Table of Contents

Summary of Contents for Toro 74995

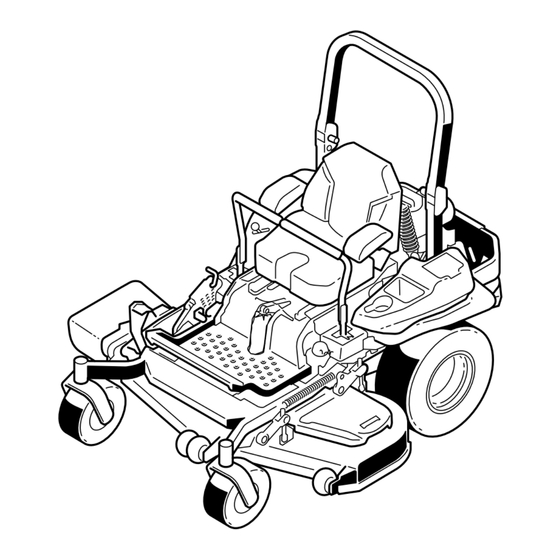

- Page 1 Form No. 3400-686 Rev B Z Master ® Professional 5000 Series Riding Mower with 52in TURBO FORCE ® Side Discharge Mower Model No. 74995—Serial No. 316000001 and Up *3400-686* B Register at www.Toro.com. Original Instructions (EN)

- Page 2 Authorized Service arrester, as defined in Section 4442, maintained in Dealer or Toro Customer Service and have the model effective working order or the engine is constructed, and serial numbers of your product ready.

-

Page 3: Table Of Contents

Safety ............... 4 Servicing the Fuel Tank........48 Safe Operating Practices........4 Electrical System Maintenance ......49 Toro Mower Safety..........6 Servicing the Battery......... 49 Slope Indicator ........... 7 Servicing the Fuses .......... 50 Safety and Instructional Decals ......8 Jump-Starting the Machine....... -

Page 4: Safety

Do not operate unless they are Manual. Modifications to this machine should only functioning properly. be made by either the manufacturer or an Authorized Toro Dealer. Operation This product is capable of amputating hands and feet. • Lightning can cause severe injury or death. If... - Page 5 Maintenance and Storage Make the necessary repairs before resuming operations. • Disengage drives, set the parking brake, stop • Keep your hands and feet away from the cutting the engine, and remove the key or disconnect unit. spark-plug wire. Wait for all movement to stop before adjusting, cleaning, or repairing.

-

Page 6: Toro Mower Safety

Do not store the machine or a fuel container inside The following list contains safety information specific where there is an open flame, such as near a to Toro products and other safety information that you water heater or furnace. must know. -

Page 7: Slope Indicator

Slope Indicator g011841 Figure 3 This page may be copied for personal use. 1. The maximum slope you can safely operate the machine on is 15 degrees. Use the slope chart to determine the degree of slope of hills before operating. Do not operate this machine on a slope greater than 15 degrees. Fold along the appropriate line to match the recommended slope. -

Page 8: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. decal58-6520 58-6520 decal106-2655 1. Grease 106-2655 1. Warning—do not touch or approach moving belts; remove the ignition key and read the instructions before servicing or performing maintenance. - Page 9 decal110-2068 110-2068 1. Read the Operator's Manual. decal112-9028 112-9028 1. Warning—stay away from moving parts; keep all guards in place. decal107-3069 107-3069 1. Warning—there is no rollover protection when the roll bar is down. decal114-4466 2. To avoid injury or death from a rollover accident, keep the 114-4466 roll bar in the fully raised and locked position and wear the seat belt.

- Page 10 decal115-9625 115-9625 1. Parking 2. Parking brake—engaged brake—disengaged decal116-1716 decal117-0346 116-1716 117-0346 1. Fuel 6. Hour meter 1. Fuel leak hazard—read the Operator's Manual; do not 2. Empty 7. PTO attempt to remove the roll bar; do not weld, drill, or modify the roll bar in any way.

- Page 11 decal117-3864 117-3864 1. Read the Operator’s 2. Fill to bottom of filler neck; Manual. warning—do not overfill the tank. decal126-4398 126-4398 1. Read the Operator’s 3. Unlock manual 2. Lock decal121-7586 121–7586 1. Fast 3. Slow 2. Variable speed control 4.

- Page 12 decaloemmarkt Manufacturer's Mark 1. Indicates the blade is identified as a part from the original machine manufacturer. decalbatterysymbols Battery Symbols Some or all of these symbols are on your battery 1. Explosion hazard 6. Keep bystanders a safe distance from the battery. 7.

- Page 13 decal125-9383 125–9383 1. Check hydraulic oil every 50 operating hours. 3. Check the tire pressure every 50 operating hours. 2. Read the Operator’s Manual for information on lubricating 4. Read the Operator’s Manual before servicing or performing the machine. maintenance.

- Page 14 decal132-0871 132-0871 Note: This machine complies with the industry standard stability test in the static lateral and longitudinal tests with the maximum recommended slope indicated on the decal. Review the instructions for operating the machine on slopes in the Operator’s Manual as well as the conditions in which you would operate the machine to determine whether you can operate the machine in those conditions on that day and at that site.

-

Page 15: Setup

Setup Product Overview Removing the Shipping Straps WARNING The springs are compressed by the shipping straps. When the straps are cut, the seat will raise up quickly by approximately 8.9 cm (3-1/2 inches). Remove the shipping straps before operating the machine. - Page 16 Safety-Interlock Indicators There are symbols on the hour meter and they indicate with a black triangle that the interlock component is in the correct position (Figure Battery-Indicator Light When you initially turn the ignition key to the R position for a few seconds, the battery voltage displays in the area where the hours are normally displayed.

-

Page 17: Specifications

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or Distributor or go to www.Toro.com for a list of all approved attachments and accessories. -

Page 18: Operation

Operation DANGER In certain conditions during fueling, static Note: Determine the left and right sides of the electricity can be released causing a spark machine from the normal operating position. which can ignite the gasoline vapors. A fire or explosion from gasoline can burn you and Adding Fuel others and can damage property. -

Page 19: Checking The Engine-Oil Level

Checking the Engine-Oil Add the correct amount of gas stabilizer/conditioner to the gas. Level Note: A fuel stabilizer/conditioner is most effective when mixed with fresh gasoline. To minimize the Before you start the engine and use the machine, chance of varnish deposits in the fuel system, use check the oil level in the engine crankcase;... -

Page 20: Entering The Operating Position

Entering the Operating Position Use the mower deck as a step to get into the operating position (Figure 10). g029797 Figure 10 1. Mower deck Think Safety First Please read all safety instructions and symbols in the safety section. Knowing this information could help you or bystanders avoid injury. -

Page 21: Operating The Parking Brake

Operating the Parking DANGER Brake Operating the machine while the roll bar is down may lead to serious injury or death in Always set the parking brake when you stop the the event of a rollover. machine or leave it unattended. Always keep the roll bar in the fully raised and locked position and use the seat belt. -

Page 22: Operating The Mower Blade-Control Switch (Pto)

Operating the Mower Blade-Control Switch (PTO) The blade-control switch (PTO) starts and stops the mower blades and any powered attachments. Engaging the Blade-Control g008946 Figure 17 Switch (PTO) Note: Engaging the blade-control switch (PTO) with the throttle position at half or less causes excessive wear to the drive belts. -

Page 23: Starting And Stopping The Engine

g008948 Figure 19 1. On 2. Off Starting and Stopping the Engine Starting the Engine g029634 Figure 20 Raise the ROPS up, lock it into place, sit on the seat, and fasten the seat belt. Move the motion-control levers to the Turn the ignition key to the S position TART... -

Page 24: Using The Safety-Interlock System

Stopping the Engine Using the Safety-Interlock System CAUTION Children or bystanders may be injured if they CAUTION move or attempt to operate the machine while it is unattended. If the safety-interlock switches are disconnected or damaged, the machine could Always remove the ignition key and set the operate unexpectedly, causing personal parking brake when leaving the machine injury. -

Page 25: Driving Forward Or Backward

Testing the Safety-Interlock Driving Forward or System Backward Service Interval: Before each use or daily The throttle control regulates the engine speed as measured in rpm (revolutions per minute). Place Test the safety-interlock system before you use the the throttle control in the F position for best machine each time. -

Page 26: Stopping The Machine

Driving Forward Driving Backward Move the levers to the center, unlocked position. Note: The engine shuts off if you move the traction-control levers with the parking brake engaged. To go backward, slowly pull the motion-control levers rearward (Figure 26). To stop, pull the motion-control levers to the N EUTRAL position. -

Page 27: Adjusting The Height Of Cut

Adjusting the Height of Cut Using the Transport Lock The transport lock has 2 positions and is used with the deck-lift pedal. There is a L position and an U position for the transport position of the NLOCK mower deck (Figure 27). - Page 28 Adjusting the Height-of-Cut Pin Adjust the height-of-cut from 25 to 140 mm (1 to 5-1/2 inches) in 6 mm (1/4 inch) increments by moving the clevis pin into different hole locations. Move the transport lock to the L position. Push on the deck-lift pedal with your foot and raise the mower deck to the Transport position (also the 140 mm or 5-1/2 inch cutting-height position) as shown in...

-

Page 29: Adjusting The Anti-Scalp Rollers

Adjusting the Anti-Scalp Rollers Whenever you change the height of cut, adjust the height of the anti-scalp rollers. Disengage the blade-control switch (PTO), move the motion-control levers to the N EUTRAL LOCK position, and set the parking brake. Stop the engine, remove the key, and wait for all moving parts to stop before leaving the operating position. -

Page 30: Adjusting The Flow-Baffle-Cam Locks

Adjusting the Flow-Baffle-Cam Locks This procedure is applicable only to machines with flow-baffle locks. Certain models have nuts and bolts in place of the flow-baffle locks and can be adjusted the same. You can adjust the mower-discharge flow for different types of mowing conditions. -

Page 31: Positioning The Flow Baffle

Tall, dense grass mowing conditions. • Wet conditions. g005832 Figure 32 • Lowering the engine power consumption. • Increased ground speed in heavy conditions. g005834 Figure 34 Note: This position is similar to the benefits of the Toro SFS mower. -

Page 32: Positioning The Seat

Positioning the Seat Adjusting the MyRide™ Suspension System The seat can move forward and backward. Position the seat where you have the best control of the The MyRide™ suspension system adjusts to provide machine and are most comfortable. a smooth and comfortable ride. Adjusting the rear To adjust the seat, move the lever sideways to unlock 2 shock assemblies is the easiest and quickest the seat... -

Page 33: Using The Drive-Wheel Release Valves

The front shock assembly is set at the middle position and is normally not adjusted. To adjust the front shock assembly, open the floor pan and adjust it by using a spanner wrench (Toro Part No. 132-5069) or slip-joint pliers (Figure 39). -

Page 34: Using The Side Discharge

Note: Make sure that the release valves are in the DANGER fully horizontal position when operating the machine Without a grass deflector, discharge cover, or or severe damage to the hydraulic system can occur. a complete grass-catcher assembly mounted Disengage the blade-control switch (PTO) and in place, you and others are exposed to blade turn the ignition key to off. -

Page 35: Transporting The Machine

Transporting the Machine Loading the Machine Use a heavy-duty trailer or truck to transport the Use extreme caution when loading or the unloading machine. Ensure that the trailer or truck has all the machine onto a trailer or a truck. Use a full-width necessary brakes, lighting, and marking as required ramp that is wider than the machine for this procedure. - Page 36 WARNING Loading a machine onto a trailer or truck increases the possibility of a tip-over and could cause serious injury or death. • Use extreme caution when operating a machine on a ramp. • Ensure that the ROPS is in the up position and use the seat belt when loading or unloading the machine.

-

Page 37: Operating Tips

Alternate the mowing direction to keep the grass as necessary. If a blade is damaged or worn, replace standing straight. This also helps disperse clippings, it immediately with a genuine Toro replacement blade. which enhances decomposition and fertilization. Mowing at Correct Intervals Normally, mow every 4 days. -

Page 38: Maintenance

• Adjust the caster-pivot bearing. Every 500 hours • Check the parking-brake adjustment. • Change the hydraulic filters and hydraulic oil when using Toro® HYPR-OIL™ 500 hydraulic oil (more often in dirty or dusty conditions). • Replace the inner air filter. -

Page 39: Lubrication

CAUTION If you leave the key in the ignition switch, someone could accidently start the engine and seriously injure you or other bystanders. Remove the key from the ignition before you perform any maintenance. Lubrication Adding Light Oil or Spray Lubrication Grease more frequently when operating conditions are extremely dusty or sandy. -

Page 40: Greasing The Mower

Greasing the Mower Grease the drive-belt idler arm (Figure 46). Service Interval: Every 50 hours—Grease the mower-deck spindles and idler arm. Yearly—Grease the pump-belt idler arm. Yearly—Grease the front caster pivots (more often in dirty or dusty conditions). Yearly—Repack the front caster-wheel bearings (more often in dirty or dusty conditions). -

Page 41: Lubricating The Caster-Wheel Hubs

Lubricating the Insert the second bearing and new seal into the wheel. Caster-Wheel Hubs Apply a thread-locking compound to the second spacer nut and thread it onto the axle with the Service Interval: Yearly wrench flats facing outward. Shut off the engine, wait for all moving parts to Torque the nut to 8 to 9 N∙m (75 to 80 in-lb), stop, remove the key, and engage the parking loosen the nut, then torque it to 2 to 3 N∙m (20... -

Page 42: Engine Maintenance

Engine Maintenance WARNING Contact with hot surfaces may cause personal injury. Keep you hands, feet, face, clothing, and other body parts away the muffler and other hot surfaces. Servicing the Air Cleaner g030481 Figure 50 Service Interval: Every 150 hours 1. -

Page 43: Servicing The Engine Oil

Installing the Filters Servicing the Engine Oil Important: To prevent engine damage, always Oil Type: Detergent oil (API service class SL, SM, operate the engine with both air filters and the SN, or higher) cover installed. Oil Capacity: with a filter change, 1.9 L (2 US qt) If you are installing new filters, check each filter for shipping damage. - Page 44 Changing the Engine Oil Service Interval: Every 100 hours (more often in dirty or dusty conditions). Note: Dispose of the used oil at a recycling center. Start the engine and let it run for 5 minutes. g029644 Note: This warms the oil so that it drains better. Park the machine so that the rear is slightly lower than the front to ensure that the oil drains completely.

- Page 45 Changing the Engine-Oil Filter Slowly pour approximately 80% of the specified oil into the filler tube and slowly add the Service Interval: Every 200 hours (more often in dirty additional oil to bring it to the F mark (Figure or dusty conditions). 54).

-

Page 46: Servicing The Spark Plug

Servicing the Engine-Oil Cooler Removing the Spark Plug Shut off the engine, remove the key, and wait Service Interval: Every 200 hours for all moving parts to stop before leaving the Keep the oil cooler free of debris by cleaning the operating position. -

Page 47: Checking The Spark Arrester (If Equipped)

Installing the Spark Plug Tighten the spark plug(s) to 24.4 to 29.8 N·m (18 to 22 ft-lb). g029646 g027478 Figure 58 Install the left hydraulic unit shroud (Figure 57). g027735 Checking the Spark Plug Figure 60 Important: Replace the spark plug(s) when it has: a black coating, worn electrodes, an oily film, cracks or reuse is questionable. -

Page 48: Fuel System Maintenance

Fuel System Maintenance WARNING Fuel-system components are under high pressure. The use of improper components can result in system failure, gasoline leakage, and possible explosion. Use only approved fuel lines and fuel filters. Servicing the Electronic Fuel-Injection System g008963 Figure 61 This machine contains an electronic fuel-injection 1. -

Page 49: Electrical System Maintenance

Electrical System Remove the battery as shown in (Figure 62). Maintenance Servicing the Battery Service Interval: Monthly g029644 DANGER Battery electrolyte contains sulfuric acid, which is a deadly poison and causes severe burns. Do not drink electrolyte and avoid contact with skin, eyes, or clothing. -

Page 50: Servicing The Fuses

Charging the Battery Servicing the Fuses The electrical system is protected by fuses. It requires WARNING no maintenance, however, if a fuse blows check the Charging the battery produces gasses that component and circuit for a malfunction or short. can explode. The fuses are located on right console next to the seat (Figure... -

Page 51: Jump-Starting The Machine

Jump-Starting the Machine vent caps on both batteries. Be sure that the vehicles do not touch and that both electrical Check and clean corrosion from the battery systems are off and at the same rated system terminals before jump-starting. Ensure that the voltage. -

Page 52: Drive System Maintenance

Drive System Make the final connection on the engine block of the stalled vehicle (not to the negative battery Maintenance post) away from the battery and stand back (Figure 67). Checking the Seat Belt Service Interval: Before each use or daily Inspect the seat belt for wear, cuts, and proper operation of the retractor and buckle. -

Page 53: Adjusting The Tracking

Adjusting the Tracking Disengage the blade-control switch (PTO). Drive to an open, flat area and move the motion-control levers to the N EUTRAL LOCK position. Move the throttle midway between the F positions. Move both motion-control levers forward until they both hit the stops in the T-slot. Check which way the machine tracks. -

Page 54: Checking The Tire Pressure

Checking the Tire Pressure Checking the Wheel Hub Slotted Nut Service Interval: Every 50 hours/Monthly (whichever comes first) Service Interval: After the first 100 hours Maintain the air pressure in the rear tires at 90 kPa Every 500 hours (13 psi). Uneven tire pressure can cause uneven cut. Check the tires when they are cold, to get the most Check and ensure that the torque of the slotted nut is accurate pressure reading. -

Page 55: Adjusting The Caster-Pivot Bearing

Adjusting the Caster-Pivot Using the Clutch Shim Bearing Some later model year units have been built with clutches that contain a brake shim. When the clutch Service Interval: Every 500 hours/Yearly (whichever brake has worn to the point where the clutch no longer comes first) engages consistently, you can remove the shim to extend the clutch life. - Page 56 Verify that 12 V is present at the clutch connector Using a 0.010 inch thick-feeler gauge, verify when the you engage the blade-control switch that a gap is present between the rotor and (PTO). armature face on both sides of the brake pole as shown in Figure 77 Figure...

-

Page 57: Cooling System Maintenance

Cooling System Perform the following safety check: Sit on the seat and start the engine. Maintenance Make sure that the blades do not engage when the blade-control switch (PTO) is in the O position Cleaning the Engine Screen and the clutch is disengaged. and Engine-Oil Cooler Note: If the clutch does not... -

Page 58: Cleaning The Engine Cooling Fins And Shrouds

Cleaning the Engine Cleaning the Hydraulic Cooling Fins and Shrouds Units Service Interval: Every 100 hours/Yearly (whichever Service Interval: Before each use or daily comes first) Disengage the blade-control switch (PTO) and Disengage the blade-control switch (PTO) and set the parking brake. set the parking brake. -

Page 59: Brake Maintenance

Brake Maintenance Adjusting the Parking Brake Service Interval: After the first 100 hours Every 500 hours thereafter Check that the brake is adjusted properly before adjusting. Drive the machine onto a level surface. Disengage the blade-control switch (PTO), move g026961 the motion-control levers to the N EUTRAL LOCK... -

Page 60: Belt Maintenance

Belt Maintenance Inspecting the Belts Service Interval: Every 50 hours Replace the belt if it is worn. The signs of a worn belt include squealing while the belt is rotating; the blades slipping while cutting grass; and frayed edges, burn marks, and cracks on the belt. -

Page 61: Replacing The Hydraulic-Pump Drive Belt

g027730 Figure 85 g009039 Figure 86 1. Idler pulley 5. Left hydraulic-pump pulley Replacing the 2. Clutch pulley 6. Square hole in idler arm 3. Pump-drive belt 7. Idler spring Hydraulic-Pump Drive 4. Right hydraulic-pump pulley Belt Disengage the blade-control switch (PTO) and Use a ratchet in the square hole in the idler arm set the parking brake. -

Page 62: Controls System Maintenance

Controls System Maintenance Adjusting the Control-Handle Position There are 2 height positions for the control levers—high and low. Remove the bolts to adjust the height. Disengage the blade-control switch (PTO), move the motion-control levers to the N EUTRAL LOCK position, and set the parking brake. Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position. - Page 63 Temporarily install a jumper wire across the Start the engine. terminals in the connector of the main wire Note: Engage the parking brake and move harness. the motion-control levers out before starting the engine. You do not need to be in the seat because of the jumper wire being used.

-

Page 64: Adjusting The Motion-Control Damper

Adjusting the Check that the machine does not creep in neutral when you disengage the parking brakes. Motion-Control Neutral-Lock Pivot Adjusting the Motion-Control Damper You can adjust the flanged nut to obtain the desired motion-control lever resistance when you move them You can adjust the top damper mounting bolt to obtain to the N position. -

Page 65: Hydraulic System Maintenance

Hydraulic System Maintenance Servicing the Hydraulic System Hydraulic Oil Type:Toro ® HYPR-OIL ™ 500 hydraulic oil or Mobil ® 1 15W-50. Important: Use the oil specified. Other fluids could damage the hydraulic system. Each Hydraulic System Oil Capacity: 1.5 L (52 oz) - Page 66 Mobil ® 1 oil (more often in dirty or dusty conditions). Every 500 hours—Change the hydraulic filters and hydraulic oil when using Toro ® HYPR-OIL ™ 500 hydraulic oil (more often in dirty or dusty conditions).

-

Page 67: Mower Deck Maintenance

Mower Deck Maintenance Leveling the Mower Deck Setting Up the Machine Note: Ensure that the mower deck is level before matching the height of cut (HOC). Position the mower on a flat surface. Disengage the blade-control switch (PTO), move g029840 Figure 95 the motion-control levers to the N EUTRAL... - Page 68 Note: Fine-tune the adjuster screw by turning it to get Loosen or tighten the single-point 7.6 mm (3 inch) height (Figure 97). adjustment bolt enough to move the height-of-cut plate mounting bolts at least 1/3 Note: To increase the height, turn the adjuster the length of the available travel in their slots.

-

Page 69: Servicing The Cutting Blades

Servicing the Cutting Checking for Bent Blades Disengage the blade-control switch (PTO), move Blades the motion-control levers to the N EUTRAL LOCK position, and set the parking brake. To ensure a superior quality of cut, keep the blades sharp. For convenient sharpening and replacement, Shut off the engine, remove the key, and wait keep extra blades on hand. - Page 70 To ensure optimum performance and continued safety conformance of Note: Maintain the original angle. the machine, use genuine Toro replacement blades. Replacement blades made by other manufacturers Note: The blade retains balance if you remove may result in nonconformance with safety standards.

-

Page 71: Removing The Mower Deck

Installing the Blades Removing the Mower Deck Install the blade onto the spindle shaft (Figure Before servicing or removing the mower deck, lock 105). out the spring-loaded deck arms. Important: The curved part of the blade WARNING must point upward toward the inside of the mower to ensure proper cutting. - Page 72 g029652 Figure 107 1. Right stabilizer 2. Deck strut (right side shown) 3. Remove the shoulder bolt and nut. 4. Remove the shoulder bolt and nut. g009038 Raise the deck struts and secure them in the Figure 106 up position. 1.

-

Page 73: Replacing The Grass Deflector

Replacing the Grass Cleaning Deflector Cleaning under the Mower WARNING Service Interval: Before each use or daily An uncovered discharge opening could allow Disengage the blade-control switch (PTO), move the lawn mower to throw objects at you or the motion-control levers to the N EUTRAL LOCK bystanders, resulting in serious injury. -

Page 74: Storage

Storage Run the engine to distribute conditioned fuel through the fuel system (5 minutes). Shut off the engine, allow it to cool, and Cleaning and Storage drain the fuel tank; refer to Servicing the Fuel Tank (page 48). Disengage the blade-control switch (PTO), set the parking brake, turn the ignition key to the Restart the engine and run it until it stops. -

Page 75: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The malfunction indicator light (MIL) 1. The engine is too hot. 1. Turn the engine off and let it cool. comes on. 2. There is old gas in the gas tank. 2. Use new gas. 3. - Page 76 Problem Possible Cause Corrective Action The engine loses power. 1. The engine load is excessive. 1. Reduce the ground speed. 2. The air cleaner is dirty. 2. Clean the air-cleaner element. 3. The oil level in the crankcase is low. 3.

- Page 77 Problem Possible Cause Corrective Action The clutch does not engage. 1. The fuse is blown. 1. Replace the fuse. Check the coil resistance, battery charge, charging system, and wiring connections, and replace components if necessary. 2. There is low voltage supply at the 2.

-

Page 78: Schematics

Schematics g013119 Wire Diagram (Rev. A) - Page 79 Notes:...

- Page 80 Customers who have purchased Toro products outside the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor's service or have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.