Table of Contents

Advertisement

Quick Links

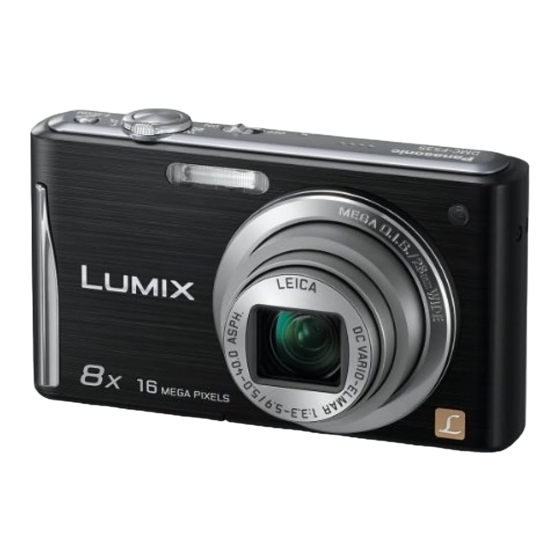

DMC-FS35EB

Model No.

DMC-FS35EE

DMC-FS35EF

DMC-FS35EG

DMC-FS35EP

DMC-FH25P

DMC-FH25PC

DMC-FH25PR

DMC-FH25PU

DMC-FH25GA

DMC-FH25GC

DMC-FH25GF

DMC-FH25GH

DMC-FH25GK

DMC-FH25GN

DMC-FH25GT

DMC-FH24P

Vol. 1

© Panasonic Corporation 2011 Unauthorized copy-

ing and distribution is a violation of law.

ORDER NO. DSC1102004CE

B26

Digital Camera

Advertisement

Chapters

Table of Contents

Summary of Contents for Panasonic Lumix DMC-FS35EB

- Page 1 ORDER NO. DSC1102004CE Digital Camera DMC-FS35EB Model No. DMC-FS35EE DMC-FS35EF DMC-FS35EG DMC-FS35EP DMC-FH25P DMC-FH25PC DMC-FH25PR DMC-FH25PU DMC-FH25GA DMC-FH25GC DMC-FH25GF DMC-FH25GH DMC-FH25GK DMC-FH25GN DMC-FH25GT DMC-FH24P Vol. 1 © Panasonic Corporation 2011 Unauthorized copy- ing and distribution is a violation of law.

-

Page 2: Table Of Contents

Colour [DMC-FH25] (S)...Silver Type (except PC/PR/GT) [DMC-FS35] (K)...Black Type (S)...Silver Type (except EF) (R)...Red Type (except PR/GT) (K)...Black Type (A)...Blue Type (only P/PC/PU/GK/GN) (R)...Red Type (except EE) (V)...Violet Type (only P/PC/PR/PU/GT) (A)...Blue Type (except EF) [DMC-FH24] (V)...Violet Type (except EE/EF) (K)...Black Type TABLE OF CONTENTS PAGE... -

Page 3: Safety Precautions

1 Safety Precautions 1.1. General Guidelines 1.3. Leakage Current Hot Check 1. IMPORTANT SAFETY NOTICE (See Figure 1.) There are special components used in this equipment 1. Plug the AC cord directly into the AC outlet. Do not use which are important for safety. These parts are marked by an isolation transformer for this check. -

Page 4: How To Discharge The E.capacitor On Flash Top P.c

1.4. How to Discharge the E.Capacitor on Flash Top P.C.B. CAUTION: 1. Be sure to discharge the E.capacitor on FLASH TOP P.C.B.. 2. Be careful of the high voltage circuit on FLASH TOP P.C.B. when servicing. [Discharging Procedure] 1. Refer to the disassemble procedure and remove the necessary parts/unit. 2. -

Page 5: Warning

2 Warning 2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Elec- trostatically Sensitive (ES) Devices. The following techniques should be used to help reduce the incidence of component damage caused by electrostatic discharge (ESD). -

Page 6: Caution For Ac Cord(For Eb/Gc

A replacement fuse cover can be purchased from your local 2.3.2.3. How to Replace the Fuse Panasonic Dealer. 1. Remove the Fuse Cover with a screwdriver. If the fitted moulded plug is unsuitable for the socket outlet in your home then the fuse should be removed and the plug cut off and disposed of safety. -

Page 7: How To Replace The Lithium Battery

NOTE: This Lithium battery is a critical component. (Type No.: ML421 Manufactured by Energy Company, Panasonic Corporation.) It must never be subjected to excessive heat or discharge. It must therefore only be fitted in requirement designed specifically for its use. -

Page 8: Service Navigation

3 Service Navigation 3.1. Introduction This service manual contains technical information, which allow service personnel’s to understand and service this model. Please place orders using the parts list and not the drawing reference numbers. If the circuit is changed or modified, the information will be followed by service manual to be controlled with original service manual. 3.2. -

Page 9: How To Define The Model Suffix (Ntsc Or Pal Model)

3.4. How to Define the Model Suffix (NTSC or PAL model) There are eight kinds of DMC-FS35, FH25, FH24, regardless of the colours. • a) DMC-FH24P • b) DMC-FH25P/PC • c) DMC-FS35EB/EF/EG/EP • d) DMC-FS35EE • e) DMC-FH25GT • f) DMC-FH25GK •... - Page 10 3.4.2. INITIAL SETTINGS: After replacing the MAIN P.C.B., be sure to perform the initial settings after achieving the adjustment by ordering the following pro- cedure in accordance with model suffix of the unit. 1. IMPORTANT NOTICE: Before proceeding Initial settings, be sure to read the following CAUTIONS. 2.

- Page 11 [CASE 1. After replacing MAIN P.C.B.] When MAIN P.C.B. has just been replaced, all of the model suffix is displayed as follows. (Five pages in total) [CASE 2. Other than “After replacing MAIN P.C.B.”] • Step 5. Choose the model suffix in “INITIAL SETTINGS”: (Refer to “CAUTION 1”) [Caution: After replacing MAIN P.C.B.] The model suffix can been chosen, JUST ONE TIME.

- Page 12 • Step 6. Chose the model number in “INITIAL SETTINGS”: (Only for “P” models.) This step is necessary only for “P”. Only for model suffix with “P”, there are two kind of model; (DMC-FH25 and DMC-FH24) ,due to difference of sales chan- nel.Therefore, not only model suffix, but also model number (FH25 or FH24) has to be set up in the “INITIAL SETTINGS”.

-

Page 13: Specifications

4 Specifications... -

Page 14: Location Of Controls And Components

17 Microphone 18 Shutter button 19 [E.ZOOM] button 20 Tripod receptacle 1617 18 19 21 Card/Battery door 22 DC coupler cover When using an AC adaptor, ensure that the Panasonic DC coupler (optional) and AC adaptor (optional) are used. - Page 15 Selecting the [Rec] Mode Slide the [Rec]/[Playback] selector switch to [ Press [MODE]. Press / / / to select the mode. Press [MENU/SET]. List of [Rec] Modes Intelligent Auto Mode The subjects are recorded using settings automatically selected by the camera. Normal Picture Mode The subjects are recorded using your own settings.

-

Page 16: Service Mode

6 Service Mode 6.1. Error Code Memory Function 1. General description This unit is equipped with history of error code memory function, and can be memorized 16 error codes in sequence from the latest. When the error is occurred more than 16, the oldest error is overwritten in sequence. The error code is not memorized when the power supply is shut down forcibly (i.e.,when the unit is powered on by the battery, the battery is pulled out) The error code is memorized to FLASH-ROM when the unit has just before powered off. - Page 17 • 3. Error Code List The error code consists of 8 bits data and it shows the following information.

-

Page 18: Ics (Indication Of Additional Camera Settings When Picture Was Taken) Function

Important notice about "Error Code List" 1) About "*" indication: The third digit from the left is different as follows. - In case of 0 (example: 18001000) When the third digit from the left shows "0", this error occurred under the condition of INITIAL SETTINGS has been completed. - Page 19 3. How to read 4. How to exit: Simply, turn the power off. (Since ICS function is executed under the condition of temporary cancellation of "INITIAL SETTINGS", it wake up with normal condition when turn off the power.)

-

Page 20: Service Fixture & Tools

7 Service Fixture & Tools 7.1. Service Fixture and Tools The following Service Fixture and tools are used for checking and servicing this unit. -

Page 21: When Replacing The Main P.c.b

7.2. When Replacing the Main P.C.B. After replacing the MAIN P.C.B., be sure to achieve adjustment. The adjustment instruction is available at “software download” on the “Support Information from NWBG/VDBG-AVC” web-site in “TSN system”, together with Maintenance software. 7.3. Service Position This Service Position is used for checking and replacing parts. -

Page 22: Disassembly And Assembly Instructions

8 Disassembly and Assembly Instructions 8.1. Disassembly Flow Chart This is a disassembling chart. When assembling, perform this chart conversely. 8.2. PCB Location... -

Page 23: Disassembly Procedure

8.3. Disassembly Procedure 8.3.1. Removal of the Rear Case Unit and Front Case Unit Item Removal Rear Case Unit (Fig. D1) Card Front Case Unit Battery 6 Screws (A) 3 Screws (B) (Fig. D2) 2 Locking tabs Rear Case Unit 2 Locking tabs Front Case Unit Sub P.C.B. - Page 24 8.3.3. Removal of the LCD Unit (Fig. D2) 8.3.2. Removal of the Sub P.C.B. (Fig. D4) (Fig. D3)

- Page 25 8.3.5. Removal of the Flash Top P.C.B. (Fig. D5) 8.3.4. Removal of the Top Case Unit (Fig. D7) (Fig. D6)

- Page 26 8.3.6. Removal of the Lens Unit (Fig. D9) 8.3.7. Removal of the Main P.C.B. (Fig. D8) (Fig. D10)

- Page 27 8.3.8. Removal of the Battery Case 8.3.9. Removal of the Battery Door Unit and Jack Door (Fig. D12) NOTE: (When Installing) Make sure to confirm the following points when installing. • The Screw is tightened enough. • Installing conditions are fine. (No distortion, no abnormal- space.) •...

-

Page 28: Lens Disassembly Procedure

8.4. Lens Disassembly Procedure Precaution: 1. Do not remove the CCD when disassembling or re- assembling the lens in order to maintain it clean. When remove it, refer to item "8.6.". 2. Keep dust or dirt away from the lens. 3. - Page 29 9. Remove the 4 solders (C). 2. Remove the master flange unit. 10. Remove the lens FPC unit to the direction of arrow (3). 8.4.2. Removal of the Master Flange Unit 1. Unscrew the 4 screws (C).

- Page 30 8.4.3. Removal of the 1st Lens Frame 8.4.4. Removal of the 2nd Lens Frame Unit/2nd Lens Frame Unit/Both Unit/Both Sides Cam Frame/2nd Sides Cam Frame/2nd 3rd Direct 3rd Direct Frame/3rd Lens Frame Frame/3rd Lens Frame Unit Unit 1. Push the both sides cam frame from the lens front side in 1.

- Page 31 8.4.5. Removal of the 2nd 3rd Direct 8.4.7. Removal of the 2nd Lens Frame Frame Unit 1. Remove the 2nd 3rd direct frame in the direction of the 1. Turn the 2nd lens frame unit in the direction of the arrow arrow.

-

Page 32: Assembly Procedure For The Lens

8.4.8. Removal of the 1st Direct Frame 8.5. Assembly Procedure for the Unit Lens 1. Remove the 1st direct frame unit in the direction of the 8.5.1. Phase alignment of the Penetration arrow. Cam Frame and Drive Frame Unit 8.4.9. Removal of the Drive/Penetration Frame Unit 1. - Page 33 8.5.2. Phase alignment of the Drive/Pene- 8.5.3. Phase alignment of the 2nd Lens tration Frame Unit and Fixed Frame Frame Unit and Both Sides Cam Unit Frame...

- Page 34 8.5.4. Phase alignment of the 3rd Lens 8.5.5. Phase alignment of the 2nd 3rd Frame Unit and 2nd Lens Frame Direct Frame and 2nd Lens Frame Unit/Both Sides Cam Frame Unit/Both Sides Cam Frame/3rd Lens Frame Unit...

- Page 35 8.5.6. Phase alignment of the 2nd Lens Frame Unit/Both Sides Cam Frame/ 2nd 3rd Direct Frame/3rd Lens Frame Unit and 1st Lens Frame Unit...

- Page 36 8.5.7. Phase alignment of the 1st Lens 8.5.8. Phase alignment of the 1st Direct Frame Unit/2nd Lens Frame Unit/ Frame Unit/1st Lens Frame Unit/ Both Sides Cam Frame/2nd 3rd 2nd Lens Frame Unit/Both Sides Direct Frame/3rd Lens Frame Unit Cam Frame/2nd 3rd Direct Frame/ and 1st Direct Frame Unit 3rd Lens Frame Unit and Fixed Frame Unit/Drive Frame Unit/Pene-...

- Page 37 8.5.9. Install of the Master Flange Unit 8.5.10. Install of the Lens FPC Unit and Zoom Motor...

-

Page 38: Removal Of The Ccd Unit

8.6. Removal of the CCD Unit 8.8. Application Grease Method To prevent the CCD unit from catching the dust and dirt, do not remove the CCD unit except for replacing. The grease application parts of lens unit are as follows. Apply grease additionally in the specified position if necessary. -

Page 39: Measurements And Adjustments

9 Measurements and Adjustments 9.1. Introduction When servicing this unit, make sure to perform the adjustments necessary based on the part(s) replaced. Before disassembling the unit, it is recommended to back up the camera data stored in flash-rom as a data file. IMPORTANT NOTICE (After replacing the MAIN P.C.B.) After replacing the MAIN P.C.B., it is necessary to use the “DIAS”... - Page 40 9.2.2. Flash-Rom Data Backup When trouble occurs, it is recommended to backup the Flash-rom data before disassembling the unit. There are two kinds of Flash-rom data backup methods: [ ROM_BACKUP (Method of Non-PC backup) ] 1. Insert the SD-card into the camera. 2.

-

Page 41: Details Of Electrical Adjustment

9.3. Details of Electrical Adjustment 9.3.1. How to execute the Electrical Adjustment It is not necessary to connect the camera to a PC to perform adjustments. “Flag reset operation” and “Initial setting operation” are required when carrying out the alignment, follow the procedure below. 9.3.1.1. - Page 42 9.3.1.3. Execute Adjustment (In case of “OIS Adjustment”) 1. Perform step “9.3.1.1.” to “9.3.1.2.”, to reset the OIS flag status “F” (Set) to “0” (Reset) 2. Press [ DISP. ] button after Flag reset. OIS Adjustment screen is displayed on the LCD panel. (Refer to Fig.3-3) 3.

- Page 43 9.3.2. Adjustment Specifications The following matrix table shows the relation between the replaced part and the Necessary Adjustment. When a part is replaced, make sure to perform the necessary adjustment(s) in the order indicated. The table below shows all the information necessary to perform each adjustment.

-

Page 45: After Adjustment

9.4. After Adjustment 9.4.1. Initial Setting Since the initial setting has been released to execute the built-in adjustment software, it should be set up again before shipping the camera to the customer. Refer to the procedure described in “3.4.2. INITIAL SETTINGS” for details. [ IMPORTANT ] 1. -

Page 46: Maintenance

10 Maintenance 10.1. Cleaning Lens and LCD Panel Do not touch the surface of lens and LCD Panel with your hand. When cleaning the lens, use air-Blower to blow off the dust. When cleaning the LCD Panel, dampen the lens cleaning paper with lens cleaner, and the gently wipe the its surface. Note: The Lens Cleaning KIT ;... - Page 47 DSC1102004CE S1. About Indication of The Schematic Diagram Service Manual S1.1. Important Safety Notice COMPONENTS IDENTIFIED WITH THE MARK HAVE THE SPECIAL CHARACTERISTICS Diagrams and Replacement FOR SAFETY. WHEN REPLACING ANY OF THESE COMPONENTS USE ONLY THE SAME TYPE. 1.Although reference number of the parts is indicated on the P.C.B. drawing and/or Parts List schematic diagrams, it is NOT mounted on the P.C.B.

-

Page 48: S2. Voltage Chart

S2. Voltage Chart Note) Indicated voltage values are the standard values for the unit measured by the DC electronic circuit tester (high-impedance) with the chassis taken as standard. Therefore, there may exist some errors in the voltage values, depending on the internal impedance of the DC circuit tester. S2.1. -

Page 49: S3. Block Diagram

S3. Block Diagram S3.1. Overall Block Diagram (28mm ~ 224mm) IC3001 CCD SIGNAL PROCESSOR X6001 (24MHz) 1/2.33" 16 MEGA PIX CDS, AGC, A/D, TG, CCD DRIVER ZOOM OIS UNIT IRIS SHUTTER FOCUS CARD IC3003 REGULATOR MICROPHONE IC9101 SYSTEM IC IC9101 SYSTEM IC SPEAKER MOTOR DRIVE,... -

Page 50: S4. Schematic Diagram

S4. Schematic Diagram S4.1. Interconnection Diagram FLASH TOP P.C.B. M8001 (COMPONENT SIDE) MICROPHONE PS8001 : (FOIL SIDE) P8002 RL8001 RL8002 SPEAKER BATTERY FP9001 CON CHK CCD THERMO SUBSW2 SUBSW1 MSUBSW MSUB V15D V13Z V13Y V13X V12Z V12Y V12X PP9001 LCD UNIT FP9003 CCD GND CCD GND... -

Page 51: S4.2. Flash Top Schematic Diagram

S4.2. Flash Top Schematic Diagram T/W_SW i.A. CAUTION: FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE 2.0A 32V FUSE. ATTENTION: POUR UNE PROTECTION CONTINUE LES RISQUES S8004 2.0A 32V D' INCENDIE N' UTILISERQUE DES FUSIBLE DE MÉME TYPE 2.0A 32V. K0F111A00541 SHUTTER_SW 2.0A 32V... -

Page 52: S4.3. Ccd Flex Schematic Diagram

S4.3. CCD Flex Schematic Diagram FT3101 CON_CHK CCD_GND 42 41 40 39 38 37 36 35 34 33 V12Y MSUBSW CCD_GND V12X φV12X CCD_GND [33]MSUB [42]φV12Z φV12 CCD_OUT [32]MSUBSW φH4 [1]φV12Y φV11 φH2 CCD_GND φV10 φSUB CCD_GND IC3101 R3107 φV9 φH1 CCD_GND MN34590PLHAV... -

Page 53: S4.4. Lens Flex Schematic Diagram

S4.4. Lens Flex Schematic Diagram POSITIVE VOLTAGE LINE FZHP LED PHOTO CO. BARREL ENCODER SENSOR FZHP ABS (FULL RETRACT) FZHP VCC YHO+ HALL SENSOR (Y) OIS UNIT YHO- IRIS- IRIS- DC SOLENOID (IRIS) IRIS+ IRIS+ SHUTTER UNIT DC SOLENOID (SHUTTER) XDR- DRIVE COIL (X) XDR+... -

Page 54: S5. Print Circuit Board

S5. Print Circuit Board S5.1. Flash Top P.C.B. DMC-FS35/FH25/FH24 Flash Top P.C.B. (Component Side) CL800 ET8003 R8003 TL8004 R8002 F8001 C8001 R8021 C8003 CL8005 Q8001 CL8008 CL8010 CL8011 CL8032 D8001 CL8031 (Component Side) - Page 55 DMC-FS35/FH25/FH24 Flash Top P.C.B. (Component Side) CL8006 CL8004 PS8001 ET8005 F8021 L8001 TL8001 TL8007 P8002 TL8002...

- Page 56 C8022 LB8001 S8002 S8001 CL8026 C8017 (Foil Side) DMC-FS35/FH25/FH24 Flash Top P.C.B. (Foil Side) S-10...

- Page 57 M8001 S8002 TL8003 CL8001 ET8004 T8001 RL8002 RL8001 R8038 R8037 DMC-FS35/FH25/FH24 Flash Top P.C.B. (Foil Side) S-11...

-

Page 58: S5.2. Ccd Flex P.c.b

S5.2. CCD Flex P.C.B. (Component Side) C3101 TH3101 R3108 Q3101 IC3101 (Foil Side) DMC-FS35/FH25/FH24 CCD Flex P.C.B. S-12... -

Page 59: S5.3. Lens Flex P.c.b

S5.3. Lens Flex P.C.B. ZOOM MOTOR UNIT CO. BARREL ENCODER OIS UNIT (FULL RETRACT) SHUTTER UNIT Pin 1 ZOOM ENCODER 1 ZOOM ENCODER 2 Pin 41 FOCUS MOTOR UNIT DMC-FS35/FH25/FH24 LENS FLEX P.C.B. S-13... - Page 60 S-14...

-

Page 61: S6. Replacement Parts List

ELECTROSTATIC DISCHARGE (ESD) TO ELECTROSTATICALLY SENSITIVE (ES) DEVICES section. Definition of Parts supplier: 1. Parts marked with [ENERGY] in the remarks column are supplied from Panasonic Corporation Energy Company. 2. Parts marked with [SPC] in the remarks column are supplied from AVC-CSC-SPC. - Page 62 DMC-FS35EG-S Ref.No. Part No. Part Name & Description Remarks Ref.No. Part No. Part Name & Description Remarks VEP56126C MAIN P.C.B. 1 (RTL) E.S.D. VEP59094A SUB P.C.B. 1 (RTL) E.S.D. VEP58149A FLASH TOP P.C.B. 1 (RTL) E.S.D. VEK0R36 CCD UNIT 1 [SPC] E.S.D. VEP58149A FLASH TOP P.C.B.

- Page 63 DMC-FS35EG-S Ref.No. Part No. Part Name & Description Remarks Ref.No. Part No. Part Name & Description Remarks VEP56126C MAIN P.C.B. 1 (RTL) E.S.D. VXW1229 LENS UNIT (W/O CCD) 1 [SPC] VEP58149A FLASH TOP P.C.B. 1 (RTL) E.S.D. VEK0R36 CCD UNIT 1 [SPC] E.S.D.

- Page 64 DMC-FS35EG-S Ref.No. Part No. Part Name & Description Remarks Ref.No. Part No. Part Name & Description Remarks VPF1372-A CAMERA BAG 1 P,PC,PU DE-A91BA/SX BATTERY CHARGER 1 P,PC,PU ----- BATTERY 1 P,PC,PU K1HY08YY0019 USB CABLE W/PLUG 1 25P,PC,PU K1HY08YY0020 AV CABLE W/PLUG 1 25P,PC,PU VFC4297-B HAND STRAP...

- Page 65 DMC-FS35EG-S Ref.No. Part No. Part Name & Description Remarks Ref.No. Part No. Part Name & Description Remarks VQT3D45 BASIC O/I 1 25GT VPF1372-A CAMERA BAG 1 EXCEPT P,PC,PU (CHINESE(TRADITIONAL)) DE-A92AA/SX BATTERY CHARGER 1 35EG,EP,EF,EB,EE, 25GN VQT3D46 BASIC O/I 1 25GK DE-A92DA/SX BATTERY CHARGER 1 25PR...

-

Page 66: S7. Exploded View

S7. Exploded View S7.1. Frame and Casing Section 21-3 21-2 21-1 31-1 B101 B102 B103 104-1 104-3 B106 B107 104-2 B108 B104 B109 B110 B111 112-2 112-2 112-3 112-1 B105 S-20... -

Page 67: S7.2. Packing Parts And Accessories Section (1

S7.2. Packing Parts and Accessories Section (1) (PC only) Stick the UPC LABEL (Ref. No. 221) for [PC] model on the original UPC place. (PC only) S-21... -

Page 68: S7.3. Packing Parts And Accessories Section (2

S7.3. Packing Parts and Accessories Section (2) (GT only) (DMC-FH25PR) (DMC-FS35EE/EF/EG/EP DMC-FH25GA/GF) (DMC-FS35EB DMC-FH25GC/GH) (DMC-FH25GK/GT) (DMC-FH25GN) S-22...