil bails up or clumps Engine runs but tiller 1. Tine control is not engaged. won't move 2. V-belt not correctly adjusted. -

Page 18: Repair Parts

REPAIR PARTS TILLER - - MODEL NUMBER HANDLES PART DESCRiPTiON 532 43 27-09 Panel, Control 532 16 57-87 Grip, HandJe 898 00 01-29 Nut, Flange 872 01 05-08 Bolt, Carriage 532 18 14-78 Assembly, Panel and Tube 532 18 85-32 Lever, Control, Tine... - Page 19 REPAIR PARTS TILLER BELT GUARD AND PULLEY belt guard PART DESCRiPTiON 532 18 03-77 Assembly, Bracket, Belt Guard 532 00 94-84 Clip, Cable 532 08 67-77 Screw #10-24 x 1/2 874 61 08-12 Bolt, Hex Head 1/2-20 x 3/4 873 68 06-00...

- Page 20 REPAIR PARTS TILLER - - MODEL NUMBER WHEEL AND DEPTH STAKE ASSEMBLY PART DESCRIPTION 532 O0 91-94 Pin, Clevis 874 76 05-20 Bolt, Hex Head 5/16-18 x 1-1/4 874 76 05-12 Bolt, Hex Head 5/16-18 x 3/4 873 22 05-00...

-

Page 21: Tine Assembly

REPAIR PARTS TILLER TINE ASSEMBLY PART DESCRIPTION 532 15 69-34 Tine, Outer, R.H. 532 00 31-46 Retainer, Spring 532 15 69-32 Tine, Inner, R.H. - - MODEL NUMBER 917.299390 PART 532 15 69-31 532 15 69-33 532 00 49-29 tine_ipb_3 DESCRIPTION Tine, Inner, L.H. - Page 22 REPAIR PARTS TILLER - - MODEL NUMBER TRANSMiSSiON PART DESCRiPTiON 874 76 05-24 Bolt, Hex 5/16-18 x 1-1/2 Gr. 2 874 78 06-52 Bolt, Hex 3/8-18 x 3-1/4 819 13 13-11 Washer 13/32 x 13/18 x 11 873 90 06-00...

- Page 23 REPAIR PARTS TILLER DECALS - - MODEL NUMBER 917.299390 PART DESCRiPTiON 532 43 24-16 Decal. Logo 532 42 91-96 Decal. Logo 532 43 24-18 Decal. Logo Decal. Panel Control Inst. 532 43 29-87 Decal. Hand Placement 532 11 08-14 532 12 00-76 Decal.

- Page 24 TILLER - - MODEL NUMBER BRIGGS ENGINE - MODEL [_0_O_OR'SM_NU_L] [I_2_R_L_C_M_N_NG,N_] 48 SHORT BLOCK 415 _ 15A _ 13 _¢:_ 365_ 190@__ NUMBER 121002, TYPE NUMBER 1026 1026 _k_j" 917.299390 1380-B8 I I_0_RM_NU_LI 1029 ... S _ ... 1022 914A...

- Page 25 TILLER BRIGGS ENGINE - MODEL NUMBER 1270 6921 ' '\ %" _'" 95 _'_ q'£ "_186 51_i\ 1133 1 _._._ " 276 _'-" _ / 1005 1070 _,_ 332-_ - - MODEL NUMBER 917.299390 121002, TYPE NUMBER 190_ (_¢'% ''2_...

- Page 26 TILLER - - MODEL NUMBER BRIGGS ENGINE - MODEL 358 ENGINE GASKET 1210 I 1211 NUMBER 121002, TYPE NUMBER 1022 883_ 1022 597_ 689 (% 917.299390 1380-B8 121 CARBURETOR OVERHAUL 104 _% 127 0 276 63j 1036 EMISSIONS 633 _)

- Page 27 TILLER BRIGGS ENGINE = MODEL NUMBER PART DESCRIPTION 699510 Cylinder Assembly 399269 Kit-Bushing/Seal 299819s Seal-Oil (Magneto 797439 Head-Cylinder 698210 Gasket-Cylinder 790632 Tube-Breather 699485 Gasket-Crankcase 699482 Screw (Cylinder 691686 Plug-Oil Drain 691682 Plug-Oil Drain 797070 Crankshaft 699696 Cover-Crankcase 692550 Seal-Oil (PTO Side)

- Page 28 TILLER - - MODEL NUMBER BRIGGS ENGINE - MODEL PART DESCRIPTION 695087 Gear-Timing 692564 Retainer-E Ring 790278 Gear-Idler 797441 Stud-Rocker 693583 Guard-Muffler 699632 Screw (Muffler 493880s Terminal-Spark 795440 Seal-Valve 691115 Seat-Valve 691893 Gasket-Exhaust 699480 Screw (Rocker 914A 797444 Screw (Rocker...

- Page 29 SERVICE OTES...

-

Page 30: Service Notes

SERVICE NOTES... - Page 31 SERVICE OTES...

- Page 32 It is the Owner's and Retailer's responsibilityto make certain that the Warranty Registration Card is properly filled out and mailed to Husqvarna Forest & Garden Company. This card should be mailed within ten (10) days from the date of purchase in order to confirm the warranty and to facilitate post-sale service.