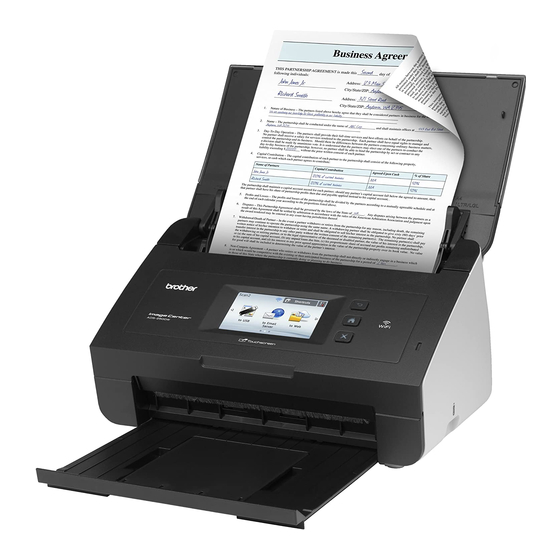

Brother ADS-2600W Service Manual

Hide thumbs

Also See for ADS-2600W:

- Quick setup manual (37 pages) ,

- Manual (20 pages) ,

- Product safety manual (20 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Manual

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Brother ADS-2600W

- Page 1 Brother Advanced Document Scanner SERVICE MANUAL MODEL: ADS-2500W/2600W/2500WE/2600WE Read this manual thoroughly before maintenance work. Keep this manual in a convenient place for quick and easy reference at all times. Jul., 2012 SM-PT052 Confidential...

- Page 2 © Copyright Brother 2012 All rights reserved. No part of this publication may be reproduced in any form or by any means without permission in writing from the publisher. All other product and company names mentioned in this manual are trademarks or registered trademarks of their respective holders.

- Page 3 TRADEMARKS BROTHER is either a trademark or a registered trademark of Brother Industries, Ltd. Microsoft, Windows, Windows Vista, Windows Server, Outlook and Internet Explorer are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

-

Page 4: Table Of Contents

CONTENTS REGULATION ......................v SAFETY INFORMATION................... ix CHAPTER 1 SPECIFICATIONS 1. SPECIFICATIONS LIST ....................... 1-1 General ..........................1-1 Network Connectivity ......................1-3 Service Information......................1-3 Consumable Parts ....................... 1-3 Paper ........................... 1-4 1.5.1 Paper handling ......................1-4 1.5.2 Media specifications ....................1-4 Scanner .......................... - Page 5 Troubleshooting for Software Problems ................2-33 4.4.1 Does not respond to operation from a computer ........... 2-33 4.4.2 Cannot read data ....................2-33 Troubleshooting for Control Panel Problems..............2-34 4.5.1 Nothing is displayed on the LCD ................2-34 4.5.2 Control panel is inoperable..................2-34 4.5.3 Touch panel is inoperable ..................

- Page 6 9.13 Document detection sensor PCB / Document detection actuator / Document scanning position sensor PCB / Document scanning position actuator / Double feeding sensor (Sent) / Separation pad ASSY ............3-27 9.14 Second side CIS unit ......................3-32 9.15 Top cover / Document guide LS / Document guide RS ............. 3-33 9.16 Back cover S........................

- Page 7 CHAPTER 5 SERVICE FUNCTIONS 1. MAINTENANCE MODE........................ 5-1 How to Enter Maintenance Mode ..................5-1 1.1.1 Method of entering end-user accessible maintenance mode ........5-1 1.1.2 Method of entering maintenance mode for service personnel ........ 5-2 List of Maintenance Mode Functions ................... 5-3 Details of Maintenance Mode Functions................

-

Page 8: Regulation

European Community. The Declaration of Conformity (DoC) can be downloaded from Brother Solutions Center. Visit http://support.brother.com/ and: • select “Europe”... - Page 9 The purpose of the International ENERGY STAR Program is to promote the development and popularization of energy-efficient office equipment. ® As an ENERGY STAR Partner, Brother Industries, Ltd. has determined that this product ® meets the ENERGY STAR specifications for energy efficiency. Confidential...

- Page 10 • This transmitter must not be co-located or operated in conjunction with any other antenna or transmitter. Important • Changes or modifications not expressly approved by Brother Industries, Ltd. could void the user’s authority to operate the equipment. • A specific shielded interface cable should be used to ensure compliance with the limits for a Class B digital device.

- Page 11 Wireless connection (Mexico only) (ADS-2500WE only) The operation of this equipment is subject to the following two conditions: (1) it is possible that this equipment or device may not cause harmful interference, and (2) this equipment or device must accept any interference, including interference that may cause undesired operation.

-

Page 12: Safety Information

SAFETY INFORMATION WARNING WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injuries. CAUTION CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injuries. Important Important indicates a potentially hazardous situation which, if not avoided, may result in damage to property or loss of product functionality. - Page 13 To use the Machine Safely Please keep these instructions for later reference and read them before attempting any maintenance. If you do not follow these safety instructions, there is a possibility of a fire, electrical shock, burn or suffocation. WARNING DO NOT expose the machine to direct sunlight, excessive heat, open flames, corrosive gasses, moisture or dust.

- Page 14 Important • DO NOT place your machine next to sources of interference, such as speakers or the base units of non-Brother cordless telephones. Doing so may interfere with the operation of the machine's electronic components. • DO NOT connect your machine to an AC power outlet controlled by wall switches or automatic timers.

- Page 15 • DO NOT use the machine or handle the cord if the cord has become worn or frayed. If unplugging the machine, DO NOT touch the damaged/frayed part. • Brother strongly recommends that you DO NOT use any type of extension cord. This product was packaged in a plastic bag. To avoid suffocation, keep this plastic bag away from babies and children.

- Page 16 CAUTION DO NOT put pressure or weight on the machine or use it for any purpose beyond its intended purpose. Wait until pages have exited the machine before taking them out, or you could cause injury to your fingers by trapping them in a roller. DO NOT put your hands on the edge of the machine.

- Page 17 Use caution when operating the machine to prevent clothing (particularly sleeves, neckties, etc.), hair, or accessories from being drawn into the machine, otherwise injury may result. In the event that an object is drawn into the machine, immediately disconnect the machine from the power source. Important •...

-

Page 18: Chapter 1 Specifications

CHAPTER SPECIFICATIONS Confidential... - Page 19 CHAPTER 1 SPECIFICATIONS This chapter lists the specifications of each model. CONTENTS 1. SPECIFICATIONS LIST ....................1-1 1.1 General........................1-1 1.2 Network Connectivity..................... 1-3 1.3 Service Information....................1-3 1.4 Consumable Parts ....................1-3 1.5 Paper ........................1-4 1.5.1 Paper handling ................... 1-4 1.5.2 Media specifications ...................

-

Page 20: Specifications List

1. SPECIFICATIONS LIST General Model ADS-2500W ADS-2600W ADS-2500WE ADS-2600WE Scanning Method Dual CIS Resolution From ADF Max 600 x 600 dpi (Optical) Resolution (Interpolated) Max 1200 x 1200 dpi Scanning One-sided 24 ppm (2.5 seconds (A4/LTR)) Speed monochrome One-sided 24 ppm (2.5 seconds (A4/LTR)) -

Page 21: Computer Requirements

<Computer requirements> Hard Disk Space Processor Recom- Supported to install Computer Platform & Minimum Minimum mended Operating System Version Speed Interface Drivers Applications ® ® ® Windows Windows Intel 128 MB 256 MB 150 MB 1 GB ® Operating Home (SP2 or Pentium System greater) -

Page 22: Network Connectivity

Network Connectivity Model All Models Wired Network node NC-01h network type Network type 10Base-T/100Base-TX Network APOP, POP before SMTP, SMTP-AUTH, security SSL/TLS (HTTPS, SMTP), SNMP v3, 802.1x (EAP-MD5, EAP-FAST, PEAP, EAP-TLS, EAP-TTLS), Kerberos Wireless Network node NC-02w network type Network type IEEE802.11 b/g/n Network SSID(32chr),WEP64/128bit,WPA-PSK(TKIP/AES),... -

Page 23: Paper

XP in this Service Manual includes Windows XP Home Edition and Windows XP Professional. *2 For the latest driver updates for the Mac OS X you are using, visit us at http://solutions.brother.com/. Specifications are subject to change without notice. Confidential... -

Page 24: Chapter 2 Troubleshooting

CHAPTER TROUBLESHOOTING Confidential... - Page 25 CHAPTER 2 TROUBLESHOOTING This chapter details error messages and codes which the incorporated self-diagnostic function of the machine will display if any error or malfunction occurs. If any error message appears, refer to this chapter to find which parts should be checked or replaced. The latter half of this chapter provides sample problems which could occur in the main sections of the machine and related troubleshooting procedures.

- Page 26 4.7 Troubleshooting for Other Problems..............2-36 4.7.1 Machine does not turn ON ............... 2-36 4.7.2 Unusual noise is coming from the machine..........2-36 4.7.3 Cannot save data in USB flash memory ..........2-36 4.7.4 Cannot reset counters for periodic replacement parts ......2-36 4.7.5 Can not register..................

-

Page 27: Introduction

1. INTRODUCTION Troubleshooting is a collection of solution procedures that service personnel should follow if an error or malfunction occurs in the machine. It is difficult to determine troubleshooting procedures for all possible problems that may occur in the future. Therefore, this chapter describes typical problem cases and recovery procedures for these. -

Page 28: Checks Before Commencing Troubleshooting

Checks before Commencing Troubleshooting Check the following items before commencing repairs on the machine. Operating environment (1) The machine is placed on a flat, stable surface. (2) The machine is used in a clean environment where the temperature is between 5°C (41°F) and 35°C (95°F) and the relative humidity is maintained between 20% and 80%. -

Page 29: Overview

2. OVERVIEW Cross-section Drawing Document detection actuator Separation pad Front cover sensor Double feeding sensor (Sent) Pick-up roller Document scanning position actuator Top cover sensor Second side CIS unit Eject roller First side CIS unit Feed roller Double feeding sensor (Receive) Fig. -

Page 30: Paper Feeding

Paper Feeding Feed path Fig. 2-2 Confidential... -

Page 31: Operation Of Each Part

Operation of Each Part Part name Operation Pick-up roller / Separation Separates documents set in the document tray into single sheets, and feeds them into the machine. Double feeding sensor Detects whether multiple documents are fed into the machine. Feed roller Feeds the document. -

Page 32: Block Diagram

Block Diagram Double feeding sensor (sent) Document detection sensor Key PCB ASSY Home Document scanning position sensor Panel PCB ASSY Stop Buzzer Top cover sensor Touch panel ASSY LCD relay PCB ASSY Second side CIS unit Front cover Machine First side CIS unit USB host PCB ASSY Double feeding sensor PCB ASSY (Receive) -

Page 33: Main Components

Main Components Top cover Front cover Document Upper chute detection actuator earth spring Top cover Panel PCB ASSY actuator spring Document detection Double feeding actuator spring sensor (Sent) Document scanning position actuator Top cover actuator Key PCB ASSY Cover open lever shaft Top cover sensor Document scanning... -

Page 34: Error Indications

3. ERROR INDICATIONS The machine is equipped with self-diagnostic function. If the machine does not work normally, it judges that an error has occurred. Then indicates the corresponding error message on the LCD to help service men to quickly find out the problem. Error Codes Errors in the shaded columns do not usually occur during normal use. - Page 35 Error Refer Error Refer Problem Problem codes codes 4E00 An unidentified error occurred. 2-15 7600 An unidentified error occurred. 2-15 4F00 An unidentified error occurred. 2-15 7800 An unidentified error occurred. 2-15 5000 An unidentified error occurred. 2-15 7A00 An unidentified error occurred. 2-15 5100 An unidentified error occurred.

- Page 36 Error Refer Error Refer Problem Problem codes codes A black level not within the A000 An unidentified error occurred. 2-15 BD00 standard was scanned when 2-19 function code 55 was executed. A100 An unidentified error occurred. 2-15 BE00 An unidentified error occurred. 2-20 The document scanning position sensor A200...

- Page 37 Error Refer Error Refer Problem Problem codes codes DA00 An unidentified error occurred. 2-21 E900 An unidentified error occurred. 2-24 DB00 An unidentified error occurred. 2-21 EA00 An unidentified error occurred. 2-24 DC00 An unidentified error occurred. 2-21 EB00 An unidentified error occurred. 2-24 DD00 An unidentified error occurred.

-

Page 38: Error Messages

Error Messages The error messages displayed on the LCD of the machine and their description are shown in the table below. Error Refer Error Message Description codes Authentication User authentication failed. 2-35 Error Connection Error01 Unexpected error occurred in the network connection. 2-35 Connection Error02 Not connected to the network. - Page 39 Error Refer Error Message Description codes The page counter for the pick-up roller has reached the Replace Roller 2-36 limit. B000 2-18 The first side or second side CIS flat cable is not B800 2-18 Scanner Error connected correctly (This problem occurs only in B900 2-18 maintenance mode).

-

Page 40: Troubleshooting

4. TROUBLESHOOTING Error Cause and Remedy Error code 0B00 to 0D00 These errors do not usually occur during normal use. The possible causes are noise around the installation site, fluctuation of the power supply voltage, and failures in the software. An unidentified error occurred. - Page 41 Error code 3C00 to A100 These errors do not usually occur during normal use. The possible causes are noise around the installation site, fluctuation of the power supply voltage, and failures in the software. An unidentified error occurred. Step Cause Remedy Main PCB failure...

- Page 42 Error code A400 Cover is Open Close the front cover. The front cover sensor detected an open front cover. <User Check> • Close the front cover correctly. Step Cause Remedy Connection failure of the front Reconnect the front cover sensor harness. cover sensor harness Tab to push the front cover Replace the front cover.

- Page 43 Error code A900 Unable to Scan A9 See Troubleshooting in User's Guide. A scanning error occurred while scanning the image. Step Cause Remedy Program malfunction Reinstall the latest firmware. First side or second side CIS Replace the first side or second side CIS unit. unit failure Main PCB failure Replace the main PCB ASSY.

- Page 44 Error code AC00 to AF00 These errors do not usually occur during normal use. The possible causes are noise around the installation site, fluctuation of the power supply voltage, and failures in the software. An unidentified error occurred. Step Cause Remedy Main PCB failure...

- Page 45 Error code BA00 This error does not usually occur during normal use. The possible causes are noise around the installation site, fluctuation of the power supply voltage, and failures in the software. An unidentified error occurred. Step Cause Remedy Main PCB failure Replace the main PCB ASSY.

- Page 46 Error code BE00 to C600 These errors do not usually occur during normal use. The possible causes are noise around the installation site, fluctuation of the power supply voltage, and failures in the software. An unidentified error occurred. Step Cause Remedy Main PCB failure...

- Page 47 Error code CB00 to CF00 These errors do not usually occur during normal use. The possible causes are noise around the installation site, fluctuation of the power supply voltage, and failures in the software. An unidentified error occurred. Step Cause Remedy Main PCB failure...

- Page 48 Error code E001 Unable to Update 0001 Check the firmware update file and try again. The capacity of machine memory reached its maximum when installing the firmware. Error code E002 Unable to Update 0002 Check the firmware update file and try again. Designated folder could not be found in USB flash memory when installing the firmware.

- Page 49 Error code E008 Unable to Update E008 Firmware can not be installed as other function is running. Step Cause Remedy Main PCB failure Replace the main PCB ASSY. Error code E100 Program error Step Cause Remedy Firmware installation failure Reinstall the latest firmware.

- Page 50 Error code E700 to EC00 These errors do not usually occur during normal use. The possible causes are noise around the installation site, fluctuation of the power supply voltage, and failures in the software. An unidentified error occurred. Step Cause Remedy Main PCB failure...

- Page 51 Error code FA00 to FF00 These errors do not usually occur during normal use. The possible causes are noise around the installation site, fluctuation of the power supply voltage, and failures in the software. An unidentified error occurred. Step Cause Remedy Main PCB failure...

-

Page 52: Troubleshooting For Image Defects

Troubleshooting for Image Defects 4.2.1 Defect examples Light Faulty registration Dark or bluish white Completely Vertical streaks White vertical blank streaks Hue defect Expanded image Fig. 2-5 4.2.2 Troubleshooting according to image defect Light <User Check> - Check that the contrast setting is not too light. - Clean the CIS glass. - Page 53 Faulty registration Step Cause Remedy Document scanning position Reattach the document scanning position actuator caught in sections of the actuator. machine Dark or bluish white <User Check> - Check that the contrast setting is not too dark. Step Cause Remedy Incorrect white level correction data Execute the maintenance mode function...

- Page 54 Vertical streaks <User Check> - Clean the CIS glass. - Clean the document pressure bar. Step Cause Remedy First side or second side CIS unit Replace the first side or second side CIS failure unit. White vertical streaks <User Check>...

- Page 55 Expanded image Step Cause Remedy The maintenance mode function Execute the maintenance mode function "Acquire white level data and set "Acquire white level data and set CIS scan CIS scan area" are not set. area". (Refer to "1.3.11" in Chapter The firmware is outdated Install the latest version firmware.

-

Page 56: Troubleshooting For Document Paper Feeding Problems

Troubleshooting for Document Paper Feeding Problems 4.3.1 Multiple documents are fed <User Check> - Check that paper used for the document is not thinner than the standard. If it is too thin, use a carrier sheet. - Check that the document is not damp. If it is damp, dry it or use a carrier sheet. - Check that the machine is not scanning a glossy paper used in magazines and others. -

Page 57: Document Becomes Jammed

4.3.3 Document becomes jammed <User Check> - Check that the document size is within the standard. If it is too small, use a carrier sheet. - Check that the document is not wrinkled. If wrinkled, use a carrier sheet. - Check that the document is not torn. If torn, use a carrier sheet. - Check that the front cover is closed correctly. -

Page 58: Document Is Not Picked Up And Fed

4.3.4 Document is not picked up and fed <User Check> - Check that paper used for the document is not thinner than the standard. If it is too thin, use a carrier sheet. - Check that the front cover is closed correctly. - Check that the separation pad cover is closed correctly. -

Page 59: Troubleshooting For Software Problems

Troubleshooting for Software Problems End users can solve problems related to software, for instance, scanning is not possible from a computer although scanning can be performed from the machine, as long as they follow the User Check items. If the problem still cannot be solved, follow each procedure according to the step number in the tables below. -

Page 60: Troubleshooting For Control Panel Problems

Troubleshooting for Control Panel Problems 4.5.1 Nothing is displayed on the LCD <User Check> - Check that the AC power cord is connected correctly. Step Cause Remedy AC power cord failure Replace the AC power cord. Connection failure of the key PCB Reconnect the key PCB harness. -

Page 61: Touch Panel Is Inoperable

4.5.3 Touch panel is inoperable Step Cause Remedy Key PCB attachment failure Reattach the key PCB. Connection failure of the key PCB Reconnect the key PCB harness. harness Connection failure of the touch Reconnect the touch panel sensor FPC. panel sensor FPC Connection failure of the front cover Reconnect the front cover sensor harness. -

Page 62: Troubleshooting For Other Problems

Troubleshooting for Other Problems 4.7.1 Machine does not turn ON <User Check> - Connect the AC power cord correctly. Step Cause Remedy Connection failure of the panel PCB Reconnect the panel PCB harness. harness Connection failure of the top cover Reconnect the top cover sensor harness. -

Page 63: Can Not Register

4.7.5 Can not register <User Check> - Check that the number of items registered has not been exceeded. - Check the network connection. - Check the relevant section in the Network Setting Guide. Step Cause Remedy Main PCB failure Replace the main PCB ASSY. 4.7.6 Machine does not operate <User Check>... -

Page 64: Chapter 3 Disassembly/Reassembly

CHAPTER DISASSEMBLY/REASSEMBLY Confidential... - Page 65 CHAPTER 3 DISASSEMBLY/REASSEMBLY This chapter describes procedures for disassembling and reassembling the machine with related notes. The provided disassembly order flow enables you to take in the disassembly procedure of related part at a glance. At the start of disassembling, you can check the disassembly order flow which guides you through a shortcut to get to the part.

- Page 66 9.19 Main motor ........................ 3-39 9.20 Front cover sensor ....................3-40 9.21 Double feeding sensor PCB ASSY (Receive)............3-41 9.22 First side CIS unit...................... 3-42 9.23 One way clutch ......................3-43 Confidential...

-

Page 67: Safety Precautions

1. SAFETY PRECAUTIONS To avoid creating secondary problems by mishandling, follow the warnings and precautions below during maintenance work. • Be careful not to lose screws, washers, or other parts removed. • Be sure to apply grease to applicable positions specified in this chapter. •... -

Page 68: Packing

2. PACKING Confidential... -

Page 69: Screw Catalogue

3. SCREW CATALOGUE Screw pan (S/P washer) Taptite bind B Screw pan (S/P washer) Taptite bind B M3x6DA M3x10 Screw pan (S/P washer) Taptite bind B M3.5x6 M4x12 Taptite cup B Taptite cup B M3x10 Taptite cup S Taptite cup S M3x6 Confidential... -

Page 70: Screw Torque List

4. SCREW TORQUE LIST Note: • To check the shape of each screw, refer to "3. SCREW CATALOGUE" in this chapter. Tightening Location of screw Screw type Q'ty torque N · m (kgf · cm) Bottom cover Taptite cup B M3x10 0.50.1 (51) Side cover L Taptite cup B M3x10... -

Page 71: Lubrication

5. LUBRICATION Lubrication oil type Lubrication point Quantity of lubrication (Maker name) FLOIL GE-676 (Kanto Kasei) One way clutch 1 place 1.5 mm dia. ball One way clutch Fig. 3-1 Confidential... -

Page 72: Overview Of Gears

6. OVERVIEW OF GEARS One way clutch Gear 60/20 LD6056 LD6054 Feed roller gear LD6070 Gear 67 LD6053 Eject roller gear LD6070 Gear 20/50 Gear 40/24 LD6051 LD6052 * Part codes of these gears are subject to change without notice. Fig. -

Page 73: Harness Routing

7. HARNESS ROUTING Main PCB ASSY Double feeding sensor harness Second side CIS flat cable (Receive) (RD, WH, BK, NB) USB host PCB harness First side CIS flat cable (GN, RD, WH, BK, YG) Front cover sensor harness (WH) Power supply PCB harness (WH) Earth harness (GN) Main motor... - Page 74 Panel PCB ASSY Document detection Double feeding sensor sensor harness (WH) Panel flat cable harness (Sent) (WH) Top cover sensor harness (WH) Panel PCB harness (WH) Earth harness (BL) Earth harness (BK) Earth harness (WH) Document scanning position sensor harness (YW) Frame R Front cover sensor Core...

- Page 75 Power supply unit Power supply harness holder Power harness (BL, BR) Power supply PCB ASSY Wireless LAN PCB ASSY Wireless LAN PCB ASSY Wireless LAN harness Harness colors are subject to change for some reason. Confidential...

-

Page 76: Disassembly Flow Chart

8. DISASSEMBLY FLOW CHART Disassembly / Re-Assembly (second) 9.2 Separation 9.3 Pick-up roller 9.13 Separation 9.14 Second side 9.15 Top cover arm / Separation ASSY pad ASSY CIS unit 20/20 spring 10/10 5/10 9.15 Document guide LS / Document guide RS 9.4 Output tray 15/15 9.7 Main PCB... -

Page 77: Disassembly Procedure

9. DISASSEMBLY PROCEDURE Preparation Disconnecting Cables and Removing Accessories Prior to proceeding with the disassembly procedure, (1) Disconnect the following: • AC power cord • USB cable (if connected) • LAN cable (if connected) LAN cable USB cable AC power cord Fig. -

Page 78: Separation Pad Assy

Separation pad ASSY (1) Open the top cover, and push the cover release lever to open the front cover. (2) Push the two hooks on the separation pad cover inward to open it. Hooks Front cover Separation pad cover Top cover Cover release lever Fig. - Page 79 (3) Push the two hooks on the separation arm inward to open the separation arm, and remove the separation spring from the front cover. Note: • Be careful not to damage the separation arm by opening it too much. • Do not close the front cover when the separation arm is opened to prevent the separation arm to be damaged.

-

Page 80: Pick-Up Roller Assy

Pick-up roller ASSY (1) Slide the document guide L and R outward. (2) Push the two hooks inward to open the pick-up roller cover ASSY. Slide the pick-up roller cover ASSY in the direction of arrow 2a to remove the boss A, and in the direction of arrow 2b to remove the boss B. -

Page 81: Output Tray

Output tray (1) Turn over the machine to pull out the output tray. Note: • When turning over the machine, spread a sheet to prevent the top cover to be scratched. (2) Remove the four taptite cup B M3x10 screws, and remove the bottom cover from the machine. -

Page 82: Side Cover L

Side cover L (1) Turn over the machine and open the top cover. Push the cover release lever to open the front cover. (2) Remove the taptite cup B M3x10 screw, and release the hook A to open the bottom. Release the remaining four hooks by swinging the side cover L in the direction of the arrow, and remove the side cover L from the machine. -

Page 83: Main Pcb Assy

Main PCB ASSY (1) Turn over the machine. Remove the two taptite cup S M3x6 screws, and remove the earth harness (BL) and the main PCB shield plate. Note: • When turning over the machine, spread a sheet to prevent top cover to be scratched. - Page 84 (2) Disconnect all harnesses and flat cables connected to the main PCB ASSY. Power supply PCB harness Main motor Main PCB ASSY harness Panel PCB Wireless LAN harness harness Front cover sensor harness USB host Second side Double feeding sensor First side CIS PCB harness CIS flat cable...

-

Page 85: Usb Host Pcb Assy

USB host PCB ASSY (1) Remove the taptite bind B M3x10 screw to remove the earth harness (BK). (2) Release the USB host PCB harness, the front cover sensor harness, the double feeding sensor harness (Receive), and the earth harness (BK) from the securing fixtures. (3) Remove the two taptite bind B M4x12 screws. -

Page 86: Wireless Lan Pcb Assy

Wireless LAN PCB ASSY (1) Release the hook to remove the wireless LAN PCB ASSY. (2) Disconnect the wireless LAN harness from the wireless LAN PCB ASSY. Wireless LAN PCB ASSY Hook Wireless LAN harness Fig. 3-15 HARNESS ROUTING: Refer to “5. -

Page 87: Front Cover L/R

9.10 Front cover L/R (1) Slide the front cover L in the direction of arrow 1a. Engage the rib on the front cover L with the notch on the machine to pull out and remove the front cover L from the machine in the direction of arrow 1b. -

Page 88: Panel Assy

9.11 Panel ASSY (1) Remove the taptite bind B M3x10 screw, then remove the earth harness (YW). (2) Release the hook to remove the core of the second side CIS flat cable from the machine, then release the second side CIS flat cable, the panel PCB harness, the earth harness (BL), and the earth harness (YW) from the securing fixtures. - Page 89 (6) Remove the two taptite bind B M3x10 screws, and release the four hooks. Slide the upper chute in the direction of the arrow and release the six tabs from the upper chute. Taptite bind B M3x10 Upper chute Tabs Tabs Hooks Panel ASSY...

- Page 90 (7) Open the upper chute from the panel ASSY. (8) Remove the taptite cup S M3x6 screw to remove the earth harness (BL), and then pull out the earth harness (BL) from the hole on the upper chute. (9) Remove the two panel harness holders, and disconnect the panel PCB harness from the panel PCB ASSY, and then pull out the panel PCB harness from the hole on the upper chute.

-

Page 91: Panel Pcb Assy / Key Pcb Assy / Rubber Key / Top Cover Sensor / Top Cover Actuator

9.12 Panel PCB ASSY / Key PCB ASSY / Rubber key / Top cover sensor / Top cover actuator (1) Disconnect the panel flat cable from the panel PCB ASSY and the key PCB ASSY. (2) Remove the two taptite cup S M3x6 screws and the two taptite bind B M3x10 screws to remove the panel PCB shield. - Page 92 (8) Remove the taptite bind B M3x10 screw to remove the top cover sensor holder from the panel ASSY. (9) Release the two hooks to remove the top cover sensor from the top cover sensor holder. (10) Lift the top cover actuator and remove it from the boss on the panel ASSY along with the top cover actuator spring.

-

Page 93: Document Detection Sensor Pcb / Document Detection Actuator / Document Scanning Position Sensor Pcb / Document Scanning Position Actuator / Double Feeding Sensor (Sent) / Separation Pad Assy

9.13 Document detection sensor PCB / Document detection actuator / Document scanning position sensor PCB / Document scanning position actuator / Double feeding sensor (Sent) / Separation pad ASSY (1) Remove the document detection sensor harness, the document scanning position sensor harness, and the double feeding sensor harness (Sent) from the upper chute film, and release the upper chute film from the two hooks on the upper chute. - Page 94 (6) Remove the taptite cup S M3x6 screw, and lift the upper chute earth spring. (7) Push the two hooks on the upper chute outward, and remove the cover open lever shaft from the upper chute. (8) Remove the upper chute earth spring from the upper chute. (9) Remove the two taptite bind B M3x10 screws, and remove the double feeding sensor holder from the upper chute.

- Page 95 (11) Push the two hooks on the separation pad cover inward to open the separation pad cover. (12) Engage the separation pad cover with the groove on the upper chute, and slide it in the direction of arrow 12b while pulling its shaft in the direction of arrow 12a using spring peg or other tools.

- Page 96 (14) Release the hook, then remove the document detection actuator and the document detection actuator spring from the upper chute. (15) Remove the document detection actuator spring from the document detection actuator. (16) Remove the two taptite bind B M3x10 screws. Then remove the earth harness (WH) and the pinch roller support plate from the upper chute.

- Page 97 (19) Remove the double feeding sensor earth spring from the upper chute. (20) Remove the two pinch roller springs to remove the pinch roller shaft from the upper chute. Pinch roller shaft Pinch roller spring Pinch roller spring Double feeding sensor earth spring Upper chute Fig.

-

Page 98: Second Side Cis Unit

9.14 Second side CIS unit (1) Turn over the upper chute. (2) Release the two hooks, lift the second side CIS unit, and disconnect the second side CIS flat cable from it. (3) Pull out the second side CIS flat cable from the hole on the upper chute. (4) Remove the CIS spring from the upper chute. -

Page 99: Top Cover / Document Guide Ls / Document Guide Rs

9.15 Top cover / Document guide LS / Document guide RS (1) Slide the document guide L and R inward. (2) Remove the boss on the left side of the top cover, the hook on the document guide L, the hook on the document guide R, and the boss on the right side of the top cover in this order, then remove the top cover from the machine. -

Page 100: Back Cover S

9.16 Back cover S (1) Push both arms of the back cover S outward to remove them from the both bosses, and remove the back cover S from the machine. (2) Remove the back cover S spring from the back cover S. Back cover S Boss Back cover S spring... -

Page 101: Back Cover

9.17 Back cover (1) Remove the four taptite cup B M3x10 screws, and release the two hooks A to open the bottom. Then release the upper three hooks from the three ribs to remove the back cover from the machine. (2) Remove the taptite cup B M3x10 screw, and remove the security slot earth plate from the back cover. -

Page 102: Power Supply Pcb Assy

9.18 Power supply PCB ASSY (1) Turn over the machine to remove the main PCB shield frame and the USB earth plate from Main PCB shield frame Hook Main PCB shield frame USB earth plate Hook Fig. 3-34 Assembling Note: •... - Page 103 (2) Disconnect the power supply PCB harness from the guide behind the machine, and pull it out from the hole on the machine. (3) Remove the screw pan (S/P washer) M3.5x6 screw and the four taptite bind B M3x10 screws to remove the power supply earth harness, the main PCB earth plate, and the power supply unit from the machine.

-

Page 104: Power Supply Pcb Assy

(4) Remove the power supply harness guide while pushing the hook. Disconnect the power supply PCB harness from the power supply PCB ASSY, and remove the power supply upper frame from the power supply lower frame. (5) Release the power harness from the securing fixture, and remove the power supply harness holder. -

Page 105: Main Motor

9.19 Main motor (1) Remove the taptite cup S M3x6 screw to remove the earth harness (YW). (2) Release the main motor harness from the securing fixtures, and pull it out from the main motor. (3) Release the hook to remove the core of the first side CIS flat cable from the lower frame. (4) Remove the four taptite cup B M3x10 screws to remove the lower frame from the lower chute ASSY. -

Page 106: Front Cover Sensor

9.20 Front cover sensor (1) Remove the taptite cup B M3x10 screw to remove the front cover sensor holder from the lower chute ASSY. (2) Release the two hooks to remove the front cover sensor from the front cover sensor holder. Hook Front cover sensor Hook... -

Page 107: Double Feeding Sensor Pcb Assy (Receive)

9.21 Double feeding sensor PCB ASSY (Receive) (1) Remove the two taptite bind B M3x10 screws to remove the CIS earth plate and the double feeding sensor upper shield from the lower chute ASSY. (2) Remove the double feeding sensor PCB ASSY (Receive), and pull out the double feeding sensor harness (Receive) from the hole on the lower chute ASSY. -

Page 108: First Side Cis Unit

9.22 First side CIS unit (1) Turn over the lower chute ASSY. Release the hook from the hole on the lower chute ASSY, and remove the first side CIS unit from the lower chute ASSY while lifting and pulling it in the direction of the arrow. -

Page 109: One Way Clutch

9.23 One way clutch (1) Release the hook to remove the gear 60/20 from the lower chute ASSY. (2) Release the hook to remove the one way clutch from the lower chute ASSY. Lower chute ASSY Separate Gear 60/20 roller shaft Hook Hook One way clutch... -

Page 110: Chapter 4 Adjusting And Updating Settings As Required After Parts Replacement

CHAPTER ADJUSTING AND UPDATING SETTINGS AS REQUIRED AFTER PARTS REPLACEMENT Confidential... - Page 111 CHAPTER 4 ADJUSTING AND UPDATING SETTINGS AS REQUIRED AFTER PARTS REPLACEMENT This chapter describes adjustments and updating of settings, which are required if the main PCB ASSY and some other parts have been replaced. CONTENTS 1. IF YOU REPLACE THE MAIN PCB ASSY..............4-1 1.1 Installing Firmware ....................

-

Page 112: If You Replace The Main Pcb Assy

1. IF YOU REPLACE THE MAIN PCB ASSY <What to do after replacement> • Installing firmware (Panel Main Firm / Main Firm) • Setting by country • Initializing the EEPROM of the main PCB ASSY • Setting serial number • Acquiring white level data •... -

Page 113: Installing Firmware

Installing Firmware 1.1.1 Checking firmware version Check whether the firmware installed on the main PCB is the latest version. If it is the latest version, there is no need to install the firmware. If it is not, be sure to install the firmware to the main PCB as described in "1.1.2 Installing firmware"... -

Page 114: Installing Firmware

(12) Open the temporary folder and double-click "Filedg32.exe" to start it, then select the "Brother Maintenance USB Printer". (13) Drag and drop the main firmware (LZXXXX_$.upd) in the same folder onto the "Brother Maintenance USB Printer" icon. The firmware file is loaded to the machine, and installing to the flash ROM starts. -

Page 115: Setting Serial Number

(3) In the [Product Category] field, select the [4 Other-Model]. (4) Select [ADS 2012 MODEL] in the left bottom field of the BrUsbSn. (5) In the [Port] field, select the port number assigned to the Brother Maintenance USB Printer. If the port number is unknown, follow the steps below to check it. -

Page 116: Acquiring White Level Data

Acquiring White Level Data <ADS-2500W/2600W> (1) Press the [5] key twice in the initial state of maintenance mode. (2) Press the [Start] key. "SCANNER AREA SET" is displayed on the LCD, and white level data is acquired. The machine returns to the initial state of maintenance mode. <ADS-2500WE/2600WE>... - Page 117 Setting Double Feeding Sensor Threshold (1) Connect the machine to your computer using the USB cable in the initial state of maintenance mode. (2) Double-click "BrADSmt1.exe" that was saved into the computer to start it. (3) Select the model name in the [Select model:] box, and click the [Start] button. The double feeding sensor threshold is reset.

-

Page 118: Checking Operation After Repair

Checking Operation after Repair Perform the steps below to check the machine's condition after repair or adjustment. (1) Prepare two DS-001 (LD1625001) test charts and set them to the document tray so that both sides of the test chart can be scanned. (2) Press and hold the key for approximately five seconds while the machine is in the ready state. - Page 119 (10) After the scanning, compare the scanned data on the test chart which framed red in the figure below with the ones in the limit sample. If the result is worse than the limit sample, perform procedures in "Acquire white level data and set CIS scan area" again. And then wipe the first and second side CIS glass with a dry cleaning cloth four times in the same direction, and follow the instructions above again to scan.

-

Page 120: If You Replace The Cis Unit

2. IF YOU REPLACE THE CIS UNIT <What to do after replacement> • Checking firmware version • Acquiring white level data (function code: 55) • Checking operation after repair Checking Firmware Version Check whether the firmware installed on the main PCB for ADS-2500W/2600W is F version or later, and the one for ADS-2500WE/2600WE is E version. -

Page 121: Acquiring White Level Data

Acquiring White Level Data (function code: 55) <ADS-2500W/2600W> (1) Press the [5] key twice in the maintenance mode. "Press START" is displayed on the LCD. (2) Press the [Start] key. "SCANNER AREA SET" is displayed on the LCD, and white level data is acquired. -

Page 122: Checking Operation After Repair

Checking Operation after Repair Perform the steps below to check the machine's condition after repair or adjustment. (1) Prepare two DS-001 (LD1625001) test charts and set them to the document tray so that both sides of the test chart can be scanned. (2) Press and hold the key for approximately five seconds while the machine is in the ready state. - Page 123 (10) After the scanning, compare the scanned data on the test chart which framed red in the figure below with the ones in the limit sample. If the result is worse than the limit sample, perform procedures in "Acquire white level data and set CIS scan area" again. And then wipe the first and second side CIS glass with a dry cleaning cloth four times in the same direction, and follow the instructions above again to scan.

-

Page 124: If You Replace The Double Feeding Sensor

3. IF YOU REPLACE THE DOUBLE FEEDING SENSOR <What to do after replacement> • Setting double feeding sensor threshold • Checking double feeding function What you need to prepare (1) Sheet for double feeding sensor threshold setting (LD6340001) (2) Double feeding sensor threshold setting tool (BrADSmt1.exe) Copy this file into the temporary folder created on the C drive. -

Page 125: Checking Double Feeding Sensor Operation

When the setting is completed normally, "OK" is displayed on the screen. If any error is detected during setting, "ERROR" is displayed on the screen. (7) Unplug the AC power cord of the machine. Checking Double Feeding Sensor Operation Perform the steps below to check the machine's condition after repair or adjustment. (1) Set the sheet for double feeding sensor threshold setting in the ADF, and execute the maintenance mode function "Check ADF"... -

Page 126: If You Replace The Panel Assy

4. IF YOU REPLACE THE PANEL ASSY <What to do after replacement> • Adjusting touch panel (function code: 61) • Checking LCD operation (function code: 12) • Checking control panel operation (function code: 13) What you need to prepare (1) Touch panel stylus Adjusting Touch Panel (1) Press the [6], and then the [1] key in the initial state of maintenance mode. -

Page 127: If You Replace The Pick-Up Roller / Separation Pad

5. IF YOU REPLACE THE PICK-UP ROLLER / SEPARATION PAD <What to do after replacement> • Resetting pick-up roller / separation pad counters Resetting Pick-up Roller / Separation Pad Counters Refer to the User's Guide to reset the pick-up roller and separation pad counters. 4-16 Confidential... -

Page 128: Service Functions

CHAPTER SERVICE FUNCTIONS Confidential... - Page 129 CHAPTER 5 SERVICE FUNCTIONS This chapter describes the maintenance mode which is exclusively designed for the purpose of checking the settings and adjustments using the buttons on the control panel. This chapter also covers not-disclosed-to-users function menus, which activate settings and functions or reset the parts life.

-

Page 130: Maintenance Mode

1. MAINTENANCE MODE Maintenance mode is exclusively designed for checking, setting, and adjusting the machine using the buttons on the control panel. These buttons allow you to execute sensor operation check, test printing, log information and error code display, or worker switch (WSW) setting. How to Enter Maintenance Mode 1.1.1 Method of entering end-user accessible maintenance mode The maintenance mode functions should only be accessed by service personnel. -

Page 131: Method Of Entering Maintenance Mode For Service Personnel

1.1.2 Method of entering maintenance mode for service personnel <Operating Procedure> (1) While the machine is in the ready state, press and hold the button. The following display appears on the LCD. (2) Press and hold the 4th box with no display. The following display appears on the LCD. (3) Press the [*], [2], [8], [6], and [4] keys on the LCD in this order. -

Page 132: List Of Maintenance Mode Functions

List of Maintenance Mode Functions Function code Function Refer to: Initialize EEPROM parameters ADF performance test Set worker switches (WSW) Check LCD operation Check control panel button operation Save NetConfig data Display software version Check sensor operation 5-10 Change USB No. return value / Adjust left-end print start 5-11 position on second side when duplex printing Fine-tune scanning position... -

Page 133: Details Of Maintenance Mode Functions

Details of Maintenance Mode Functions 1.3.1 Initialize EEPROM parameters (function code: 01, 91) <Function> This function is used to initialize the setting values for operation parameters, user switches, and worker switches (WSW) registered in the EEPROM. Entering function code 01 initializes most EEPROM areas. -

Page 134: Adf Performance Test (Function Code: 08)

1.3.2 ADF performance test (function code: 08) <Function> This function is used to test the performance of the automatic document feeder (ADF). The scanned pages of documents fed by the ADF are counted and the result is displayed on the LCD. -

Page 135: Set Worker Switches (Wsw) (Function Code: 10)

1.3.3 Set worker switches (WSW) (function code: 10) <Function> Worker switches shown in the table below can be used to set functions to satisfy various requirements. The switch setting can be changed using the buttons on the control panel. Worker switches are factory set to conform with the laws and regulations of the country the machine is shipped to. -

Page 136: Check Lcd Operation (Function Code: 12)

1.3.4 Check LCD operation (function code: 12) <Function> This function is used to check that the LCD on the control panel is operating normally. <Operating Procedure> (1) Press the [1], and then the [2] key in the initial state of maintenance mode. Displays shown in the table below appear on the LCD. -

Page 137: Check Control Panel Button Operation (Function Code: 13)

1.3.5 Check control panel button operation (function code: 13) <Function> This function is used to check that the buttons on the control panel operate normally. <Operating Procedure> (1) Press the [1], and then the [3] key in the initial state of maintenance mode. "00" is displayed on the LCD. -

Page 138: Display Software Version (Function Code: 25)

1.3.7 Display software version (function code: 25) <Function> This function is used to check the firmware creation date and check sum information. <Operating Procedure> (1) Press the [2], and then the [5] key in the initial state of maintenance mode. The firmware version is displayed on LCD as "TOTAL:Ver*". -

Page 139: Check Sensor Operation (Function Code: 32)

1.3.8 Check sensor operation (function code: 32) <Function> This function is used to check that sensors are operating normally. <Operating Procedure> (1) Press the [3], and then the [2] key in the initial state of maintenance mode. The sensor operating conditions defined in the table below are applied, and "DFDRACTC" is displayed on the LCD. -

Page 140: Change Usb No. Return Value / Adjust Left-End Print Start Position On Second Side When Duplex Printing (Function Code: 45)

1.3.9 Change USB No. return value / Adjust left-end print start position on second side when duplex printing (function code: 45) Change USB No. return value <Function> ® When the operating system (OS) installed on the computer is Windows Vista , and the machine is connected to this computer using USB2.0FULL, the OS may not be able to obtain the USB device serial number depending on the computer and USB device. -

Page 141: Fine-Tune Scanning Position (Function Code: 54)

1.3.10 Fine-tune scanning position (function code: 54) <Function> This function is used to adjust the scanning start/end positions. <Operating Procedure> (1) Press the [5], and then the [4] key in the initial state of maintenance mode. "SCAN ADJ SELECT" is displayed on the LCD. After two seconds, "SUB"... -

Page 142: Acquire White Level Data And Set Cis Scan Area (Function Code: 55)

1.3.11 Acquire white level data and set CIS scan area (function code: 55) ADS-2500W/2600W ■ <Function> This function is used to obtain the white level of the CIS scanner, and store this data and the scan area in the EEPROM of the main PCB. <Operating Procedure>... - Page 143 (6) Close the ADF cover and press the [Start] key. The machine saves the scanning compensation data to EEPROM and returns to the initial state of maintenance mode. (7) Turn OFF the power of the machine to finish it. Note: •...

-

Page 144: Adjust Touch Panel (Function Code: 61)

• This adjustment requires a touch panel stylus with a thin tip. A commercially available stylus designed for electronic dictionaries or personal digital assistance (PDA) can be used. If one is not available at hand, order a "STYLUS" from Brother's parts list. <Operating Procedure>... -

Page 145: Setting By Country (Function Code: 74)

0103 Korea 0121 Austria 0103 Russia 0148 Denmark 0103 GENERAL 0103 Spain 0103 India 0121 Italy 0103 South Africa 0141 Portugal 0103 This code list is current as of July 2012. Please contact Brother for the latest information. 5-16 Confidential... -

Page 146: Display Machine Log Information (Function Code: 80)

1.3.14 Display machine log information (function code: 80) <Function> This function is used to display the log information on the LCD. <Operating Procedure> (1) Press the [8], and then the [0] key in the initial state of maintenance mode. "00:00 22:36 OK" is displayed on the LCD. (2) Pressing the [ ] key displays the next item. -

Page 147: Display Machine Error Code (Function Code: 82)

1.3.15 Display machine error code (function code: 82) <Function> This function is used to display the latest error code on the LCD. <Operating Procedure> (1) Press the [8], and then the [2] key in the initial state of maintenance mode. "MACHINE ERR XXXX"... -

Page 148: Wiring Diagram

CHAPTER WIRING DIAGRAM Confidential... - Page 149 CHAPTER 6 WIRING DIAGRAM This chapter provides the wiring diagram for the connections of the PCBs. CONTENTS 1. WIRING DIAGRAM ....................... 6-1 Confidential...

- Page 150 1. WIRING DIAGRAM Confidential...

- Page 151 CHAPTER PERIODICAL MAINTENANCE Confidential...

-

Page 152: Periodical Maintenance Parts

CHAPTER 7 PERIODICAL MAINTENANCE CONTENTS 1. PERIODICAL MAINTENANCE PARTS ................ 7-1 Confidential... - Page 153 1. PERIODICAL MAINTENANCE PARTS There are no parts that must be replaced periodically. Confidential...

- Page 154 APPENDIX SERIAL NUMBERING SYSTEM Confidential...

- Page 155 APPENDIX 1 SERIAL NUMBERING SYSTEM Serial number label (1 location) <How to Read> Serial number Product identification Serial number (6-digit) code Manufacturing factory No. Year of manufacture 2: 2012 3: 2013 Month of manufacture A : January E : May J : September B : February F : June...

- Page 156 APPENDIX DELETING USER SETTING INFORMATION This appendix provides instructions on how to delete user setting information recorded in the machine. Confidential...

- Page 157 APPENDIX 2 DELETING USER SETTING INFORMATION Initializes setting values registered in EEPROM including operation parameter and user switch. <Operation Procedure> (1) Press the key. (2) Press the [ ] or [ ] key to display "Initial Setup" on the LCD, and press the [Initial Setup] box.

- Page 158 APPENDIX INSTALLING MAINTENANCE DRIVER Confidential...

-

Page 159: Operating Procedure

APPENDIX 3 INSTALLING MAINTENANCE DRIVER To identify multiple terminals connected to the computer via USB, the computer needs to configure the corresponding number of virtual USB devices using a driver or software. If you connect multiple machines to your computer, the same number of virtual USB devices will be automatically configured on your computer.