Husqvarna 450 Operator's Manual

Husqvarna saw user manual

Hide thumbs

Also See for 450:

- Spare parts (42 pages) ,

- Workshop manual (708 pages) ,

- Owner's manual (108 pages)

Table of Contents

Advertisement

Operator's Manual

Read these instructions carefully and make sure

you understand them before using the 450.

Manual del operador

Lea cuidadosamente estas instrucciones y asegúrese

de que las comprende bien antes de usar el 450.

Manuel d'utilisation

Veuillez lire attentivement ces instructions et assurez-vous de

bien les comprendre avant d'utiliser la machine modèle 450.

450

Advertisement

Table of Contents

Summary of Contents for Husqvarna 450

- Page 1 450. Manual del operador Lea cuidadosamente estas instrucciones y asegúrese de que las comprende bien antes de usar el 450. Manuel d’utilisation Veuillez lire attentivement ces instructions et assurez-vous de bien les comprendre avant d’utiliser la machine modèle 450.

-

Page 2: Table Of Contents

Remove the saw from the container using proper lifting techniques. Discard or recycle the packing material per your regional laws. In your container will be the 450 saw, blade shaft wrench, an owner’s manual, an engine owner’s manual, a part list, a warranty card, a joint protector sample pack, a diamond blade, a skid plate, and a ramp for unloading the saw. -

Page 3: I Ntroduction, Personal Safety

The 450 is designed as a residential and light commercial Ultra Early Entry concrete saw. The pat- ented Soff-Cut Ultra Early Entry dry cutting system controls random cracking of concrete through the early timing of the saw cutting usually within one to two hours after finishing process is completed. The patented low noise and low dust blade block and skid plate technology in conjunction with the Husqvarna blades al- lows for Ultra Early Entry sawing the same day while minimizing chipping and spalling. -

Page 4: Registration Of The Product

MODEL No: ________________ ENGINE MODEL: _____________ ENGINE TYPE: ______________ The 450 model and serial number as well as the engine model number, engine type and code are critical in order to obtain the correct service parts. In this manual a Safety Alert Symbol identify safety information about hazards which can result in death, serious injury and/or property damage. -

Page 5: Safety Warnings

The blade should fit snugly on clean, undamaged, tri-arbor shaft. • Use only Husqvarna Excel Series blades or blades marked with a maximum operating speed greater than 3200 rpm. • Never operate the saw without the blade block assembly securely in place including blade cover, lexan shields and skid plate installed in working order. -

Page 6: Excel Series Blades

Remove the blade block cover (A) by turning the two locking knobs counter-clockwise. Insert the blade wrench supplied with the saw on the blade shaft bolt (B) on the end of the blade shaft in the blade block (C). Rotate the blade shaft counter-... -

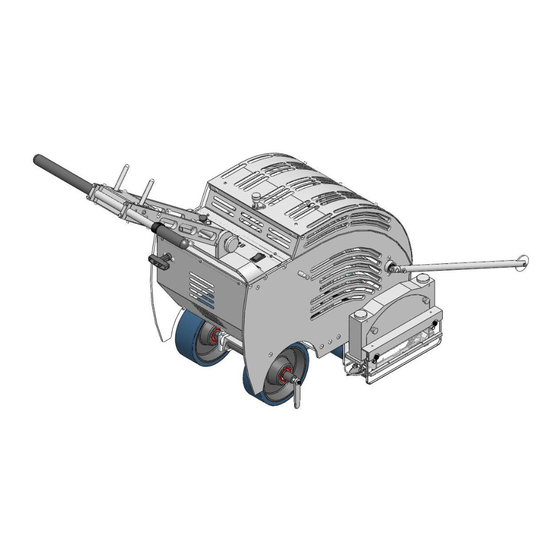

Page 7: What Is What

Model number and serial number What is what? Oil fill & dipstick Air cleaner C. Fuel shut off lever D. Fuel tank Oil drain hose Engine choke G. Hour meter/Tachometer H. Hood Engine on/off switch Front guide Rear guide Recoil starter M. -

Page 8: Operating Instructions

Rear guide Blade block Front guide wheel Experience is very important when running the 450 saw. A skilled worker is highly recommended. Always do an inspec- tion of the saw before starting the engine. Open the hood (H) and check the fuel (D) and oil level (A) per the enclosed engine manual. -

Page 9: Fuel And Fuel Safety Warnings

Always place containers on the ground away from your vehicle when filling. - Remove the 450 from the truck or trailer and refuel it on the ground. If this is not possible, then refuel the equipment with a portable container, rather than from a gasoline dispenser nozzle. -

Page 10: Maintenance

Replace engine oil. Grease blade shaft bearings. Check blade drive belt and belt tensioner. Do not modify the saw! Use only Husqvarna Construc- tion Products replacement parts. Use of unauthorized parts may create a danger or damage the engine. Daily... -

Page 11: Sawing Contraction Joints

Husqvarna sawed contraction joints should be a minimum of 1/8th the concrete depth and a minimum of 1”... -

Page 12: Maximizing The Soff-Cut System

Cut is being specified more today than ever, sometimes the ultra early-entry spec is not always followed on the job site. In order for the Soff-Cut system and an experienced Husqvarna contractor to do a satisfactory job, four components must exist to meet the “specification”:... -

Page 13: Troubleshooting

- Insure the slab is in clean with no debris that could raise the skid plate or saw while cutting. - Use Husqvarna joint protectors at all cut intersections. - Clean excess concrete debris from the blade block assembly. - Check that the scrapers in the blade block are not bent or binding. -

Page 14: Technical Specifications

TECHNICAL SPECIFICATIONS Weight and Dimensions 450 Weight – dry Weight with gasoline and oil full Length Width Height Blade Material cut Blade type Blade rotation Blade shaft speed Cutting depth Cutting distance from wall Average cutting rate - Estimate only. Speed will vary with job conditions and concrete mixes. -

Page 15: Warranty

HUSQVARNA EQUIPMENT WARRANTY New 450 sold by Husqvarna Construction Products are warranted to be free from manufacturing defects in normal service for a period of six (6) months for labor and up to one (1) year on parts from date of purchase by the original consumer purchaser or date of introduction into rental company fleet. - Page 16 505 41 78-08 Printed In U.S.A. 2009-13...