Siemens SIWAREX WL230 Operating Instructions Manual

Base plate and elastomeric bearing sb-s sa

Hide thumbs

Also See for SIWAREX WL230:

- Equipment manual (50 pages) ,

- Operating instructions manual (44 pages) ,

- Manual (36 pages)

Table of Contents

Advertisement

Quick Links

SB-S SA

SIWAREX WL230

Base plate and elastomeric bearing

SB-S SA

Operating Instructions

03/2013

A5E31529044A-01

___________________

Introduction

___________________

Notes on handling the

product

___________________

Description

___________________

Application planning

___________________

Installation

___________________

Service and maintenance

___________________

Technical specifications

___________________

Dimension drawings

___________________

Ordering data

___________________

Appendix

1

2

3

4

5

6

7

8

9

A

Advertisement

Table of Contents

Summary of Contents for Siemens SIWAREX WL230

- Page 1 ___________________ SB-S SA Introduction ___________________ Notes on handling the product ___________________ Description SIWAREX WL230 ___________________ Application planning Base plate and elastomeric bearing ___________________ SB-S SA Installation ___________________ Service and maintenance Operating Instructions ___________________ Technical specifications ___________________ Dimension drawings ___________________ Ordering data...

- Page 2 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 3: Table Of Contents

Table of contents Introduction ............................. 7 Purpose of this documentation ...................... 7 History ............................7 Product package ..........................7 1.3.1 Product package for base plate ..................... 7 1.3.2 Product package for elastomeric bearing ..................8 Environmental protection ....................... 8 Notes on handling the product ......................... 9 Description ............................ - Page 4 Table of contents Installing the grounding cable ..................... 33 Dismantling..........................33 Service and maintenance ........................35 Servicing and maintenance ......................35 Care and maintenance of elastomer components ..............36 Technical specifications ........................39 Dimension drawings ..........................41 Dimensional drawing of base plate / elastomeric bearing ............41 Dimension drawing of the grounding cable .................

- Page 5 Table of contents Tables Table 8- 1 Dimensions SB-S SA 0.5 t / 1 t, 2 t, 5 t ..................41 Table 9- 1 Ordering information for base plate ..................... 43 Table 9- 2 Ordering information for elastomeric bearing ................43 Table 9- 3 Ordering information for grounding cable ..................

- Page 6 Table of contents SB-S SA Operating Instructions, 03/2013, A5E31529044A-01...

-

Page 7: Introduction

Introduction Purpose of this documentation These instructions contain all the information you need for commissioning and using the device. It is aimed at persons who install the device mechanically and commission it, as well as at service and maintenance engineers. History The following versions of this documentation have been released to date. -

Page 8: Product Package For Elastomeric Bearing

Introduction 1.4 Environmental protection 1.3.2 Product package for elastomeric bearing The product package consists of the following components: ● Information sheet ● Elastomeric bearing, retaining bracket Note Other product package information You can find sketches of the elastomeric bearing parts in the section Installation (Page 23). -

Page 9: Notes On Handling The Product

All obligations on the part of Siemens AG are contained in the respective sales contract, which also contains the complete and solely applicable liability provisions. The provisions defined in the sales contract for the responsibility for defects are neither extended nor limited by the remarks in this document. - Page 10 Therefore they are not subject to the EC directive 94/9 EC (ATEX). Trademarks SIWAREX ® is a registered trademark of Siemens AG. All other names appearing in these instructions may be trademarks; use of such names by third parties for their own purposes may infringe upon owners rights.

-

Page 11: Description

● Self-centering effect on the load bearing implement Elastomeric bearing for SIWAREX WL230 SB-S SA The self-centering elastomeric bearing for SIWAREX WL230 SB-S SA type load cells is especially well suited for installation in roller table, single-point and container scales. -

Page 12: Lifting Protection

Supporting structures complying with the general rules of mechanical engineering must therefore be designed by the customer for installing the base plate or elastomeric bearing. As an alternative installation units from the product range of Siemens can be used. 3.1.2 Lifting protection The lifting protection prevents the load bearing implements from being lifted off of the load cells. -

Page 13: Layout And Function

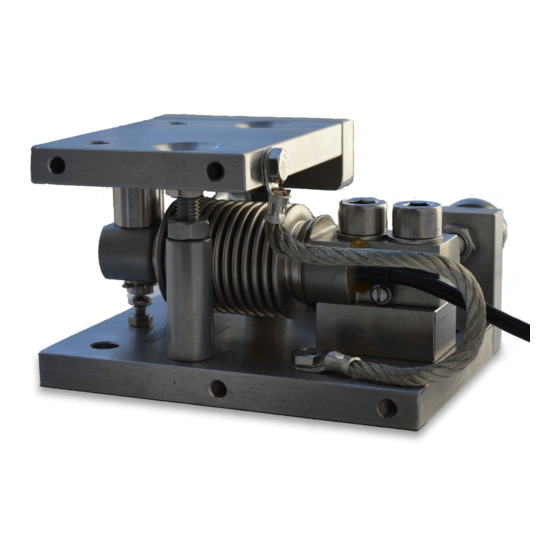

Description 3.2 Layout and function Layout and function 3.2.1 Design / function of base plate and elastomeric bearing Design The base plate and the elastomeric bearing consist of the following components: ● Elastomeric bearing ● Retaining bracket ● Base plate Together with the load cell, the elastomeric bearing represents a self-centering bearing unit. -

Page 14: Figure 3-4 Sectional View

Description 3.2 Layout and function Function Elastomeric bearings provide lateral guidance of the load cells and the base plate. Together with the load cell, both form a self-centering unit. Figure 3-4 Sectional view SB-S SA Operating Instructions, 03/2013, A5E31529044A-01... -

Page 15: Design And Function Of The Grounding Cable

Description 3.2 Layout and function 3.2.2 Design and function of the grounding cable Design The grounding cable consists of a fine-gauge copper wire with a cross-section of 50 mm well as two Ø 10 mm lugs. Function The grounding cable represents an electrical bypass via the load cell and elastomeric bearing unit. - Page 16 Description 3.2 Layout and function SB-S SA Operating Instructions, 03/2013, A5E31529044A-01...

-

Page 17: Application Planning

The following can be used as dummies, for example: ● A copy of the installation unit by means of a welded construction for installation work ● A SIWAREX WL230 compact installation unit This option is only useful as an alternative to elastomeric bearings. -

Page 18: Load Pick-Up

Application planning 4.3 Load pick-up Load pick-up Mounting surfaces The following requirements apply for the mounting surfaces of base plates and elastomeric bearings: ● The positional and angular deviations of the mounting surfaces to each other should correspond to the general tolerances for welded constructions in EN ISO 13920. ●... -

Page 19: Overload Protection

Application planning 4.4 Overload protection Overload protection NOTICE Irreparable faults and damage to the load cells When using load cells with small rated loads, always provide overload protection in order to protect the cells from becoming damaged. This applies both to the measuring direction and the transverse direction. -

Page 20: Guide Elements

Application planning 4.5 Guide elements Guide elements Use the guide elements in the following cases: ● A weight should be determined under the influence of transverse forces. ● Horizontal movement of the load bearing implement should be prevented. A change in the distance between the support points, for example as a result of expansion of the load bearing implement due to heat, must not lead to mutual tensioning of the guide elements. - Page 21 Application planning 4.5 Guide elements To ensure that no force components occur in the measuring direction, you must install guide elements at precise right angles to the effective direction of the load cells. Three guide elements are sufficient to statically fix a weighing platform or container. Note Weighing errors With four guide elements, there is a risk of the guide elements mutually tensioning, which in...

-

Page 22: Protection Against Explosion

Application planning 4.6 Protection against explosion Protection against explosion Protection against explosion There is no potential risk of ignition from the base plates and elastomeric bearings of load cells. This means base plates and elastomeric bearings are not subject to the EC Directive 94/9 EC (ATEX). -

Page 23: Installation

Installation Safety information/instructions Load cells are precision components and must therefore be handled carefully. Particular care must be taken during transport and installation. WARNING Danger to life from falling loads • Load cells are not machine components which have been constructed with the normal safety factors. - Page 24 Installation 5.1 Safety information/instructions NOTICE Damage to load cells through incorrect mounting • Provide indented claws or crane eyebolts on the load carrier to ensure that hoisting gear can be used safely. • Load cells must never be overloaded. Put the load carrier down slowly for this reason. With load cells of smaller rated loads in particular, there is a risk of stretching the load cell bodies when attaching force transfer devices, for example, when tightening locknuts.

-

Page 25: Installing The Base Plate And Elastomeric Bearing

Installation 5.2 Installing the base plate and elastomeric bearing Installing the base plate and elastomeric bearing 5.2.1 General installation information The installation conditions vary widely. The dead load of the load bearing implement can be very low or relatively high. You might be dealing with a container, platform or a roller table. The following installation instructions can therefore only describe the general procedures. -

Page 26: Preparing The Load Cell

Installation 5.2 Installing the base plate and elastomeric bearing 5.2.3 Preparing the load cell NOTICE Damage to the load cell The following applies to prevent damage to the load cells: • Observe the operating instructions for the load cell. • Do not carry the load cell by its connection cables. •... -

Page 27: Prepare The Elastomeric Bearing

Installation 5.2 Installing the base plate and elastomeric bearing 5.2.5 Prepare the elastomeric bearing ① Retaining bracket ② Elastomeric bearing Figure 5-3 Product package for elastomeric bearing 1. Unpack the elastomeric bearing. 2. Read the accompanying information sheet. 3. Check the delivered unit. SB-S SA Operating Instructions, 03/2013, A5E31529044A-01... -

Page 28: Bolt The Load Cell To The Base Plate

Adhere to the tightening torques: • SIWAREX WL230 SB-S SA load cell with a rated load of 0.5 t, 1 t, 2 t: 80 Nm • SIWAREX WL230 SB-S SA load cell with a rated load of 5 t: 391 Nm... -

Page 29: Install The Elastomeric Bearing In The Load Cell

Installation 5.2 Installing the base plate and elastomeric bearing 5.2.7 Install the elastomeric bearing in the load cell Procedure Figure 5-5 Install the elastomeric bearing in the load cell 1. Position the elastomeric bearing and insert into the receptacle of the load cell. 2. -

Page 30: Install The Load Cell With Elastomeric Bearing Unit

Installation 5.2 Installing the base plate and elastomeric bearing 5.2.8 Install the load cell with elastomeric bearing unit Safety guidelines WARNING Death or serious bodily injury A falling load bearing implement can lead to serious bodily injury or considerable material damage depending on the potential risk. -

Page 31: Figure 5-6 Insert The Elastomeric Bearing Unit

Installation 5.2 Installing the base plate and elastomeric bearing Install the elastomeric bearing unit Adapt the procedure to the installation conditions. Figure 5-6 Insert the elastomeric bearing unit 1. Insert the elastomeric bearing unit. 2. Bolt the base plate to the bottom mounting plate. 3. -

Page 32: Checking The Installation

Installation 5.2 Installing the base plate and elastomeric bearing 5.2.9 Checking the installation NOTICE Damage to the load cell and elastomeric bearing Ensure that the load cells and elastomeric bearing are installed correctly, for example, by checking the mounting dimensions and oscillation distances. Incorrect assembly can result in damage to the load cell and elastomeric bearing. -

Page 33: Installing The Grounding Cable

Installation 5.3 Installing the grounding cable Installing the grounding cable 1. Prepare a permanently contacting bolted connection such as M10 on the load bearing implement and foundation for securing the grounding cable. 2. Screw the grounding cable tight. Dismantling For the disassembly of load cells, the same safety rules and requirements apply as for installation and assembly. - Page 34 Installation 5.4 Dismantling SB-S SA Operating Instructions, 03/2013, A5E31529044A-01...

-

Page 35: Service And Maintenance

Service and maintenance Servicing and maintenance Important notes on cleaning NOTICE Damage to load cells, measurement errors • Dirt must not be allowed to accumulate in the vicinity of a load cell. • Do not subject cable glands and seals directly to the jet of a pressure washer. •... -

Page 36: Care And Maintenance Of Elastomer Components

Service and maintenance 6.2 Care and maintenance of elastomer components Care and maintenance of elastomer components General information The physical properties of most rubber products change under poor storage conditions or with improper treatment. The following examples of changes, however, can make them unusable: ●... - Page 37 Service and maintenance 6.2 Care and maintenance of elastomer components Cleaning The following applies to cleaning: ● We recommend the use of a pH-neutral detergent. Do not use cleaning agents containing non-polar solvents (e.g., gasoline)! ● Rinse the components with water after cleaning, if needed. ●...

- Page 38 Service and maintenance 6.2 Care and maintenance of elastomer components SB-S SA Operating Instructions, 03/2013, A5E31529044A-01...

-

Page 39: Technical Specifications

Technical specifications Elastomeric bearing Value at rated load Variable 500 kg Maximum permitted ±4 mm ±4 mm ±4 mm ±4 mm lateral deflection Vertical stiffness 5.9 kN/mm 5.9 kN/mm 28.98 kN/mm 28.98 kN/mm Horizontal stiffness 0.16 kN/mm 0.16 kN/mm 0.54 kN/mm 0.54 kN/mm Deflection at rated 0.68 mm... - Page 40 Technical specifications SB-S SA Operating Instructions, 03/2013, A5E31529044A-01...

-

Page 41: Dimension Drawings

Dimension drawings Dimensional drawing of base plate / elastomeric bearing The following dimensional drawing shows the SIWAREX WL230 SB-S SA base plates and elastomeric bearing. All dimensions are in millimeters. Figure 8-1 Dimensional drawing of base plate and elastomeric bearing Table 8- 1 Dimensions SB-S SA 0.5 t / 1 t, 2 t, 5 t... -

Page 42: Dimension Drawing Of The Grounding Cable

Dimension drawings 8.2 Dimension drawing of the grounding cable Dimension drawing of the grounding cable Figure 8-2 Dimension drawing of the grounding cable SB-S SA Operating Instructions, 03/2013, A5E31529044A-01... -

Page 43: Ordering Data

Ordering data Table 9- 1 Ordering information for base plate Base plate Designation Rated load Order number SB-S SA 500 kg / 1 t 7MH5707-4AB00 7MH5707-4GB00 7MH5707-4PB00 The load cells are not included. Table 9- 2 Ordering information for elastomeric bearing Elastomeric bearing Designation Rated load... - Page 44 Ordering data SB-S SA Operating Instructions, 03/2013, A5E31529044A-01...

-

Page 45: A Appendix

Service & Support on the Internet In addition to our documentation, we offer a comprehensive knowledge base online on the Internet at: Services & Support (http://www.siemens.com/automation/service&support) There you will find: ● The latest product information, FAQs, downloads, tips and tricks. - Page 46 Appendix A.1 Technical support Additional Support Please contact your local Siemens representative and offices if you have any questions about the products described in this manual and do not find the right answers. Find your contact partner at: Partner (http://www.automation.siemens.com/partner) A signpost to the documentation of the various products and systems is available at: Documentation (http://www.siemens.com/weighing/documentation)

-

Page 47: Index

Index Servicing and maintenance, 35 Guide element, 20 Additional Support, 46 Hotline, 45 Application, 11 Installation, 31 Cleaning, 35 Elastomeric bearing unit, 31 Customer Support Hotline, 45 Installing the grounding cable, 33 Installing the load cell, 30 Installing the load cell, 30 Internet, 45 Design Elastomeric bearing unit, 13... - Page 48 Index Service, 45 Support, 45 Support point, 18 SB-S SA Operating Instructions, 03/2013, A5E31529044A-01...