Summary of Contents for Toro 29516

- Page 1 Form No. 3433-525 Rev A 24in Stand-On Aerator Model No. 29516—Serial No. 404320000 and Up *3433-525* A Register at www.Toro.com. Original Instructions (EN)

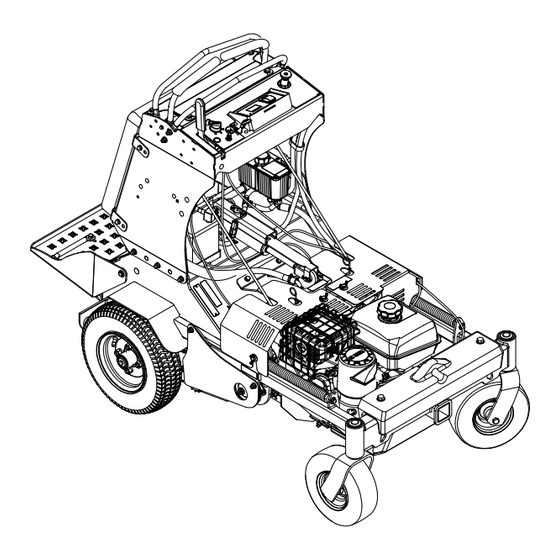

- Page 2 This product complies with all relevant European Dealer or Toro Customer Service and have the model directives; for details, see the separate product and serial numbers of your product ready. Figure 1 specific Declaration of Conformity (DOC) sheet. identifies the location of the model and serial numbers on the product.

-

Page 3: Table Of Contents

Contents Electrical System Maintenance ......35 Checking the Safety Interlock ......35 Jump Starting a Discharged Battery....35 Safety ............... 4 Servicing the Battery......... 37 Safety Alert Symbol ..........4 Drive System Maintenance ........38 General Safety ........... 5 Checking the Drive Tire Air Pressure....38 Safety and Instructional Decals ...... -

Page 4: Safety

Safety Alert and Error Messages ......... 53 Schematics ............. 56 Safety Alert Symbol This Safety Alert Symbol (Figure 3) is used both in this manual and on the machine to identify important safety messages which must be followed to avoid accidents. -

Page 5: General Safety

General Safety operation, operator controls, and safety signs and instructions to operate the machine. Never let This machine is capable of amputating hands and feet children or untrained people operate or service the equipment. Local regulations may restrict the age and of throwing objects. - Page 6 decal126-7875 126-7875 1. Fuse location 4. Auxiliary (15 A) 2. Relay location 5. Start relay 3. Main (20 A) 6. Not used decal121-6163 121-6163 1. Press to lower the tines. 2. Release to raise the tines. decal133-8062 133-8062 decal135-3685 135-3685 1.

- Page 7 decal135-1854 135-1854 1. Parking brake 4. Depth setting—lock 2. Tine engagement lockout 5. Read the Operator’s switch Manual before performing maintenance. 3. Tines—down 135-2013 STOP decal135-2013-1 135-2013 1. Operator weight adjustment 5. Throttle—slow 9. Parking brake—engage 2. Increase 6. Engine—on 10.

- Page 8 decal135-2014 135-2014 1. Fast 6. Wheels and tines rotate when moving 11. Thrown object hazard—pick up debris backward. before operating the machine. 2. Slow 7. Warning—read the Operator’s Manual. 12. Warning—shut off the engine, engage the parking break, and remove the key before leaving the machine.

-

Page 9: Setup

Setup Loose Parts Use the chart below to verify that all parts have been shipped. Procedure Description Qty. – No parts required Check the battery charge. – No parts required Checking the transmission fluid. – No parts required Check the auxiliary hydraulic fluid level. CE conversion kit, Part No. -

Page 10: Checking The Transmission Fluid

Checking the Transmission Fluid No Parts Required Procedure The transmission is shipped with transmission fluid. Check the transmission fluid level and, if necessary, add fluid to the specified level; refer to Transmission Fluid Specification (page 44) Checking the Transmission Fluid Level (page 44). -

Page 11: Product Overview

Controls Product Overview g232039 Figure 4 1. Platform 4. Motion-control levers 2. Parking brake handle 5. Fuel cap g249566 3. Engine controls Figure 5 1. Tine ground engagement 6. Hour meter/tine foot switch engagement display 2. Right motion-control lever 7. Throttle 3. -

Page 12: Hour Meter/Tine Engagement Display

Note: The lockout feature is engaged each time the Aerating Hours Electronic depth Parking brake engine is switched off. control setting indicator indicator for the tines Motion-Control Levers Alert and Error Engine Hours Maintenance Messages Reminders and The motion-control levers are located on each side of Alerts the top console and control the forward and reverse Battery voltage... - Page 13 Note: The brake handle engages a parking brake in each of the transmissions. • To engage the parking brake, pull the handle back toward you. • To release the parking brake, push the handle all the way forward away from you. When parking on a slope, chock or block the wheels in addition to engaging the parking brake.

-

Page 14: Specifications

Contact functioning properly. Do Not operate unless they your Authorized Service Dealer or authorized Toro are functioning properly. distributor or go to www.Toro.com for a list of all approved attachments and accessories. • Do Not operate the machine when people, especially children, or pets are in the area. -

Page 15: Adding Fuel

Fuel Safety Fuel Specification • Use extreme care in handling fuel. It is flammable Petroleum Use unleaded gasoline with an octane rating of 87 and its vapors are explosive. fuel or higher ((R+M)/2 rating method). • Extinguish all cigarettes, cigars, pipes, and other Use an unleaded-gasoline blend with up to 10% sources of ignition. -

Page 16: Performing Daily Maintenance

Performing Daily Move the bar backward to obtain the slowest speed. Maintenance On both sides, tighten the nuts and bolts. Before starting the machine each day, perform each Important: Make sure that the nuts and bolts are use/daily maintenance procedures that follow: tight, so the front reference/speed control bar does not move during operation. -

Page 17: During Operation

During Operation Uneven terrain could overturn the machine or cause the operator to lose their balance or footing. Determine the left and right sides of the machine from • Be sure all drives are in neutral and parking brake the normal operating position. is engaged before starting engine. - Page 18 • Stop engine, wait for all moving parts to stop: – Before refueling. • Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the machine and the working activity. Never assume that children will remain where you last saw them.

-

Page 19: Using The Smart Controller/Electronic Depth Control

Using the Smart Information Screens Controller/Electronic Depth The main information screens include: • The Startup Screens Control • The Default Screen (engine-on) • The Tine Engagement Display Hour Meter/Tine Engagement • Maintenance Reminders and Alerts Display • Alerts and Error Messages The smart controller/electronic depth control monitors the overall electrical system and displays information Start-up Screens... - Page 20 • The fourth screen displays the number of hours until The hour meter displays engine hours when the the engine oil maintenance is required. hour glass symbol is flashing. • The display turns off after 5 minutes after the ignition key is switched to the position.

-

Page 21: Opening And Closing The Fuel Shutoff Valve

Maintenance Reminder Screens Service Transmission Reminder The transmission oil maintenance reminder (Figure The hour meter displays the number of engine 23) counts down from the initial break-in service hours until either the engine oil or transmission oil interval of 100 engine hours and then counts down maintenance is due. -

Page 22: Lowering The Tines

On a cold engine, push the choke lever forward remove a longer plug. Tap the top of the switch into the O position. On a warm engine, leave to raise the tine depth to remove a shorter plug. the choke in the O position. -

Page 23: Driving The Machine

transporting the machine, or when the machine is parked inside a building. Driving the Machine CAUTION Machine can spin very rapidly by positioning one lever too much ahead of the other. You may lose control of the machine, which may cause damage to the machine or injury. -

Page 24: Drive-Wheel Release Valves

Releasing Valves to Push the Machine If you must push the machine by hand, you must release the drive-wheel release valves. Engage the parking brake, shut off the engine, remove the key, and allow all the moving parts to stop. Move the lever to the larger opening of the slot (Figure 28). -

Page 25: After Operation

Hauling the Machine Pull the lever upward until the washer is outside of the frame (Figure 28). Use a heavy-duty trailer or truck to transport the Move the release-valve lever back to the narrow machine. Ensure that the trailer or truck has all the portion of the slot, and release the lever (Figure necessary lighting and marking as required by law. - Page 26 WARNING Loading a machine on a trailer or truck increases the possibility of backward tip-over. Backward tip-over could cause serious injury or death. • Use extreme caution when operating a machine on a ramp. • Use only a single, full-width ramp; Do not use individual ramps for each side of the machine.

-

Page 27: Maintenance

Maintenance Download a free copy of the electrical or hydraulic schematic by visiting www.Toro.com and searching for your machine from the Manuals link on the home page. WARNING Maintenance Safety Removal or modification of original Information equipment, parts and/or accessories... - Page 28 WARNING Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid accidentally injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result. – If equipped, make sure all hydraulic fluid hoses and lines are in good condition and all hydraulic connections and fittings are tight before applying...

-

Page 29: Recommended Maintenance Schedule(S)

Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Change the engine oil. • Check the transmission output shaft nut torque specification. After the first 5 hours • Check transmission mount bolt torque. • Change the auxiliary hydraulic reservoir filter and fluid. After the first 100 hours •... -

Page 30: Pre-Maintenance Procedures

Pre-Maintenance Lubrication Procedures Lubricating the Chains CAUTION Service Interval: Before each use or daily Raising the machine for service or Important: Do not lubricate the chains with maintenance relying solely on mechanical penetrating oil or solvents. Use an oil or chain or hydraulic jacks could be dangerous. -

Page 31: Lubricating The Grease Fittings

Lubricating the Grease Engine Maintenance Fittings Servicing the Air Cleaner Note: See the chart below for service intervals. Service Interval: Every 50 hours—Clean the foam Shut off the engine, wait for all moving parts to pre-cleaner (more frequently in stop, and remove the key. Engage the parking dusty conditions). -

Page 32: Servicing The Engine Oil

Checking the Engine-Oil Level Wipe dirt away from the base and the cover with a moist rag. Service Interval: Before each use or daily Note: Be careful to prevent dirt and debris from Important: Do not operate the engine with the oil entering the air duct leading to the carburetor. - Page 33 Changing the Engine Oil Service Interval: After the first 5 hours Every 100 hours (more often under severe conditions.) Note: Dispose of the used oil at a recycling center. Park the machine so that the drain side is slightly lower than the opposite side to assure the oil drains completely.

-

Page 34: Servicing The Spark Plug

Note: You can exit the Service Engine screen at any time by turning the key to either the OFF or the START positions. Servicing the Spark Plug Service Interval: Every 160 hours g206628 Type for all Engines: NGK BR6HS, Champion Figure 40 RTL86C, or equivalent Air Gap: 0.76 mm (0.030 inch) -

Page 35: Checking The Spark Arrester

If the machine does not pass either of the tests Fire may result in personal injury or property that follow, Do not operate the machine. Contact your authorized Toro distributor. damage. Do not refuel or run engine unless a spark Checking the Engine Starting arrester is installed. - Page 36 Choose jumper cables with color coded or DANGER polarity labeled cables or clamps. Jump starting a weak battery that is cracked, frozen, has low electrolyte level, or an Connecting the Jumper Cables open/shorted battery cell, can cause an explosion resulting in serious personal injury. CAUTION Do not jump start a weak battery if these Connecting the jumper cables incorrectly...

-

Page 37: Servicing The Battery

Starting the Engine and Removing Allowing batteries to stand for an extended period of time without recharging them results in reduced the Jumper Cables performance and service life. To preserve optimum Start the engine. battery performance and life, charge batteries in storage when the open circuit voltage drops to 12.4 V. -

Page 38: Drive System Maintenance

Drive System Remove the screw, washer, and ground cable from the engine. Connect the negative battery Maintenance cable. Note: If time does not permit charging the battery or if charging equipment is not available, Checking the Drive Tire Air connect the negative battery cables and run the vehicle continuously for 20 to 30 minutes to Pressure charge the battery. -

Page 39: Checking The Torque Of The Wheel Lug Nuts

Checking the Torque of the Important: Do not overtighten the chain. Significant chain wear can occur and will Wheel Lug Nuts shorten the life of an overtightened chain. Service Interval: Yearly Torque the wheel lug nuts (Figure 43) to 115 to 142 N∙m (85 to 105 ft-lb). -

Page 40: Adjusting The Motion Control Tracking

Allow the control levers to return to neutral Rotate the adjustment rod on the left side of the and loosen the 2 jam nuts on the hex machine (Figure 47). adjustment linkage (Figure 46). Note: One jam nut is a right-hand thread and the other is left-hand. -

Page 41: Brake Maintenance

Brake Maintenance Belt Maintenance Adjusting the Parking Checking the Condition Brake and Tension of the Belts If the parking brake does not hold securely, an Service Interval: Every 50 hours adjustment is required. Shut off the engine, engage the parking brake, Refer to Preparing for Maintenance (page 30). -

Page 42: Checking The Transmission Drive Belt Tension

Hydraulic System Maintenance Auxiliary Hydraulic Fluid Specification Hydraulic fluid type: AW-32 hydro fluid Checking the Auxiliary Hydraulic Fluid Level g266181 Figure 51 Note: The machine is shipped with hydraulic fluid 1. Auxiliary pump drive belt 3. Flange locknuts in the reservoir. 2. -

Page 43: Changing The Auxiliary Hydraulic Reservoir Fluid And Filter

Changing the Auxiliary Hydraulic Reservoir Fluid and Filter Draining the Auxiliary Hydraulic Fluid Run the machine for approximately 15 minutes to purge any extra air out of the hydraulic g266183 system. Completely raise and lower the tines 3 times to purge the air. -

Page 44: Transmission Fluid Specification

Transmission Fluid Specification Transmission fluid type: Toro® Hypr-Oil™ 500 or Mobil® 1 15W-50 synthetic motor oil. Important: Use the specified fluid. Other fluids could cause system damage. Checking the Transmission Fluid Level Service Interval: Every 50 hours Shut off the engine, engage the parking brake, remove the key, and wait for all moving parts to stop before leaving the operating position. -

Page 45: Changing The Hydraulic Transmission Filters And Fluid

Changing the Hydraulic Installing the Transmission Filters Apply a thin coat of the specified hydraulic fluid Transmission Filters and to the rubber seal of the new filters; refer to Fluid Transmission Fluid Specification (page 44). Turn the filter clockwise until rubber seal Service Interval: After the first 100 hours contacts the filter adapter, then tighten the filter an additional 2/3 to 3/4 turn... - Page 46 Press down the multi-function switch. WARNING The transmission-oil maintenance reminder The engine must be running and the drive resets to 250 (hours), exits the service wheels must be turning so motion control transmission screen, and returns to the default adjustment can be performed. Contact screen.

-

Page 47: Operator Weight Adjustment

Operator Weight Adjustment Weight Adjustment Overview The operator weight adjustment valve is located at the left side of the control console (Figure 58). g249601 Figure 59 1. Weight control valve 3. Knob 2. Jam nut Ensure that the jam nut on the shaft of the weight control valve is tightened (Figure 59);... -

Page 48: Removing The Weight Control Knob

Tine Maintenance Release the tine ground engagement foot switch to raise the tines. While holding the position of the knob for the Checking the Tines weight control valve, tighten the jam nut. Service Interval: Before each use or daily Note: If you are having difficulty maintain the valve adjustment while tightening the jam nut, Shut off the engine, engage the parking brake,... -

Page 49: Adjusting The Tine Drive Chain

Adjusting the Return-to-Up Secure the cover panel to the chassis with the 2 thumbscrews and 2 washers (Figure 61) that Spring you removed in step 3, and torque the bolts to 37 to 45 N∙m (27 to 33 in-lb) WARNING Adjusting the Tine Drive Springs have stored energy. -

Page 50: Chassis Maintenance

Chassis Maintenance Cleaning Washing the Machine Check for Loose Hardware Wash the machine as needed using water alone Service Interval: Before each use or daily or with a mild detergent. You may use a rag when Engage parking brake, shut off the engine, washing the machine. -

Page 51: Cleaning The Debris From The Machine

Remove cooling shrouds from engine. for batteries must follow relevant federal, state, or local laws. Clean cooling fins of the engine. If a battery is being replaced or if the machine Note: Also clean dust, dirt, and oil from external containing the battery is no longer operating and is surfaces of engine, which can cause improper being scrapped, remove the battery and take it to a... -

Page 52: Storage

Check and tighten all bolts, nuts, and screws. Repair or replace any part that is damaged. Paint all scratched or bare metal surfaces. Paint is available from your authorized Toro distributor. Store the machine in a clean, dry garage or storage area. -

Page 53: Troubleshooting

Troubleshooting Alert and Error Messages Message Icon Description Resolution Voltage Error The ignition key is in the Check the battery, charging position and the smart system, and wiring. controller/electronic depth control measures that the electrical system is less than 12.3V or greater than 16V. The voltage error icon displays, and the LED status light flashes a red. - Page 54 Problem Possible Cause Corrective Action The engine does not start, starts hard, or 1. The fuel tank is empty. 1. Fill the fuel tank. fails to keep running. 2. The fuel-shutoff valve is closed. 2. Open the fuel-shutoff valve. 3. The throttle and choke are not in the 3.

- Page 55 Problem Possible Cause Corrective Action The tines do not raise. 1. There is a short in the wire harness. 1. Contact an Authorized Service Dealer. 2. The return-to-up springs are not 2. Adjust the return-to-up springs. properly adjusted. 3. The return-to-up springs are damaged. 3.

- Page 56 Schematics B+ START g231578 Electrical Schematic (Rev. A)

- Page 57 g243786 Hydraulic Schematic (Rev. A)

- Page 58 The Toro Company (“Toro”) respects your privacy. When you purchase our products, we may collect certain personal information about you, either directly from you or through your local Toro company or dealer. Toro uses this information to fulfil contractual obligations - such as to register your warranty, process your warranty claim or to contact you in the event of a product recall - and for legitimate business purposes - such as to gauge customer satisfaction, improve our products or provide you with product information which may be of interest.

- Page 59 California Proposition 65 Warning Information What is this warning? You may see a product for sale that has a warning label like the following: WARNING: Cancer and Reproductive Harm—www.p65Warnings.ca.gov. What is Prop 65? Prop 65 applies to any company operating in California, selling products in California, or manufacturing products that may be sold in or brought into California.