Table of Contents

Advertisement

SERVICE MANUAL

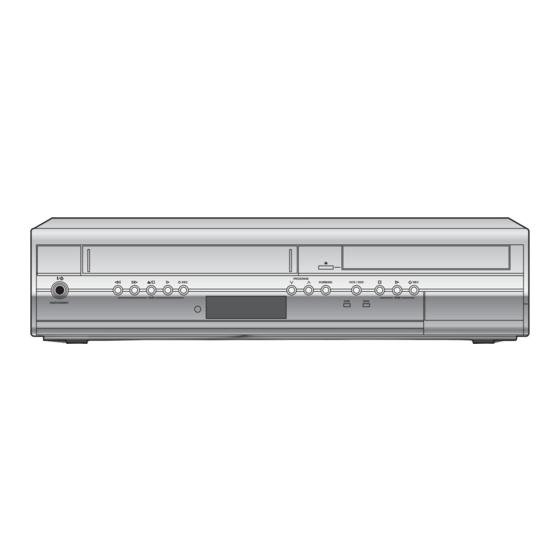

/Video Cassette Recorder

The above models are classified as green products (*1), as indicated by the underlined serial

numbers. This Service Manual describes replacement parts for the green products. When

repairing these green product(s), use the part(s) described in this manual and lead-free solder (*2).

For (*1) and (*2), see the next page.

TOSHIBA CORPORATION 2007

DVD Video Recorder

REC

VCR

FILE NO. 810-200742GR

D-VR50KF

D-VR51KF

PROGRAM

DUBBING

VCR / DVD

REC

DVD

VCR

DVD

Published in Japan, May 2007 GREEN

PAL

SECAM

Advertisement

Chapters

Table of Contents

Summary of Contents for Toshiba D-VR50KF

- Page 1 This Service Manual describes replacement parts for the green products. When repairing these green product(s), use the part(s) described in this manual and lead-free solder (*2). For (*1) and (*2), see the next page. Published in Japan, May 2007 GREEN TOSHIBA CORPORATION 2007...

- Page 2 Hazardous Substances. From July 1, 2006, the RoHS Directive will prohibit any marketing of new products containing the restricted substances. Increasing attention is given to issues related to the global environmental. Toshiba Corporation recognizes environmental protection as a key management tasks, and is doing its utmost to enhance and improve the quality and scope of its environmental activities.

-

Page 3: Table Of Contents

MAIN SECTION DVD VIDEO RECORDER & VIDEO CASSETTE RECORDER D-VR50KF/D-VR51KF Main Section I Specifications I Preparation for Servicing I Adjustment Procedures I Schematic Diagrams I BOARD’s I Exploded Views I Parts List TABLE OF CONTENTS Specifications ................1-1-1 Laser Beam Safety Precautions. -

Page 4: Specifications

SPECIFICATIONS General Input/Output System Front Panel : (AV3) DVD-Video, DVD-RW/R, DVD+RW/R, CD-DA, CD-RW/R, Video input Video Cassette Tape One RCA connector Input level : 1Vp-p (75 Ω) VCR Video Heads Four heads S-Video input Power requirements One Mini DIN 4-pin jack Y (Iuminance) 1Vp-p (75 Ω) 220–240V ±... -

Page 5: Laser Beam Safety Precautions

LASER BEAM SAFETY PRECAUTIONS This DVD player uses a pickup that emits a laser beam. Do not look directly at the laser beam coming from the pickup or allow it to strike against your skin. The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep your eyes at least 30 cm away from the pickup lens when the diode is turned on. -

Page 6: Important Safety Precautions

IMPORTANT SAFETY PRECAUTIONS Product Safety Notice K. When connecting or disconnecting the internal connectors, first, disconnect the AC plug from the Some electrical and mechanical parts have special AC outlet. safety-related characteristics which are often not evi- dent from visual inspection, nor can the protection they give necessarily be obtained by replacing them with components rated for higher voltage, wattage, etc. -

Page 7: Safety Check After Servicing

Safety Check after Servicing Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, Chassis or Secondary Conductor parts, and wires have been returned to their original positions. Afterwards, do the following tests and con- Primary Circuit firm the specified values to verify compliance with safety standards. -

Page 8: Standard Notes For Servicing

STANDARD NOTES FOR SERVICING NOTE: BOARD MEANS PRINTED CIRCUIT BOARD. Circuit Board Indications Pb (Lead) Free Solder 1. The output pin of the 3 pin Regulator ICs is When soldering, be sure to use the Pb free solder. indicated as shown. How to Remove / Install Flat Pack-IC Top View Bottom View... - Page 9 3. The flat pack-IC on the BOARD is affixed with With Soldering Iron: glue, so be careful not to break or damage the foil 1. Using desoldering braid, remove the solder from of each pin or the solder lands under the IC when all pins of the flat pack-IC.

- Page 10 With Iron Wire: 2. Installation 1. Using desoldering braid, remove the solder from 1. Using desoldering braid, remove the solder from all pins of the flat pack-IC. When you use solder the foil of each pin of the flat pack-IC on the flux which is applied to all pins of the flat pack-IC, BOARD so you can install a replacement flat pack- you can remove it easily.

- Page 11 Instructions for Handling Semi- conductors Electrostatic breakdown of the semi-conductors may occur due to a potential difference caused by electrostatic charge during unpacking or repair work. 1. Ground for Human Body Be sure to wear a grounding band (1 MΩ) that is properly grounded to remove any static electricity that may be charged on the body.

-

Page 12: Preparation For Servicing

PREPARATION FOR SERVICING How to Enter the Service Mode About Optical Sensors Caution: An optical sensor system is used for the Tape Start and End Sensors on this equipment. Carefully read and follow the instructions below. Otherwise the unit may operate erratically. What to do for preparation Insert a tape into the Deck Mechanism Assembly and press the [ O ] (VCR) button. -

Page 13: Cabinet Disassembly Instructions

CABINET DISASSEMBLY INSTRUCTIONS NOTE: BOARD MEANS PRINTED CIRCUIT BOARD. 1. Disassembly Flowchart REMOVAL This flowchart indicates the disassembly steps to gain REMOVE/*UNHOOK/ LOC. PART Fig. access to item(s) to be serviced. When reassembling, UNLOCK/RELEASE/ Note follow the steps in reverse order. Bend, route, and UNPLUG/DESOLDER dress the cables as they were originally. - Page 14 Reference Notes CAUTION 1: Locking Tabs (L-1) and (L-2) are fragile. [4] Jack Bracket Be careful not to break them. (S-4) 1-1. Release five Locking Tabs (L-1). 1-2. Release three Locking Tabs (L-2) 1-3. Disconnect Connector (CN1505), and remove the Panel Front. 2.

- Page 15 (S-7) (S-8) (S-10) (S-6A) (S-6B) [8] Panel [12] BOARD Rear Unit Power Supply (S-7) (S-11) (S-7) [13] BOARD Holder CN1503 Fig. D5 CN1504 Fig. D7 [11] Panel Rear (S-12) (S-9) (S-14) (S-14) (S-15) (S-13C) Washer [10] Motor DC Fan [9] Fan Holder Fig.

- Page 16 [15] Deck Cylinder Assembly Assembly FE Head ACE Head Assembly SW507 LD-SW Plate Earth [18] BOARD Rear Jack [16] BOARD [19] BOARD Power Switch Main (with [19] BOARD Main BOARD AFV) [15] Deck Assembly Cam Gear Desolder (S-17) from bottom Hole Shaft (S-18)

- Page 17 (S-19) (S-19) (S-19) (S-19) [20] Deck Pedestal [21] Front Bracket R (S-20) Fig. D10 1-6-5 E9GA0DC...

- Page 18 3. How to Eject Manually Note: When rotating the gear, be careful not to damage the gear. 1. Remove the Cover Top. 2. Remove the Panel Front. 3. Remove the Front Bracket. 4. Remove the DVD Mechanism & DVD Main BOARD Assembly. 5.

-

Page 19: Electrical Adjustment Instructions

ELECTRICAL ADJUSTMENT INSTRUCTIONS NOTE: BOARD MEANS PRINTED CIRCUIT BOARD. NOTE: 1.Electrical adjustments are required after replacing circuit components and certain mechanical parts. It is important to do these adjustments only after Figure 1 all repairs and replacements have been com- pleted. -

Page 20: How To Initialize The Dvd Recorder & Vcr

HOW TO INITIALIZE THE DVD RECORDER & VCR To put the program back at the factory-default, initialize the DVD recorder & VCR as the following procedure. < DVD Section > 1. Turn the DVD recorder on. 2. Confirm that no disc is loaded or that the disc tray is open. -

Page 21: Firmware Renewal Mode

FIRMWARE RENEWAL MODE 1. Turn the power on and remove the disc on the tray. 4. Select the firmware version pressing arrow buttons, then press [ENTER]. 2. To put the DVD recorder into version up mode, Fig. d appears on the screen and Fig. e appears press [INSTANT SKIP], [6], [5], and [4] buttons on on the VFD. -

Page 22: Troubleshooting

TROUBLESHOOTING NOTE: BOARD MEANS PRINTED CIRCUIT BOARD. 1 Power Supply Section FLOW CHART NO.1 The power cannot be turned on. Is the fuse normal? See FLOW CHART No.2 <The fuse blows out.> Is normal state restored when once unplugged Check for lead or short-circuiting of primary power cord is plugged again after several seconds. - Page 23 FLOW CHART NO.6 P-ON+44V is not outputted. Check D013, C013, and their periphery, and Is 44V voltage supplied to the emitter of Q1516? service it if defective. Is the "L" pulse (approximately 0V) inputted to Is the "H" pulse (approximately 5V) inputted to the base of Q1516? the base of Q1517? Replace Q1516.

- Page 24 FLOW CHART NO.11 DVD-P-ON+3.3V is not outputted. Is 5V voltage supplied to Pin(1) of IC1505? Check D015, D016, D1032, L013, C018 and their periphery, and service it if defective. Replace IC1505. FLOW CHART NO.12 DVD-P-ON+12V is not outputted. Is 12V voltage supplied to the emitter of Q1511? Check D1031, L1013, C1037, C1039 and their periphery, and service it if defective.

- Page 25 2 DVD Section FLOW CHART NO.1 The key operation is not functioning. Are the contact point and the installation state of Re-install the key switches correctly or replace the key switches normal? the poor switch. Is the control voltage normally inputted into Pin(8) Check the key switches and their periphery, and service it if defective.

- Page 26 FLOW CHART NO.4 VIDEO E-E does not appear normally. Are the video signals inputted to each pin of Check the line between video input terminal and IC1518? each pin of IC1518. IC1518 1PIN VIDEO-IN (AV1) 1PIN → JK1502 VIDEO-IN (AV1) IC1581 IC1518 3PIN...

- Page 27 FLOW CHART NO.5 Picture does not appear normally. [In the S-VIDEO/Composite video output (JK1502, JK1506, JK2001)] Set the disc on the disc tray and playback. "A" Replace DVD MECHANISM & DVD MAIN BOARD Are the video signals inputted to each pin of CN1502? No ASSEMBLY.

- Page 28 FLOW CHART NO.6 Picture does not appear normally. [In the RGB/Component video output (JK1501, JK1502)] Set the disc on the disc tray and playback. "B" Are the video signals outputted to each pin of Replace DVD MECHANISM & DVD MAIN BOARD CN1502? ASSEMBLY.

- Page 29 "C1" Check the line between each pin of IC1516 and Are the video signals inputted to each pin of IC1516 each pin of IC1510, and service it if defective. and each pin of IC1514? IC1516 3PIN → IC1510 13PIN VIDEO-Y(I/P)-OUT (Output to JK1501) IC1516 8PIN →...

- Page 30 FLOW CHART NO.7 Audio E-E does not appear normally. Check the line between audio input terminal and each pin of IC1518, and service it if defective. No (Rear Are the audio signals inputted to each pin of input) →JK1502 IC1518 10,16PIN AUDIO-IN1 (AV1) IC1518?

- Page 31 "C" Check each line between each pin of CN1502 Are the analog audio signals inputted to each pin of IC1513? and each pin of IC1513, and service it if defective. CN1502 17PIN → IC1513 2PIN AUDIO(L)-OUT IC1513 2PIN AUDIO (L)-OUT CN1502 15PIN →...

- Page 32 FLOW CHART NO.8 Audio is not outputted during playback. Set the disc on the disc tray, and playback. Replace the DVD MECHANISM & DVD MAIN Are the analog audio signals outputted to each pin BOARD ASSEMBLY. of CN1502? CN1502 17PIN AUDIO (L)-OUT CN1502 15PIN AUDIO (R)-OUT Check each line between each pin of CN1502 Are the analog audio signals inputted to each pin...

- Page 33 "D" Are the analog audio signals outputted to each pin of IC1518? Is 12V voltage supplied to Pin(2,4) of IC1518? IC1518 21,25PIN AUDIO-OUT 1 (AV1) IC1518 22,26PIN AUDIO-OUT 2 (AV2) Check the AL+12V line and Replace IC1518. service it if defective. Are the audio signals outputted to the specific Check the periphery between Pin(21,25) of IC1518 output terminal?

- Page 34 3 VCR Section FLOW CHART NO.1 The key operation is not functioning. Are the contact point and the installation state of Re-install some key switches correctly or the key switches normal? replace some key switches. Check the key switches and their periphery, and Is the control voltage normally inputted into service it if defective.

- Page 35 FLOW CHART NO.3 Cassette tape can not be loaded. When loading a cassette tape, on Pin(10) of Check the line between the start sensor and IC501, does the "L" pulse switch to the "H" pulse? Pin(10) of IC501, and service it if defective. When loading a cassette tape, is the specified Replace the Capstan Motor Unit.

- Page 36 FLOW CHART NO.6 Capstan Motor does not rotate. Is 5V voltage supplied to Pin(2) of CN502? Check the P-ON+5V line and service it if defective. Is over approximately 2.6V voltage supplied to Check the line between Pin(5) of CN502 and Pin(5) of CN502? Pin(76) of IC501, and service it if defective.

- Page 37 FLOW CHART NO.10 Video E-E does not appear. Are the video signals inputted to each pin of Check the line between video input terminal and IC1518? each pin of IC1518. IC1518 1PIN VIDEO-IN (AV1) 1PIN → JK1502 VIDEO-IN (AV1) IC1581 3PIN →...

- Page 38 "E" Are the video signals outputted to each pin of IC1518? Is 12V voltage supplied to Pin(2,4) of IC1518? IC1518 29PIN VIDEO-OUT 1 (AV1) IC1518 30PIN VIDEO-OUT 2 (AV2) Check the AL+12V(1) line Replace IC1518. and service it if defective. Are the video signals outputted to the specific output terminal? Check the periphery of JK1502 from Pin(29) of...

- Page 39 "F" Check the line between Pin(3,13) of IC1501 and Is the audio signal supplied to Pin(4,50) of IC451? Pin(4,50) of IC451, and service it if defective. Is the 5V voltage supplied to Pin(16,32,35,36,46,55) of Check the circuit of AL+5V, P-ON+5V and IC451, or the 9V voltage supplied to Pin(69) of IC451? P-ON+9V, and service it if defective.

- Page 40 FLOW CHART NO.12 Hi-Fi audio can not be recorded normally. (E-E mode is normal.) Is the REC FM signal outputted to Pin(26) of IC451? Replace IC451. Check the line between Pin(8) of CN251 and Is the REC FM signal outputted to Pin(8) of CN251? Pin(26) of IC451, and service it if defective.

- Page 41 FLOW CHART NO.15 Hi-Fi audio can not be playbacked normally in the linear audio mode. (E-E mode is normal.) Is the audio signal outputted to Pin(11) of IC301? Is the audio signal supplied to Pin(5) of IC301? Replace Check the line between Pin(11) of IC301 and Pin(80) of IC451, and IC301.

-

Page 42: Function Indicator Symbols

FUNCTION INDICATOR SYMBOLS < VCR Section > Note: If a mechanical malfunction occurs, the power is turned off. When the power comes on again after that by pressing [ ] button, an error message is displayed on the TV screen for 5 seconds. MODE INDICATOR ACTIVE When reel or capstan mechanism is not... - Page 43 < DVD Section > Note: If an error occurs, a message with the error number appears on the screen. Recording Error Error message You cannot record on this disc as Power Calibration Area is full. Error No. Error Message Solution Error Description Priority An error occurs during data reading.

- Page 44 Error Message Solution Error Description Priority Release the disc protect This disc is protected and not setting in the Disc Setting Disc Protected Disc. recordable. menu. Disc is full. Insert the recordable disc with No available recording space. (No area for new recording) enough recording space.

-

Page 54: Schematic Diagrams / Board's And Test Points

SCHEMATIC DIAGRAMS / BOARD’S AND TEST POINTS NOTE: BOARD MEANS PRINTED CIRCUIT BOARD. Standard Notes WARNING Many electrical and mechanical parts in this chassis have special characteristics. These characteristics often pass unnoticed and the protection afforded by them cannot necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. - Page 55 LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON THE FOLLOWING PAGES: 1. CAUTION: FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE FUSE. 2. CAUTION: Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit. If Main Fuse (F1001) is blown, first check to see that all components in the power supply circuit are not defective before you connect the AC plug to the AC power supply.

-

Page 80: Waveforms

WAVEFORMS NOTE: Input: COLOR BAR SIGNAL (WITH 1KHz AUDIO SIGNAL) TP301 UPPER Pin 3 of CN1502 Pin 6 of IC1515 TP504 LOWER C-PB 0.2V RF-SW VIDEO-Cb 0.2V 20μs VIDEO-CVBS 0.5V 20μs J236 UPPER Pin 7 of CN1502 Pin 3 of CN1501 TP504 WF10 LOWER... - Page 82 DVD/CD LASER DIODE DRIVE...

-

Page 83: Ic Pin Function Descriptions

IC PIN FUNCTION DESCRIPTIONS < VCR Section > Signal Function Name IC501( SERVO / SYSTEM CONTROL ) AUDIO- 28 OUT Audio Mute Control Signal MUTE-2 Signal DVD- Function DVD Audio Mute Control Name 29 OUT AUDIO- Signal MUTE2 Input Signal from Pin 8 of IN SC2-IN SCART2 DVD-... - Page 84 Signal Signal Function Function Name Name DVD-POW- DVD Power Supply Safety Control SCART 1 8Pin Level 59 OUT 8POUT-1 by using 8POUT-1 and SAFETY Signal 8POUT-2 IN D-PFG Drum PG/FG Input Signal Control SCART 1 8Pin Level AMPVREF 60 OUT 8POUT-2 by using 8POUT-1 and V-Ref for CTL AMP 8POUT-2...

- Page 85 IC612 ( VFD DRIVER ) Signal Name Function Name Signal Name Function Name POWER- Power LED Control Signal OUT DVD-LED DVD LED Control Signal Grid Output OUT VCR-LED VCR LED Control Signal Not Used Oscillator Input Not Used +5V Power Supply DRV-DIN DRV-Serial Data Ground...

-

Page 86: Lead Identifications

LEAD IDENTIFICATIONS 2SK3566 PQ070XF01SZH KRA103M-AT/P 2SC1815-Y(TE2 F T) KRA104M-AT/P KTA-1266-GR-AT/P KRC103M-AT/P KTC3198-Y-AT/P KTA1267-Y-AT/P KTC3203-Y-AT/P KTA1273-Y-AT/P KTC3205-Y-AT/P KTA1281Y-AT/P KTC3199-(BL,Y)-AT/P 1 2 3 4 G D S E C B E C B LA70100M-TRM-E PT204-6B-12 KIA4558P/P RN1511(TE85R.F) KRC103S-RTK/P UTC4580 KTC3875S-(GR,Y)-RTK/P KTC3879-Y-RTK/P B1 E B2 EL817A MM1636XWRE MM1637XVBE... - Page 88 (P1) BOARD MCV (P4) BOARD SENSOR TU1501 ( P4 ) BOARD Sensor JW102 2B17 JW001 2B46 2B16 RM1501 BOARD Power Switch JW101 BOARD Main ( P1 ) BOARD MCV BOARD Function JW002 JW103 BOARD Front Jack (P5) BOARD AFV ( P5 ) BOARD AFV 1-18-2 E9GA1CEX...

- Page 89 (P2) DVD MECHANISM & DVD MAIN BOARD ASSEMBLY ( P2 ) DVD MECHANISM & DVD MAIN BOARD ASSEMBLY (P3) BOARD PSV 2B60 BOARD Rear Jack JW2001 ( P3 ) 2L019 BOARD PSV 2B18 BOARD Power Supply AC1001 JW1001 F1001 1-18-3 E9GA1CEX...

- Page 90 Packing X20A X20B X20C Comparison Chart of Models and Marks Model Mark D-VR50KF D-VR51KF 1-18-4 E9GA1PEX...

-

Page 91: Mechanical Parts List

MECHANICAL PARTS LIST PRODUCT SAFETY NOTE: Products marked with a Loca- Mark TSB P/N Reference No. Description ! have special characteristics important to safety. tion No. Before replacing any of these components, read 2L062 GBHB3080 SCREW B-TIGHT M3X8 BIND HEAD+ carefully the product safety notice in this service 2L066 0VM412937A... -

Page 92: Electrical Parts List

ELECTRICAL PARTS LIST PRODUCT SAFETY NOTE: Products marked with a Location TSB P/N Reference No. Description ! have special characteristics important to safety. Before replacing any of these components, read C311 CHD1JZ30F104 CHIP CERAMIC CAP .(1608) F Z 0.1μF/50V carefully the product safety notice in this service C312 CE1CMAVSL100 ELECTROLYTIC CAP . - Page 93 Location Location TSB P/N Reference No. Description TSB P/N Reference No. Description C378 CHD1JK30B103 CHIP CERAMIC CAP .(1608) B K C470 CHD1JK30B472 CHIP CERAMIC CAP .(1608) B K 0.01μF/50V 4700pF/50V C379 CE1JMAVSLR47 ELECTROLYTIC CAP . 0.47μF/ C471 CHD1JK30B103 CHIP CERAMIC CAP .(1608) B K 50V M H7 0.01μF/50V C381...

- Page 94 Location Location TSB P/N Reference No. Description TSB P/N Reference No. Description C533 CHD1JK30B473 CHIP CERAMIC CAP .(1608) B K C1519 CHD1AZ30F105 CHIP CERAMIC CAP . F Z 1μF/ 0.047μF/50V C534 CE0KMAVSL470 ELECTROLYTIC CAP . 47μF/6.3V C1520 CHD1AZ30F105 CHIP CERAMIC CAP . F Z 1μF/ M H7 C535 CHD1JZ30F104...

- Page 95 Location Location TSB P/N Reference No. Description TSB P/N Reference No. Description C1566 CE1CMASDL100 ELECTROLYTIC CAP . 10μF/16V C1609 CHD1JZ30F104 CHIP CERAMIC CAP .(1608) F Z 0.1μF/50V C1567 CE1CMASDL470 ELECTROLYTIC CAP . 47μF/16V C1610 CHD1JK30B103 CHIP CERAMIC CAP .(1608) B K 0.01μF/50V C1569 CE0KMASDL471 ELECTROLYTIC CAP .

- Page 96 Location Location TSB P/N Reference No. Description TSB P/N Reference No. Description C1663 CHD1EK30B104 CHIP CERAMIC CAP .(1608) B K D512 QDTZ001SS133 SWITCHING DIODE 1SS133(T- 0.1μF/25V C1664 CE1JMASDL1R0 ELECTROLYTIC CAP . 1μF/50V D555 QPQPS1R563ST LED SIR-563ST3F P D1501 NDLZ001N5397 DIODE 1N5397-B C1665 CHD1JK30B102 CHIP CERAMIC CAP .(1608) B K...

- Page 97 Location Location TSB P/N Reference No. Description TSB P/N Reference No. Description L402 LLARKBSTU470 INDUCTOR 47μH-K-5FT Q1517 NQSZKRC103MP NPN TRANSISTOR KRC103M- AT/P L451 LLARKBSTU470 INDUCTOR 47μH-K-5FT Q1518 NQSYKTC3205P TRANSISTOR KTC3205-Y-AT/P L452 JW5.0T BOARD JUMPER D0.6-P5.0 Q1519 NQSZKRC103MP NPN TRANSISTOR KRC103M- L501 LLAXKATTU101 INDUCTOR(100μH K)

- Page 98 Location Location TSB P/N Reference No. Description TSB P/N Reference No. Description CHIP RES. 1/10W J 1k Ω CARBON RES. 1/4W J 820 Ω R410 RRXAJR5Z0102 R583 RCX4JATZ0821 CHIP RES. 1/10W J 27k Ω CHIP RES. 1/10W J 100 Ω R411 RRXAJR5Z0273 R584...

- Page 99 Location Location TSB P/N Reference No. Description TSB P/N Reference No. Description CARBON RES. 1/4W J 820 Ω CHIP RES. 1/10W J 1k Ω R1531 RCX4JATZ0821 R1616 RRXAJR5Z0102 CARBON RES. 1/4W J 820 Ω CARBON RES. 1/4W J 75 Ω R1532 RCX4JATZ0821 R1619...

- Page 100 BOARD POWER SWITCH Location TSB P/N Reference No. Description Location CHIP RES. 1/10W J 22k Ω R1704 RRXAJR5Z0223 TSB P/N Reference No. Description CHIP RES. 1/10W J 470 Ω R1705 RRXAJR5Z0471 ---------- BOARD POWER SWITCH CHIP RES. 1/10W J 1k Ω R1706 RRXAJR5Z0102 (MCV-B)

- Page 101 BOARD PSV Location TSB P/N Reference No. Description Location D1003 NDLZ001N5397 DIODE 1N5397-B TSB P/N Reference No. Description D1004 NDLZ001N5397 DIODE 1N5397-B ! P3 P000490220 1VSA15826 BOARD PSV D1006 QDTZ001SS133 SWITCHING DIODE 1SS133(T- Consists of the following ---------- BOARD POWER SUPPLY (PSV- D1008 NDQZ000SB140 SCHOTTKY BARRIER DIODE...

- Page 102 Location Location TSB P/N Reference No. Description TSB P/N Reference No. Description CARBON RES. 1/6W J 22k Ω R1010 RCX6JATZ0223 D2006 QDTA00MTZJ11 ZENER DIODE MTZJT-7711A R1011 RN01JZLZ01R3 METAL OXIDE FILM RES. 1W J D2007 QDTA00MTZJ11 ZENER DIODE MTZJT-7711A 1.3 Ω D2008 QDTA00MTZJ11 ZENER DIODE MTZJT-7711A...

- Page 103 Location TSB P/N Reference No. Description CHD1AZ30F474 CHIP CERAMIC CAP . F Z 0.47μF/10V CE1JMASSLR22 ELECTROLYTIC CAP . 0.22μF/ 50V M H7 CCA1JZTFZ104 CERAMIC CAP .(AX) F Z 0.1μF/ CONNECTOR JTED009ER045 ANGLE PIN HEADER 9P IMSA- 6029B-1-09Z003- DIODE QDTZ001SS133 SWITCHING DIODE 1SS133(T- P000459920 NSZBA0SP3005 IC AUDIO PROCESSOR MSP3417G-QG-B8-V3...

- Page 104 DECK MECHANISM SECTION DVD VIDEO RECORDER & VIDEO CASSETTE RECORDER D-VR50KF/D-VR51KF Deck Mechanism Section I Standard Maintenance I Mechanism Alignment Procedures I Disassembly / Assembly of Mechanism I Deck Exploded Views I Deck Parts List TABLE OF CONTENTS Standard Maintenance ..............2-1-1 Service Fixture and Tools.

-

Page 105: Standard Maintenance

STANDARD MAINTENANCE Service Schedule of Components This maintenance chart shows you the standard of replacement and cleaning time for each part. Because those may replace depending on environment and purpose for use, use the chart for reference. I: Replace h: Hours : Cleaning Deck Periodic Service Schedule... - Page 106 Cleaning Cleaning of ACE Head Clean the head with a cotton swab. Cleaning of Video Head Procedure Clean the head with a head cleaning stick or chamois 1.Remove the top cabinet. cloth. 2.Dip the cotton swab in 90% ethyl alcohol and clean Procedure the ACE Head.

-

Page 107: Service Fixture And Tools

SERVICE FIXTURE AND TOOLS J-1-1, J-1-2 Ref. No. Name Part No. Adjustment J-1-1 Alignment Tape FL6A Head Adjustment of ACE Head J-1-2 Alignment Tape FL6N8 Azimuth and X Value Adjustment of ACE Head / (2 Head model) Adjustment of Envelope Waveform FL6NS8 (4 Head model) Guide Roller Adj. -

Page 108: Mechanical Alignment Procedures

MECHANICAL ALIGNMENT PROCEDURES Explanation of alignment for the tape to correctly run B. Method to place the Cassette Holder in the tape- starts on the next page. Refer to the information below loaded position without a cassette tape on this page if a tape gets stuck, for example, in the 1. -

Page 109: Tape Interchangeability Alignment

1. Tape Interchangeability Alignment Note: To do these alignment procedures, make sure that the Tracking Control Circuit is set to the preset position every time a tape is loaded or unloaded. (Refer to page 2-3-4, procedure 1-C, step 2.) Equipment required: Dual Trace Oscilloscope VHS Alignment Tape (FL6NS8) Guide Roller Adj. - Page 110 1-A. Preliminary/Final Checking and 4. If creasing or snaking is apparent, adjust the Tilt Alignment of Tape Path Adj. Screw of the ACE Head. (Fig. M6) Purpose: To make sure that the tape path is well stabilized. Azimuth Adj. Screw Symptom of Misalignment: If the tape path is unstable, the tape will be damaged.

- Page 111 5. When Guide Rollers [2] and [3] (Refer to Fig. M3) 5. To shift the CTL waveform, press [PROGRAM are aligned properly, there is no envelope drop or [PROGRAM ] button. Then make sure that either at the beginning or end of track as shown in the maximum output position of PB FM envelope Fig.

- Page 112 1-D. Azimuth Alignment of Audio/Con- 2. When the tape has been curled up or bent, turn the trol/ Erase Head alignment screw to adjust the height of REV Post. (Refer to Fig. M11 and M13.) Purpose: To correct the Azimuth alignment so that the Audio/ Control/Erase Head meets tape tracks properly.

-

Page 113: Disassembly/Assembly Procedures Of Deck Mechanism

DISASSEMBLY/ASSEMBLY PROCEDURES OF DECK MECHANISM Before following the procedures described below, be sure to remove the deck assembly from the cabinet. (Refer to CABINET DISASSEMBLY INSTRUCTIONS.) All the following procedures, including those for adjustment and replacement of parts, should be done in Eject mode;... - Page 114 REMOVAL INSTALLATION STEP START- REMOVE/*UNHOOK/ /LOC. PART ADJUSTMENT UNLOCK/RELEASE/ Fig. No. CONDITION UNPLUG/DESOLDER Loading Arm (SP) (+)Refer to Alignment DM2H, DM14H [34] [26] Assembly Sec.Page 2-5-1 Loading Arm (TU) (+)Refer to Alignment [35] [34] DM2H, DM14H Assembly Sec.Page 2-5-1 M Brake (TU) [36] [16],[26] DM1H, DM15H...

- Page 115 Top View [44] [45] [49] [46] [14] [13] [11] [15] [38] [10] [12] [37] [36] [43] [32] [41] [31] [40] [42] Fig. DM1H Bottom View [19] [35] [34] [25] [23] [24] [26] [27] [22] [28] [20] [33] Fig. DM2H 2-4-3 U29PHSDA...

- Page 116 (S-1) (S-1) (L-1) (L-3) (L-2) (S-1A) (P-1) Installation of [3] and [6] First, insert [6] diagonally in [3] as shown below. Then, install [6] in [3] while pushing (L-1) in the direction of the arrow. After installing [6] in [3], confirm that pin A of [3] enters hole A of [6] properly.

- Page 117 [11] (S-4A) (L-4) [49] (P-3) [13] [50] Removal of [11] [12] (L-12) 1) Remove screw (S-4A). 2) Unhook spring (P-2). [10] Release (L-4) while (P-2) holding [12] with a finger. Loosen a finger holding [12] and remove [11]. (S-2) Pin of [12] Pin of [10] Groove of [27] When reassembling [10] and...

- Page 118 Installation of [13] and [12] (S-5) [14] (S-6) [13] [15] Hook spring (P-3) up to [12] and [13], then install them to (P-3) the specified position so that [12] will be floated slightly while holding [12] and [13]. (Refer to Fig. A.) [12] Fig.

- Page 119 (C-1) turn [22] (S-8) [20] (L-6) [21] [19] Cap Belt Pin on [22] Installation position of Cap Belt [20] Cap Belt [27] Position of pin on [22] Fig. DM12H [19] View for A Fig. DM11H 2-4-7 U29PHSDA...

- Page 120 Installation of [26] [26] (C-3) Position of Mode Lever when installed Pin of [33] Pin of [37] (S-9) Pin of [36] (L-8) [23] (L-7) Bottom View [24] (C-5) [26] (C-4) (C-2) [28] [27] [25] [29] [30] Align [26] and [27] as shown. [27] First groove on [27] First tooth on [47]...

- Page 121 [38] [36] [43] (P-6) turn [39] (L-10) turn [42] turn [47] [48] Slide [37] Fig. DM17H (C-7) [41] (C-6) [40] Fig. DM15H [45] [44] [46] (L-11) Slide Plate (S-11) Fig. DM16H 2-4-9 U29PHSDA...

-

Page 122: Alignment Procedures Of Mechanism

ALIGNMENT PROCEDURES OF MECHANISM The following procedures describe how to align the Alignment 1 individual gears and levers that make up the tape Loading Arm (SP) and (TU) Assembly loading/unloading mechanism. Since information about the state of the mechanism is provided to the Install Loading Arm (SP) and (TU) Assembly so that System Control Circuit only through the Mode Switch, their triangle marks point to each other as shown in... -

Page 123: Deck Exploded Views

DECK EXPLODED VIEWS Deck Mechanism View 1 Mark Description Floil G-684G or Multemp MH-D (Blue grease) SLIDUS OIL #150 B494 L1467 B553 L1191 B411 B567 L1053 B410 L1051 Chassis Assembly Top View (Lubricating Point) L1322 B501 L1450 L1450 L1466 B121 B126 B492 B571... - Page 124 Deck Mechanism View 2 Mark Description Floil G-684G or Multemp MH-D (Blue grease) B587 B521 B487 SLIDUS OIL #150 B416 B591 SANKOUL FG84M (Yellow grease) B590 B522 L1406 B148 B573 B499 B508 B574 B592 B585 B518 B558 B564 B557 B414 B572 B565 L1151...

- Page 125 Deck Mechanism View 3 Mark Description Floil G-684G or Multemp MH-D (Blue grease) L1321 SLIDUS OIL #150 B347 L1321 B355 B354 B483 L1341 B425 B482 B562 B300 B563 B313 B529 B360 B359 B361 B555 B303 Some Ref. Numbers are not in sequence. B514 2-6-3 U29P4HSDEX...

-

Page 126: Deck Parts List

DECK PARTS LIST Loca- TSB P/N Reference No. Description tion No. Loca- TSB P/N Reference No. Description B557 P000483630 0VM403205A MOTOR PULLEY U5 tion No. B558 P000483820 MMDZB12MF003 LOADING MOTOR RF-500TB- P000468620 1VSA14761 CYLINDER ASSEMBLY(N236C) 12560 MK14 PAL 6HD B559 P000468020 0VSA13450 CLUTCH ASSEMBLY(HI) MK12 P000468180 1VSA12912...