Table of Contents

Advertisement

WASHING MACHINE

SERVICE MANUAL

CAUTION

READ THIS MANUAL CAREFULLY TO DIAGNOSE TROUBLES

CORRECTLY BEFORE OFFERING SERVICE.

MODEL : WD-14311(6)RD/WD-1481RD

WD-12311(6)RD

WD-14312(7)RD/WD-14310(5)RD

WD-12312(7)RD/WD-12310(5)RD

WD-10PFD, 10PFP

WD-14311RDA

WD-1485RD/WD-1488RD

AWD-14312(7)RD

AWD-12312(7)RD

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for LG WD-14311(6)RD

-

Page 1: Washing Machine

WASHING MACHINE SERVICE MANUAL CAUTION READ THIS MANUAL CAREFULLY TO DIAGNOSE TROUBLES CORRECTLY BEFORE OFFERING SERVICE. MODEL : WD-14311(6)RD/WD-1481RD WD-12311(6)RD WD-14312(7)RD/WD-14310(5)RD WD-12312(7)RD/WD-12310(5)RD WD-10PFD, 10PFP WD-14311RDA WD-1485RD/WD-1488RD AWD-14312(7)RD AWD-12312(7)RD... - Page 2 OCT. 2004 PRINTED IN KOREA P/No.:3828ER3035G...

-

Page 3: Table Of Contents

CONTENTS 1. SPECIFICATION..........................3 2. FEATURES & TECHNICAL EXPLANATION ................4 3. PARTS IDENTIFICATION ......................6 4. INSTALLATION ..........................7 5. OPERATION ..........................10 6. WIRING DIAGRAM / PROGRAM CHART ...................12 7. TROUBLE SHOOTING........................13 7-1.BEFORE SVC CHECKING ....................13 7-2.QC TEST MODE........................13 7-3.HOW TO KNOW THE WATER LEVEL FREQUENCY............13 7-4.ERROR DISPLAY ........................14 8. - Page 5 Automatic process from washing to drying. More economical by Intelligent Wash System Direct Drive system Child-Lock Low noise speed control system Auto Restart...

-

Page 6: Water Level Control

2-2.DETERMINE WASHING TIME BY FUZZY LOGIC To get the best washing performance optimal time is determined by sensing of water temperature, selected washing temperature and laundry amount. water temperature washing time the best selected FUZZY washing washing rinsing time temperature LOGIC performance spin rhythm, time... -

Page 7: Parts Identification

3. PARTS IDENTIFICATION ■ ACCESSORIES Spanner... -

Page 8: Installation

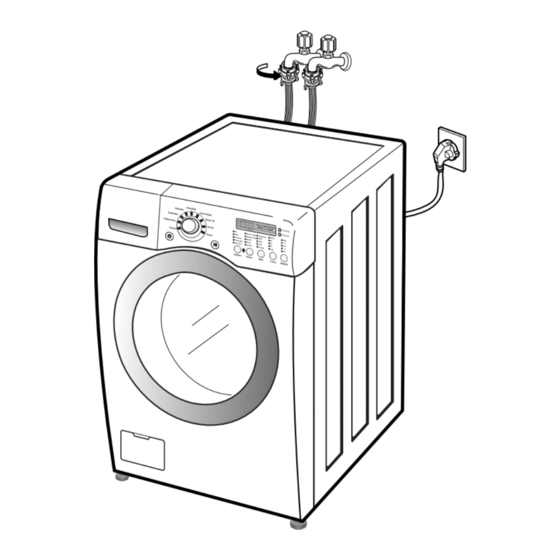

4. INSTALLATION Before servicing ask troubles of customers Check the adjustment(power supply is 220-240V~, remove the transit bolts..) Check the troubles referring to the trouble shooting. Decide service steps referring to disassembly instructions. And then, service and repair. After servicing, operate the appliance whether it works O · K or NOT. ■... - Page 9 ■ HOW TO CONNECT INLET HOSE • Check that the rubber packing is inside of the valve connector. • Connect the inlet hose firmly to prevent leak. ■ CONNECT DRAIN HOSE · Make sure that the hose is not twisted. ·...

- Page 10 TEST OPERATION Preparation for Press the POWER button. Press the Start/Pause washing. button. •Connect the power plug to •In case of Coloreds program. the outlet. •Connect the inlet hose. Check the water heating. Check automatic reverse Check the water supply. turn.

-

Page 11: Operation

5. OPERATION • Use this option to pre • Use this button to turn the power • This display shows: Press and hold PRE On/Off. a) the estimated time remaining in the lock/unlock control. cycle when operating. • When Child lock is se b) an error code when an error has been buttons are disabled detected. -

Page 12: Time Delay

• TIME DELAY event unwanted use of the washer. • Allows the start of any cycle WASH button for 3 seconds to to be delayed for 3~19 • These lights show which portion hours. of the cycle the washer is et, CHILD LOCK lights and all operating. -

Page 13: Wiring Diagram / Program Chart

6. WIRING DIAGRAM PROGRAM CHART About 1:50 About 1:15 About 55 About 1:05 About 1:00 About 30 About 2:00 About 2:50 About 33 About 46 About 28 About 17 About 30... -

Page 14: Trouble Shooting

7. TROUBLE SHOOTING 7-1.BEFORE SVC CHECKING ■ Be careful of electric shock or disconnecting the parts while trouble shooting. ■ Voltage of each terminal in 220-240V~ and DC while applying an electric current. 7-2.QC TEST MODE. ① Pressing Rinse, and Spin button simultaneously. ②... -

Page 15: 7-4.Error Display

7-5.ERROR DISPLAY. • If you press the Start/Pause button in error condition, any error except ‘ ’ will disappear and the machine will change into pause status. • In case of 『 』 , 『 』 , 『 』 , if the error is not resolved within 20 sec., and in case of other errors, if the error is not resolved within 4 min., power will be turned off automatically and the error only will be blinked. - Page 16 ERROR SYMPTOM CAUSE • MAIN PWB ASSEMBLY is out of order ☞ Replace the MAIN PWB ASSEMBLY CURRENT • Winding in the STATOR ASSEMBLY is short-circuited. ERROR ☞ Replace the STATOR ASSEMBLY • “ ” is dispplayed during a high spin ☞...

-

Page 17: Error Diagnosis And Check List

8. ERROR DIAGNOSIS AND CHECK LIST 8-1.DIAGNOSIS AND ANSWER FOR ABNORMAL OPERATION SYMPTOM GUIDE FOR SERVICE CALL NO POWER Is the power plug connected firmly to 220-240V~ outlet? Power failure? or Breaker opened? Visit to check Water inlet trouble Is " "... - Page 18 SYMPTOM GUIDE FOR SERVICE CALL • Door does not open Started with door opened? • Error displayed on the program Close the door Visit to check Check if the door switch is O K. • DRAIN TROUBLE Is " " displayed? Is the debris filter clogged with foreign Clean up material such as pin, coin and etc.?

- Page 19 SYMPTOM GUIDE FOR SERVICE CALL 。 Suds overflow from the Is low-sudsing detergent for the drum appliance. washing machine used? (In this condition, wash and spin do not operate LOW-SUDSING normally) Is the proper amount of detergent used as recommended? Recommend to reduce the using amount of detergent.

-

Page 20: Fault Diagnosis And Trouble Shooting

8-2.FAULT DIAGNOSIS AND TROUBLE SHOOTING CAUTION 1. Be careful of electric shock or disconnecting the parts while trouble shooting. 2. First of all, check the connection of each part terminal with wiring diagram. 3. If you replace the MAIN PWB ASSEMBLY, Put in the connectors correctly. NO POWER When measuring the voltage of the outlet, Check the fuse? -

Page 21: No Water Supply

NO WATER SUPPLY Is water supply shut-off? Is the tap opened? Open the tap. Check the AIR CHAMBER When you press both Rinse button and Spin button and the tube clogged simultaneously, is the water level frequency below 240? with impurity. Is the inlet valve filter clogged with impurity? Clean the filter. - Page 22 S O F T E N E R D O E S N O T F L O W I N Refer to Is water supplied? 「NO WATER SUPPLY」 Check the wiring on the Are receptacles correctly connected to the terminals dispenser.

-

Page 23: Heating Without Water

HEATING WITHOUT WATER When pressing Wash and Rinse at the same time after draining, is the water level frequency 248 ~ 262 Replace the or more? S.PRESSURE SWITCH When pressing Rinse, Spin buttons at the same ASSEMBLY time while wash, is the water level frequency between 230 - 243? Checking voltage between two pins as press the Replace the MAIN PWB... - Page 24 AC 220-240V HEATING CONTINUOUSLY ABOVE THE SETTING WATER TEMPERATURE When checking THERMISTOR on the tub is the Push the THERMISTOR THERMISTOR loosened above 2mm from tightly to the rubber. the rubber?

- Page 25 S P I N T R O U B L E Check the S.PRESSURE SWITCH Check on the spinning, is the frequency of the ASSEMBLY or HOSE (Pressure). water level 248 or more. The frequency can be If the problem is on the checked by pressing the Wash and Rinse buttons at S.PRESSURE SWITCH the same time on the program.

- Page 26 [dHE] ERROR DISPLAY Dry duct Replace the thermistor. (6322FR2046B) Condensing CHECK FOR DRY HEATER TROUBLE duct Thermistor CHECK FOR DRY FAN MOTOR TROUBLE Disassemble the cabinet cover and condensing bellows. Clean the bellows Is there any foreign object in condensing bellows.

- Page 28 20~30 Black Yellow...

-

Page 30: Disassembly Instructions

9. DISASSEMBLY INSTRUCTIONS ✽ Disassemble and repair the parts after pulling out power cord from the outlet. CONTROL PANEL ① Unscrew the screws on the top plate. PLATE ASSEMBLY(TOP) ② The plate assembly(Top) is pulled back and then upward to arrow direction. ③... - Page 31 PWB ASSEMBLY(MAIN) ① The back cover is removed. ② Two screws are unscrewed. ③ Disconnect connector from the wiring. ④ Pull the PWB assembly (Main) to arrow direction. DISPENSER ASSEMBLY ① The plate assembly(Top)and the cover(lnner)are disassembled. ② Pull the drawer to arrow direction. ③...

- Page 32 INLET VALVE ① Disconnect the wiring connector. ② Remove the valve by two screws of the valve holder. When reconnecting the connector VALVE ① (DRY) YL/BK - BK VALVE ② (PRE-WASH) GY/WH - BK VALVE ③ (NORMAL-WASH) WH/BK - BK VALVE ®È...

- Page 33 GASKET ASSEMBLY ① The cabinet gasket clamp is released. ② Two screws are unscrewed from the cabinet cover. ① Pull plat(-) screwdriver or pully knife into the both sides of filter cover, and pull in out. ① Unscrew the screw from the lower side of the cabinet cover.

- Page 34 ① Disassemble the clamp assembly. Tub Gasket Clamp ① Remove dry gasket clamp by loosening the screw. ① When reassembling the gasket, put the drain hole of the gasket downward, then assemble. Drain Hole...

- Page 35 ROTOR ASSEMBLY, STATOR ASSEMBLY, FRICTION DAMPER ① Remove the back cover. ② After loosening the bolt, Rotor, pull out the rotor. Rotor Bolt (ROTOR ASSEMBLY) ① Remove the 6 bolt from the stator. ② Disconnect the 2 connectors. HOW TO ASSEMBLE THE MOTOR (STATOR ASSEMBLY) ①...

- Page 36 PUMP ① Remove pump outlet hose. ② Remove tub pump bellows. ③ Remove cap(Remaining Hose). ④ Disconnect the wiring. ⑤ Three screws are unscrewed from the cabinet. ⑥ Remove the pump to arrow direction. HEATER ① Loosen the nut. ② Remove washing heater by pulling out. Washing Heater Ring Terminal...

- Page 37 SWITCH ASSY, DOOR LOCK ① The cabinet cover clamp is removed and the gasket is released. ② Two screws are unscrewed. ③ The door lock S/W is disconnected form the wiring connector and the strap. WHEN FOREIGN OBJECT STUCK BETWEEN DRUM AND TUB ①...

- Page 38 DRY DUCT ① Remove 6 screws and dry fan assembly. Dry fan Ass'y ② Remove 7 screws and dry duct upper. Dry Duct Upper ① Remove 2 screws and dry heater. Thermostat ② Remove thermostat. Dry Heater CONDENSING DUCT ① Remove 17 screws from Dry duct upper and Dry fan Assembly.

-

Page 39: Exploded View And Parts List

10. EXPLODED VIEW AND PART LIST 10-1.THE PART LIST OF CABINET ASSEMBLY A154 A153 A110 A140 A152 A151 A101 A102 A120 A104 A150 A103 A141 A100 A131 A485 A130 A430 A440 A134 A133 A450 A410 A200 A303 A300 A310 A275 A201 A240 A276... -

Page 40: The Exploded View Of Control Panel And Dispenser Assembly

10-2 THE EXPLODED VIEW OF CONTROL PANEL & DISPENSER ASSEMBLY F436 F324 F300 F462 F322 F321 F170 F320 F160 F466 F432 F430 F225 F441 F220 F120 F215 F110 F210 F130... -

Page 41: The Exploded View Of Drum And Tub Assembly

10-3 THE EXPLODED VIEW OF DRUM & TUB ASSEMBLY K143 K360 K350 K123 K351 F140 K411 K122 K121 K410 F465 K125 F310 F464 F463 K146 K320 K111 M105 K310 K110 K141 K311 K140 K105 K115 K410 K130 K135 K610 K512 K510 K560 K611... -

Page 42: The Exploded View Of Dryer

10-4 THE EXPLODED VIEW OF DRYER M100 M240 M130 M111 M120 M110 M216 M210 M230 M215 M101 M220...