Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Electrolux EWM0931 Series

- Page 1 SERVICE MANUAL WASHING Washing machines © ELECTROLUX ITALY S.p.A. Publication Spares Operations Europe guide to diagnostics for number Corso Lino Zanussi, 30 electronic controls 599 72 97 24 I - 33080 PORCIA /PN (ITALY) Fax +39 0434 394096 EWM0931x Edition: 04-2010...

- Page 2 Guide to diagnostics for electronic controls EWM0931x 2/67 2010 SOI/DT-mdm FCPD-dp Quality tb 599 72 97-24...

-

Page 3: Table Of Contents

Guide to diagnostics for electronic controls EWM0931x Contents INTRODUCTION..........................5 Purpose of this manual ........................5 Warnings............................5 How to proceed ..........................5 WM APPLIANCE CONTROL PANELS ....................6 DIAGNOSTIC SYSTEM........................7 Accessing diagnostic ........................7 Quitting the diagnostics system ..................... 7 Diagnostic test phases........................ - Page 4 Guide to diagnostics for electronic controls EWM0931x EC4: AGS current sensor faulty error ....................60 EF1: Drain hose blocked/kinked/too high; drain filter clogged/dirty........... 60 EF2: Excessive detergent dosing; drain hose kinked/blocked; drain filter dirty/clogged ....60 EF3: Aqua Control device triggered....................60 EF5: Unbalanced load, spin phases skipped.

-

Page 5: Introduction

Guide to diagnostics for electronic controls EWM0931x 1 INTRODUCTION 1.1 Purpose of this manual The purpose of this manual is to explain, simply and schematically, the steps any Technician should take when faced with the problems indicated by the various alarm codes on appliances with electronic controls in the EWM0931x series, PROMETEO version. -

Page 6: Wm Appliance Control Panels

Guide to diagnostics for electronic controls EWM0931x 2 WM APPLIANCE CONTROL PANELS These are the stylings available at the time of printing of this Service Manual. Others may be developed in future. K6.2 6/67 2010 SOI/DT-mdm FCPD-dp Quality tb 599 72 97-24... -

Page 7: Diagnostic System

Guide to diagnostics for electronic controls EWM0931x 3 DIAGNOSTIC SYSTEM 3.1 Accessing diagnostic All versions A5-A6 Z5-Z6 K6.2 1. Set the selector knob to position 0 (zero). 2. Press the START/PAUSE button and the nearest option button simultaneously (as shown in the figure). -

Page 8: Diagnostic Test Phases

Guide to diagnostics for electronic controls EWM0931x 3.3 Diagnostic test phases Irrespective of the type of electrical board and of the selector configuration, once the diagnostics system has been activated, turn the selector knob clockwise to run a check of the various components (as described in table 1) and read the alarms. -

Page 9: Selector Efficiency Check

Guide to diagnostics for electronic controls EWM0931x Selector efficiency check Diagnostic testing also provides the opportunity to check the efficiency of the selectors. 3.4.1 Programme selector In the control panel illustrated below, the LEDs (lit) are combined with values. When the knob is turned, some LEDs light up, and by summing up the values with which they are combined, you obtain the position of the knob (if the selector is efficient). -

Page 10: Temperature Selector

Guide to diagnostics for electronic controls EWM0931x 3.4.2 Temperature selector The same description as the programme selector applies to the temperature selector. TABLE 3 10/67 2010 SOI/DT-mdm FCPD-dp Quality tb 599 72 97-24... -

Page 11: Alarms

Guide to diagnostics for electronic controls EWM0931x 4 ALARMS Displaying the alarms to the user 4.1.1 Styling A3-Z3 The alarms are displayed by the flashing red LED of the START/PAUSE button and simultaneously through the Display. The alarms displayed to the user are listed below: E10 - Water fill difficulty (tap closed) E20 - Drain difficulty (filter dirty) E40 - Door open... -

Page 12: Reading The Alarms

Guide to diagnostics for electronic controls EWM0931x Reading the alarms The last three alarms stored in the FLASH memory of the PCB can be displayed: • Enter the diagnostic mode. • Irrespective of the type of PCB and configuration, turn the programme selector knob clockwise to the tenth position. -

Page 13: Displaying The Alarm

Guide to diagnostics for electronic controls EWM0931x 4.2.1 Displaying the alarm The alarm is displayed by a repeated flashing sequence of the START/PAUSE button with red and green light (0.5 seconds on, 0.5 seconds off with a 2.5 second pause between the sequences). •... -

Page 14: Rapid Reading Of Alarms

Guide to diagnostics for electronic controls EWM0931x 4.2.4 Rapid reading of alarms The last alarm can be displayed even if the programme selector is not in the tenth position (diagnostics) or if the appliance is in normal operating mode (e.g. during the execution of the washing programme): →... -

Page 15: Alarm Summary Table

Guide to diagnostics for electronic controls EWM0931x 4.3 ALARM SUMMARY TABLE Alarm Description Possible fault Machine status/action Reset Page No alarm ---------------- ------------ Tap closed or water pressure too low; Drain hose improperly positioned; Water fill solenoid valve faulty; Leaks from water circuit on Water fill difficulty during washing Cycle is paused with door locked START/RESET... - Page 16 Guide to diagnostics for electronic controls EWM0931x Alarm Description Possible fault Machine status/action Reset Page (Safety drain cycle) Faulty sensing by door delay system Main circuit board faulty. RESET Cycle blocked Faulty sensing by triac on door (Safety drain cycle) delay system (wrong input voltage to Main circuit board faulty.

- Page 17 Guide to diagnostics for electronic controls EWM0931x Alarm Description Possible fault Machine status/action Reset Page Communication incongruence Incorrect control/display PCB; between main PCB and display Cycle blocked ON/OFF Incorrect PCB (do not correspond to the model). (incompatible versions) Appliance configuration error Main PCB faulty (Incorrect configuration data);...

-

Page 18: Notes On The Behaviour Of Certain Alarms

Guide to diagnostics for electronic controls EWM0931x 4.4 Notes on the behaviour of certain alarms Configuration alarm E93: when this alarm is detected (on switching on the appliance), the appliance stops, the LEDs in the START/PAUSE button start to flash, displaying the complete code (family plus alarm), the display shows the alarm code provided the relevant configuration part is intact. It will not be possible to access diagnostics mode and the only available option is to turn the appliance off. -

Page 19: Cannot Access The Diagnostics Programme

Guide to diagnostics for electronic controls EWM0931x 5 CANNOT ACCESS THE DIAGNOSTICS PROGRAMME 5.1 None of the LEDs on the circuit board light up Are the power supply cable and the connection Replace/repair the power supply cable, check on the main PCB (connector J4) No →... -

Page 20: Troubleshooting Based On Alarm Codes

Guide to diagnostics for electronic controls EWM0931x 6 TROUBLESHOOTING BASED ON ALARM CODES E11: Water fill difficulty during washing Maximum water fill time for every level of the pressure switch (the time is reset every time the level is achieved) Checks to perform: Check that all the connectors are inserted correctly Run the diagnostic cycle and fill all the trays with water (phases 2,3,4) - Page 21 Guide to diagnostics for electronic controls EWM0931x Fig.1 Fig. 4 MAIN PCB Fig. 2 3.5-4.5KΩ 3.5-4.5KΩ 1) Solenoid valve for Pre-wash 2) Solenoid valve for Wash Fig.3 3.5-4.5KΩ If there are burns on the circuit board, see page 65 21/67 2010 SOI/DT-mdm FCPD-dp Quality-tb 599 72 97-24...

-

Page 22: E13: Water Leaks

Guide to diagnostics for electronic controls EWM0931x E13: Water leaks Maximum overall water fill time exceeded (sum of all water fills between one drain phase and the next to avoid exceeding the maximum volume) Checks to perform: Check that all the connectors are inserted correctly Run the diagnostic cycle and fill all the trays with water (phases 2,3,4) Are all the trays filling with water? Is the drain hose positioned... - Page 23 Guide to diagnostics for electronic controls EWM0931x Fig. 1 Fig. 4 MAIN PCB Fig. 2 3.5-4.5KΩ 3.5-4.5KΩ 1) Solenoid valve for Pre-wash 2) Solenoid valve for Wash Fig.3 3.5-4.5KΩ If there are burns on the circuit board, see page 65 23/67 2010 SOI/DT-mdm FCPD-dp Quality-tb 599 72 97-24...

-

Page 24: E21: Drain Difficulty

Guide to diagnostics for electronic controls EWM0931x E21: Drain difficulty Maximum drain time exceeded (measured for every cycle phase) Checks to perform: Check that all the connectors are inserted correctly Clean the filter and repeat the diagnostic cycle Is the drain filter clean? to check for any further alarms. - Page 25 Guide to diagnostics for electronic controls EWM0931x Fig. 1 Fig. 5 Fig. 4 MAIN PCB 155-200Ω Drain pump 155-200Ω If there are burns on the circuit board, see page 65 25/67 2010 SOI/DT-mdm FCPD-dp Quality-tb 599 72 97-24...

-

Page 26: E23: Problems With The Component (Triac) Controlling The Drain Pump

Guide to diagnostics for electronic controls EWM0931x E23: Problems with the component (triac) controlling the drain pump Checks to perform: Check that all the connectors are inserted correctly Is the resistance Replace the pump and repeat Is the resistance measurement of the pump the diagnostic cycle to check measurement of the pump approximately 155-200 Ω? - Page 27 Guide to diagnostics for electronic controls EWM0931x Fig. 4 Fig. 5 MAIN PCB 155-200Ω ∞ Ω Drain pump Fig. 6 155-200Ω If there are burns on the circuit board, see page 65 27/67 2010 SOI/DT-mdm FCPD-dp Quality-tb 599 72 97-24...

-

Page 28: E24: Sensing Circuit Of The Component (Triac) Controlling The Drain Pump Faulty

Guide to diagnostics for electronic controls EWM0931x E24: Sensing circuit of the component (triac) controlling the drain pump faulty Checks to perform: Check that all the connectors are inserted correctly Replace the circuit board and repeat the diagnostic cycle to check for any further alarms. If there are burns on the circuit board, see page 65 E31: The analogue pressure switch provides the main PCB... -

Page 29: E32: The Analogue Pressure Switch Causes An Error During Calibration

Guide to diagnostics for electronic controls EWM0931x E32: The analogue pressure switch causes an error during calibration (At the start of every cycle, the appliance drains to empty the tub and creates a level 0 to check the calibration of the analogue pressure switch) Checks to perform: Check that all the connectors are inserted correctly Drain the water from the tub. -

Page 30: E35: Water Level Too High

Guide to diagnostics for electronic controls EWM0931x E35: Water level too high The main circuit board measures a water level, using the electronic pressure switch, of more than 300 mm for longer than 15 secs. Checks to perform: Check that all the connectors are inserted correctly Drain the water from the tub. -

Page 31: E38: Internal Pressure Chamber Is Clogged

Guide to diagnostics for electronic controls EWM0931x E38: Internal pressure chamber is clogged The analogue pressure switch is not able to measure any variation in the water level for at least 30 secs during drum rotation. Checks to perform: Check that all the connectors are inserted correctly Clean the internal Drain the water from Run the diagnostic... -

Page 32: E41: Door Open (Device With 3 Connections With Flange)

Guide to diagnostics for electronic controls EWM0931x E41: Door open (device with 3 connections with flange) Maximum time exceeded (PTC = 15 seconds) Checks to perform: Check that all the connectors are inserted correctly Is the door closed Close the door correctly and correctly? repeat the diagnostic cycle to Fig. - Page 33 Guide to diagnostics for electronic controls EWM0931x (device with 3 connections with flange) Fig. 4 Fig. 9 Built-in flange Fig. 9A MAIN PCB ∞ Traditional Ω door lock with flange n Ω ∞ Ω If there are burns on the circuit board, see page 65 33/67 2010 SOI/DT-mdm FCPD-dp Quality-tb...

-

Page 34: E41: Door Open (Device With 3 Connections And No Flange)

Guide to diagnostics for electronic controls EWM0931x E41: Door open (device with 3 connections and no flange) Maximum time exceeded (PTC = 15 seconds) Checks to perform: Check that all the connectors are inserted correctly Fig. 28 Traditional door lock with 3 connections and no flange. - Page 35 Guide to diagnostics for electronic controls EWM0931x (device with 3 connections and no flange) Without built-in flange Fig. 4 Fig. 28A Fig. 28 MAIN PCB ∞ Ω Ω Traditional door lock without flange n Ω ∞ Ω If there are burns on the circuit board, see page 65 35/67 2010 SOI/DT-mdm FCPD-dp Quality-tb...

-

Page 36: E42: Problems Opening Door (Device With 3 Connections With Flange)

Guide to diagnostics for electronic controls EWM0931x E42: Problems opening door (device with 3 connections with flange) Maximum time exceeded (255 seconds) Checks to perform: Check that all the connectors are inserted correctly Fig. 9 Close the door correctly and Is the door closed repeat the diagnostic cycle to correctly? - Page 37 Guide to diagnostics for electronic controls EWM0931x (device with 3 connections with flange) Fig. 4 Fig. 9 Built-in flange Fig. 9A MAIN PCB ∞ Ω Traditional Ω doorlock with flange n Ω ∞ Ω If there are burns on the circuit board, see page 65 37/67 2010 SOI/DT-mdm FCPD-dp Quality-tb...

-

Page 38: E42: Problems Opening Door (Device With 3 Connections And No Flange)

Guide to diagnostics for electronic controls EWM0931x E42: Problems opening door (device with 3 connections and no flange) Maximum time exceeded (255 seconds) Checks to perform: Check that all the connectors are inserted correctly Fig. 28 Traditional door lock with 3 connections and no flange. - Page 39 Guide to diagnostics for electronic controls EWM0931x (device with 3 connections and no flange) Without built-in flange Fig. 4 Fig. 28A Fig. 28 MAIN PCB ∞ Ω Ω n Ω ∞ Ω If there are burns on the circuit board, see page 65 39/67 2010 SOI/DT-mdm FCPD-dp Quality-tb...

- Page 40 Guide to diagnostics for electronic controls EWM0931x E43: Problems with the component (triac) controlling the door delay system (device with 3 connections and flange) Checks to perform: Check that all the connectors are inserted correctly Detach the connectors and To check the wiring, with the measure on the component door open, measure on the (fig.

- Page 41 Guide to diagnostics for electronic controls EWM0931x E43: Problems with the component (triac) controlling the door delay system (device with 3 connections and no flange) Checks to perform: Check that all the connectors are inserted correctly Disconnect the door lock To check the wiring, with the connectors and measure on door open, measure between...

-

Page 42: E44: Door Closed "Sensing" Circuit Faulty

Guide to diagnostics for electronic controls EWM0931x E44: Door closed "sensing" circuit faulty Checks to perform: Check that all the connectors are inserted correctly Replace the circuit board and repeat the diagnostic cycle to check for any further alarms. E45: Problems with the "sensing" circuit of the component (triac) controlling the door delay system Checks to perform: Check that all the connectors are inserted correctly... -

Page 43: E51: Motor Power Triac Short-Circuited

Guide to diagnostics for electronic controls EWM0931x E51: Motor power triac short-circuited Activation of the protection system for the triac short-circuit (after 5 attempts separated by a 5-minute pause, during the cycle, immediately if recognised at the start of the cycle or during diagnostics) Checks to perform: Check that all the connectors are inserted correctly... -

Page 44: E52: No Signal From Motor Tachometric Generator (First Part)

Guide to diagnostics for electronic controls EWM0931x E52: No signal from motor tachometric generator (first part) Cycle interrupted after 5 attempts during the cycle, immediately if recognised at the start of the cycle or during diagnostics. Checks to perform: Check that all the connectors are inserted correctly Access phase 7 of the diagnostic cycle (The drum rotates at... - Page 45 Guide to diagnostics for electronic controls EWM0931x Fig. 10 Fig. 4 General earthing connection MAIN PCB Ω ∞ Ω Fig. 6 ∞ Ω Ω Fig. 12 Fig. 11 If there are burns on the circuit board, see page 65 45/67 2010 SOI/DT-mdm FCPD-dp Quality-tb 599 72 97-24...

-

Page 46: E52: No Signal From Motor Tachometric Generator (Second Part)

Guide to diagnostics for electronic controls EWM0931x E52: No signal from motor tachometric generator (second part) after 5 attempts during the cycle, immediately if recognised at the start of Cycle interrupted the cycle or during diagnostics. Checks to perform: Check that all the connectors are inserted correctly The motor never runs Replace the motor and To check the wiring, measure... - Page 47 Guide to diagnostics for electronic controls EWM0931x How to check collector motors P = motor protector 1) Check the connection blocks (wiring) and R = rotor S = stator for the presence of any protruding/kinked T = tachometric generator terminals. 2) Check for the presence of any marks / residue / water or detergent deposits on the motor and where these come from.

-

Page 48: E53: Problems With The "Sensing" Circuit Of The Component (Triac) Powering The Motor

Guide to diagnostics for electronic controls EWM0931x E53: Problems with the "sensing" circuit of the component (triac) powering the motor Checks to perform: Check that all the connectors are inserted correctly Replace the circuit board and repeat the diagnostic cycle to check for any further alarms If there are burns on the circuit board, see page 65 48/67... -

Page 49: E54: Motor Relay Contacts Sticking

Guide to diagnostics for electronic controls EWM0931x E54: Motor relay contacts sticking Voltage value on the motor circuit even when this should not be operating Checks to perform: Check that all the connectors are inserted correctly Measure between all the terminals of the Replace the circuit board and repeat the wiring connector J11-1 - J11-5 and the appliance body - see page 47 - point 3... -

Page 50: E62: Overheating During Washing

Guide to diagnostics for electronic controls EWM0931x E62: Overheating during washing The temperature of the NTC probe exceeds 88°C for more than 5 mins. Checks to perform: Check that all the connectors are inserted correctly Run the diagnostic cycle Detach the connector and and fill with water up to the measure between the Replace the heating... -

Page 51: E66: Heating Element Power Supply Relay Faulty

Guide to diagnostics for electronic controls EWM0931x E66: Heating element power supply relay faulty Checks to perform: Check that all the connectors are inserted correctly Measure between the connector J6-1/J6-2 of Replace the circuit board and repeat the the main PCB and the appliance body. (Fig. 6) diagnostic cycle to check for any further Is there any dispersion? alarms. -

Page 52: E68: Washing Heating Element Leakage

Guide to diagnostics for electronic controls EWM0931x E68: Washing heating element leakage Checks to perform: Check that all the connectors are inserted correctly Run phase 8 of the Run the diagnostic cycle Detach the connector diagnostic cycle, drain water and fill with water up to the and measure between from the tub. -

Page 53: E69: Washing Heating Element Damaged

Guide to diagnostics for electronic controls EWM0931x E69: Washing heating element damaged Checks to perform: Check that all the connectors are inserted correctly Measure the resistance Measure the resistance value directly on the value of the heating Replace the heating terminals of the heating element (Ω) between element and repeat the... -

Page 54: E6A: Heating Relay Sensing Faulty

Guide to diagnostics for electronic controls EWM0931x E6A: Heating relay sensing faulty Checks to perform: Check that all the connectors are inserted correctly Replace the circuit board and repeat the diagnostic cycle to check for any further alarms If there are burns on the circuit board, see page 65 E6H: Heating element power relay faulty (incongruence between sensing and relay status) -

Page 55: E71: Washing Ntc Probe Faulty

Guide to diagnostics for electronic controls EWM0931x E71: Washing NTC probe faulty Voltage value out of range (short-circuit or open circuit) Checks to perform: Check that all the connectors are inserted correctly Detach the connector Run phase 6 of the diagnostic cycle Run phase 8 of the and measure directly and wait for the water to fill. -

Page 56: E74: Ntc Probe Improperly Positioned

Guide to diagnostics for electronic controls EWM0931x E74: NTC probe improperly positioned Checks to perform: Check that all the connectors are inserted correctly Reposition the probe in its seat and Is the probe visibly positioned correctly in repeat the diagnostic cycle to check for its seat? any further alarms. -

Page 57: E83: Error Reading The Programme Selector Code

Guide to diagnostics for electronic controls EWM0931x E83: Error reading the programme selector code Selector position code not envisaged by the configuration data or configuration error Checks to perform: Check that all the connectors are inserted correctly Turn the appliance on, turn the programme selector to Repeat the diagnostic each setting: wait at least 10... -

Page 58: E91: Communication Error Between The Display Board And The Main Circuit Board

Guide to diagnostics for electronic controls EWM0931x E91: Communication error between the display board and the main circuit board Incongruence between configuration values on starting the appliance Checks to perform: Check that all the connectors are inserted correctly Check the wiring between the main circuit board and the display board: Replace / repair the wiring and repeat the ►... -

Page 59: E92: Protocol Incongruence

Guide to diagnostics for electronic controls EWM0931x E92: protocol incongruence Incongruence between configuration values on starting the appliance Checks to perform: Check that all the connectors are inserted correctly Possible incorrect configuration. Replace the circuit board and repeat the diagnostic cycle to check for any further alarms. E93: Appliance configuration error Incongruence between configuration values on starting the appliance Checks to perform:... -

Page 60: Ec4: Ags Current Sensor Faulty Error

Guide to diagnostics for electronic controls EWM0931x EC4: AGS current sensor faulty error Spin speed reduced to safety speed of 150 rpm Checks to perform: Check that all the connectors are inserted correctly Replace the main PCB and run the diagnostic cycle to check for any further alarms. If there are burns on the circuit board, see page 65 EF1: Drain hose blocked/kinked/too high;... -

Page 61: Eh1: Mains Frequency Incorrect

Guide to diagnostics for electronic controls EWM0931x EH1: Mains frequency incorrect Power supply frequency out of configured range Checks to perform: Check that all the connectors are inserted correctly Important! The appliance remains in alarm status until the mains frequency returns to the correct values or the appliance is switched off (programme selector set to “0”). -

Page 62: Operating Circuit Diagram Wm With Aqua Control

Guide to diagnostics for electronic controls EWM0931x 7 OPERATING CIRCUIT DIAGRAM WM WITH AQUA CONTROL 62/67 2010 SOI/DT-mdm FCPD-dp Quality-tb 599 72 97-24... -

Page 63: Key To Circuit Diagram Wm

Guide to diagnostics for electronic controls EWM0931x 7.1 Key to circuit diagram WM Appliance electrical components PCB components 1. Traditional door lock without built-in flange 2. Traditional door lock with built-in flange 3. Analogue pressure switch 4. NTC temperature probe DOOR_TY Door interlock Triac 5. -

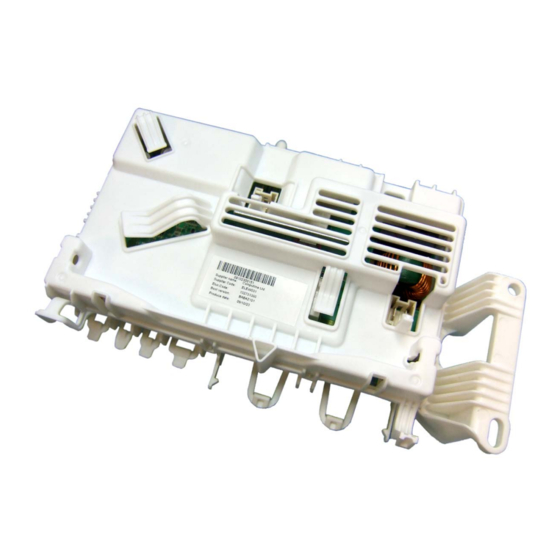

Page 64: Main Circuit Board Connectors

Guide to diagnostics for electronic controls EWM0931x 7.2 Main circuit board connectors Serial interface: J7-1 Analogue pressure switch (+5V) J9-1 ASY_IN J7-2 Analogue pressure switch (GND) J9-2 ASY_OUT J7-3 Analogue pressure switch (signal) J9-3 +5V J7-4 NTC temperature probe J9-4 GND J7-5 NTC temperature probe Communication with display board: J13-1 Wash solenoid valve (triac) -

Page 65: Burns On The Main Circuit Board Ewm0931X

Guide to diagnostics for electronic controls EWM0931x 7.3 Burns on the main circuit board EWM0931x In the event of burns on the main circuit board, check whether the problem was caused by another electrical component (short-circuits, poor insulation, water leaks). Use the figures that follow to pinpoint the component which may have caused the problem, depending on the area of the burns. - Page 66 Notes ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------ 66/67 2010 SOI/DT-mdm FCPD-dp Quality-tb 599 72 97-24...

- Page 67 67/67 2010 SOI/DT-mdm FCPD-dp Quality-tb 599 72 97-24...